Anti-backlash gear

A gear and anti-backlash technology, used in belts/chains/gears, transmission parts, mechanical equipment, etc., can solve the problems of troublesome, time-consuming and complicated structure of anti-backlash gear processing, and achieve the improvement of NVH level and the optimization of the overall structure. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

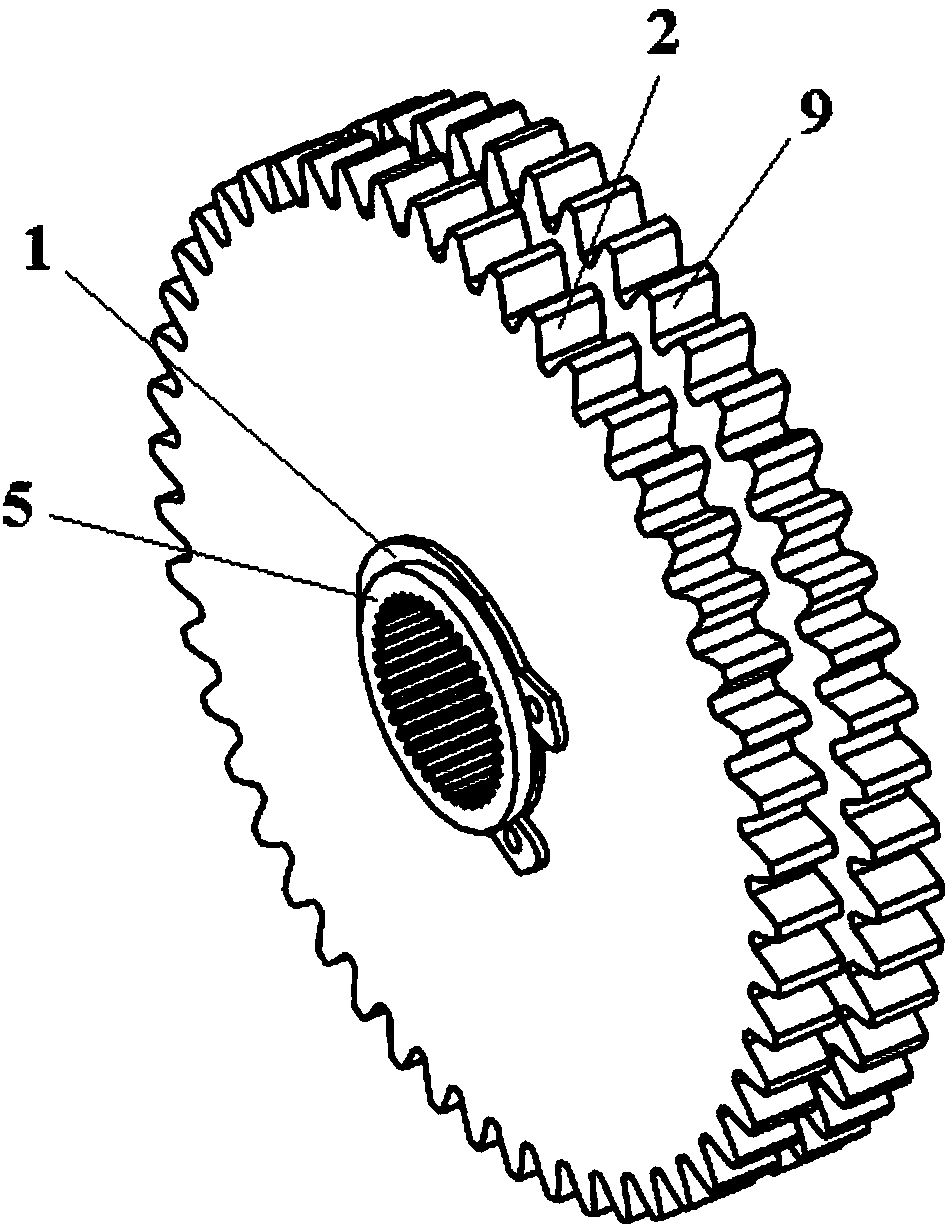

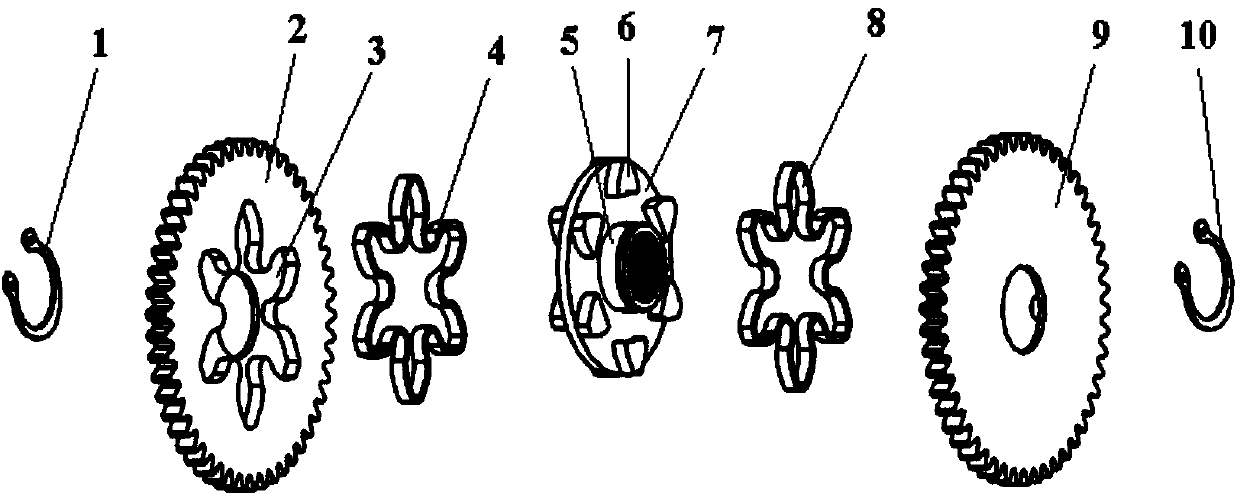

[0027] The middle hub includes a disc 7, a central cylinder 5 passing through the center of the disc 7, and a first locking projection and a second locking projection respectively arranged on both sides of the disc 7; The two ends pass through the center holes of the first side gear 2 and the second side gear 9 respectively, and the two ends of the central cylinder 5 pass through the first side gear 2 and the second side gear 9 respectively pass through the half-ring retaining spring 1 And the semi-circular circlip 10 is clamped with the first side gear 2 and the second side gear 9, so that the first side gear 2, the middle hub and the second side gear 9 are connected together, and the central cylinder 5 can be inserted into the transmission shaft , the transmission shaft drives the entire anti-backlash gear to rotate through the central cylinder 5; the first locking protrusion and the second locking protrusion are six triangular protrusions 6 evenly distributed along the circu...

Embodiment 2

[0032] In this embodiment, the first locking protrusion and the second locking protrusion are four circular protrusions uniformly distributed along the circumferential direction on the disc, and the first locking protrusion and the second locking protrusion The structures of the locking protrusions are the same, but the positions of the four circular protrusions of the first locking protrusion and the positions of the four circular protrusions of the second locking protrusion are in the circumferential direction of the disk. Relatively misaligned. The first locking notch and the second locking notch are respectively corresponding to the structure of the first locking protrusion and the second locking protrusion, and the first elastic washer and the second elastic washer are respectively corresponding to the first The shape of the locking notch corresponds to that of the second locking notch.

[0033] The anti-backlash gear of this embodiment can also achieve the effect of Emb...

Embodiment 3

[0036] In this embodiment, the first locking protrusion and the second locking protrusion are three elongated protrusions extending outward from the central cylinder of the intermediate hub on the disc and evenly distributed along the circumferential direction. , the structure of the first locking protrusion is the same as that of the second locking protrusion, but the positions of the three elongated protrusions of the first locking protrusion are the same as those of the second locking protrusion The positions of the three circular bumps are relatively misaligned in the circumferential direction of the disc. The first locking notch and the second locking notch are respectively corresponding to the structure of the first locking protrusion and the second locking protrusion, and the first elastic washer and the second elastic washer are respectively corresponding to the first The shape of the locking notch corresponds to that of the second locking notch.

[0037] The anti-bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com