Burner for diesel particulate filter regeneration

A particulate filter and burner technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

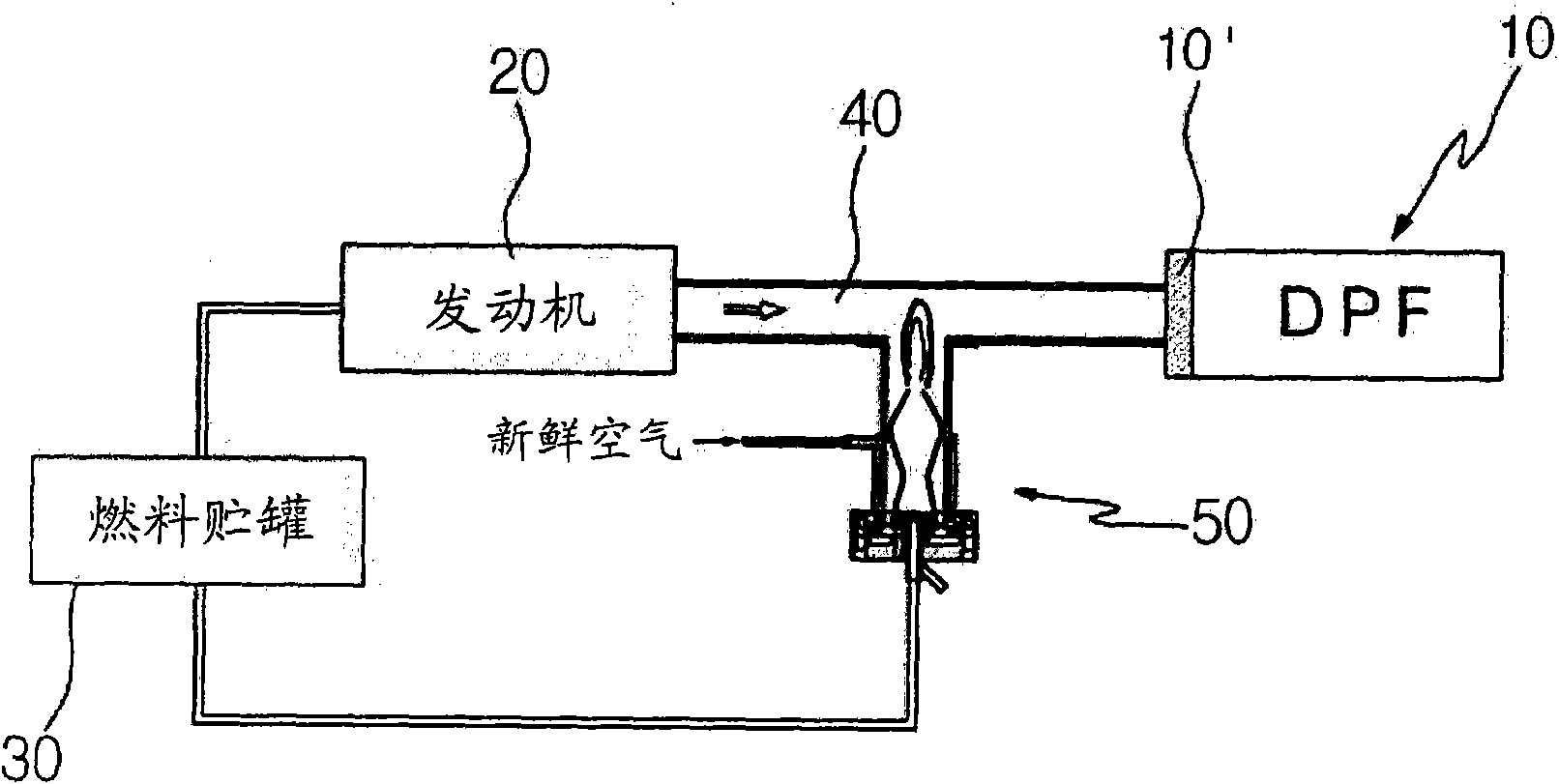

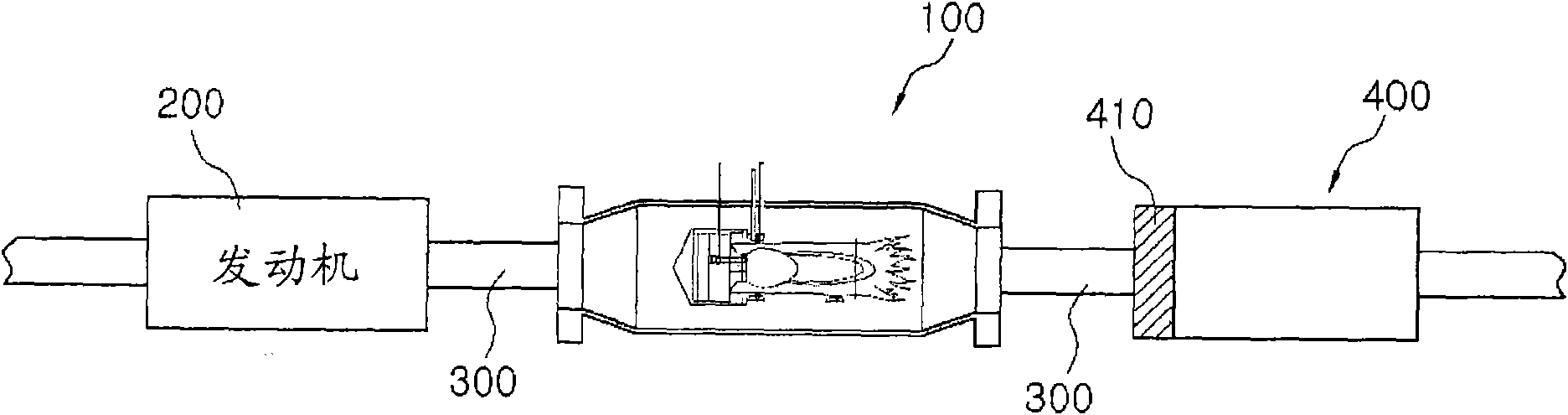

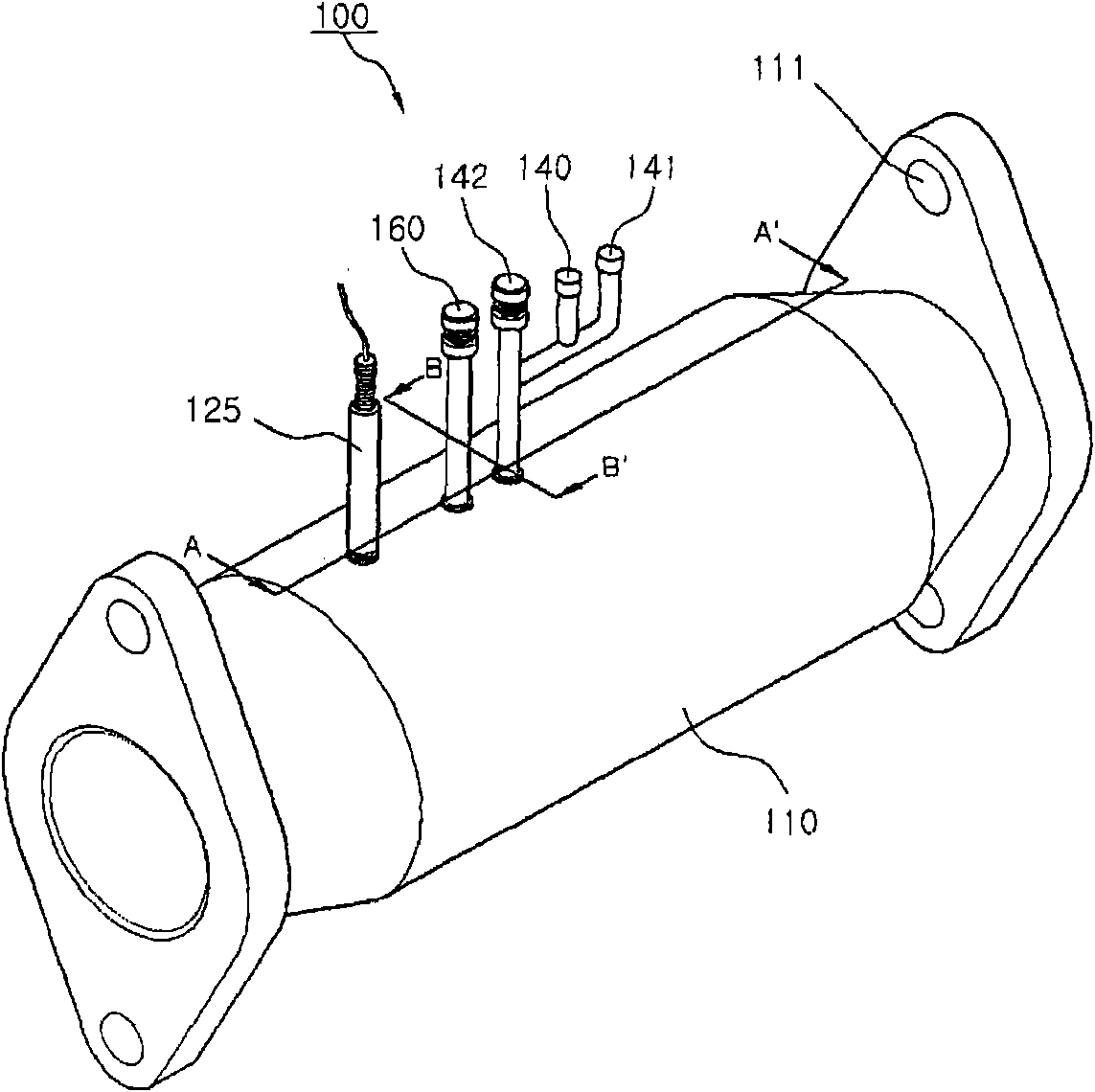

[0128] A burner for regenerating a Diesel Particulate Filter (DPF), wherein the burner generates a rotating discharge (such as plasma or arc) by applying a high voltage to a reaction cell in which there is a rotating flow of fuel and air, and generates ignition , the burner includes: a housing having a hollow interior to become part of an exhaust pipe for connecting a diesel particulate filter to an engine for filtering particulate matter produced by the engine, and the housing Comprising a fixing unit 111 coupled with exhaust pipes on both sides; a main body, which is formed inside the housing and includes a reaction unit; an electrode supporting unit, which is formed inside the main body; an electrode, one side of which is fixed to On the electrode support unit and the electrode is installed on the reaction unit of the main body; the electrode for supplying electric power to the electrode; the supply unit for supplying fuel and air from the fuel supply unit and the air supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com