Stand column

A column and body technology, applied in the field of machine tool parts, can solve the problems that affect the machining accuracy of workpieces and product quality, cannot meet the requirements of high-efficiency load cutting, and the machine tool is not tightly and firmly combined, so as to improve machining accuracy and product quality. , to meet the effect of high-efficiency load cutting and the overall compact structure of the column

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a further understanding and recognition of the structural features and the achieved effects of the present invention, the preferred embodiments and accompanying drawings are used for detailed description, as follows:

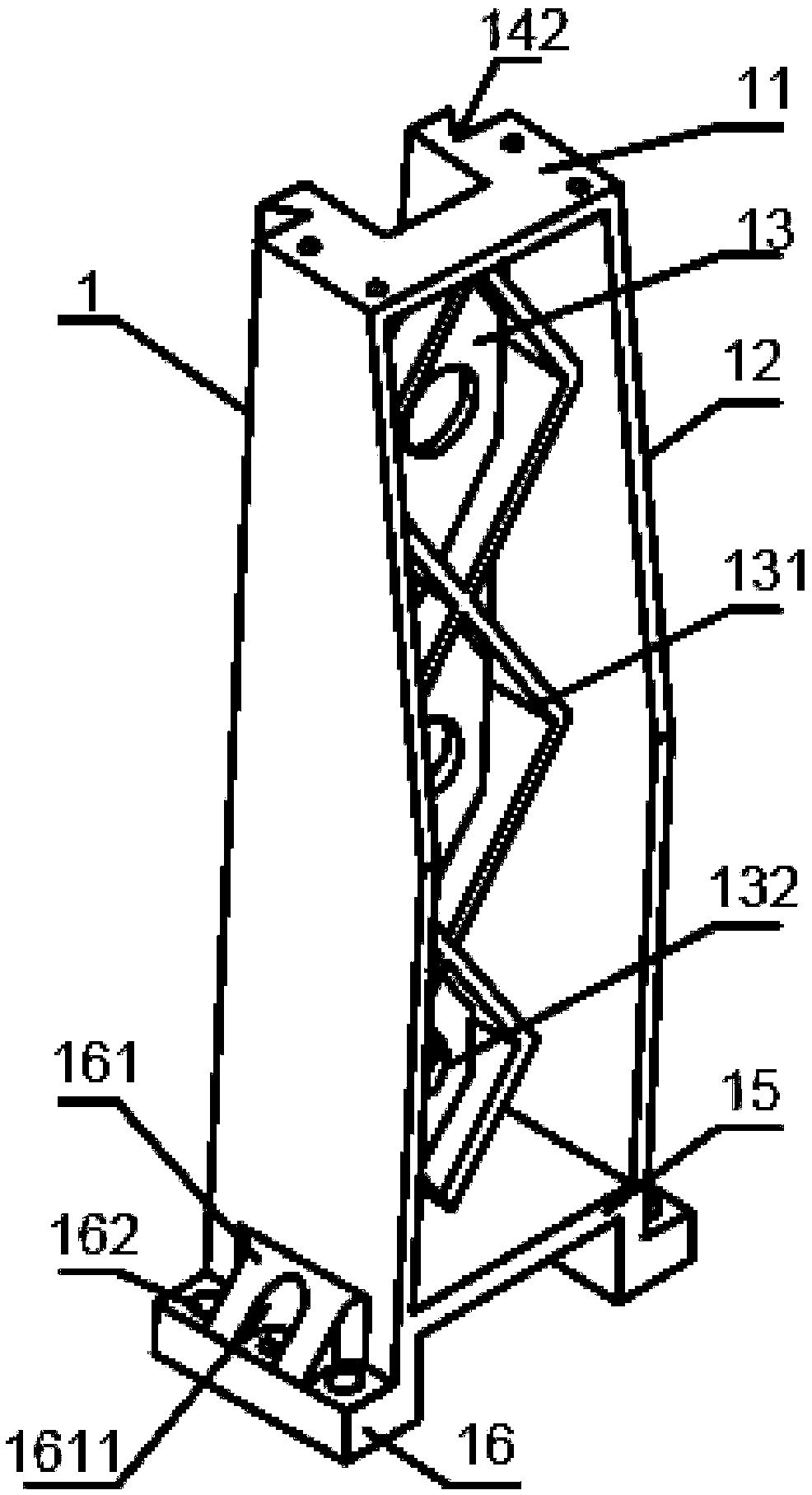

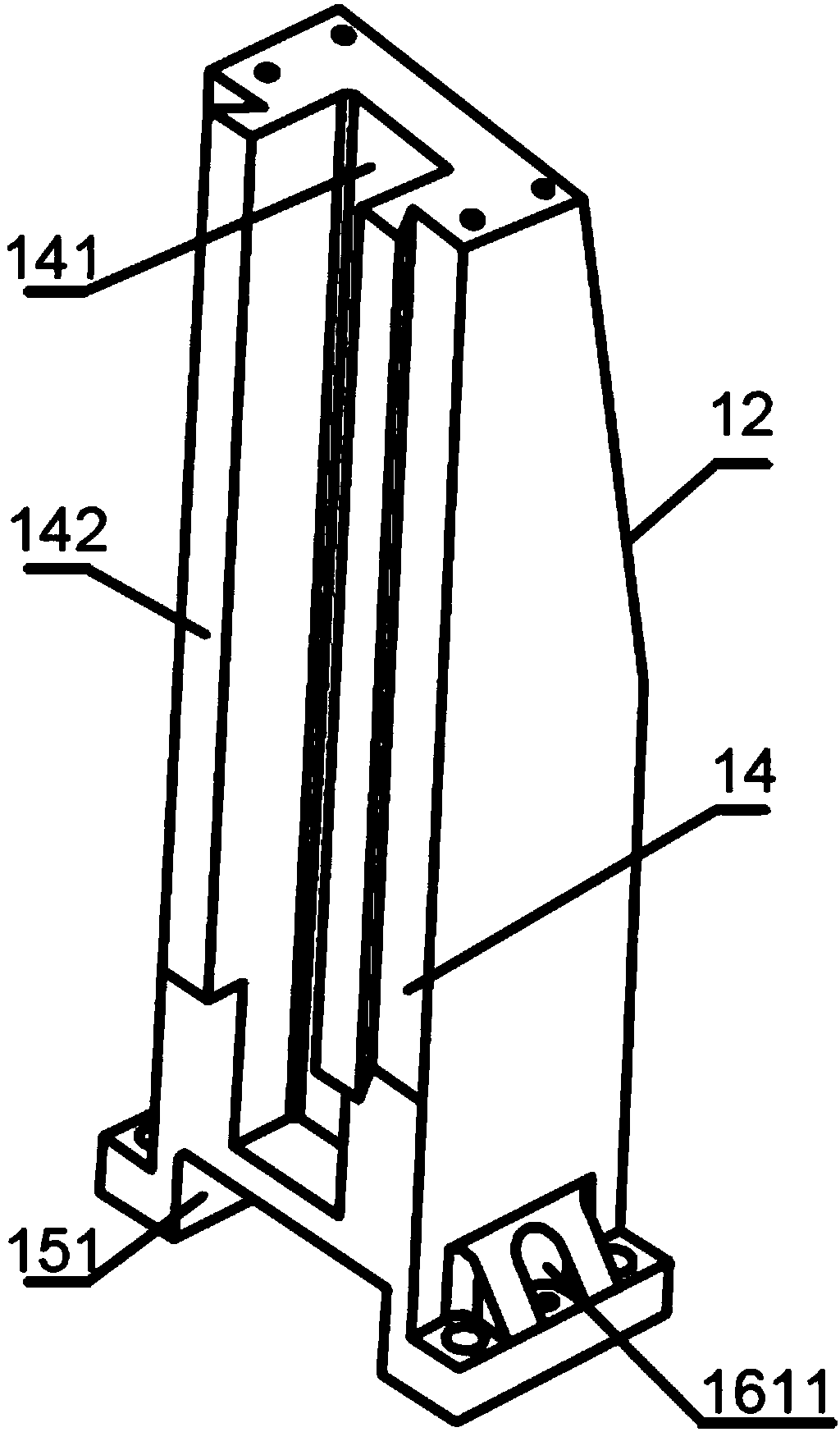

[0029] Such as figure 1 , figure 2 As shown, the column includes a column body 1, and the column body 1 includes a connection surface 13. The connection surface 13 extends vertically from the top surface 11 of the column body 1 to the bottom surface 15, and the connection surface 13 separates the column body 1 into a front cavity and a back cavity. 141, the connecting surface 13 is provided with a hoisting hole 132;

[0030] There are multiple connecting surface reinforcing ribs 131 arranged on the connecting surface 13 in the front cavity, and the connecting surface reinforcing ribs 131 connect the left side wall and the right side wall of the column body 1, and connect the top surface 11 and the bottom surface 15 of the column body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com