Coolant circulation system for turbocharger

A turbocharger and circulation system technology, applied in the direction of engine cooling, coolant flow control, power unit cooling combination arrangement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following description is merely exemplary in nature and is not intended to limit the invention, application or uses. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

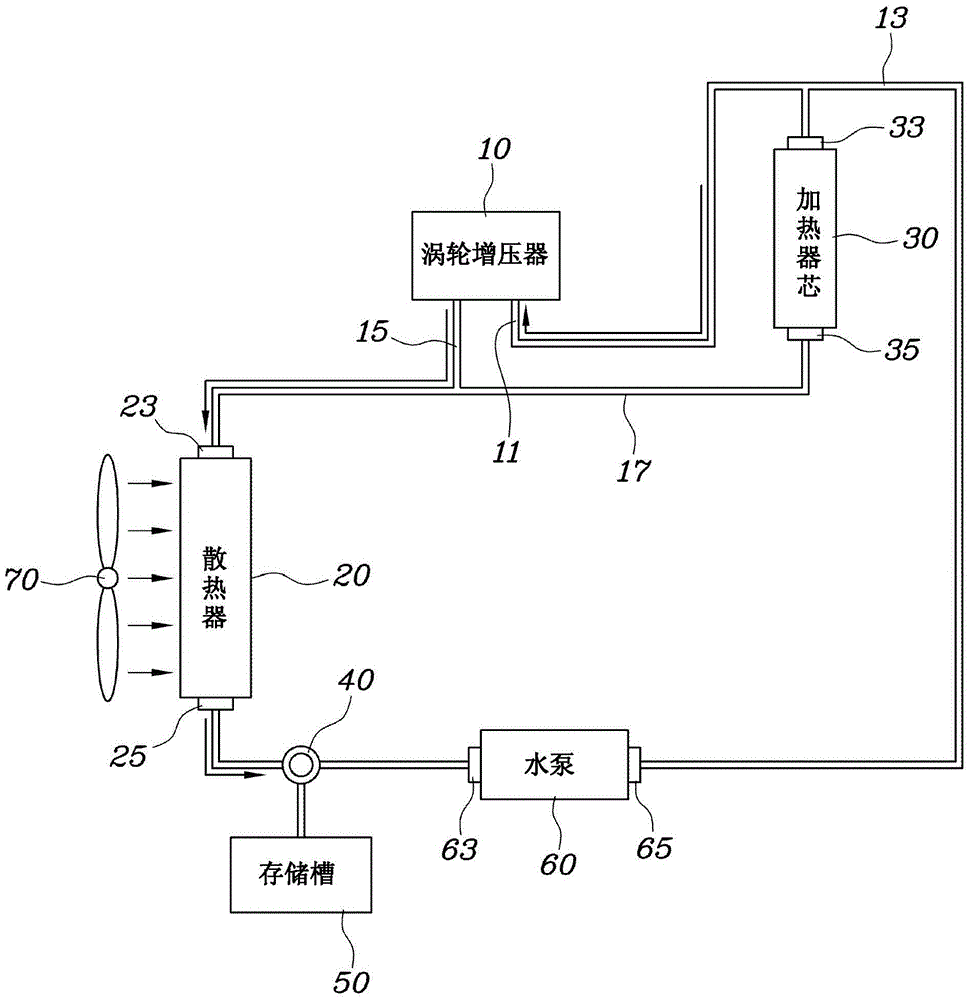

[0023] figure 2 A coolant circulation system for a turbocharger according to an exemplary embodiment of the present invention is explained. refer to figure 2 , the coolant circulation system includes a turbocharger 10 provided with a coolant outlet line 15 and a coolant inlet line 11 . The coolant outlet line 15 through which the coolant exits the turbocharger 10 is connected to a first flow path 17 which connects the inlet end 23 of the radiator to the outlet end 35 of the heater core. A coolant inlet line 11 through which coolant is supplied to the turbocharger 10 is connected to a second flow path 13 which connects the first end 65 of the water pump to the inlet end 33 of the heater core.

[0024] In conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com