Curtain type hollow fiber membrane module

A fiber membrane and curtain membrane technology, applied in the field of external pressure immersed hollow fiber membrane modules, can solve the problems of accumulation of sludge, loss of filtration capacity, and adhesion of hollow fiber membrane bundles, etc., to prevent accumulation, maintain filtration capacity, Avoid accumulated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

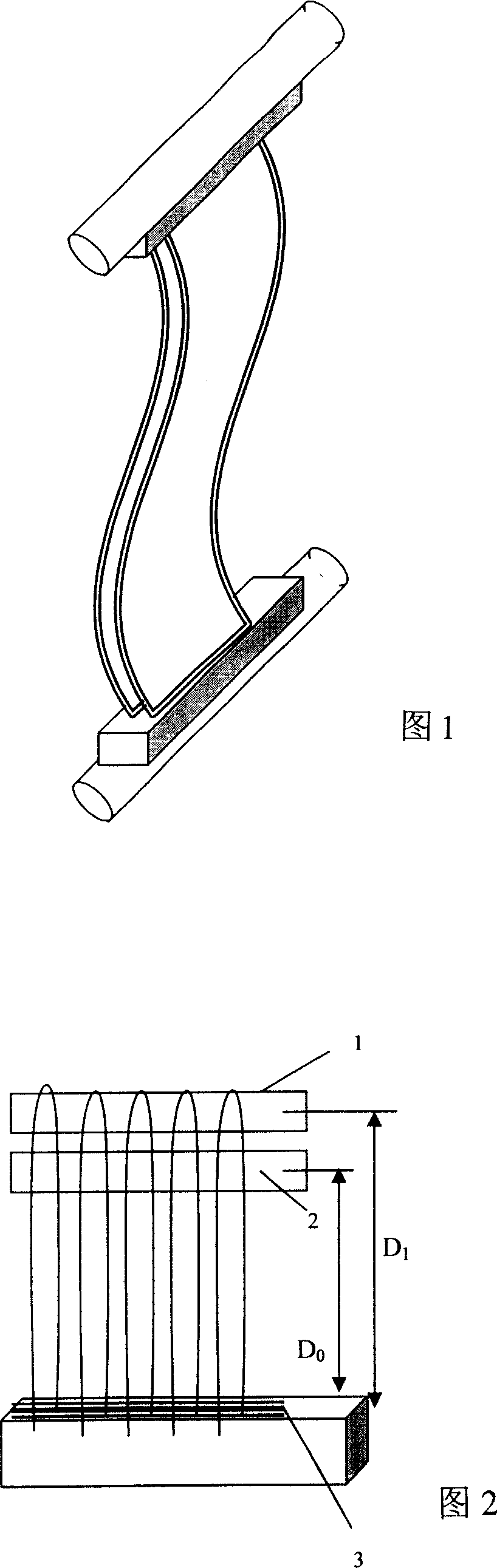

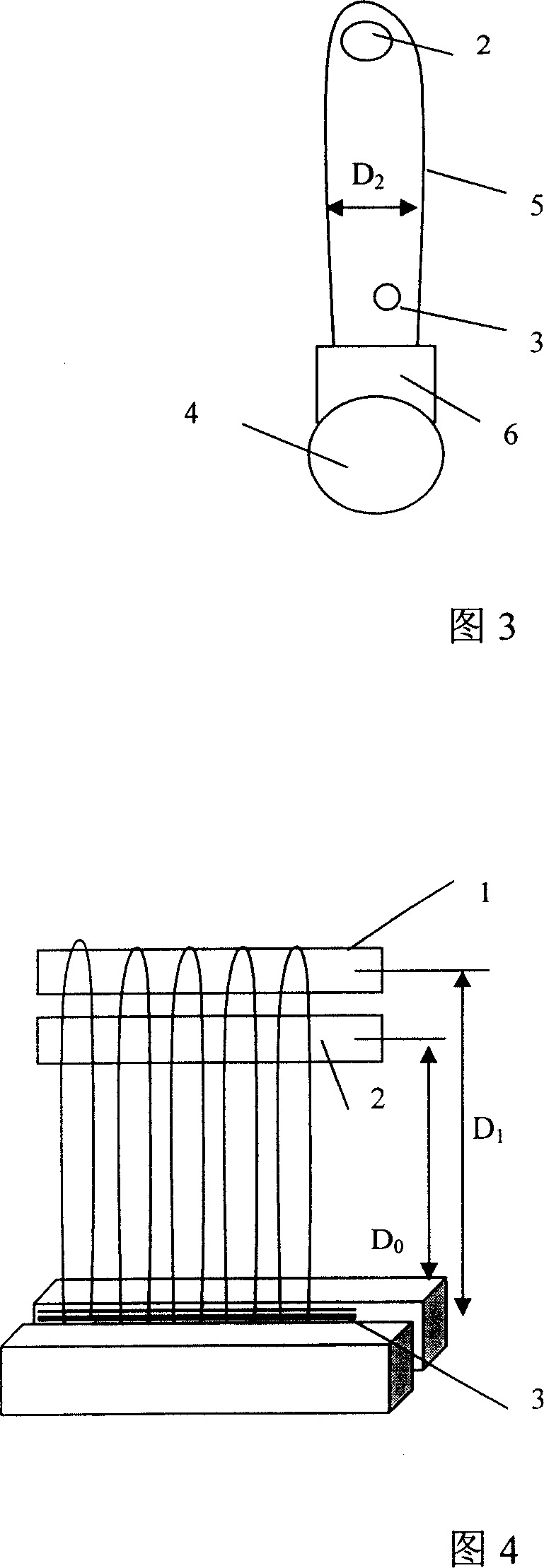

[0034] As shown in Figure 2, the single-piece hollow fiber curtain membrane is inverted U-shaped, and the insertion tube 2 is inserted into the upper space of the bent single-piece membrane, so as to prevent the membrane filaments from being messed up. The diameter of the insertion tube is 5-50 mm.

[0035] In Figure 2, mark 1 shows the position where the cannula can be when the hollow fiber membrane is tight; mark 2 is the actual position where the cannula is when the hollow fiber membrane has a certain degree of slack.

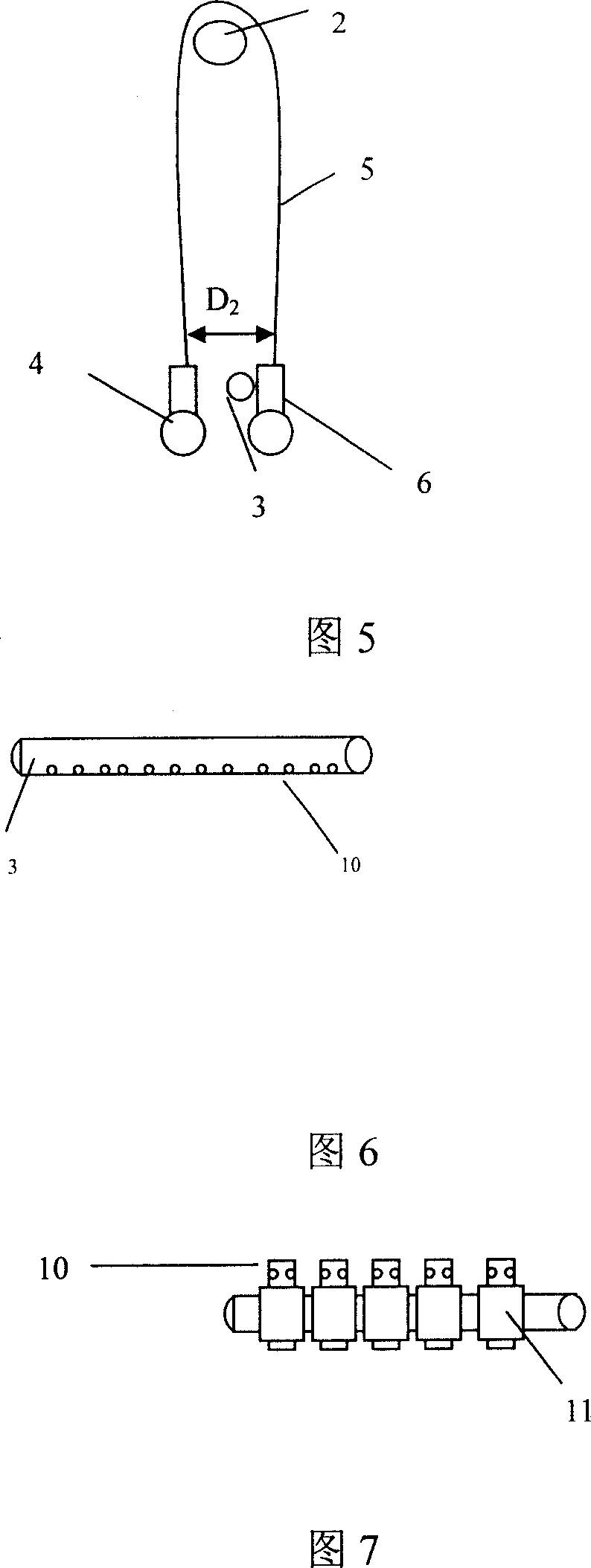

[0036] The two ends of the membrane filament of the present invention can be cast in a casting box 6 as shown in Figures 2 and 3, (Figure 3 is a side view of the hollow fiber curtain membrane structure of Figure 2 of the present invention), and can also be shown in Figures 4 and 5 As shown, it is cast in two casting boxes 6 (Fig. 5 is a side view of the hollow fiber curtain membrane structure in Fig. 4 of the present invention).

[0037] No matter which way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com