Injection concrete

A technology of shotcrete and mixture, which is applied in the field of shotcrete, can solve the problems of not finding the ratio design of shotcrete, not being able to guarantee the construction period, increasing investment, etc., and achieve the effects of improving performance indicators, high water reducing rate, and reducing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with specific embodiment, the present invention is further elaborated:

[0017] The sprayed concrete in the water-rich area of the present invention comprises cement, sand and gravel mixture, steel fiber, quick-setting agent, and special admixture, and the special admixture is that the main chemical composition is SiO 2 and AL 2 o 3 Inorganic neutral nano-sized zeolite, the particle size of Buddha stone is 327.7×10 -9 m, can also include silica fume, water reducer.

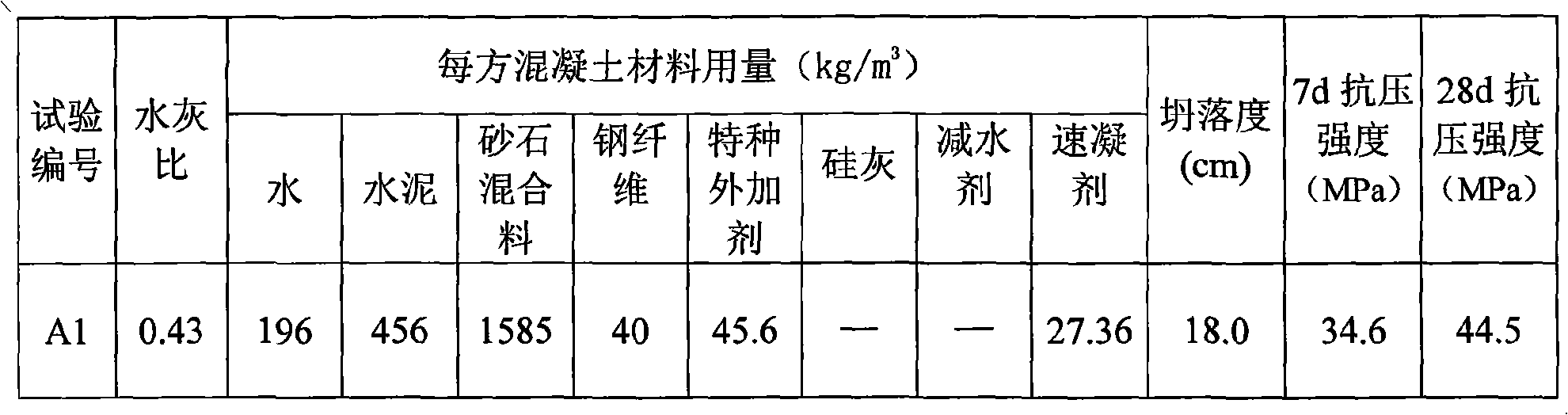

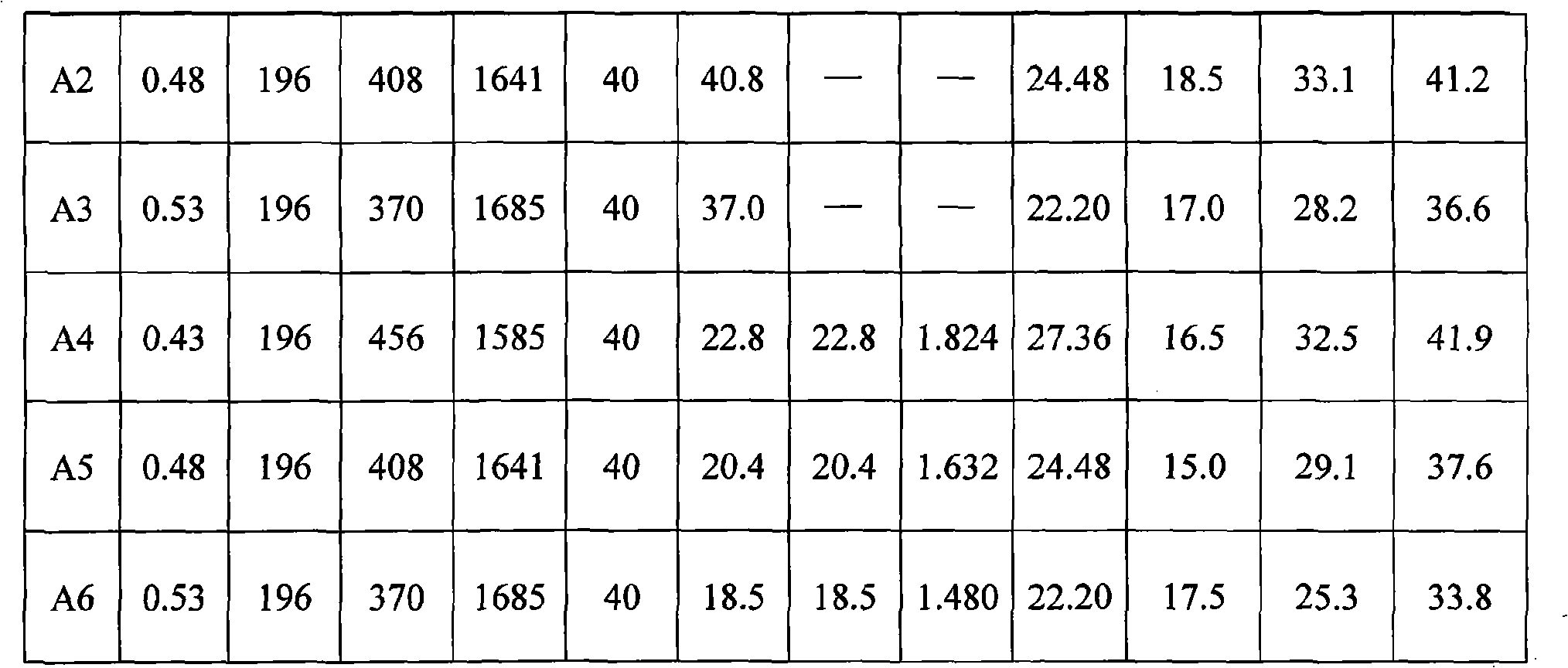

[0018] The concrete proportioning of above formula sees the following table:

[0019]

[0020]

[0021] The water-cement ratio range of the shotcrete mix ratio is between 0.43 and 0.53 (excluding the admixture ratio), and the water-cement ratio range of the admixture is between 0.39 and 0.48.

[0022] The above proportions have been tested, 1) Unit density ≥ 23KN / m 3 ; 2) Compressive strength ≥ 38MPa; 3) Flexural strength ≥ 5.8MPa; 4) Tensile strength ≥ 2.8MPa; 6) Elastic m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com