Method capable of recovering filter performance of roll type membrane assemblies for household water purifiers

A technology of filtration performance and rolled membrane, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

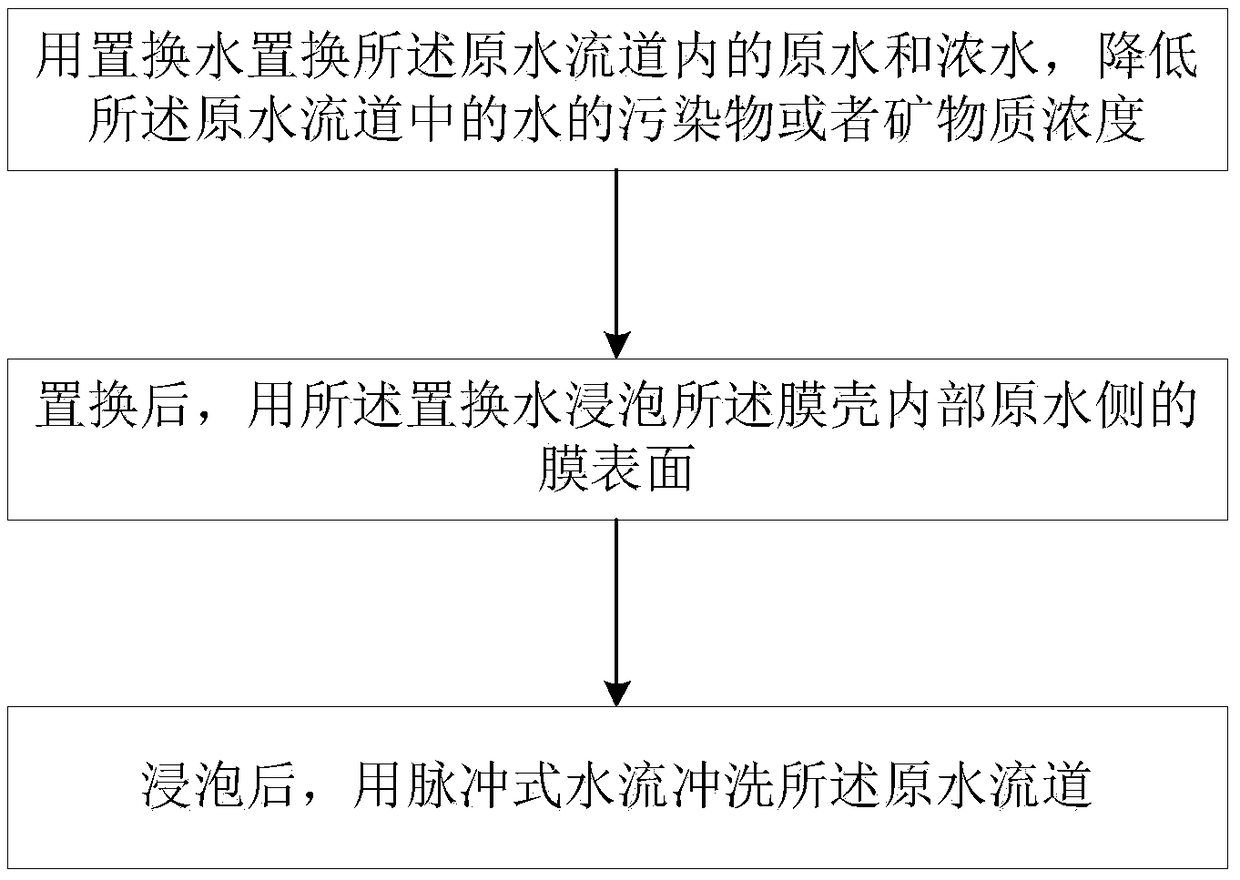

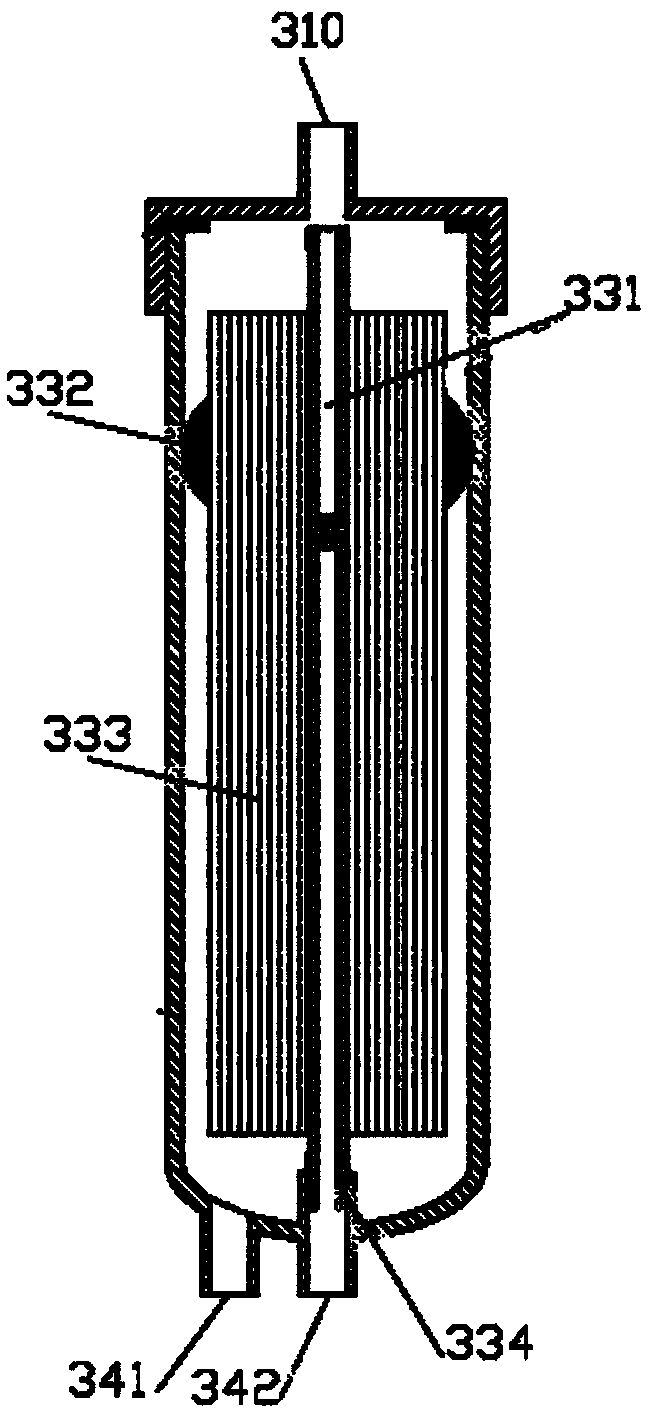

[0039] Such as figure 1 Shown is a flowchart of a method for recovering the filtration performance of the roll-type membrane module used in a household water purifier according to the present invention, wherein the roll-type membrane module is arranged inside the membrane shell of the membrane processor of the water purifier, and the membrane The shell is provided with a water inlet, a water outlet and a concentrated water discharge port. The water inlet is connected to the inlet of the raw water flow channel inside the coiled membrane module, and the outlet of the raw water flow channel is connected to the concentrated water discharge port. The outlet of the outlet is connected to the water outlet, and the method includes the following steps:

[0040] Replacement step: After the spiral membrane module has been filtered for a period of time, some pollutants that block the membrane may be deposited on the surface of the raw water side of the membrane. The raw water and concent...

Embodiment 2

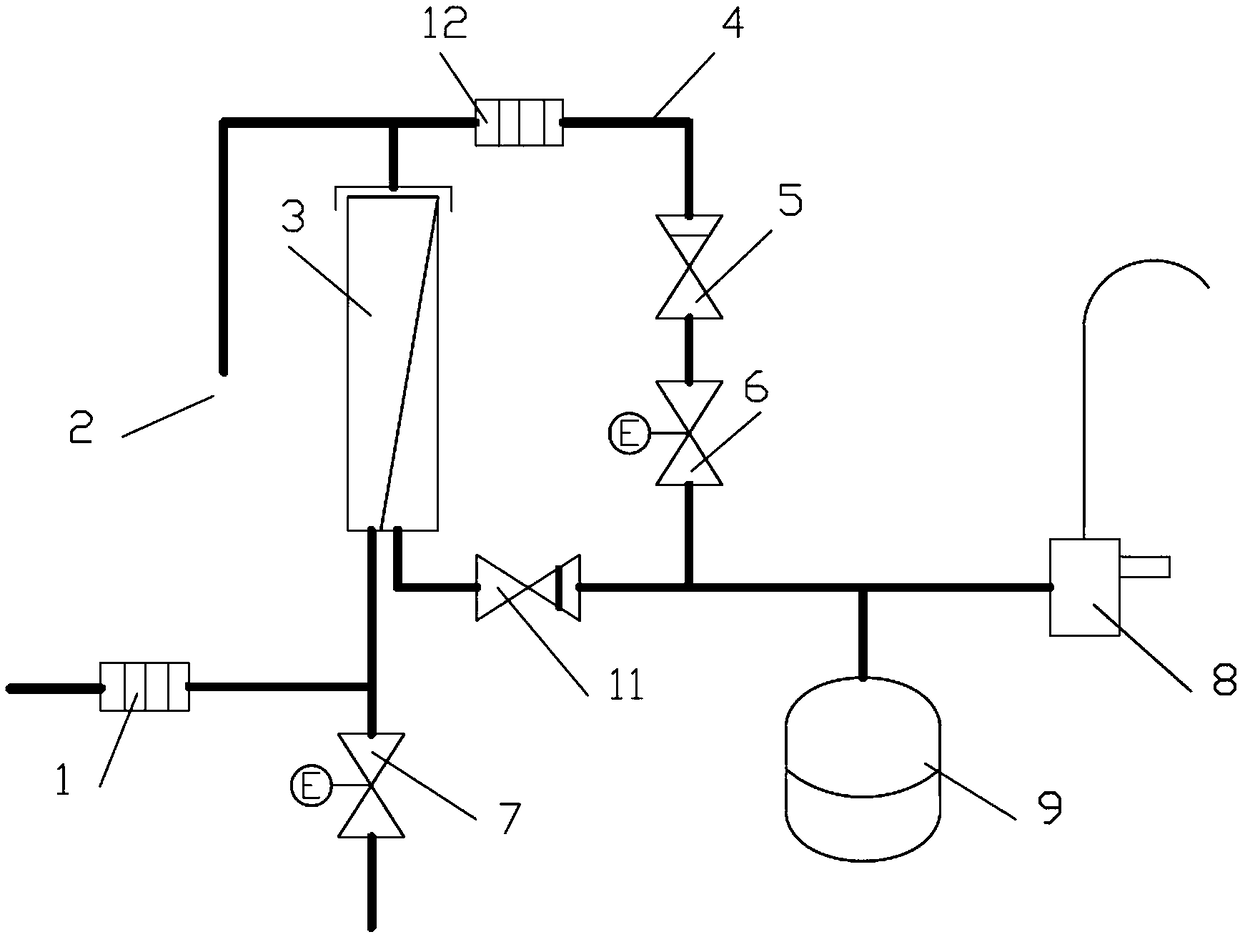

[0056] Such as Figure 4 Shown is a flow chart of another method of the present application that can restore the filtration performance of the roll-type membrane module on a household water purifier, wherein the roll-type membrane module is arranged inside the membrane shell of the membrane processor of the water purifier, The membrane casing is provided with a water inlet, a water outlet and a concentrated water discharge port. The water inlet is connected to the inlet of the raw water channel inside the coiled membrane module, and the outlet of the raw water channel is connected to the concentrated water discharge port. The clean water flow inside the coiled membrane module The outlet of the channel is connected to the water outlet, and the method includes the following steps:

[0057] Replacement and backwashing steps: After the spiral membrane module has been filtered for a period of time, some pollutants that block the membrane may be deposited on the surface of the raw w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com