Method for preparing tar, coal gas and semi-coke by virtue of pyrolysis of bituminous coal

A semi-coke and tar technology, used in coke ovens, petroleum industry, special forms of dry distillation, etc., can solve the problems of easy blockage of the follow-up system, complicated process flow, and large amount of entrained dust, so as to improve the utilization rate of raw materials and reduce the dust content. volume, the effect of increasing gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

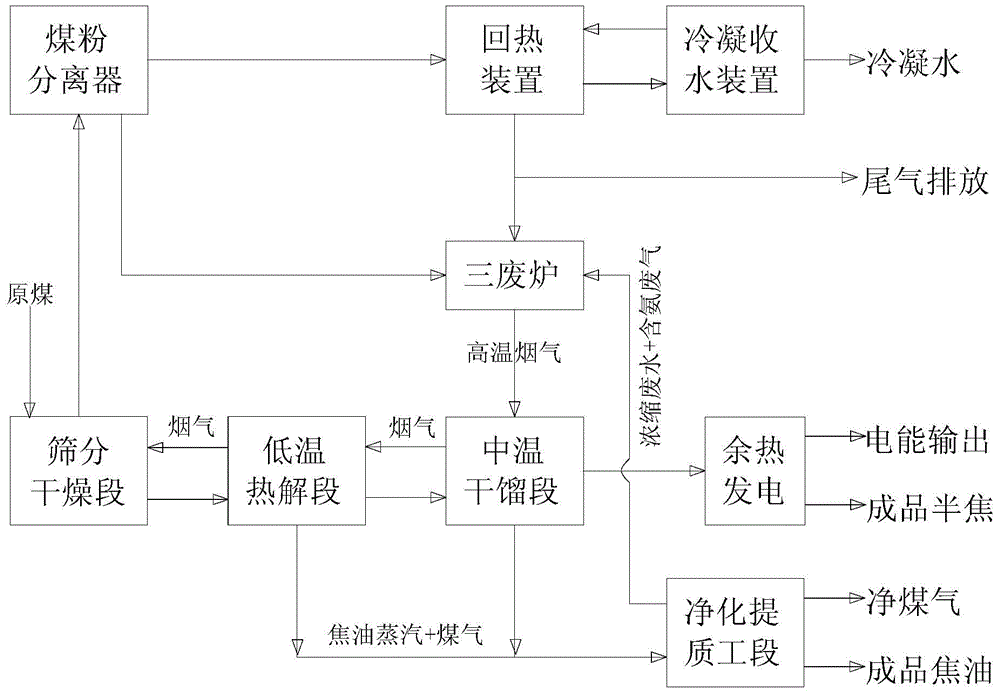

Method used

Image

Examples

Embodiment 1

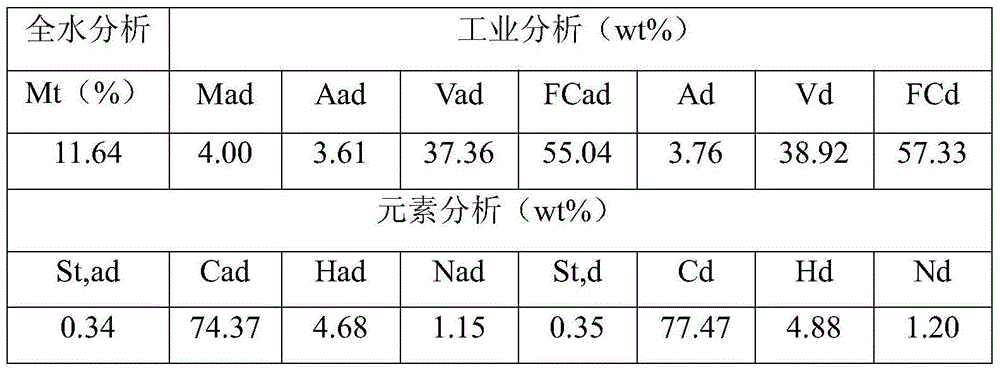

[0038] The raw material coal of embodiment is long-flame coal, and raw material analysis data is as shown in table 1:

[0039] Table 1 raw material analysis table

[0040]

[0041] a. Send the raw coal with particle size ≤ 30mm to the screening and drying section. The raw coal is heated and dried by hot flue gas to a moisture content of 4%, and the raw coal is screened by wind force with hot flue gas. The coal powder with a particle size below 1mm is heated by hot flue gas The gas is sent to the pulverized coal separator for separation.

[0042] b. The sieved and dried raw coal with a particle size greater than 1mm is sent to the low-temperature pyrolysis section. The raw coal is heated to about 560°C by an external heat source, and the raw coal is pyrolyzed to generate hot semi-coke solid products, a large amount of tar steam and a small amount of gas ; The time of low temperature pyrolysis is 38 minutes.

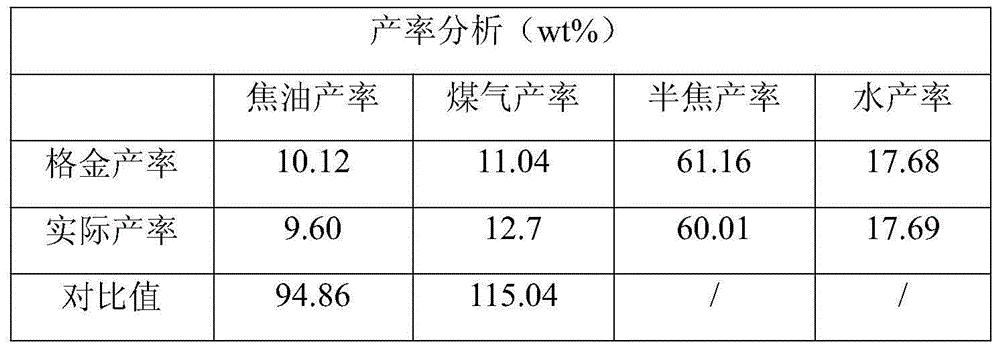

[0043]c. The hot semi-coke solid product generated in the low-te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com