Multi-dimensional space filter material scrubbing method

A technology of multi-dimensional space and filter materials, applied in the direction of separation methods, chemical instruments and methods, loose filter material filters, etc., can solve the problems that can only reach 85%, and achieve the improvement of total filtration capacity and cleaning cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

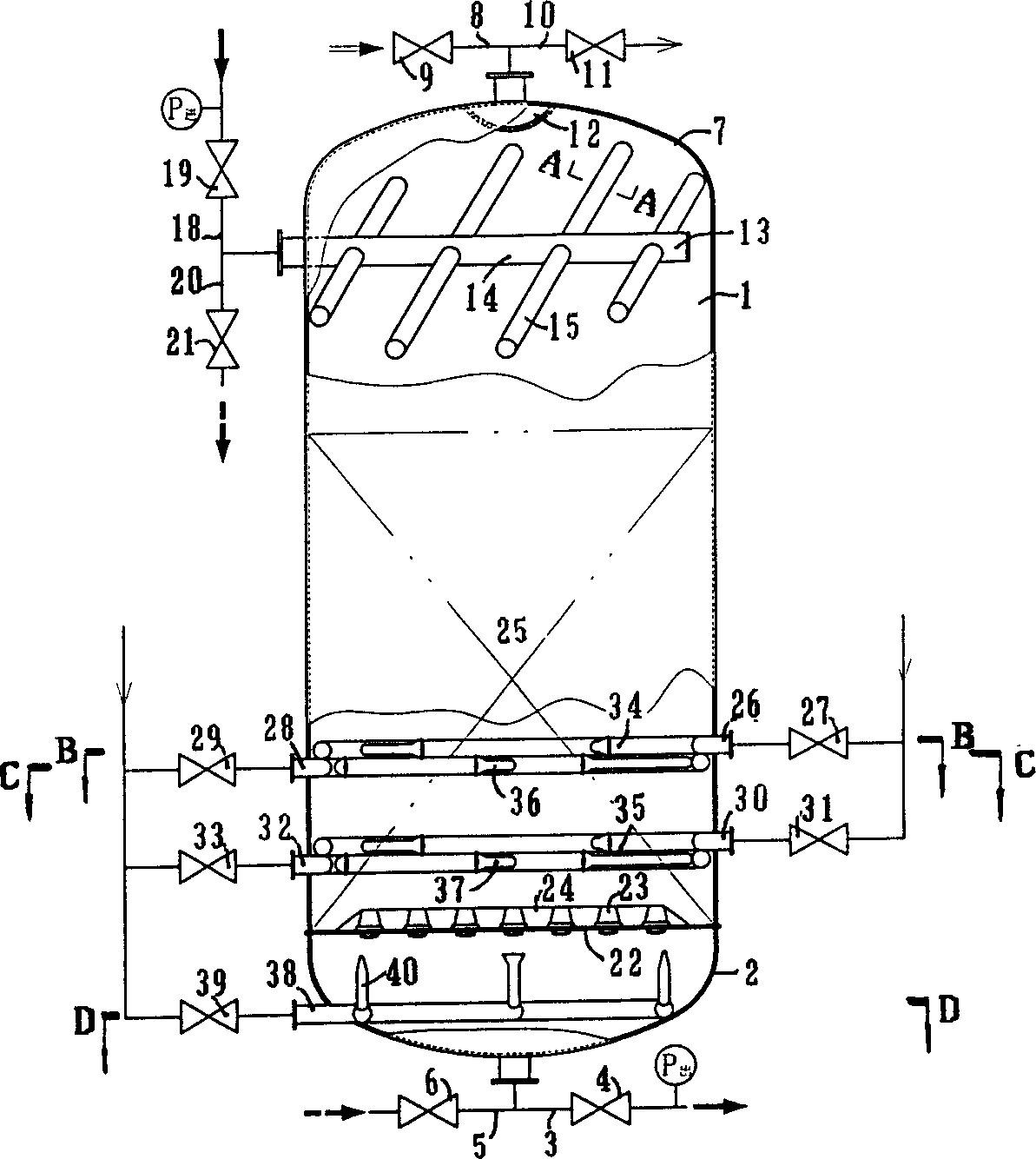

[0031] A method for scrubbing filter material in a multi-dimensional space of the present invention is described by using equipment for filling filter material in a filter as shown in the accompanying drawings.

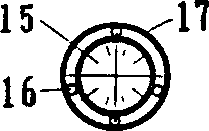

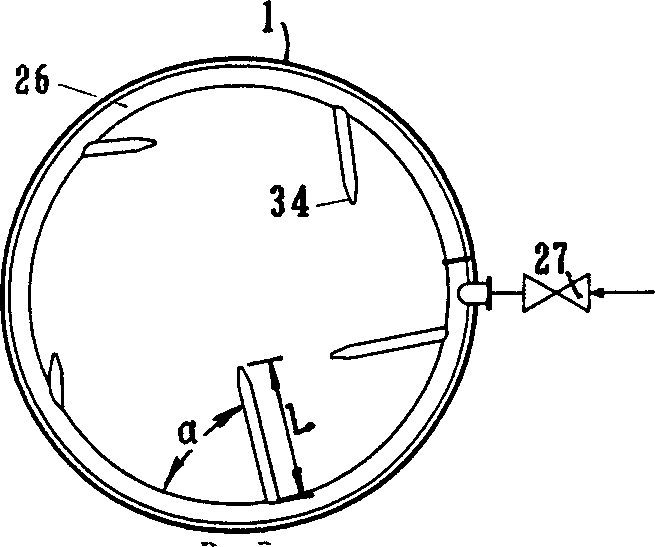

[0032] For the above filters, see figure 1 , in the usual vertical filter structure. There is a cylindrical cylinder body 1 with a radius of R, and the center connecting pipe at the center of the lower head 2 at the lower end of the cylinder body communicates with and connects with the filtered water outlet pipe 3 and the filtered water outlet valve 4 and the pressure gauge P 出 , Scrub water inlet pipe 5 and scrub water inlet valve 6 thereof. The scrubbing water inlet pipe is sent into the upward pressure water flow through the central connecting pipe of the lower head to form an upward scrubbing water flow to the filter material. The center of the upper head 7 center of the upper end of the cylindrical body takes over and is connected with the scrub feed pipe 8 and...

Embodiment 2

[0058] A method for scrubbing filter material in multi-dimensional space of the present invention is illustrated by using the filter used in Example 1. The filter material 25 filled in the cylinder above the filter plate of the filter is manganese sand (mineral particles), ceramsite (mineral miscellaneous) anthracite, activated carbon, and quartz sand.

[0059]Use above-mentioned filter, when filtering well water, mineral water, the manganese sand (mineral particle) filter material in the filter intercepts the ferromanganese ion in well water, mineral water and is polluted. When filtering electroplating wastewater and garbage wastewater, the ceramsite (mineral impurities) filter material in the filter intercepts metal ions in electroplating wastewater and garbage wastewater to make up for pollution. Can adopt embodiment 1 to add activating agent to scrub program and clean. The active agent used in cleaning is dilute acid and dilute lye. Scrubbing process of the present inven...

Embodiment 3

[0072] A method for scrubbing filter material in multi-dimensional space of the present invention is illustrated by using the filter used in Example 1. The filter material 25 filled in the cylinder above the filter plate of the filter is fiber balls, anthracite, and quartz sand.

[0073] Use above-mentioned filter, when filtering sodium chloride and ammonium chloride solution, fiber ball in the filter, quartz sand filter material intercept sodium chloride, the suspension in the ammonium chloride solution and be polluted. Can adopt embodiment 1 to add activating agent to scrub program and clean. The active agent used in cleaning is dilute lye and dilute acid. Scrubbing process of the present invention is as follows:

[0074] First open the scrubbing water inlet valve 6 at the bottom of the filter, send the upward pressure water flow from below the filter material 25 through the scrubbing water inlet pipe 5, and open the scrubbing exhaust valve 11 at the top of the filter. Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com