Purifying separator

A purification separation and controller technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of lower production efficiency, increased maintenance workload, and decreased filtration performance, so as to ensure filtration performance and reduce maintenance. Work load, productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

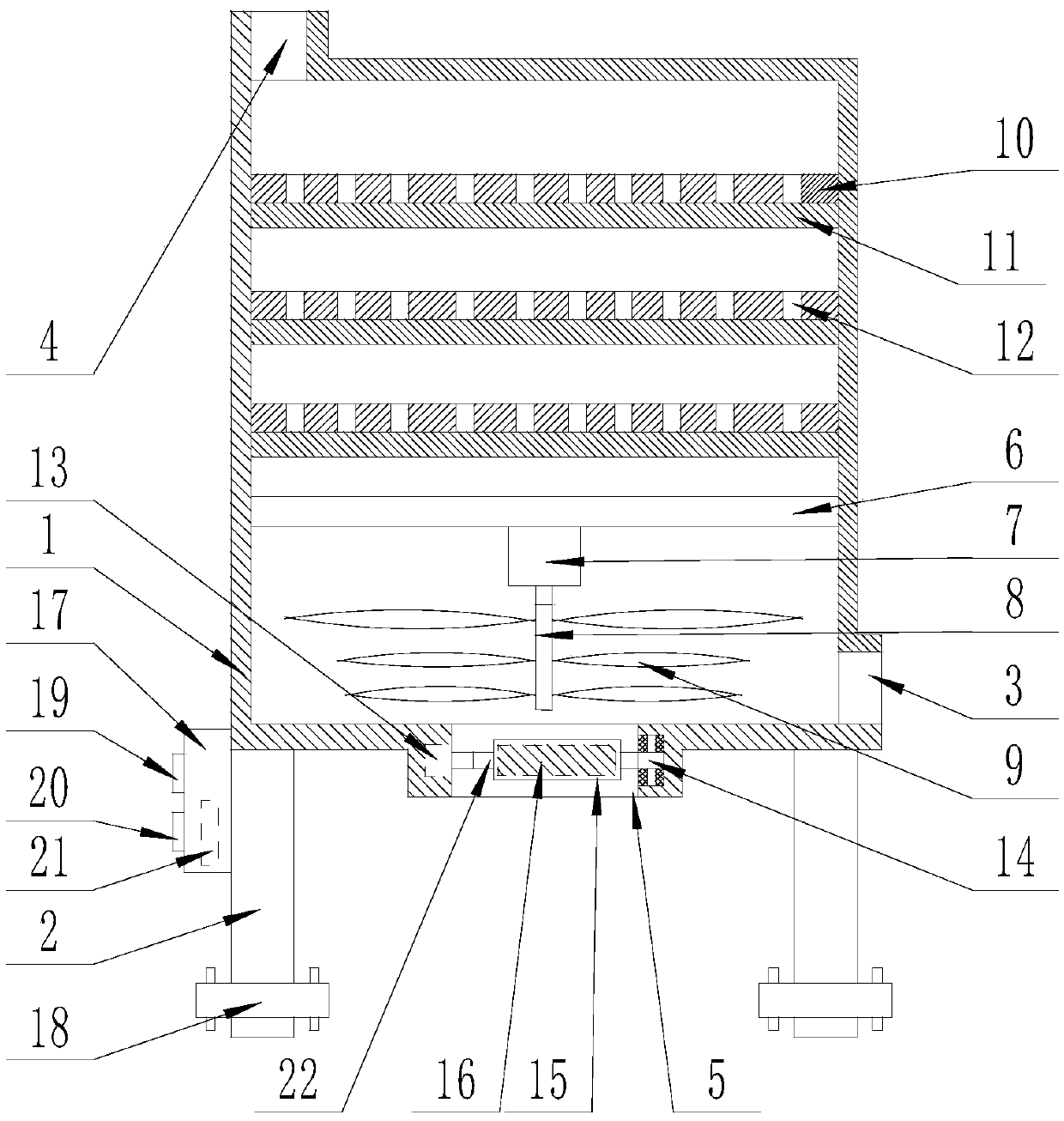

[0017] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, a purifying separator comprises a rectangular box (1), the four corners of the bottom of the rectangular box (1) are provided with columns (2), and the outer surface of the lower end of the rectangular box (1) is provided with There is an air inlet (3), the upper surface of the rectangular box (1) is provided with an air outlet (4), the lower surface of the rectangular box (1) is provided with a slag outlet (5), and the rectangular box (1) is provided with a slag outlet (5). The box body (1) is provided with a crossbeam (6), on which a motor (7) is fixedly installed, and a vertical rotating shaft (8) is fixedly connected to the rotating end of the motor (7), so that Multi-layer blades (9) are fixedly set on the rotating shaft (8), and the rectangular box (1) at the upper end of the beam (6) is provided with multi-layer partitions (10), and each layer of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com