Patents

Literature

42results about How to "Simple locking method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

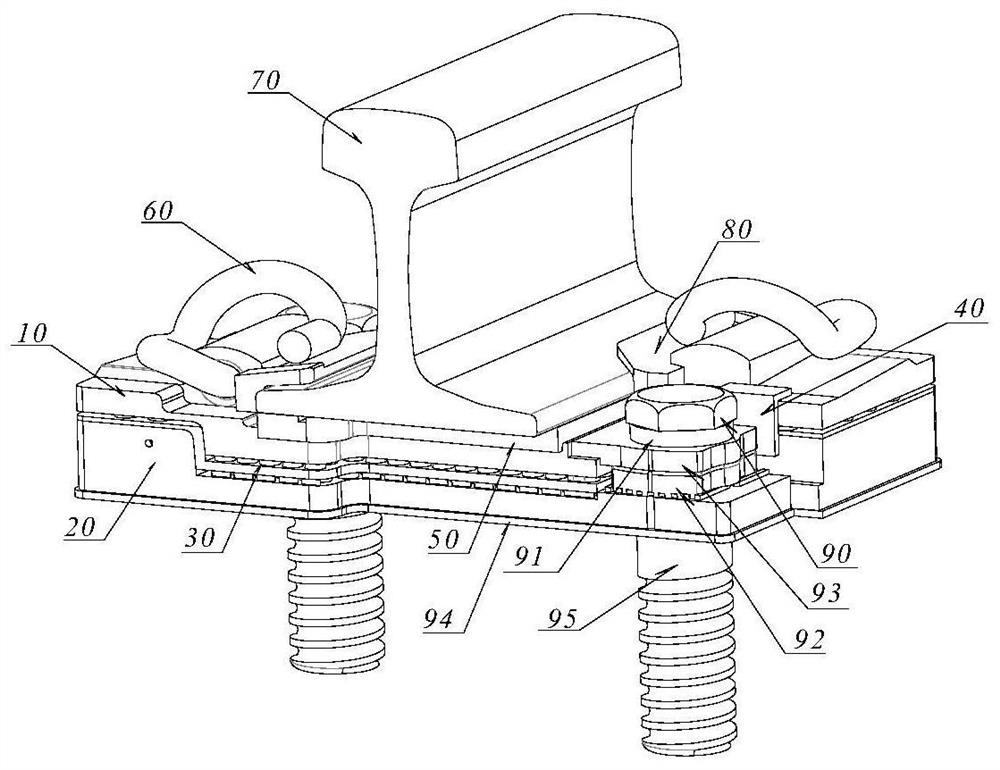

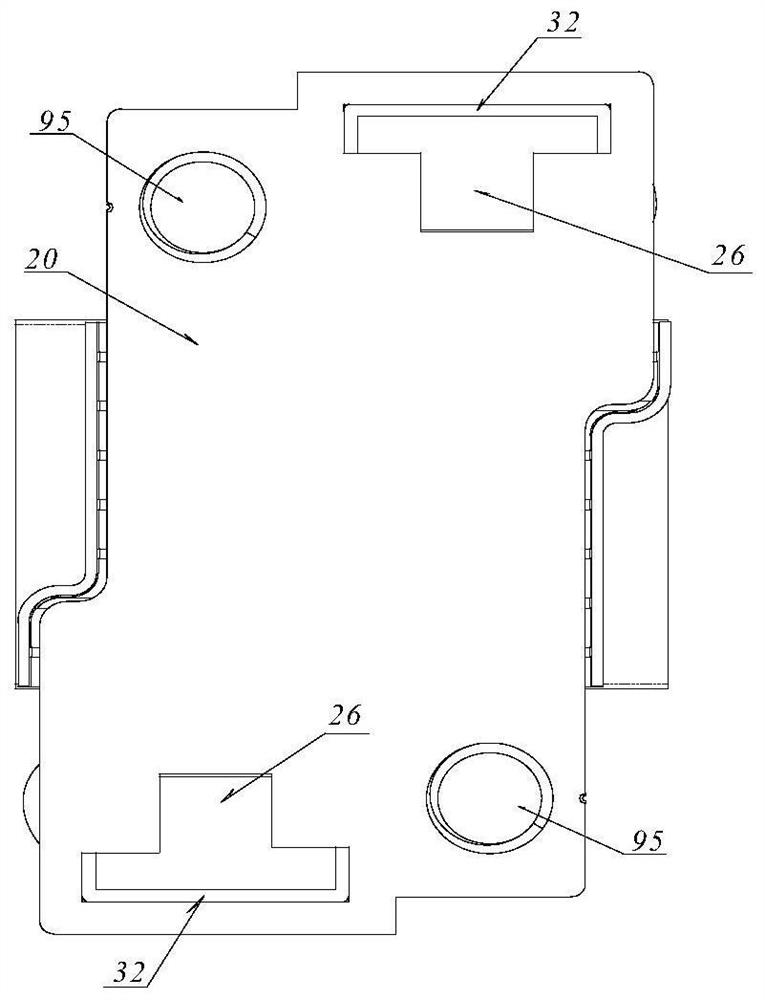

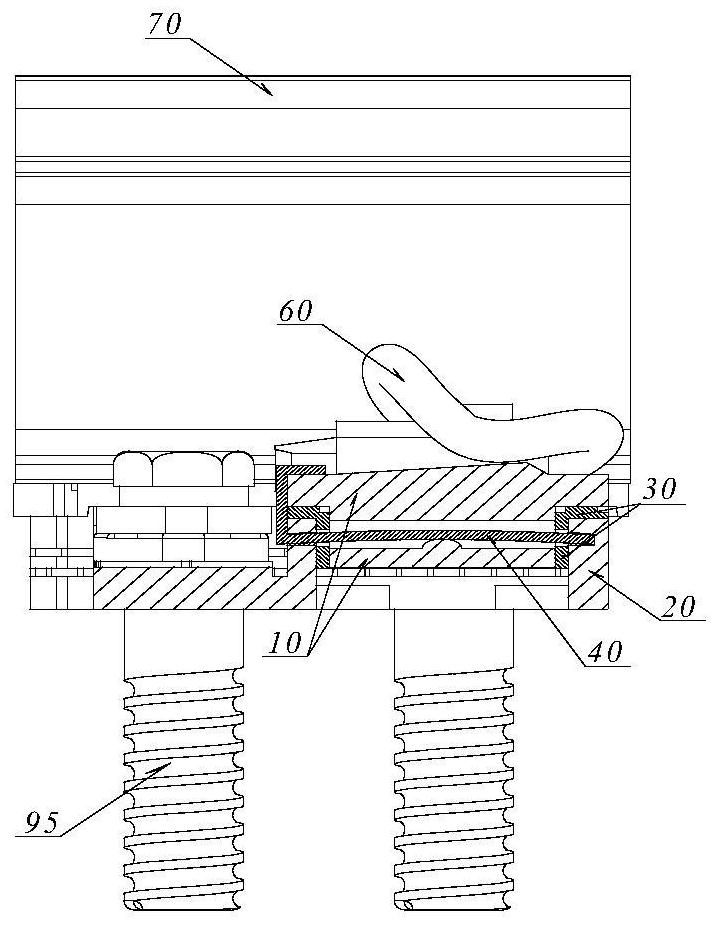

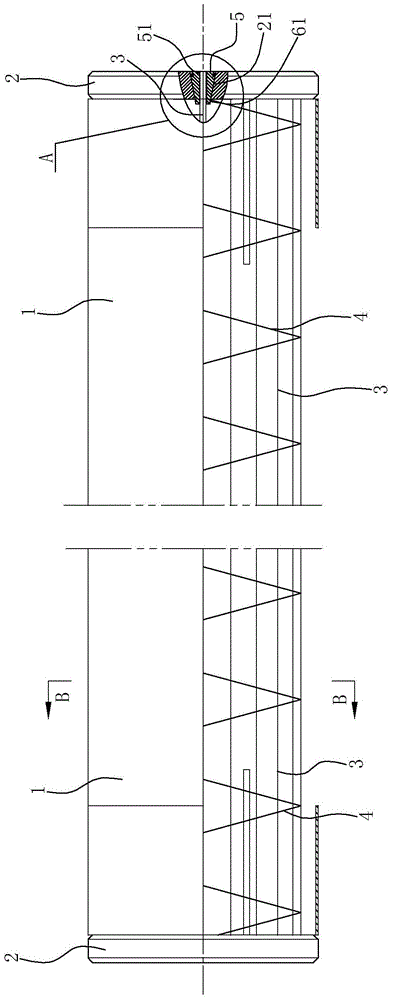

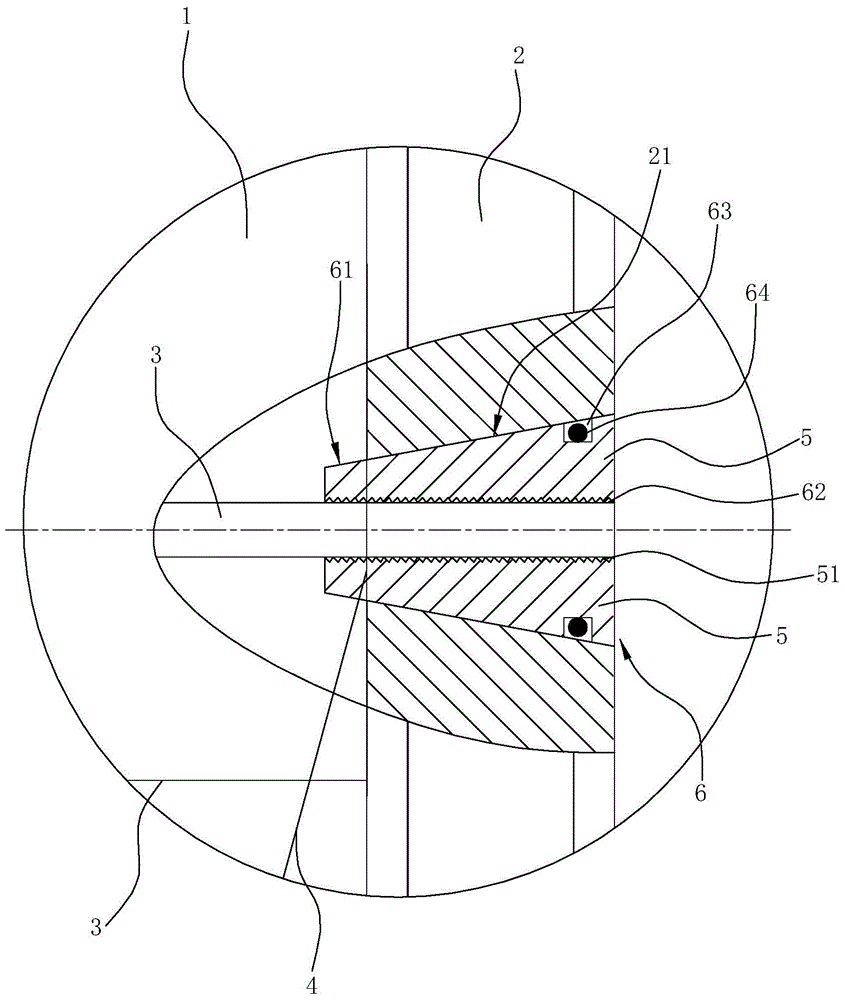

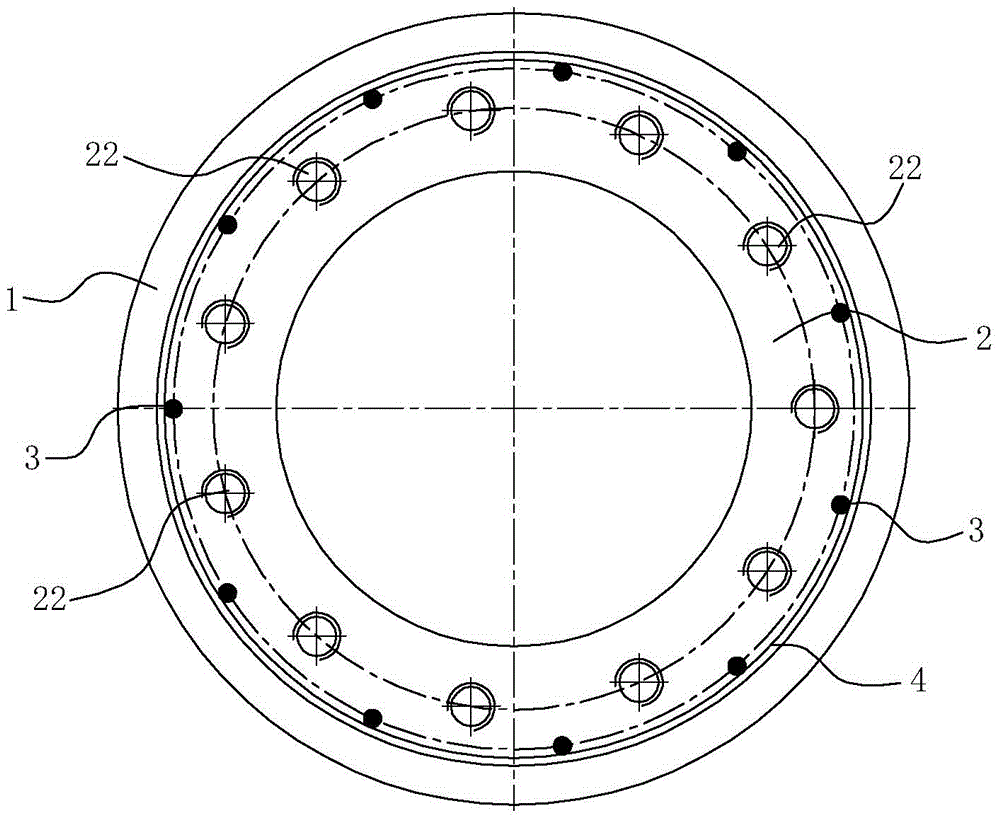

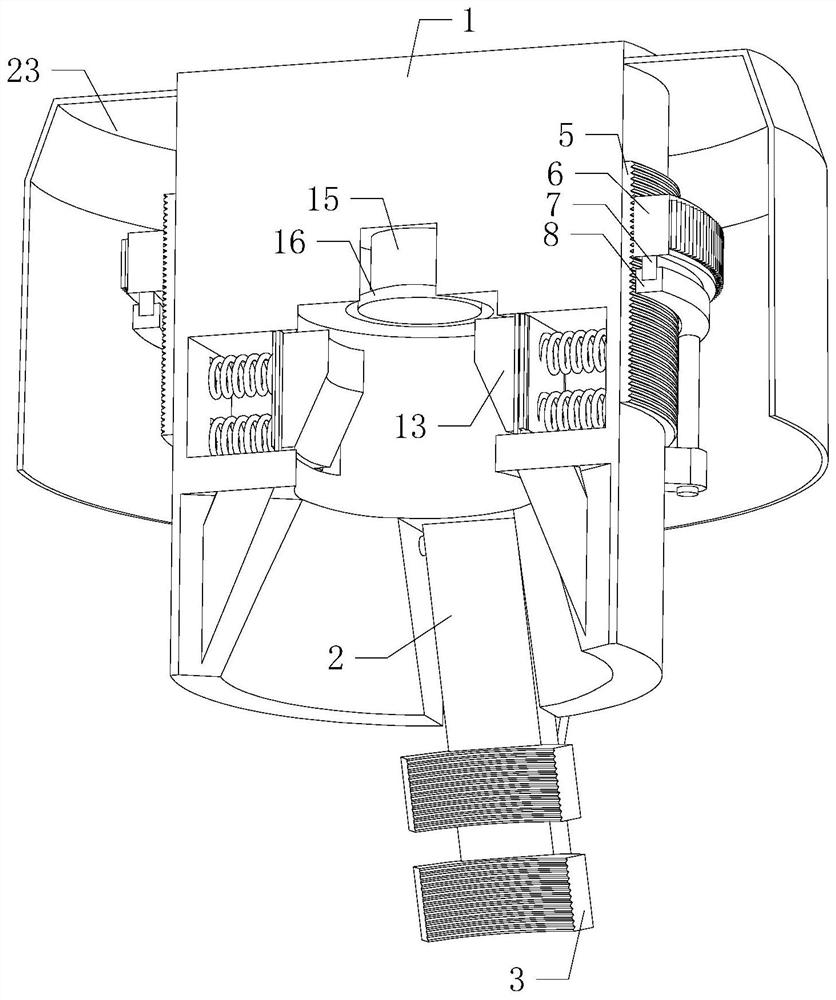

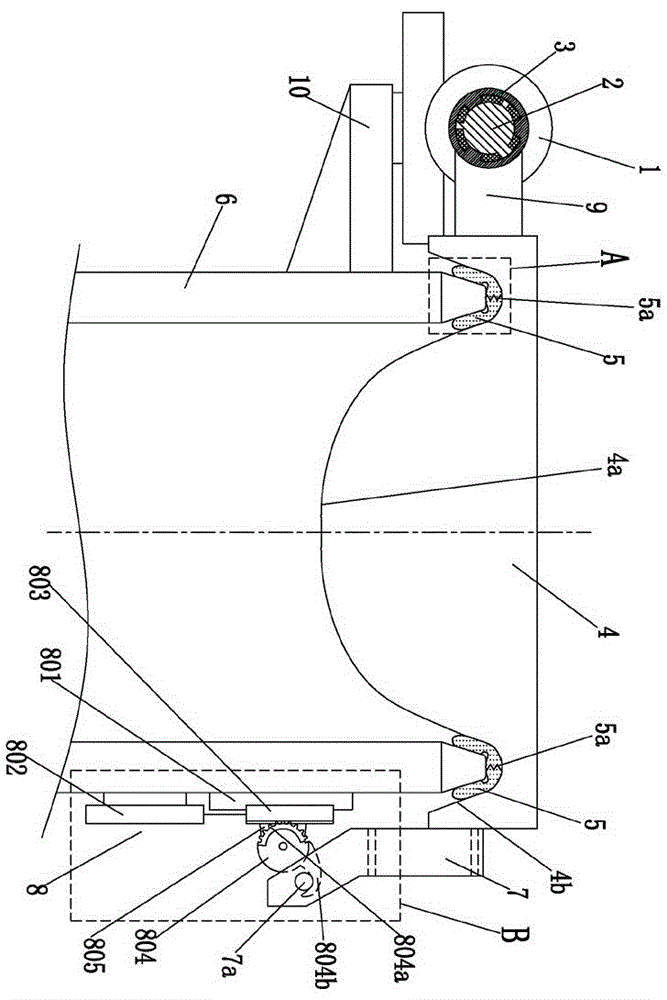

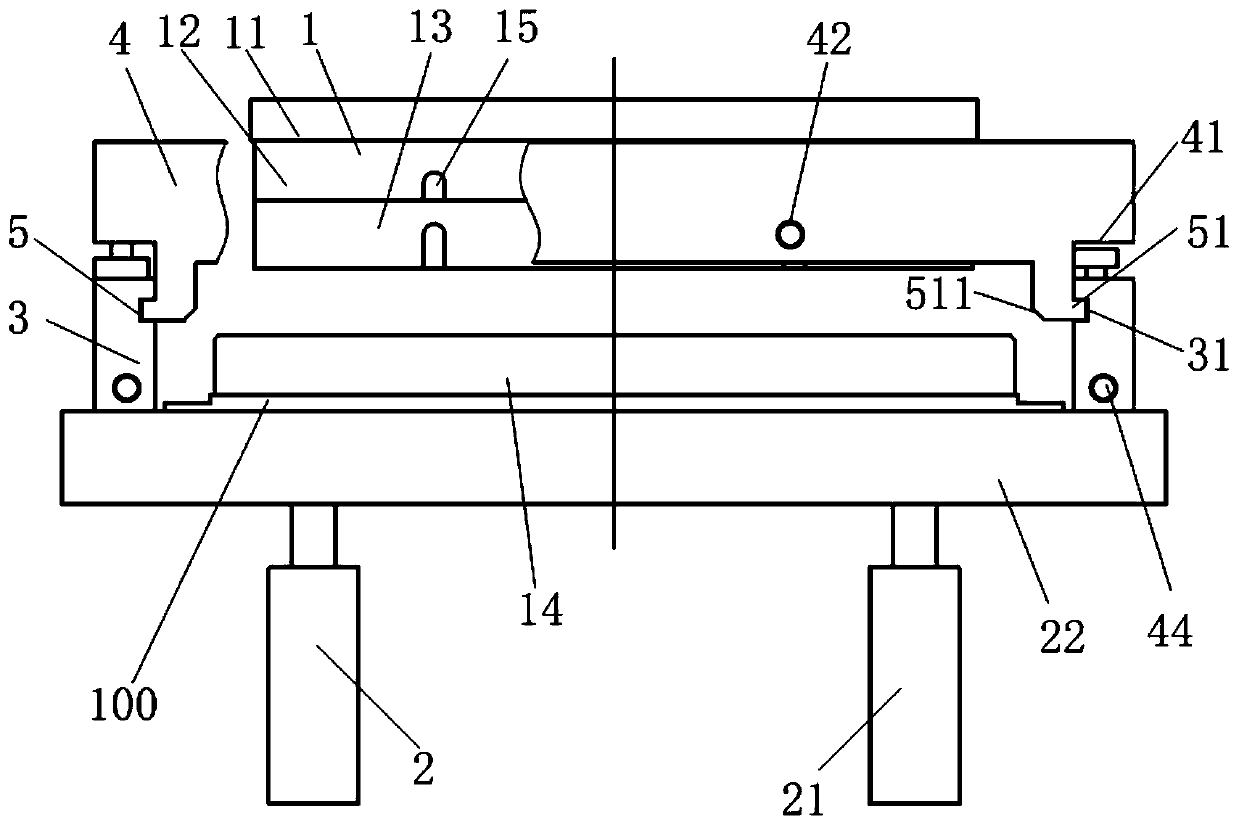

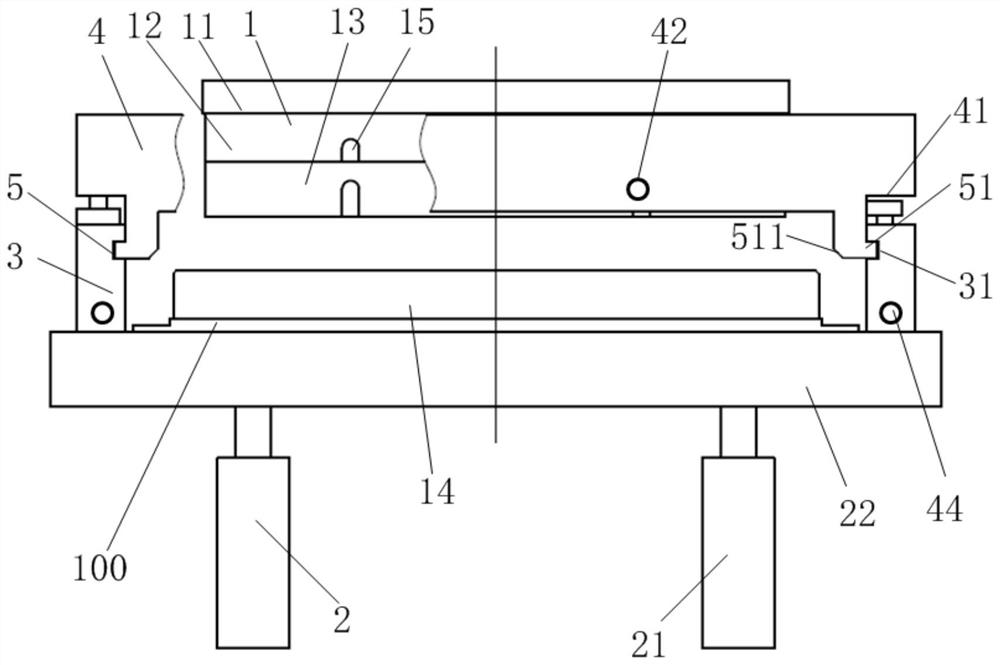

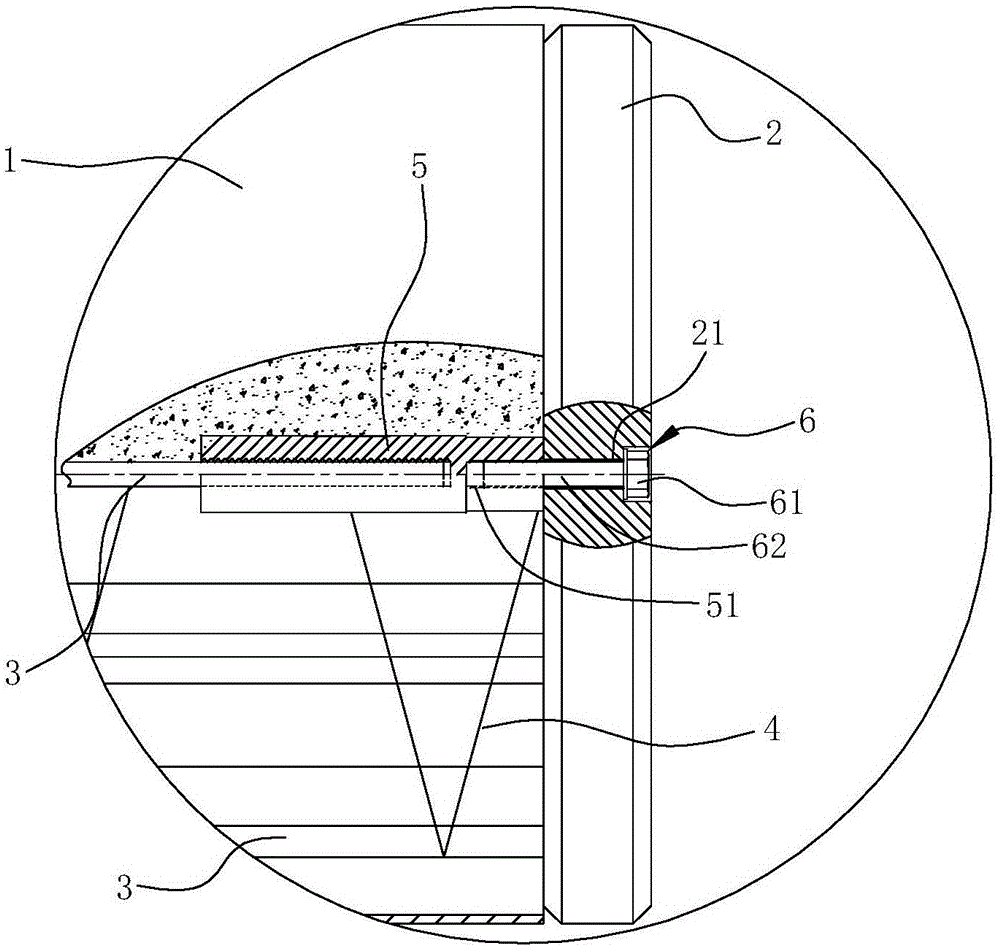

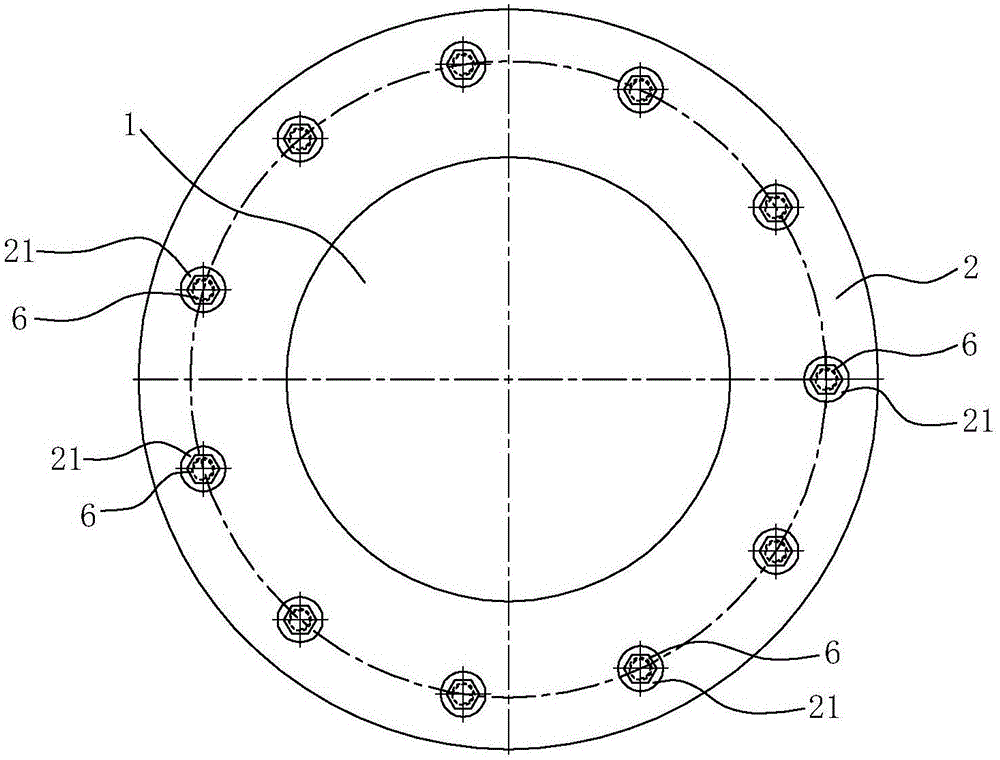

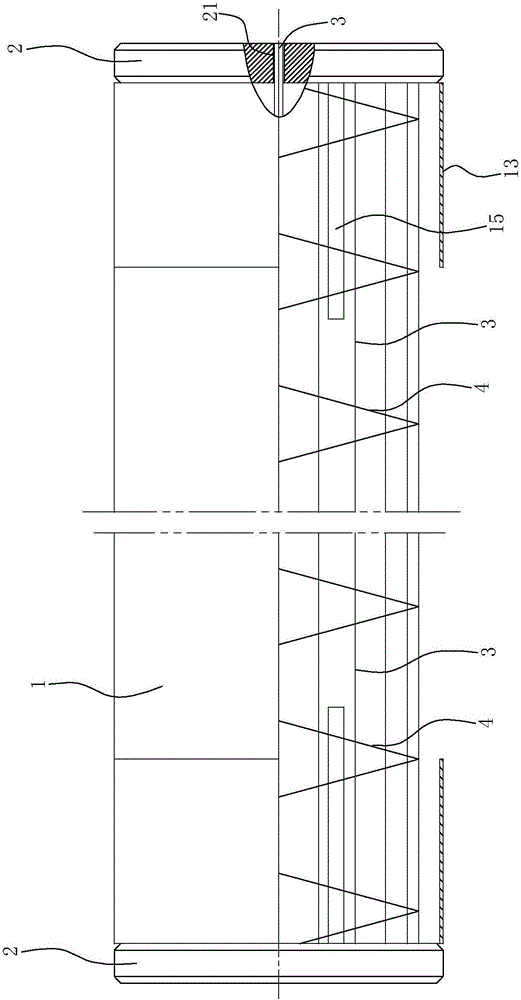

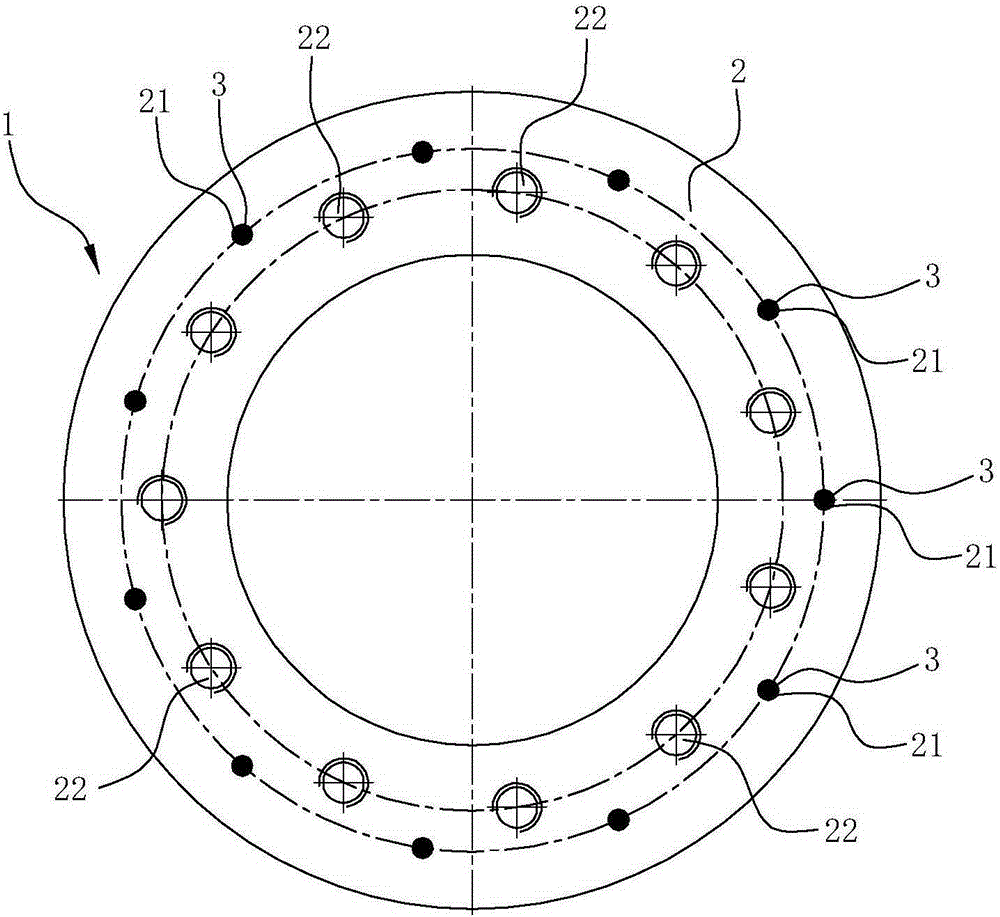

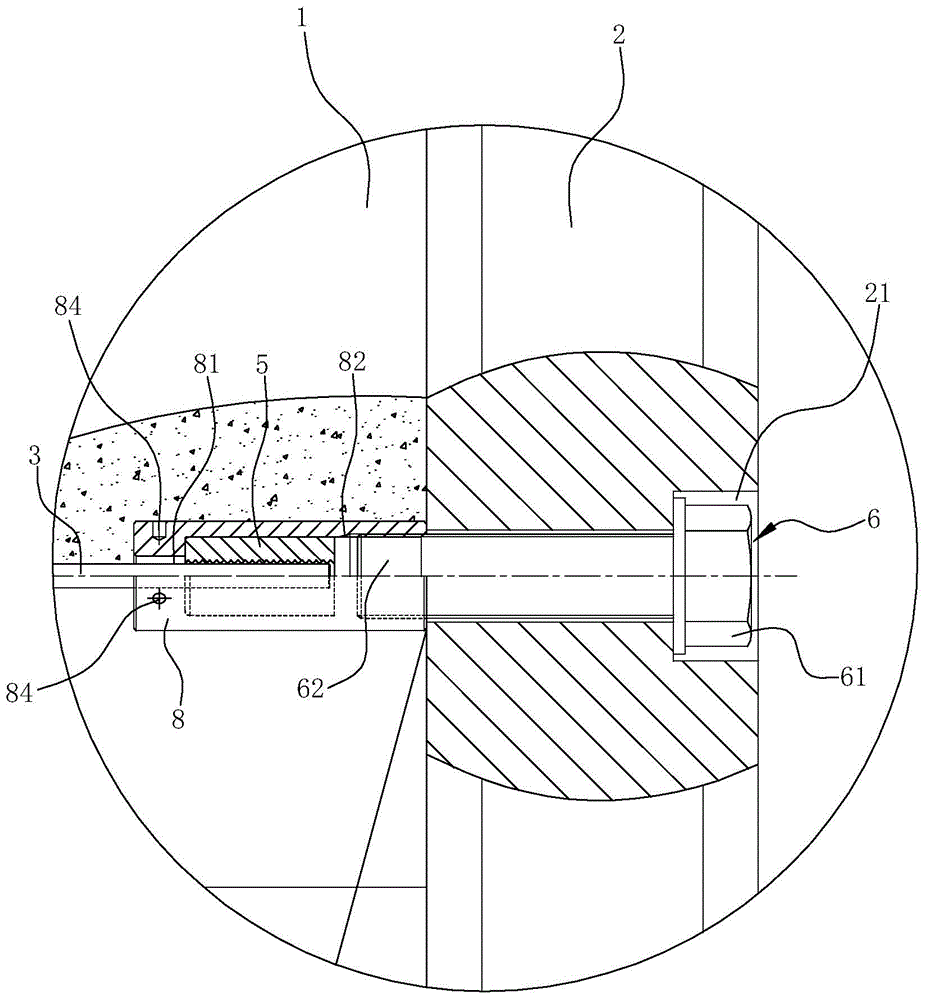

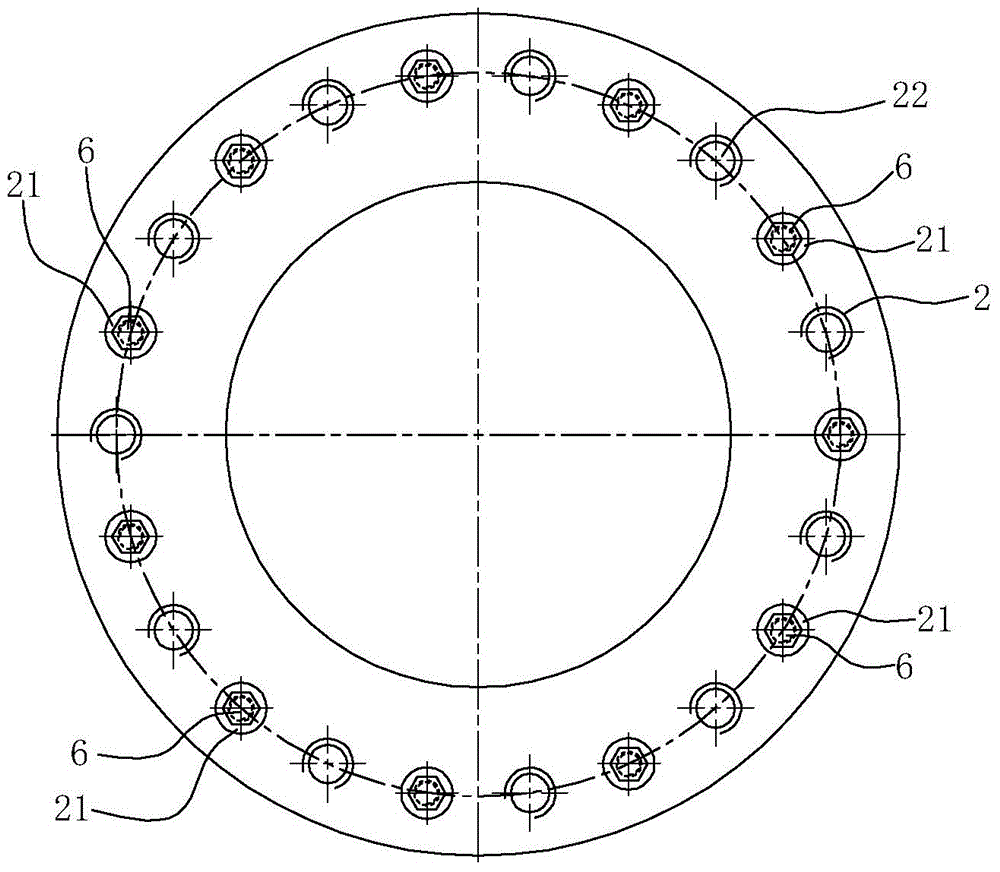

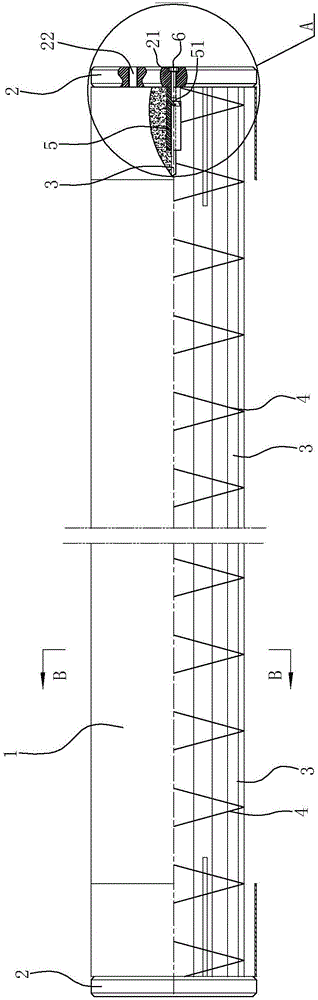

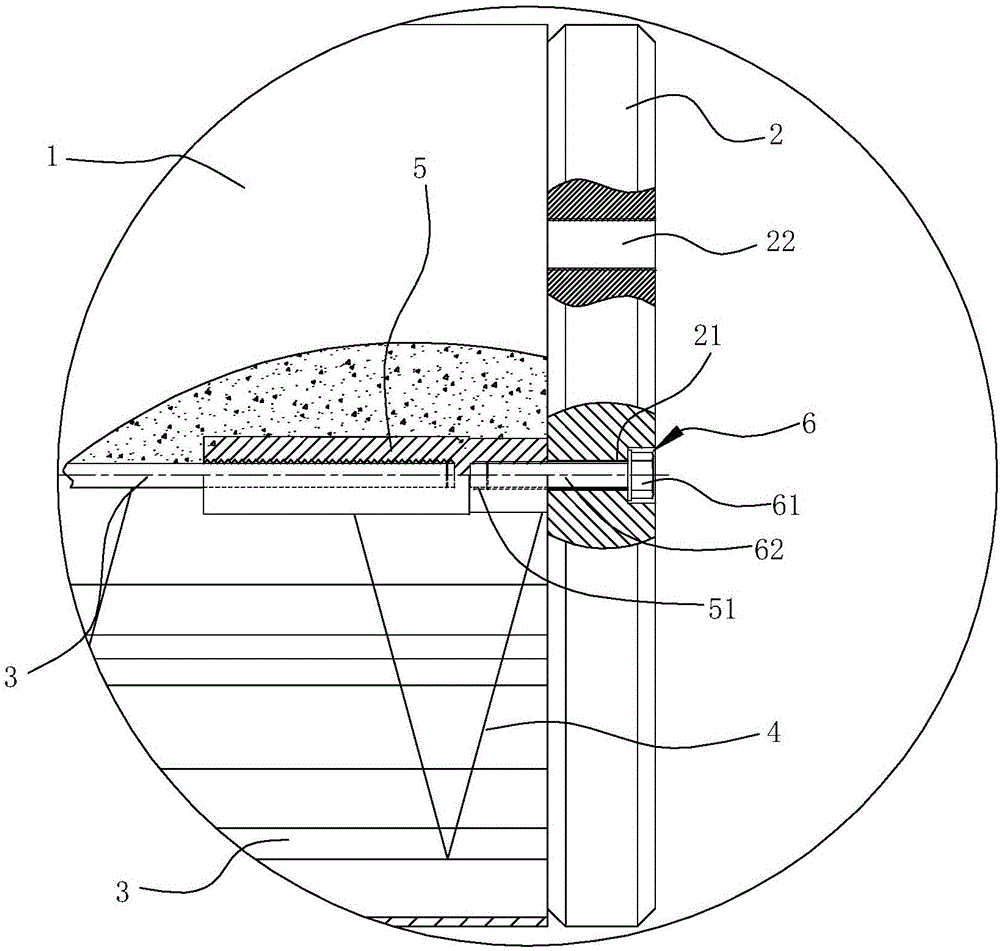

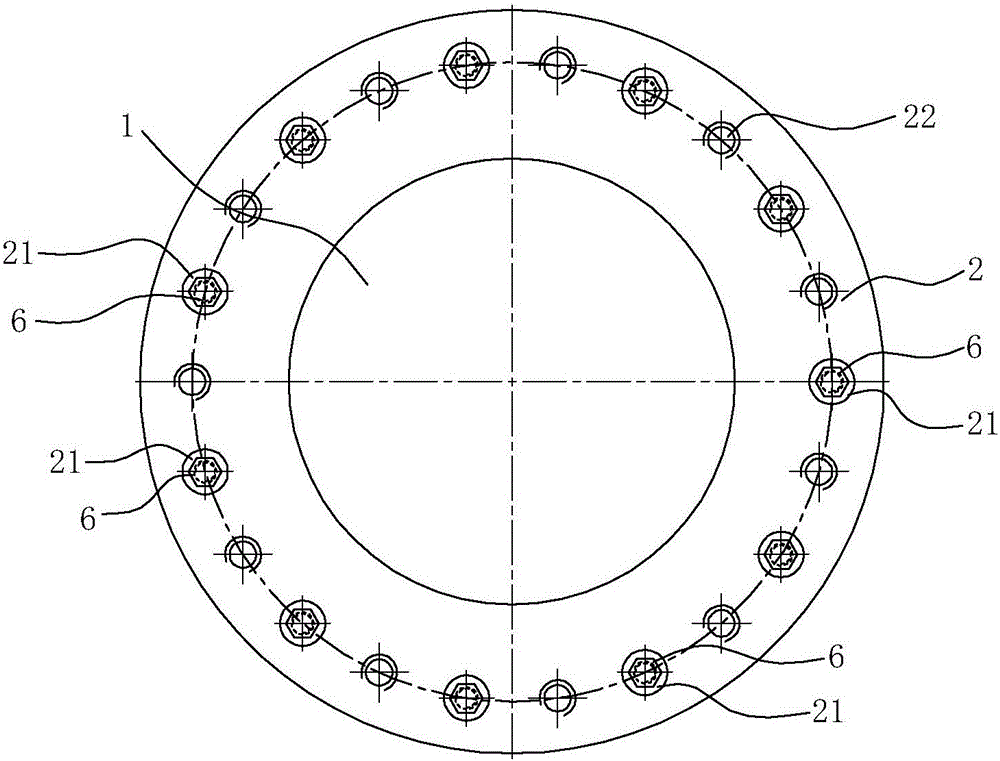

Double-layer rail vibration reduction fastener with blocking shoulder

The invention relates to a double-layer rail vibration reduction fastener with a blocking shoulder, which aims to simplify the locking mode of the double-layer vibration reduction fastener, relieve the vibration of an elastic strip, overcome the problem that a connecting part is easy to wear, improve the transverse and longitudinal rigidity and deflection rigidity of the fastener and effectively reduce the noise and the wear of a steel rail in the operation process. The vibration isolation sleeper comprises an under-plate insulating substrate, a lower iron substrate, a vibration isolation substrate and an upper iron substrate which are sequentially stacked from bottom to top from the surface of the sleeper, and is characterized in that corresponding square limiting blocking shoulders are arranged on the two sides of the vibration isolation substrate and the two sides of the lower iron substrate; locking pins which longitudinally penetrate through the lower iron substrate, the vibrationisolation substrate limiting blocking shoulder and the lower protruding portion of the upper iron substrate and vertically lock the lower iron substrate, the vibration isolation substrate limiting blocking shoulder and the lower protruding portion are arranged on the two sides of the steel rail. The lower iron substrate and the vibration isolation substrate are anchored on the sleeper through anchor bolts; an under-rail substrate is laid on the plate face of the middle of the upper iron substrate, a steel rail is located on the under-rail substrate, and an elastic strip installed and locked on the upper iron substrate acts on the steel rail through an insulation gauge cushion block and tightly presses the steel rail.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD +1

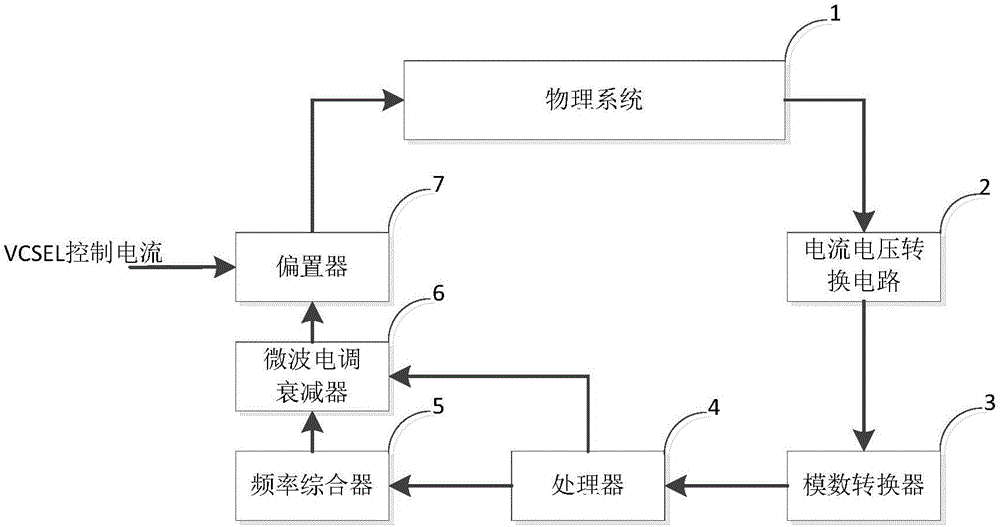

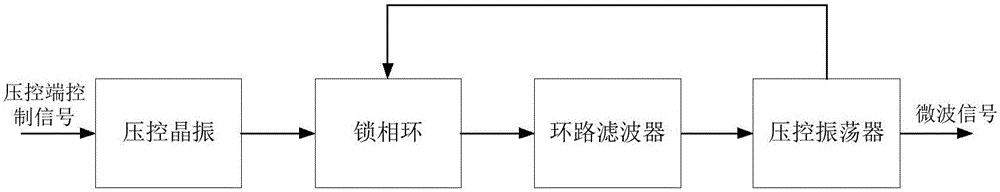

CPT atomic frequency standard laser frequency modulation index locking device and method

ActiveCN106788426AReduce short-term frequency stability deteriorationImproved long-term frequency stability performancePulse automatic controlPhase discriminationAtomic frequency standard

The invention discloses a CPT atomic frequency standard laser frequency modulation index locking device and method. The power of a microwave signal superposed on VCSEL drive current is modulated; simultaneously, synchronous phase-discrimination of a light inspection signal is carried out, so that a signal that the extreme value of a Doppler absorption line is changed with the modulation index of a frequency modulation laser is obtained; furthermore, the signal is converted into a negative feedback correction signal; and the microwave power is controlled by utilization of obtained negative feedback of the correction signal, so that the modulation index of the frequency modulation laser is stabilized. The device is simple in structure; a laser frequency modulation index locking function can be realized by increasing a few components in the existing CPT atomic frequency standard device; the CPT spectral line signal obtained by the device is the strongest after locking; furthermore, change of the CPT atomic frequency standard performance due to the factors, such as random temperature change and aging of a microwave device, can be reduced; the CPT atomic frequency standard performance can be improved; and the CPT atomic frequency standard laser frequency modulation index locking device and method disclosed by the invention are suitable for small CPT atomic frequency standards.

Owner:WUHAN INST OF PHYSICS & MATHEMATICS CHINESE ACADEMY OF SCI

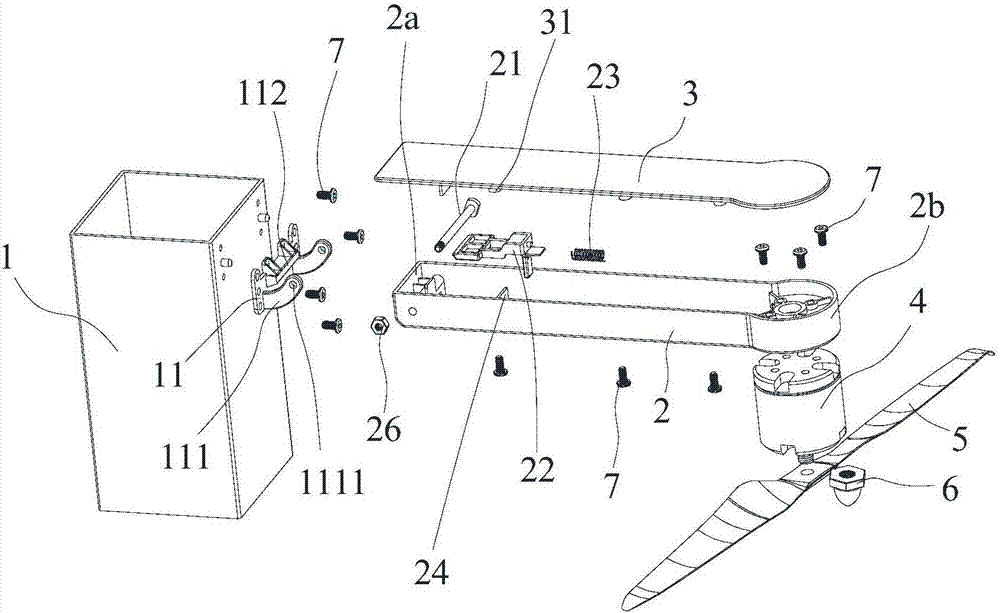

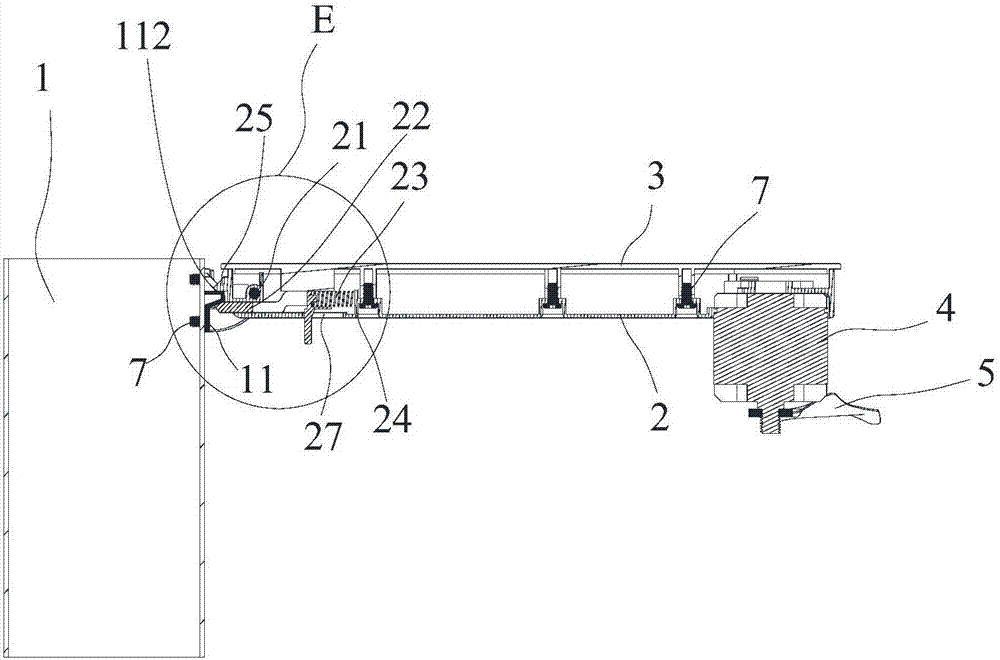

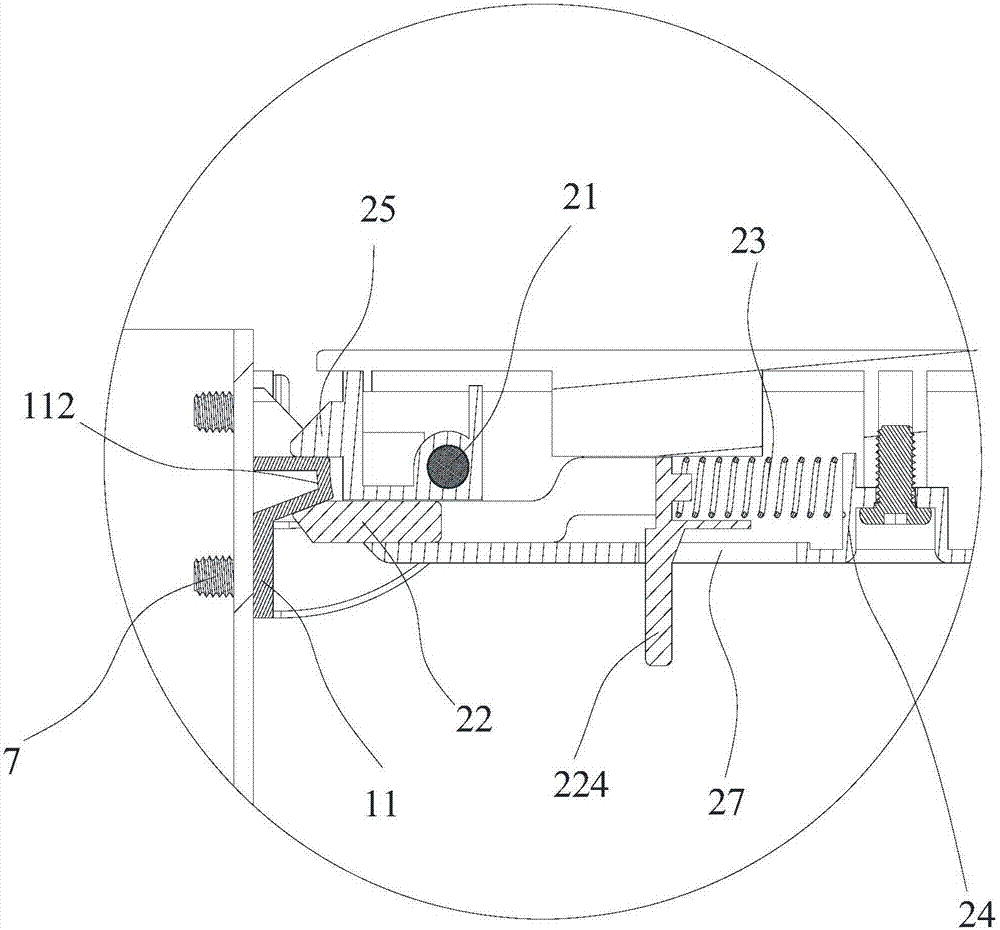

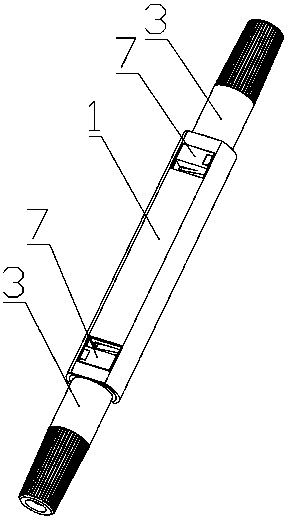

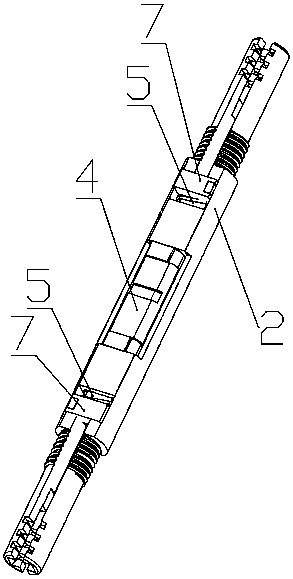

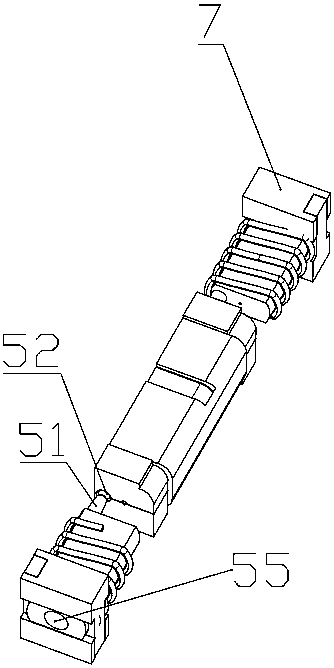

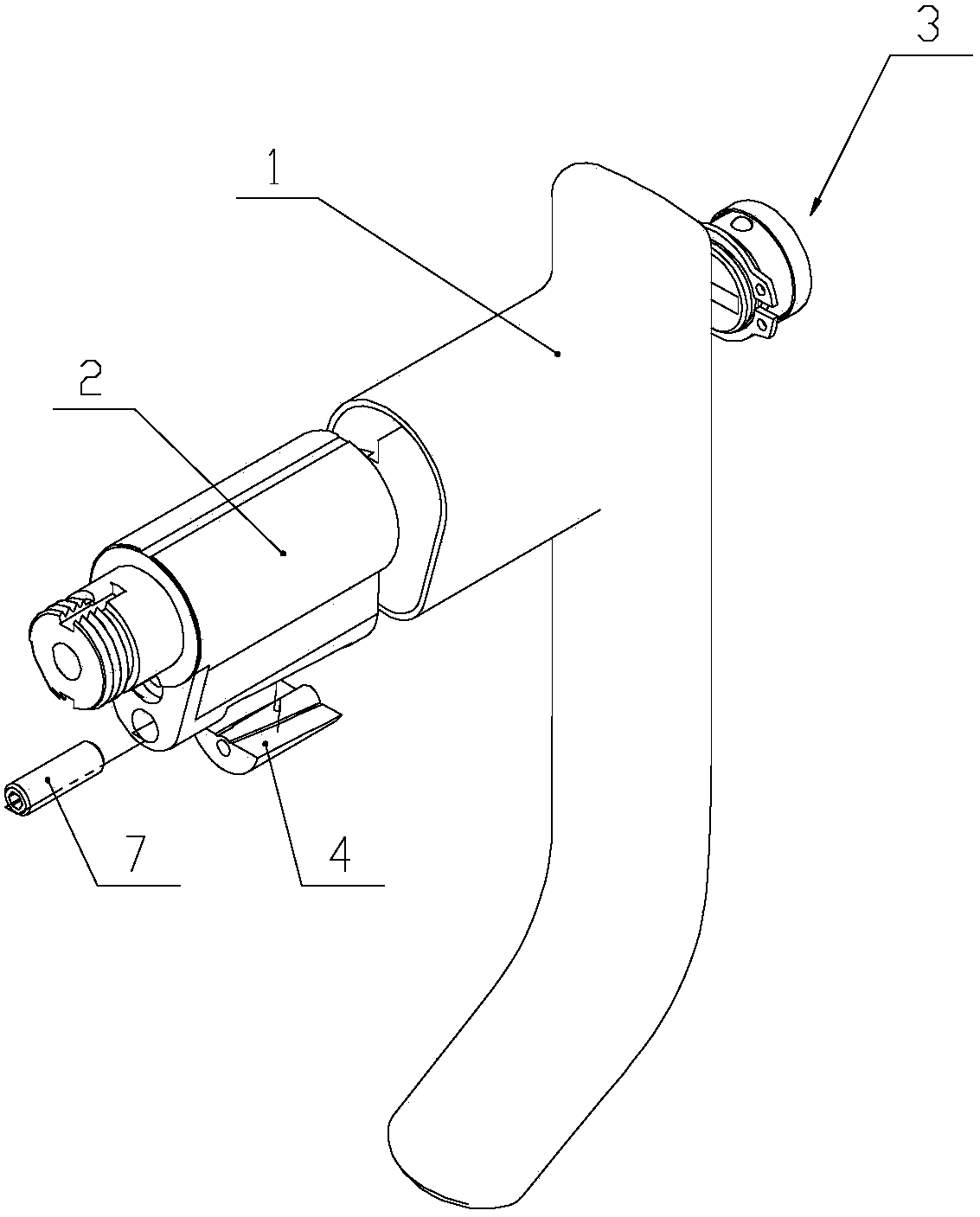

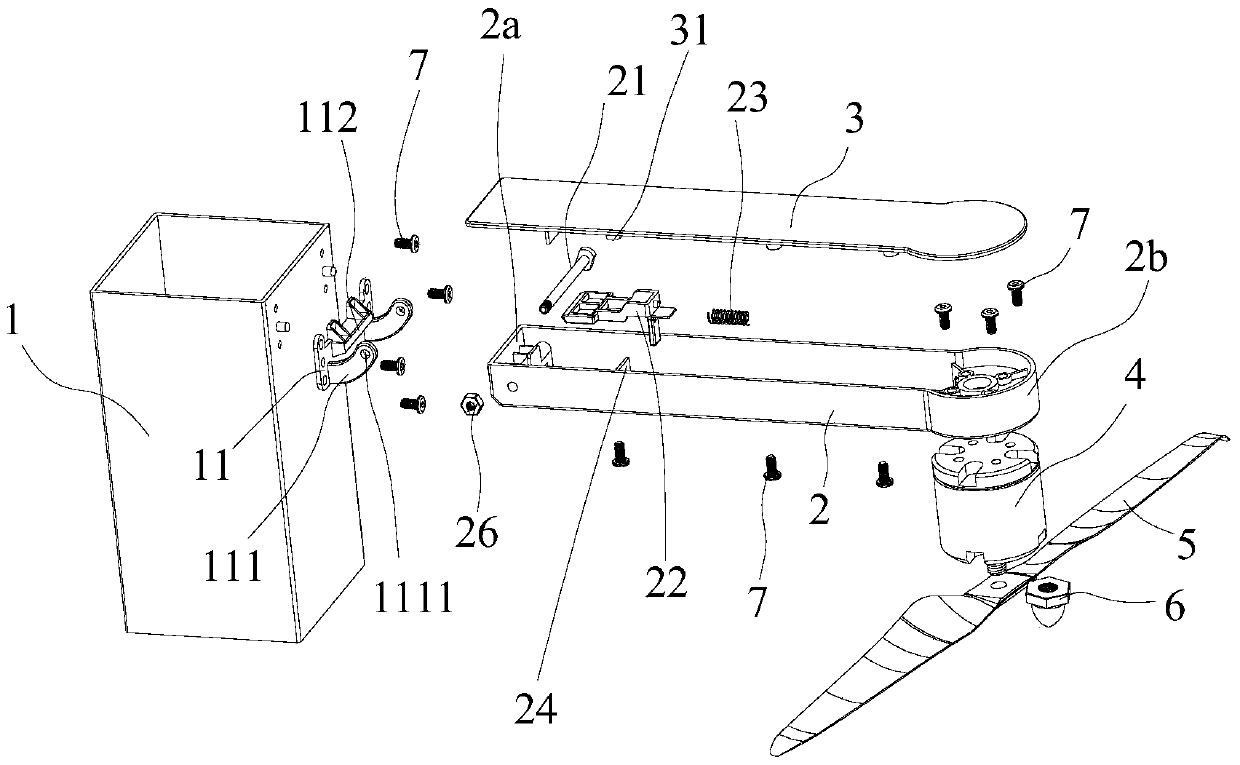

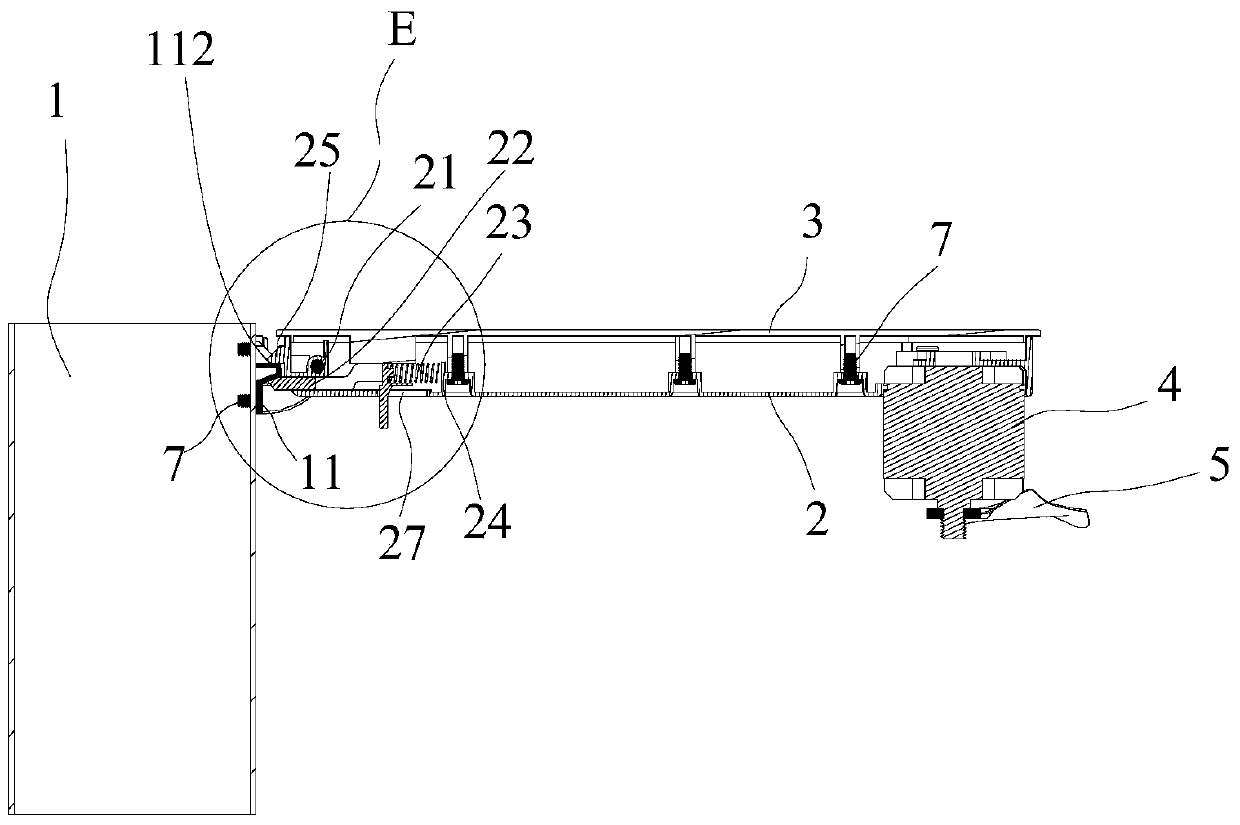

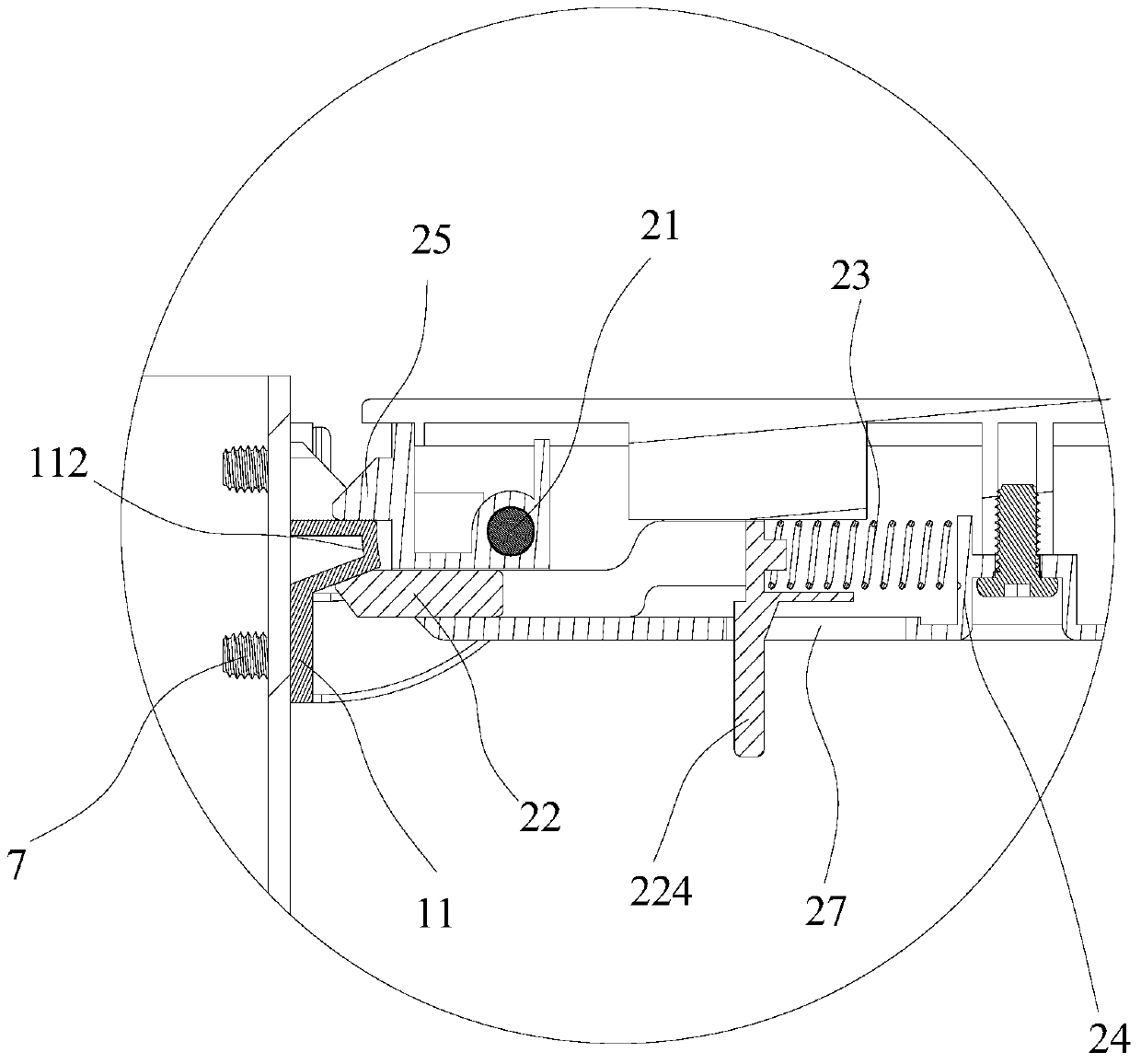

Unmanned aerial vehicle

ActiveCN107458574ASave internal spaceEasy to operateFuselage framesAir-flow influencersLocking mechanismUncrewed vehicle

The invention provides an unmanned aerial vehicle. According to the unmanned aerial vehicle, the problems that according to an existing unmanned aerial vehicle achieving unfolding and folding of vehicle arms, the structure is complex, the occupied space is large, and the size of the unmanned aerial vehicle is increased are solved. The unmanned aerial vehicle comprises a vehicle body and a plurality of vehicle arms. A plurality of supporting seats the same as the vehicle arms in number are arranged on the vehicle body. Limiting bumps are arranged on the supporting seats. Fixed locking parts and moving locking mechanisms are arranged at the hinging ends of the vehicle arms. According to the unmanned aerial vehicle, the limiting bumps are arranged on the supporting seats, and the fixed locking parts and the moving locking mechanisms are arranged at the hinging ends of the vehicle arms so that the unfolding locking function of the vehicle arms of the unmanned aerial vehicle can be achieved; and meanwhile, through driving mechanisms arranged on locking sliding blocks, locking of the sliding blocks can be relieved, and thus folding of the vehicle arms is achieved. The vehicle arms are attached and locked more firmly and more smoothly; the locking mode of the vehicle arms is simple and practical, the number of involved parts is relatively small, the occupied space is small, and the internal space of the unmanned aerial vehicle can be effectively saved; and assembly is convenient, the cost is low, and folding and unfolding operation is convenient and rapid.

Owner:BYD CO LTD

Pre-tensioning method centrifugal concrete pile with steel strands and manufacturing method

ActiveCN103882856AImprove performanceFirmly connectedCeramic shaping apparatusBulkheads/pilesPre stressRebar

The invention relates to a pre-tensioning method centrifugal concrete pile with steel strands. The pre-tensioning method centrifugal concrete pile comprises a hollow concrete pile body, end plates and a steel bar cage. The steel bar cage comprises main prestressing bars and stirrups, wherein the main prestressing bars are axially arranged, and the stirrups are wound around the main bars. The pre-tensioning method centrifugal concrete pile is characterized in that the main prestressing bars are the steel strands, the steel strands of at least one end of the steel bar cage are combined with extrusion anchor devices, the peripheries of the extrusion anchor devices are sleeved with connecting sleeves, the connecting sleeves are provided with stepped through holes, the connecting sleeves are provided with threads for connection, a plurality of connecting counter holes are formed in the end plates, a threaded connecting piece is arranged inside each connecting counter hole, the end plates are connected with the threads for connection on the connecting sleeves through the threaded connecting pieces, and the end plates are further provided with a plurality of threaded connecting holes used for connection. According to the pre-tensioning method centrifugal concrete pile with the steel strands, in the pile manufacturing process, the steel strands combined with the extrusion anchor devices can be fixedly connected with the end plates through the connecting sleeves, tensioning plates of the end plates are fixedly connected in a threaded mode, the steel strands used as the main bars in the steel bar cage are tensioned and applied, and the anti-bending, anti-shearing and anti-tensioning performance is greatly improved. The invention further relates to a manufacturing method of the pre-tensioning method centrifugal concrete pile.

Owner:俞向阳

A method of manufacturing a pretensioned centrifugal concrete pile with steel strands

ActiveCN103741674BImprove performanceSimple locking methodCeramic shaping apparatusBulkheads/pilesPre stressPore diameter

The invention relates to a pretensioned centrifugal concrete pile with steel stranded wires. The pretensioned centrifugal concrete pile comprises a concrete pile body and a rebar cage, and the rebar cage comprises prestressed main rebars, stirrups and end plates. The pretensioned centrifugal concrete pile is characterized in that the prestressed main rebars are the steel stranded wires, multiple conical holes which gradually expand from inside to outside in pore diameter are formed in at least one end plate and correspond to the steel stranded wires one by one, multiple clamping pieces are placed in each conical hole, clamping teeth are arranged on the inner surface of each clamping piece, the clamping pieces are spliced to form clamping head components used for hooping the steel stranded wires, the outer peripheral face of each clamping head component forms a cone face matched with the corresponding conical hole, the center of each clamping head component forms an inner tooth hole, and each steel stranded wire penetrates the inner tooth hole in the corresponding clamping head component and is locked by the inner tooth hole. The pretensioned centrifugal concrete pile is practical. The invention further relates to a manufacturing method of the pretensioned centrifugal concrete pile.

Owner:俞向阳

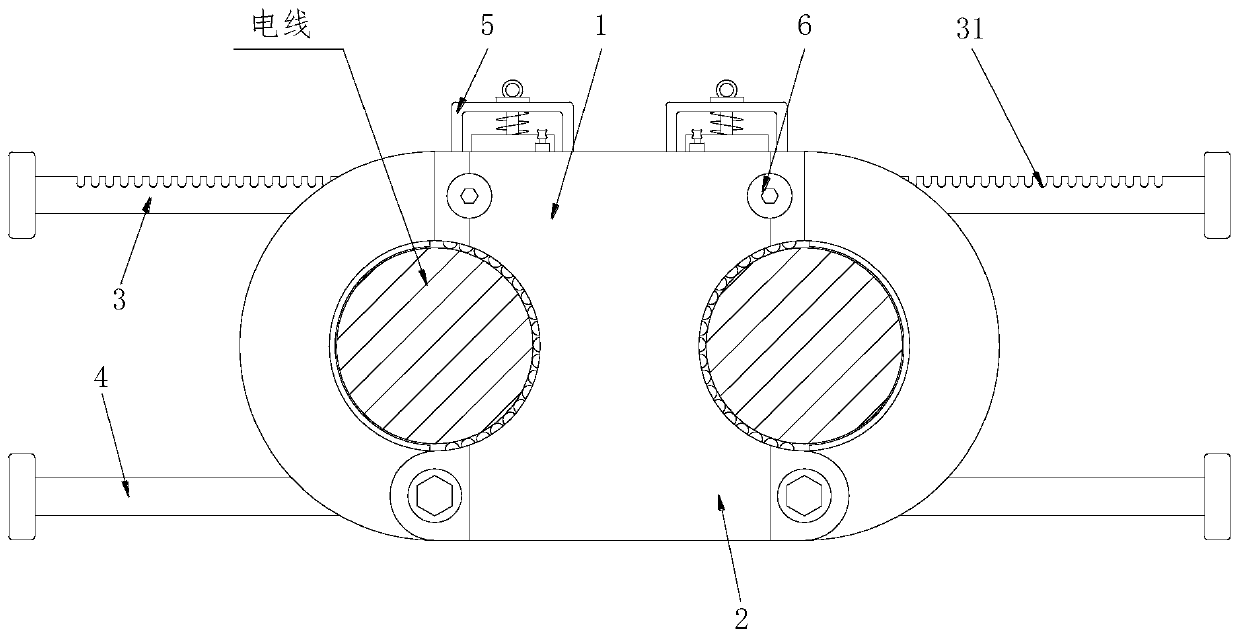

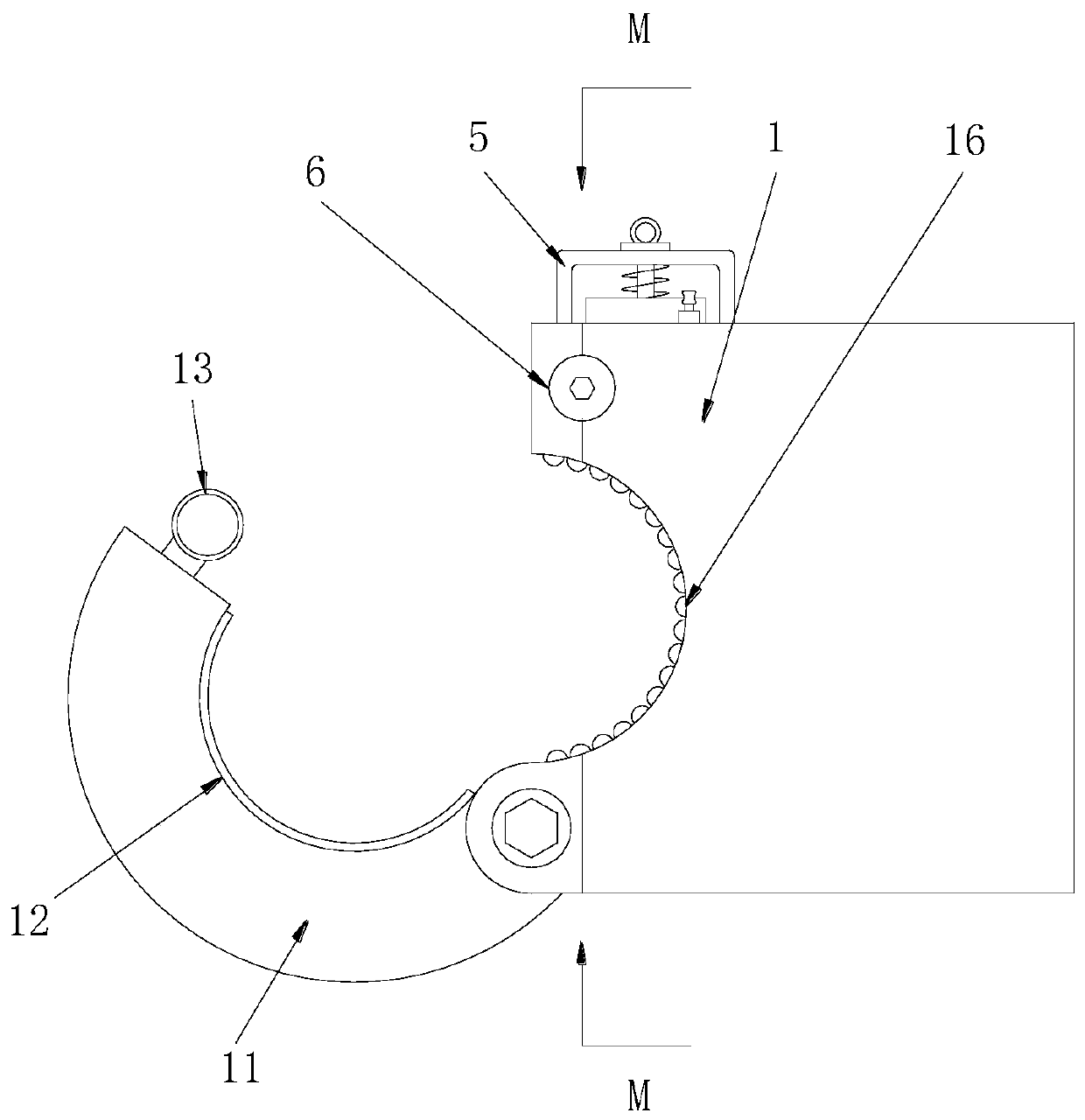

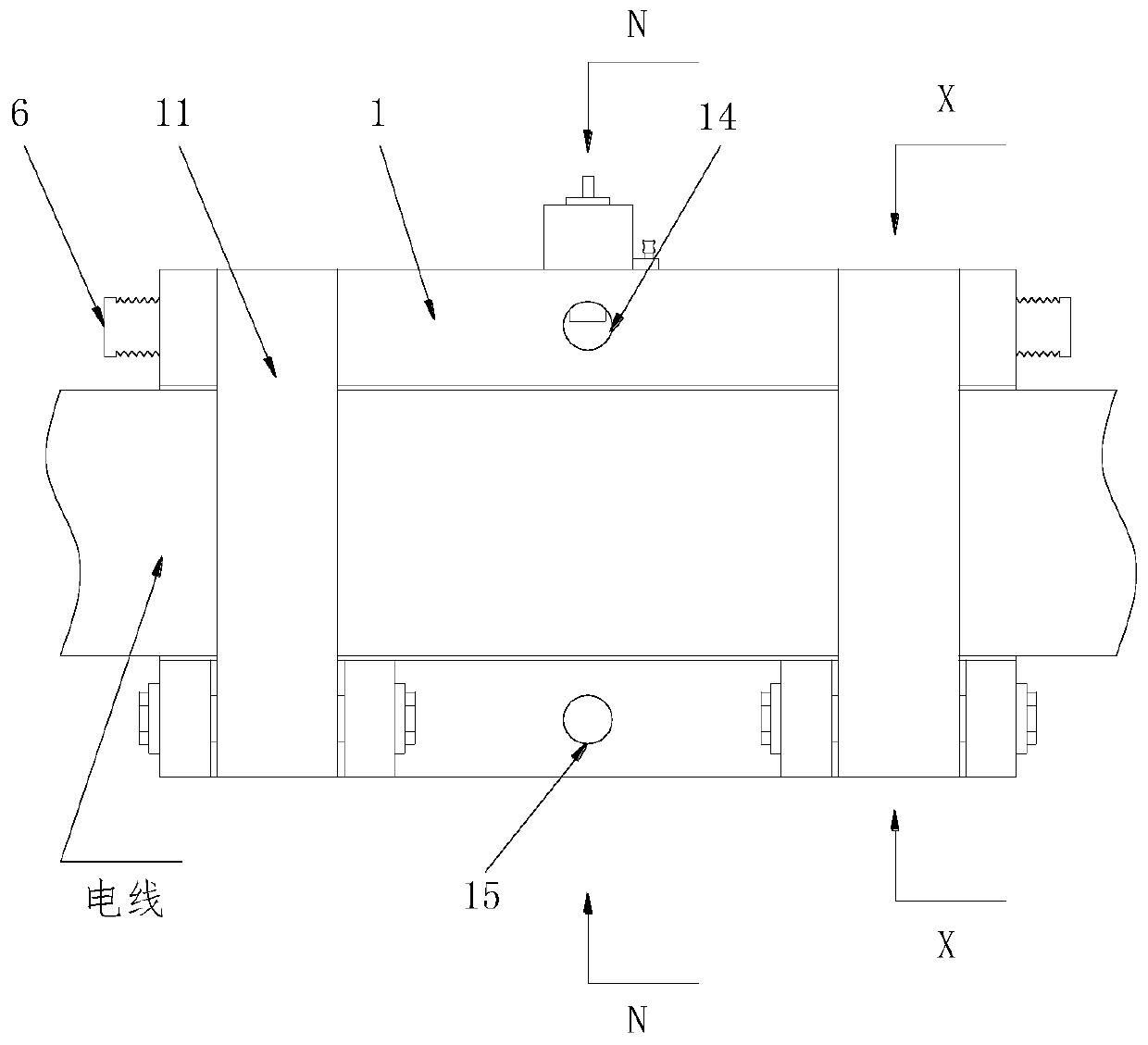

Electric power fitting line stay wire fixing wire clamp

ActiveCN111244837AFixed firmlySimple locking methodElectrical apparatusWire fixationStructural engineering

The invention relates to an electric power fitting line stay wire fixing wire clamp. The clamp comprises a first fixing block, a second fixing block, a limiting rod, a connecting rod, a locking mechanism and an air pressure mechanism; the first fixing block and the second fixing block are two components of the same structure. Locking mechanisms are arranged at the tops of the first fixing block and the second fixing block; air pressure mechanism mechanisms are mounted on the two side walls of the first fixing block and the second fixing block; the first fixing block and the second fixing blockare connected and fixed through a limiting rod and a connecting rod. A semicircular fixing groove is formed in one side of the first fixing block. The firmness of electric wire fixing is effectivelyimproved in a multi-stage fixing mode, meanwhile, the electric wire fixing device is suitable for fixing electric wires with different spacing requirements, and the practicability is higher. The electric wire fixing device has the advantages that the electric wire fixing device can be used for fixing the electric wires with different spacing requirements.

Owner:广东汇杰电力集团有限公司

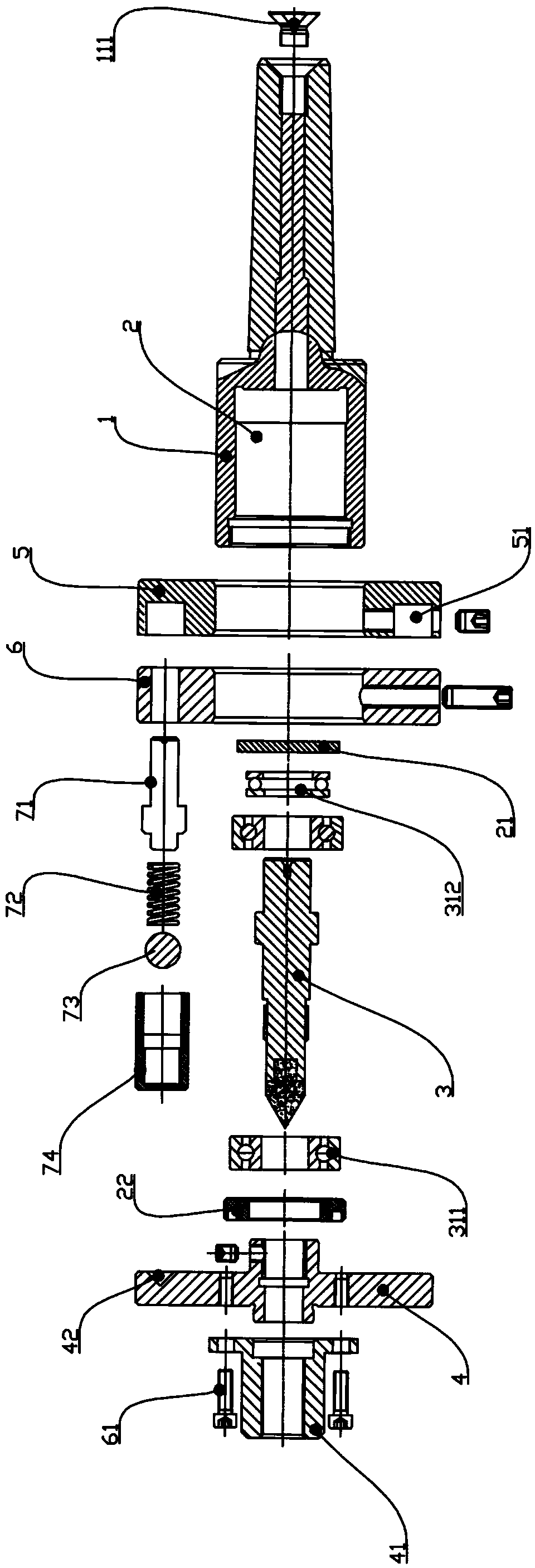

Automatic locking device for core roller of ring rolling machine

ActiveCN112170746AImprove practicalityImprove reliabilityMetal rollingStructural engineeringMechanical equipment

The invention relates to the technical field of mechanical equipment, in particular to an automatic locking device for a core roller of a ring rolling machine. Through automatically locking and fixingthe core roller, the physical strength and the time spent when a bolt is adopted for fastening can be effectively saved, the locking mode of the core roller is simplified, the installation time of the core roller is shortened, quick disassembly and assembly of the core roller are facilitated, the working efficiency is improved, meanwhile, the firmness of the core roller is improved, the occurrence of the phenomenon that the core roller falls off due to the fact that the bolt is loosened when the bolt is fastened is avoided, the safety of the equipment is improved, and practicability and reliability are improved. The automatic locking device for the core roller of the ring rolling machine comprises a fixing column, three sets of first push plates and three sets of second push plates, wherein the top of the fixing column is installed on an external ring rolling machine; an inserting hole is formed in the middle of the bottom end of the fixing column in a communicating mode; the lower side of the inner wall of the inserting hole is a conical surface; three sets of installing grooves are annularly and evenly formed in the lower side of the outer wall of the fixing column in a communicating mode; the inner sides of the three sets of installation grooves communicate with the inner part of the inserting hole; and the upper sides of the three sets of first push plates are respectivelypositioned in the three sets of installation grooves.

Owner:ZHUCHENG SHENGYANG MACHINERY

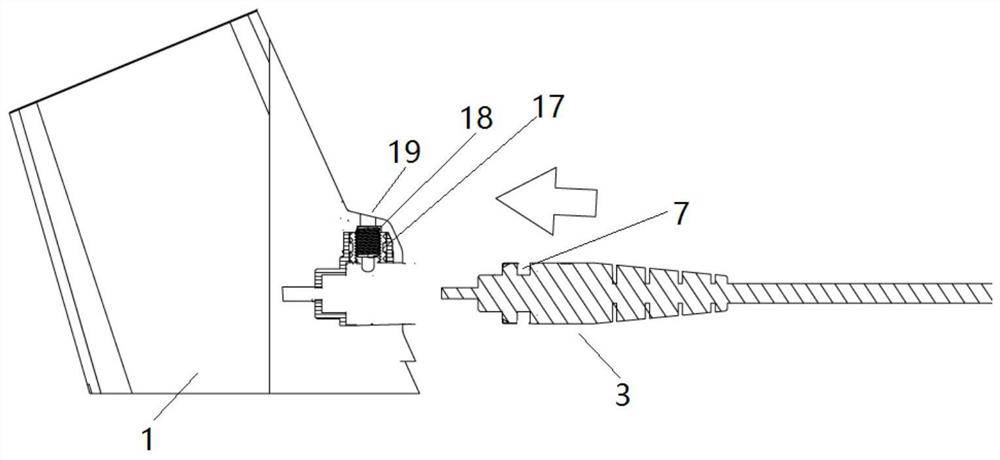

Cable adapter

The invention discloses a cable adapter, and relates to the technical field of optical fiber communication. The cable adapter comprises an outer shell, a main body and a tail sleeve abutted with bothheads of the main body; the outer shell coats the main body along axial direction, and the main body is hollow and provided with a built-in clamping mechanism; both ends of the clamping mechanism areprovided with import pieces embedded in the main body and capable of performing reciprocated slippery movement along the length direction of the main body; the clamping mechanism is provided with a first state where the import piece is inserted to the clamping mechanism along the length direction and opened to make a cable enter and a second state where the import piece retreats the clamping mechanism and then tightly clamps the cable; a push buckle exposed at outside of the outer shell is fixedly arranged on the import piece. The cable adapter has the advantages of simplifying user operationand expanding product using environment, and being good in product quality and long in service life.

Owner:湖南中科光电有限公司

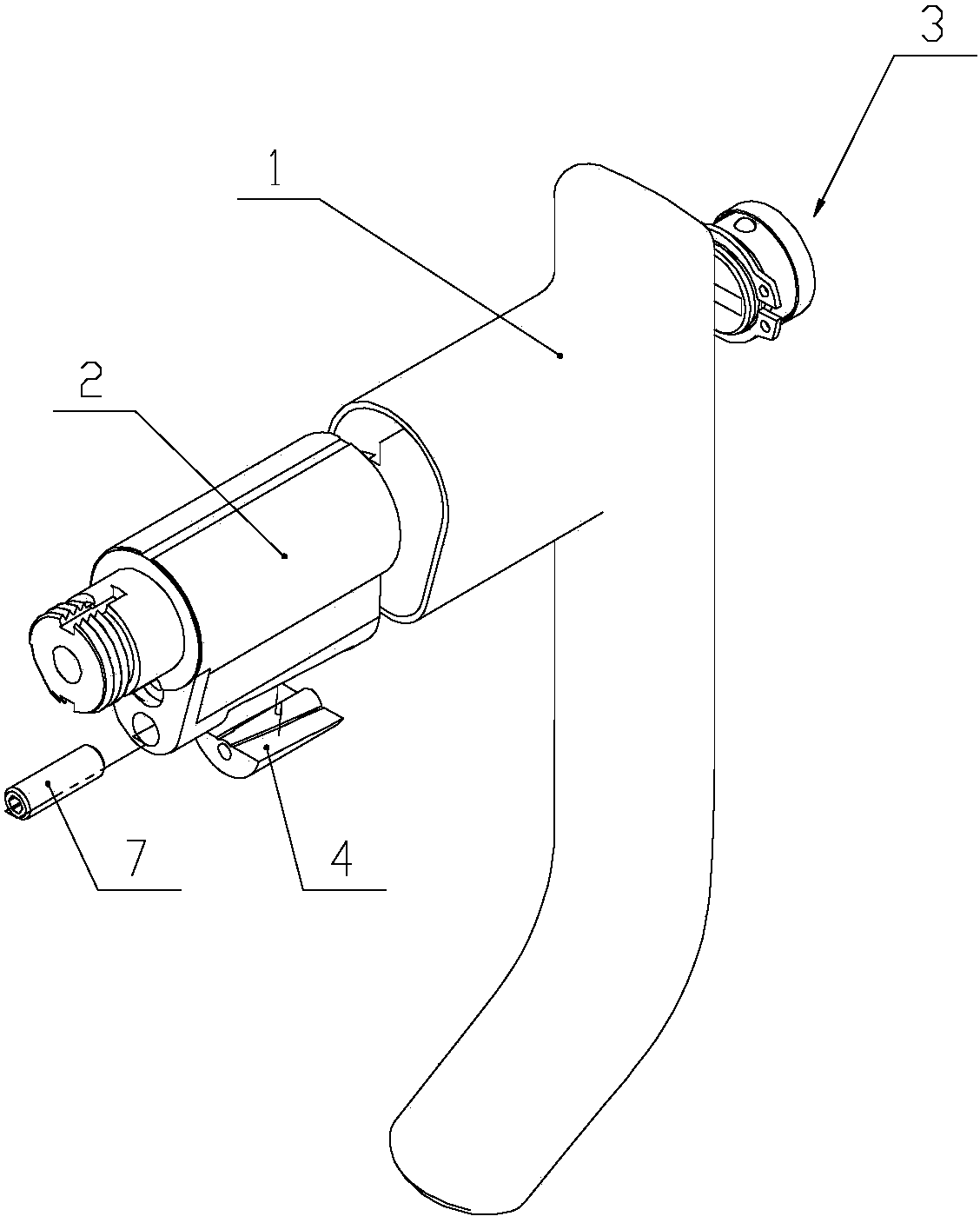

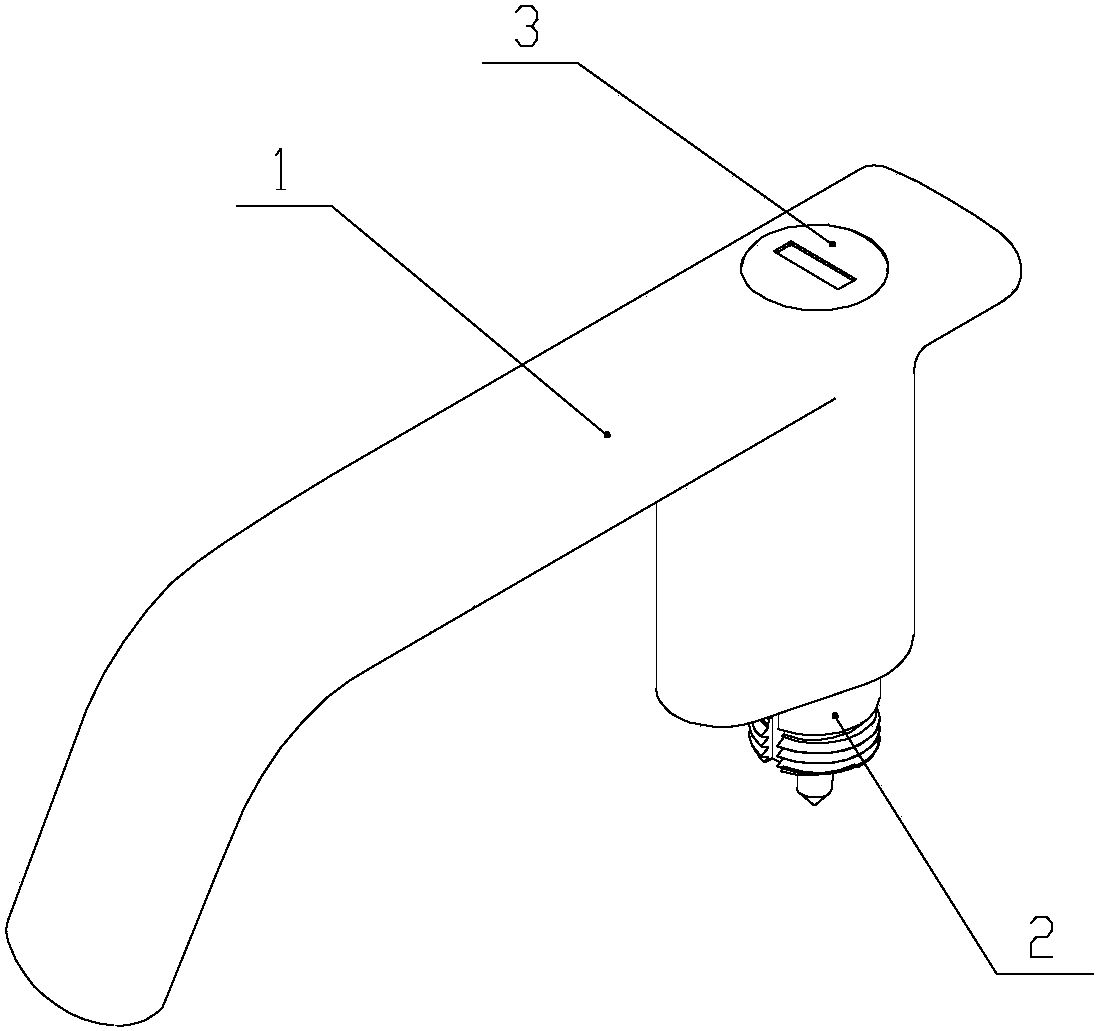

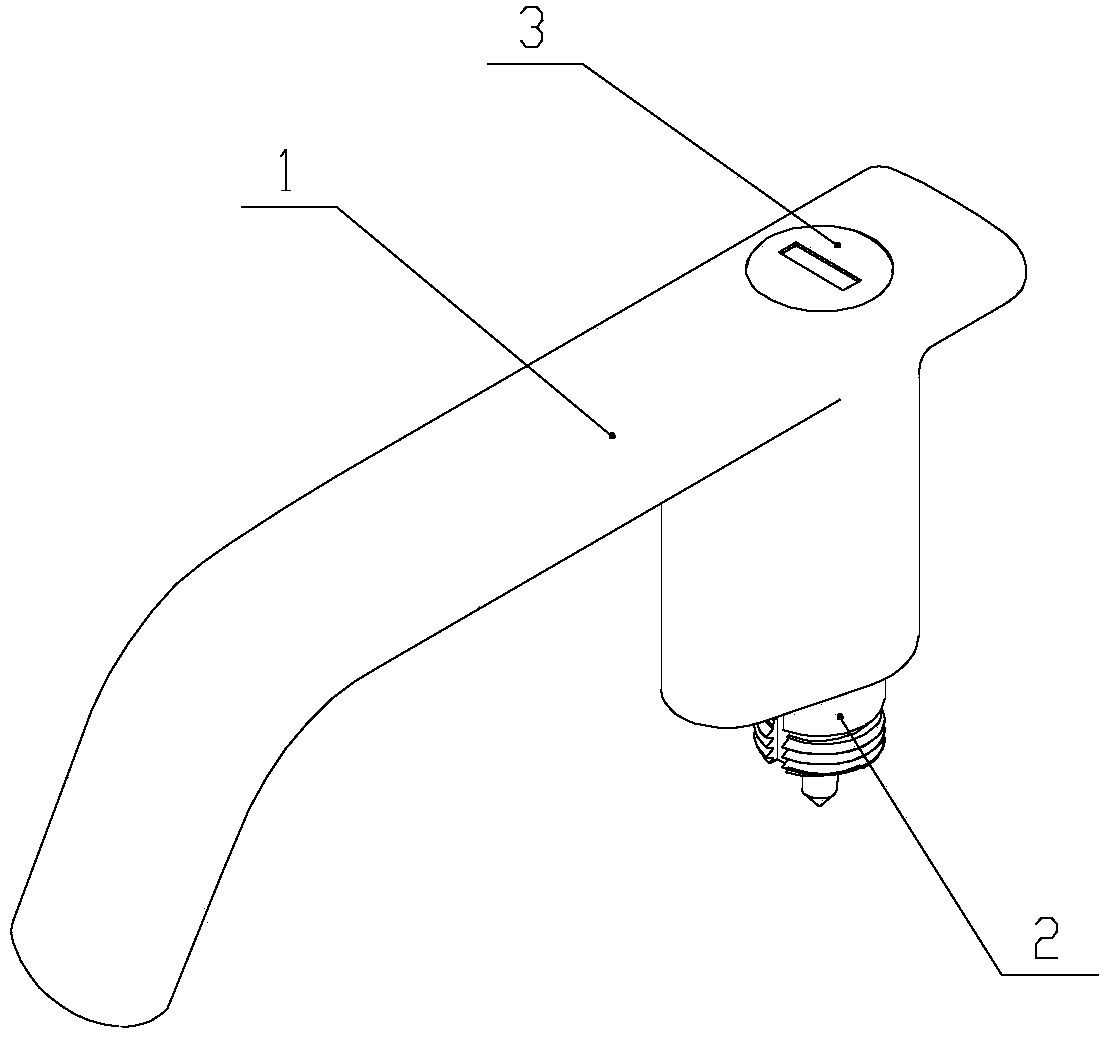

Built-in handle

ActiveCN105952262AImprove securityImprove wear resistanceBuilding locksHandle fastenersForeign matterEngineering

The invention discloses a built-in handle. The built-in handle comprises a handle shell and a handle lock cylinder located in the handle shell, wherein a dustproof structure is arranged at a position corresponding to an outer lock hole on the handle shell; the handle lock cylinder is locked in the handle shell via an inclined block. According to the built-in handle, the inclined block is used for locking the handle lock cylinder and the handle shell; the locking manner is more simple, efficient and reliable; the safety of the handle lock cylinder is improved; secondly, the dustproof structure protects the lock hole in the lock cylinder from being damage by dust or other foreign matters, so that the usage performance of the handle lock cylinder is ensured, and the service life of the handle lock cylinder is prolonged; furthermore, the handle shell is formed by welding two symmetrical half shells; the welding process is reliable, so that the performance of the handle shell is excellent; the large-scale production and the streamlined operation are facilitated; the service life of the product is prolonged; the production cost is reduced.

Owner:NANJING EASTHOUSE ELECTRIC CO LTD

Feeding door device of vertical station special tank type food waste container

ActiveCN106628744ASmooth and reliable rotationImprove shock absorptionRefuse receptaclesFood wasteSanitation

The invention discloses a feeding door device of vertical station special tank type food waste container, which belongs to the technology field of environmental sanitation. The feeding door device of vertical station special tank type food waste container, which belongs to the technology field of environmental sanitation, comprises an oscillating cylinder, a cylinder support, a feeding opening cover, a lock frame, a hook lock assembly and a connecting drive assembly used for connection with the feeding opening cover and the end of the oscillating cylinder. The hook lock assembly comprises a guide rail, an outer support, a lock plate, a straight rack and a locking cylinder. An arc rack with outward meshing is arranged on the edge of the lock plate. A hook extending outward is arranged on the edge of the lock plate. The hook and the arc rack are staggered. A lock rod is arranged on the lock frame; the arc rack on the edge of the lock plate engages with the straight rack. When the feeding opening cover covers the waste container, The straight rack moves in a straight line under the drive of the locking cylinder, so the straight rack drives the lock plate to rotate and makes the hook hook the lock rod. The feeding door device of vertical station special tank type food waste container is characterized by a strong locking force and a shock resistant.

Owner:YANGZHOU JINWEI ENVIRONMENTAL PROTECTION TECH CO LTD

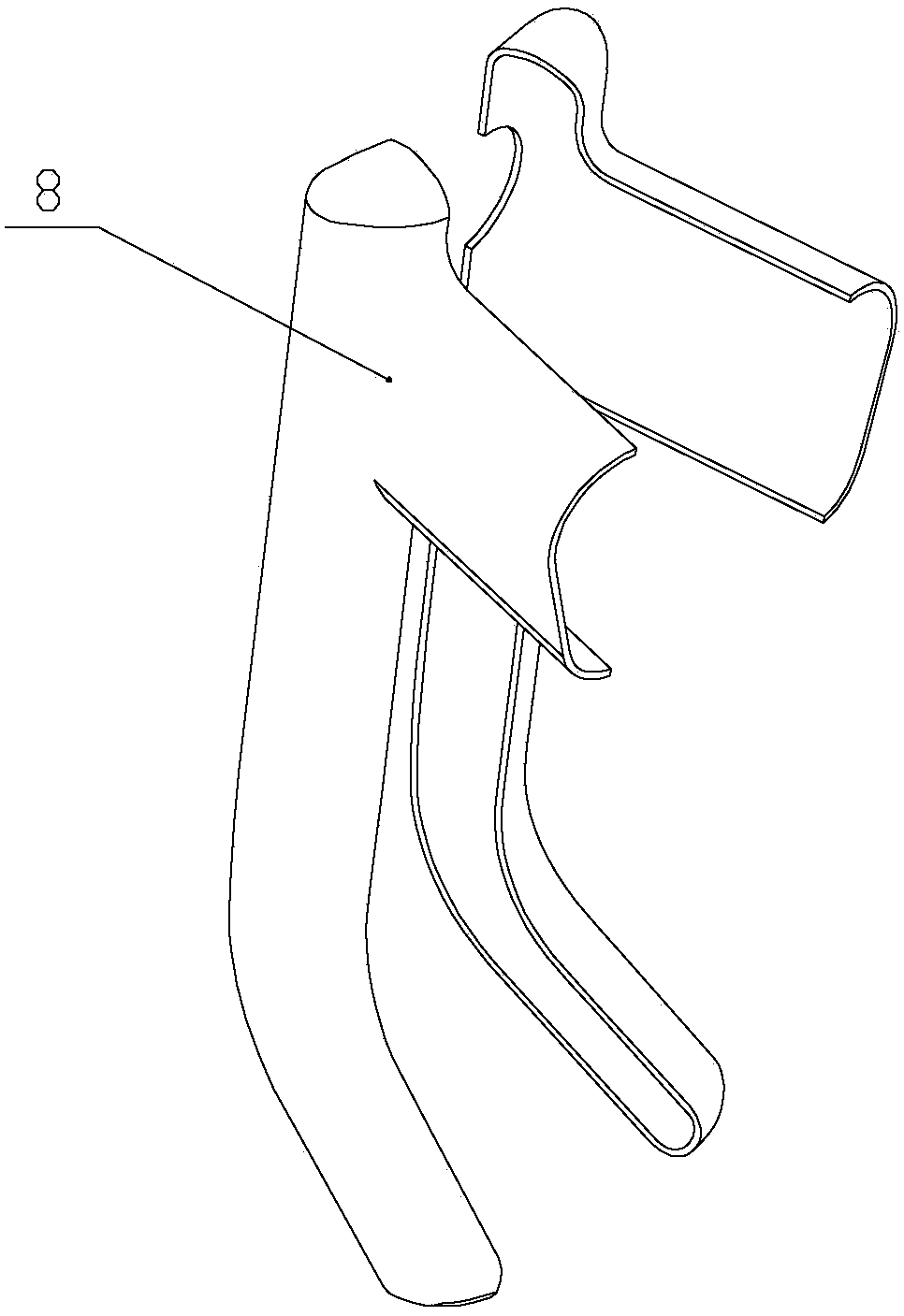

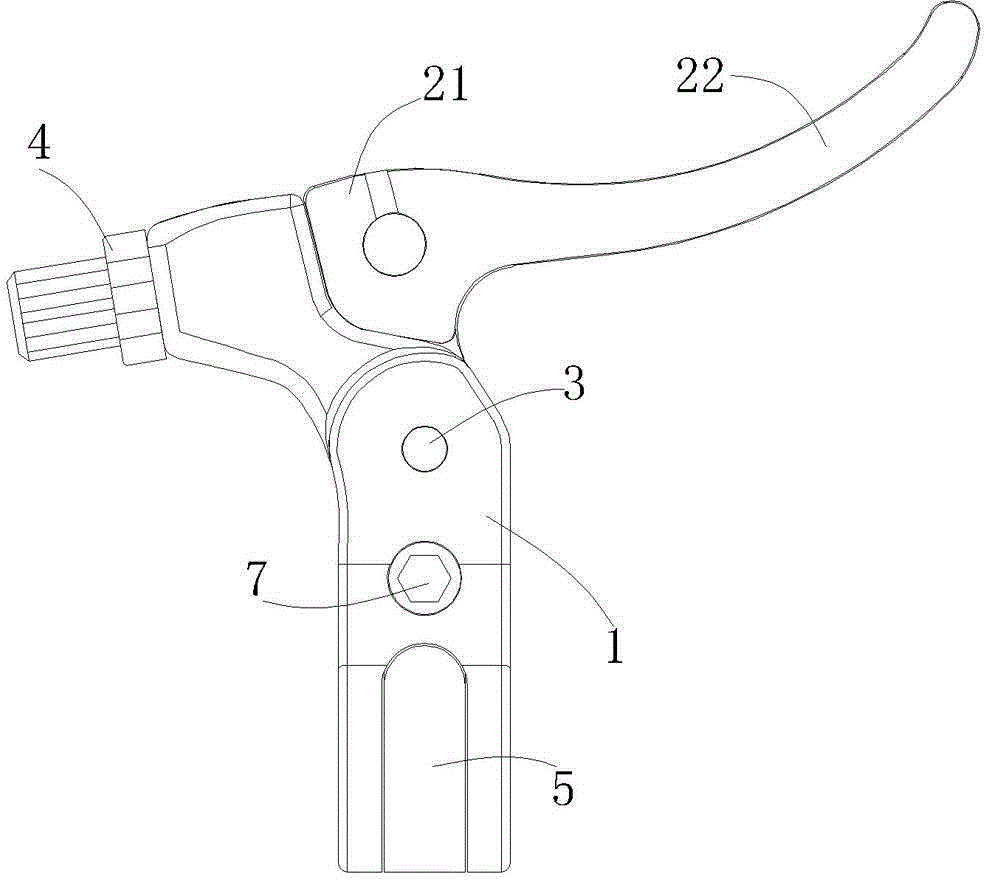

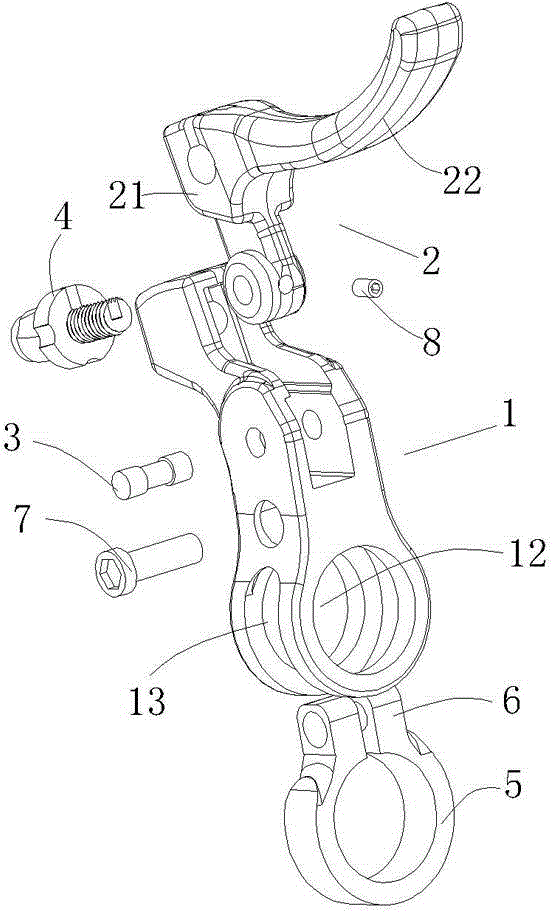

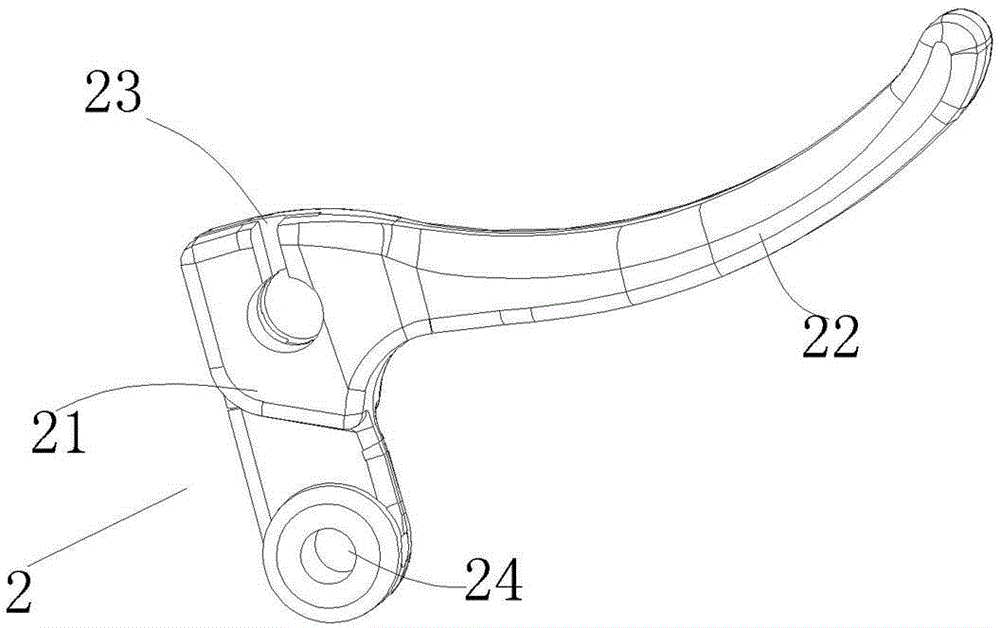

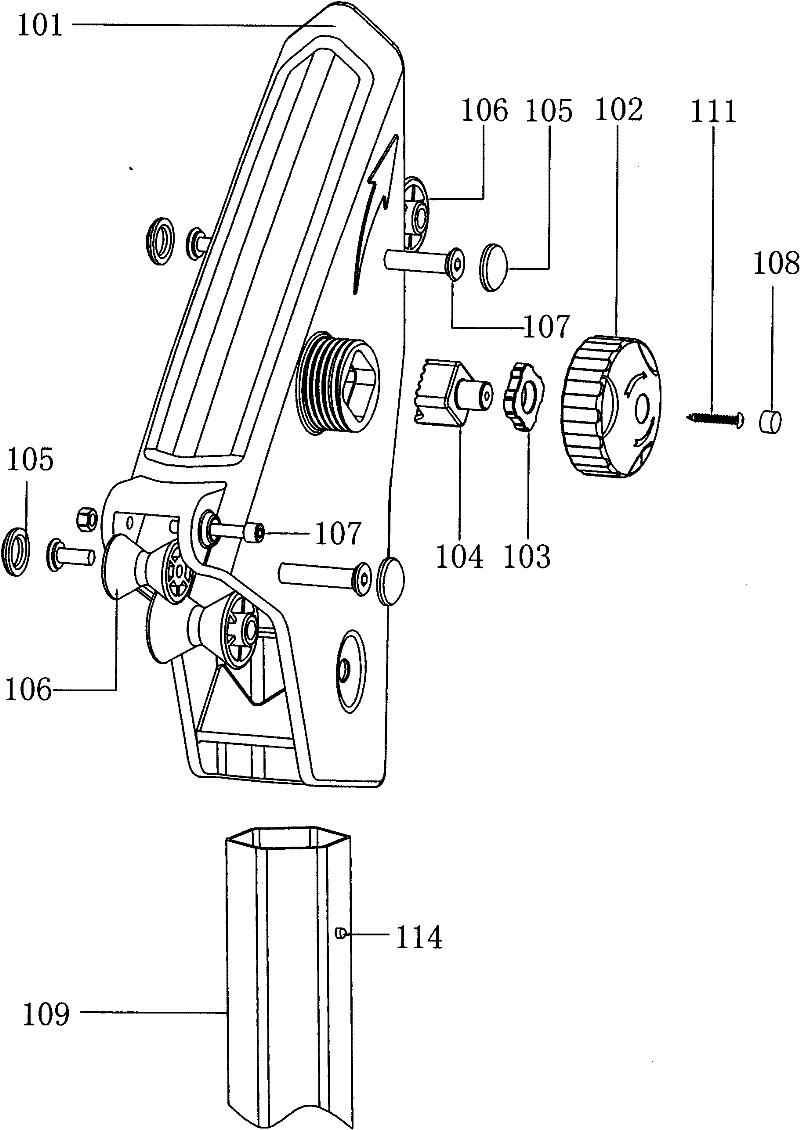

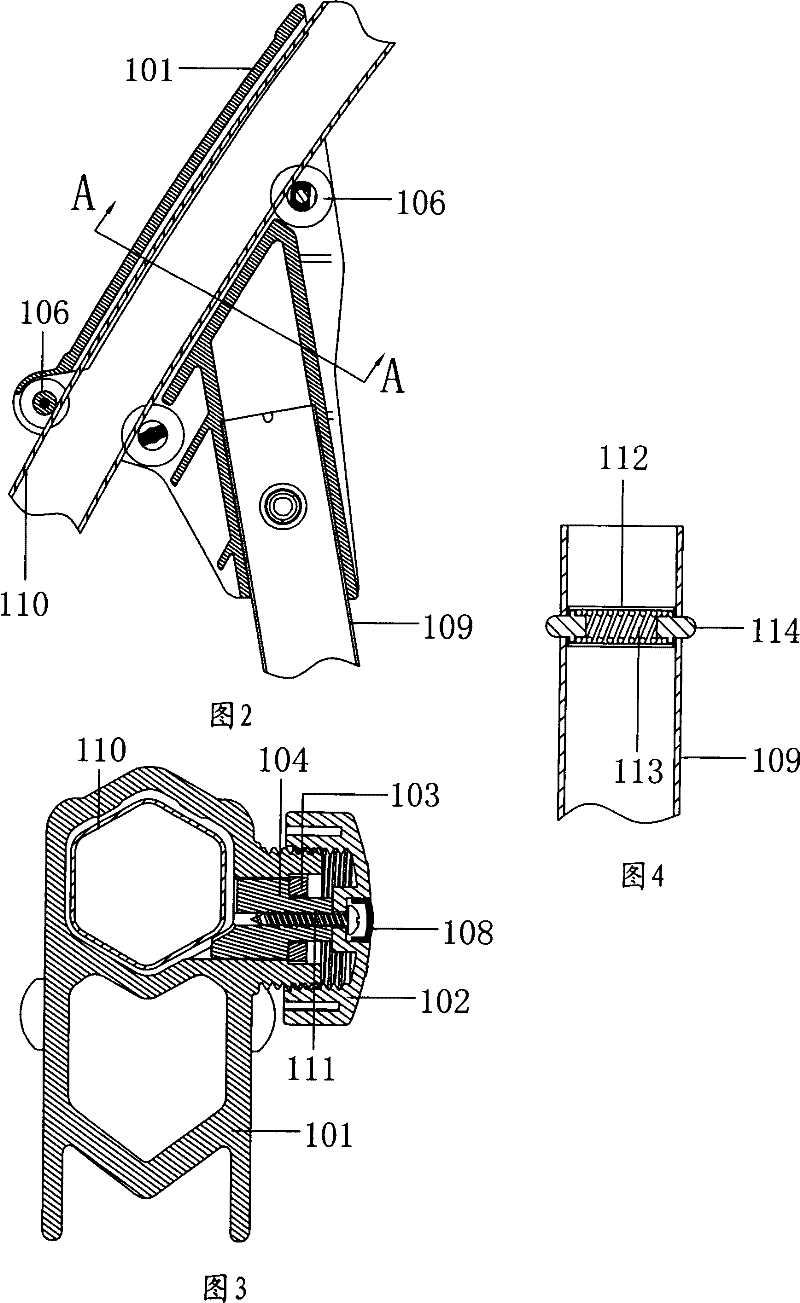

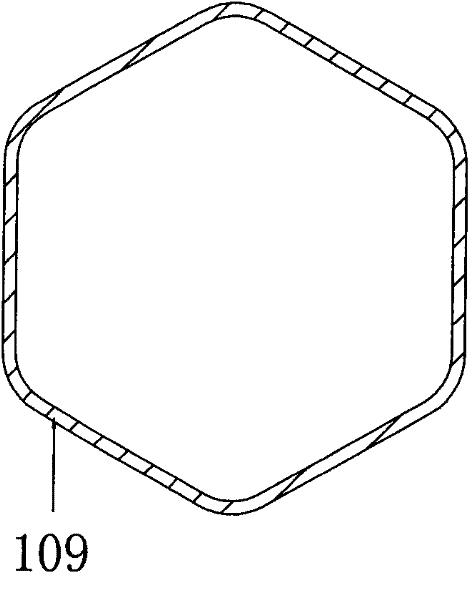

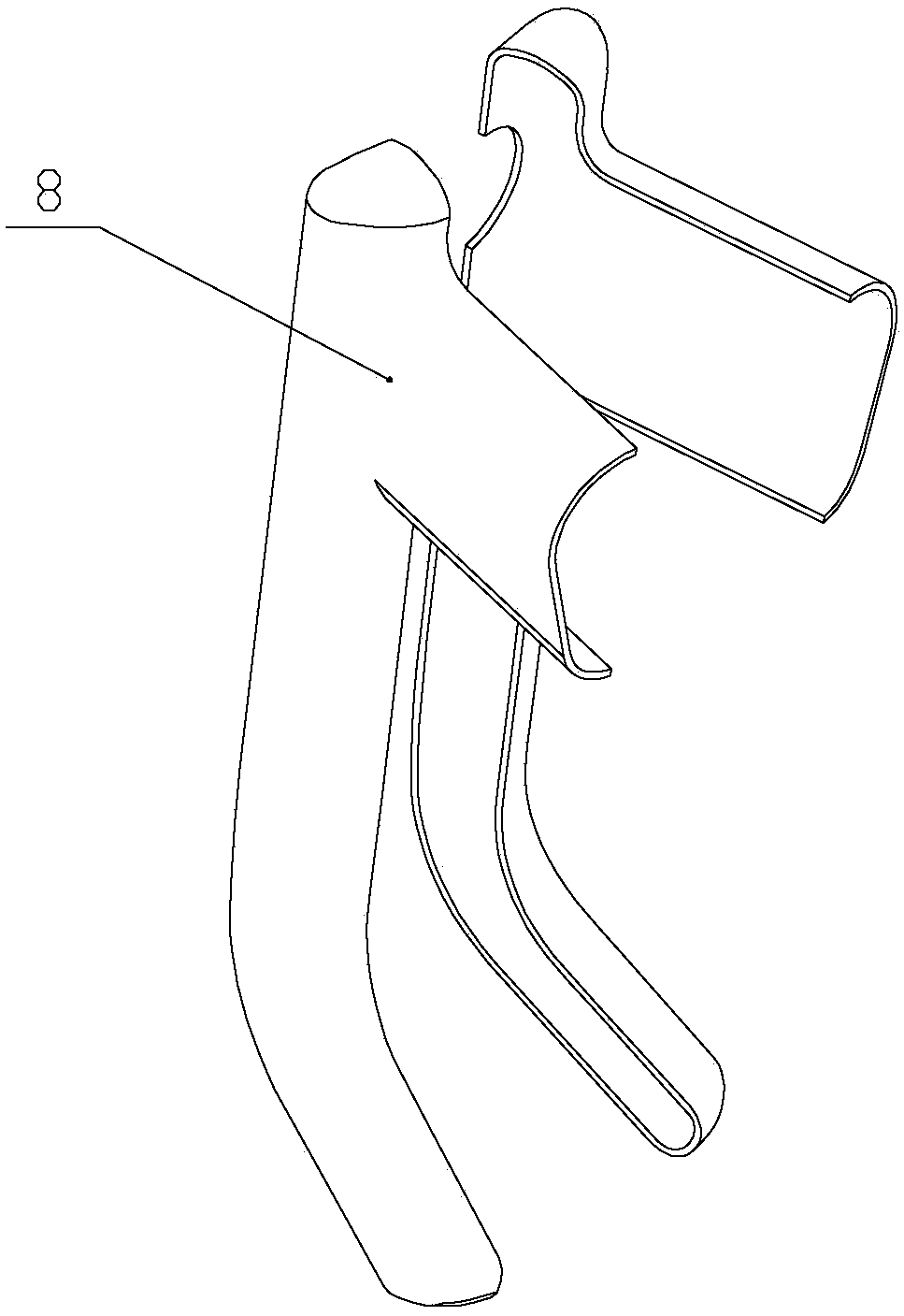

Bicycle brake crank

The invention discloses a bicycle brake crank which comprises a base frame and a handle. The handle comprises a handle body. One side of the upper end of the handle body extends to form an arc-shaped handheld portion. A brake cable installation groove is formed in the upper end of the handle body. A through hole is formed in the lower end of the handle body. A handle installation groove is formed in one side of the upper end of the base frame. The handle is riveted into the handle installation groove through a rivet penetrating through the through hole. The other end of the upper end of the base frame is connected with a fine adjusting nut. A pipe hole is formed in the lower end of the base frame. An annular groove coaxial with the pipe hole is formed in the side face of the lower end of the base frame. A locking circular ring is arranged in the annular groove. The upper end of the locking circular ring is provided with an opening and extends upwards to form an extension base. The extension base is located in the base frame and fixed into the base frame through a fixing screw. The bicycle brake crank has the technical advantages that the base frame and a handlebar are locked through the locking circular ring, the locking method is simple, and the locking effect is good; the locking circular ring and the base frame can be separately colored, the visual impression of the bicycle brake crank is improved, and the ornamental value is achieved.

Owner:宁波力盟机械有限公司

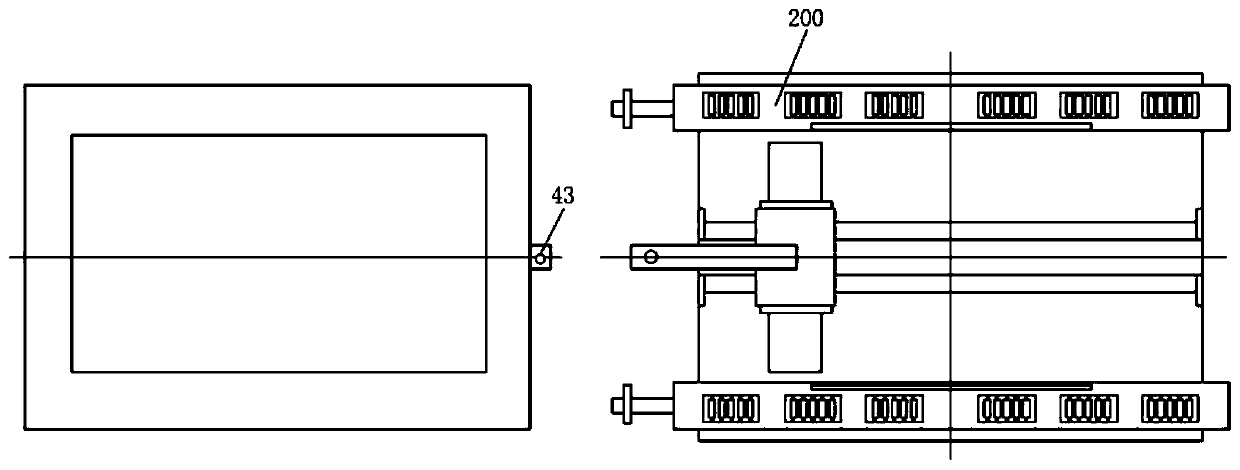

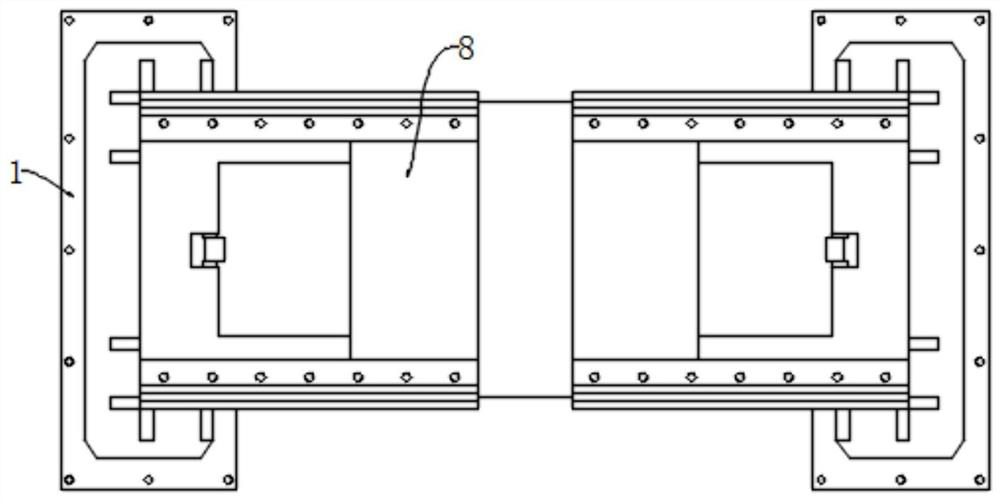

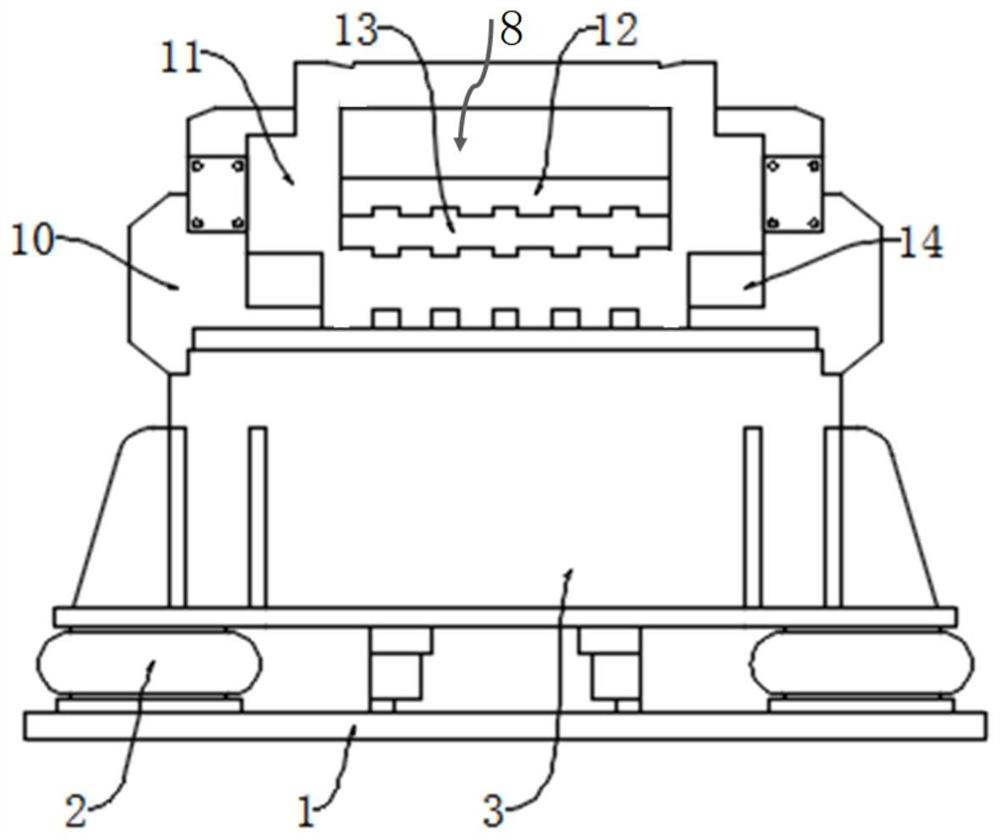

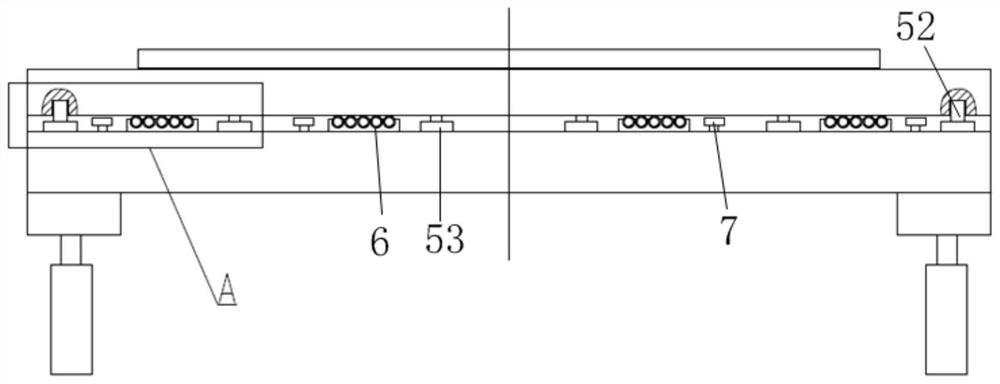

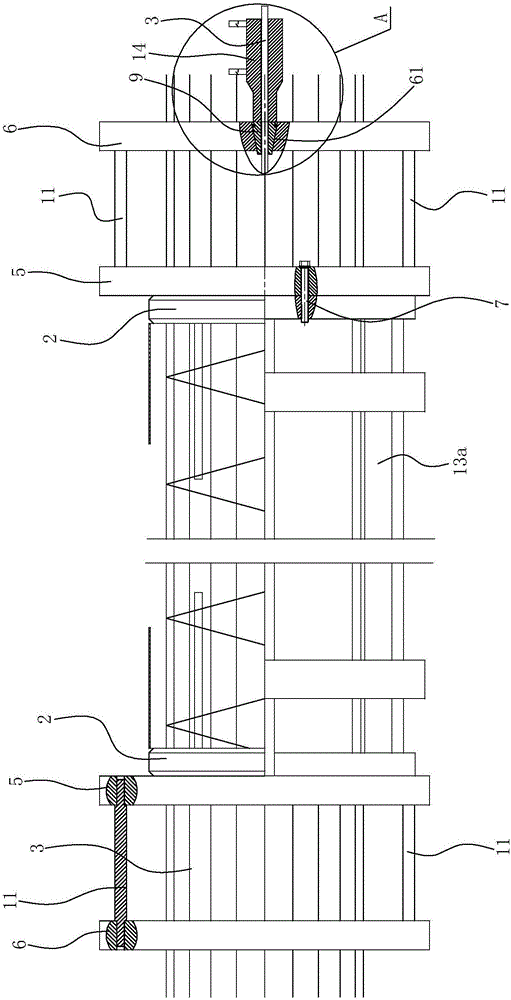

Die replacing system of large-tonnage press

ActiveCN110861208AReduce frictional resistanceRealize normal brick pressingAuxillary shaping apparatusMould fastening meansStructural engineeringMechanical engineering

The invention discloses a die replacing system of a large-tonnage press. The die replacing system of the large-tonnage press comprises a base, a lower die assembly and ejecting devices which are arranged on the base, a die frame arranged on the outer side of the lower die assembly, side rails arranged on the two sides of the die frame and a die replacing device used for replacing the lower die assembly; a die locking mechanism is arranged between the lower die assembly and the die frame and used for locking and unlocking the lower die assembly and the die frame; locking mechanisms are arrangedbetween the die frame and the side rails and used for locking or unlocking the die frame and the side rails; the ejecting devices are connected with the side rails and used for driving the die frameto float; and rolling assemblies and guiding assemblies are arranged on the side rails. According to the die replacing system of the large-tonnage press, quick die replacing can be achieved, and the die replacing safety and reliability are improved.

Owner:FOSHAN HENGLITAI MACHINERY

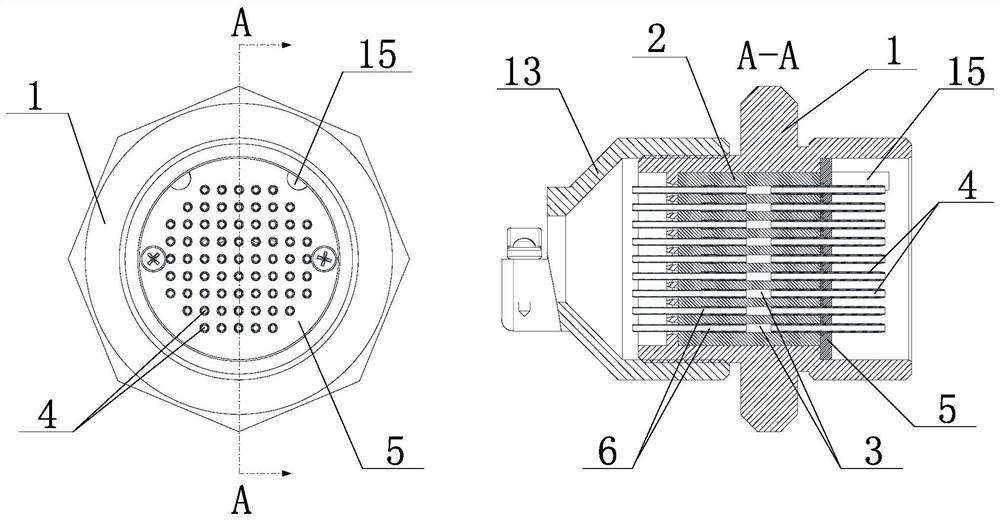

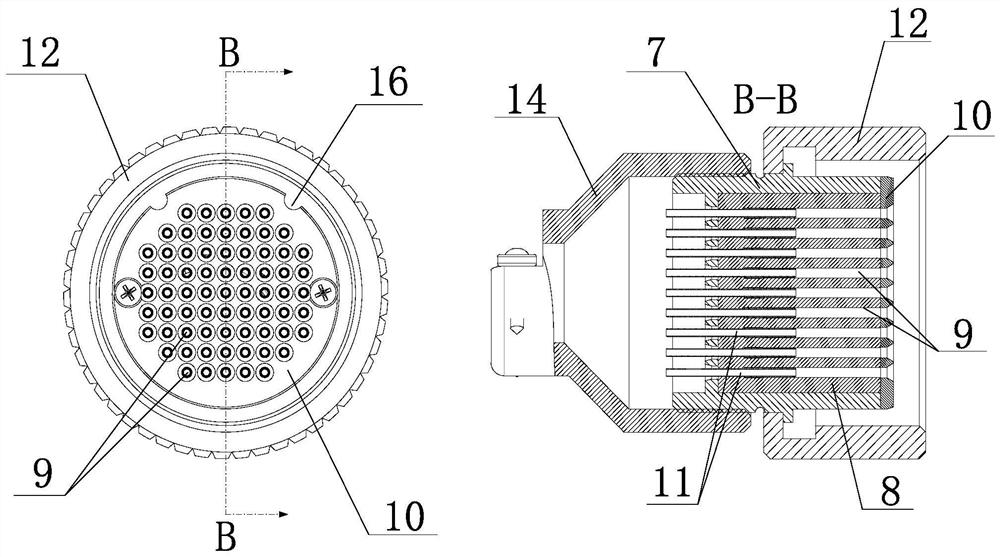

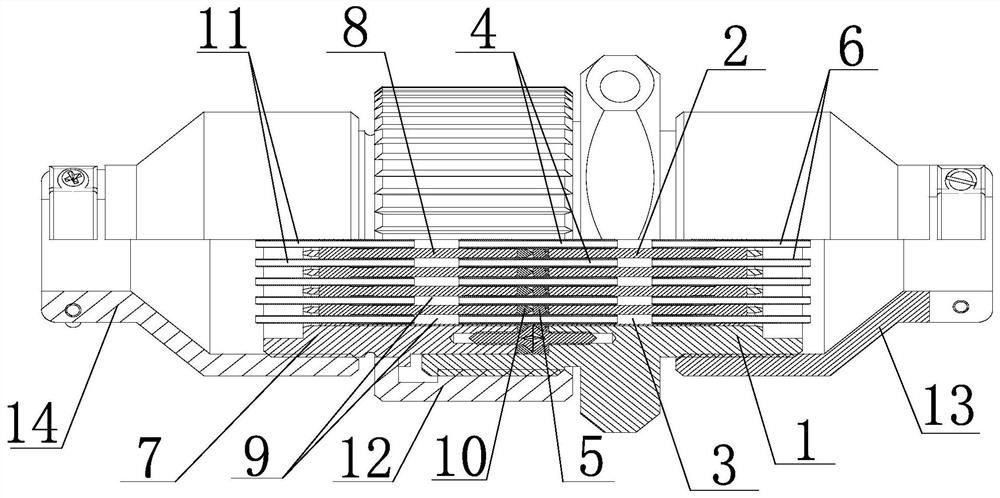

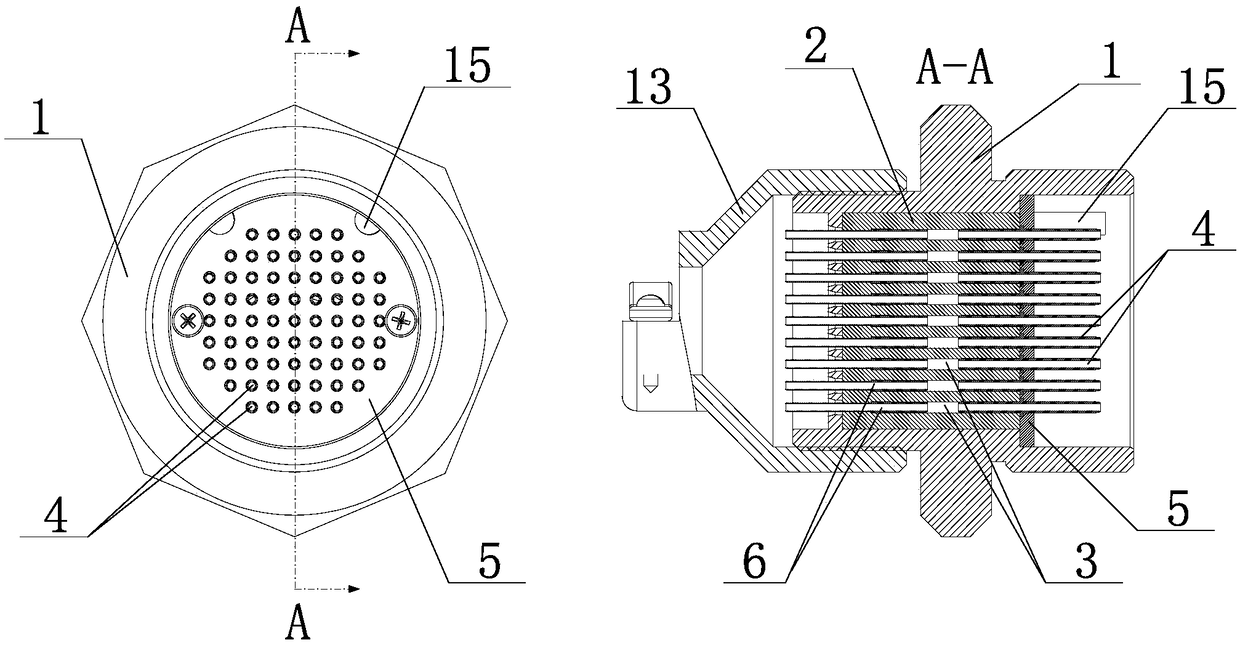

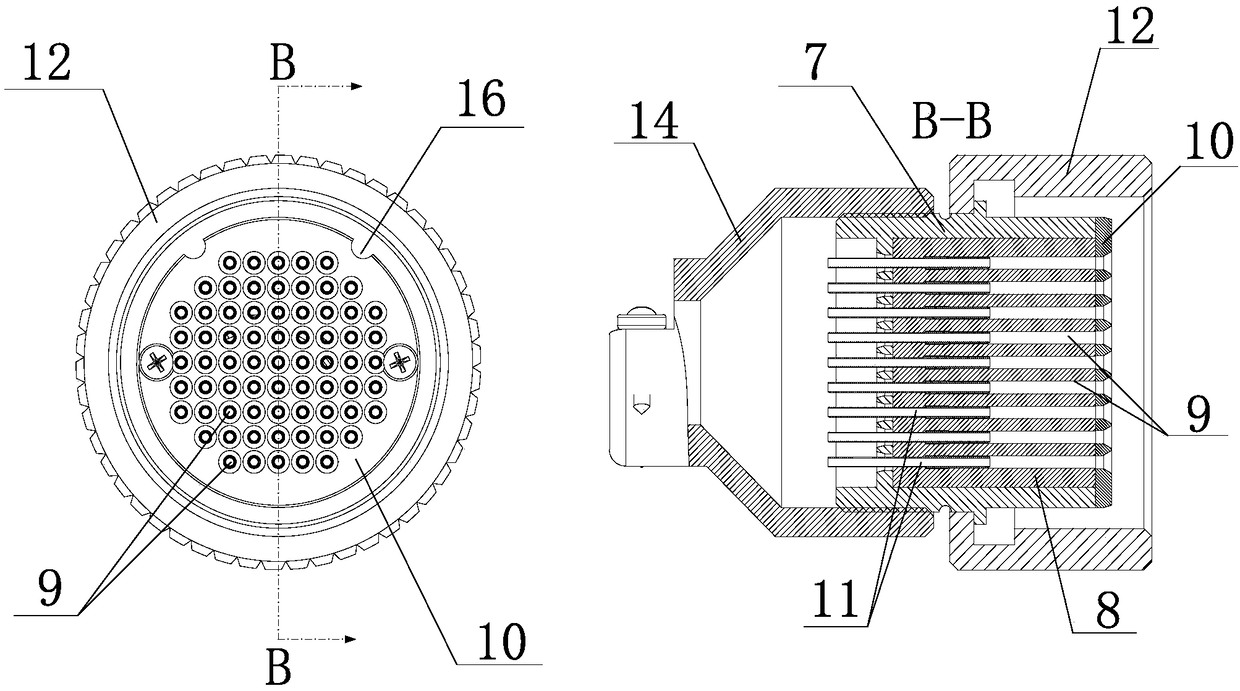

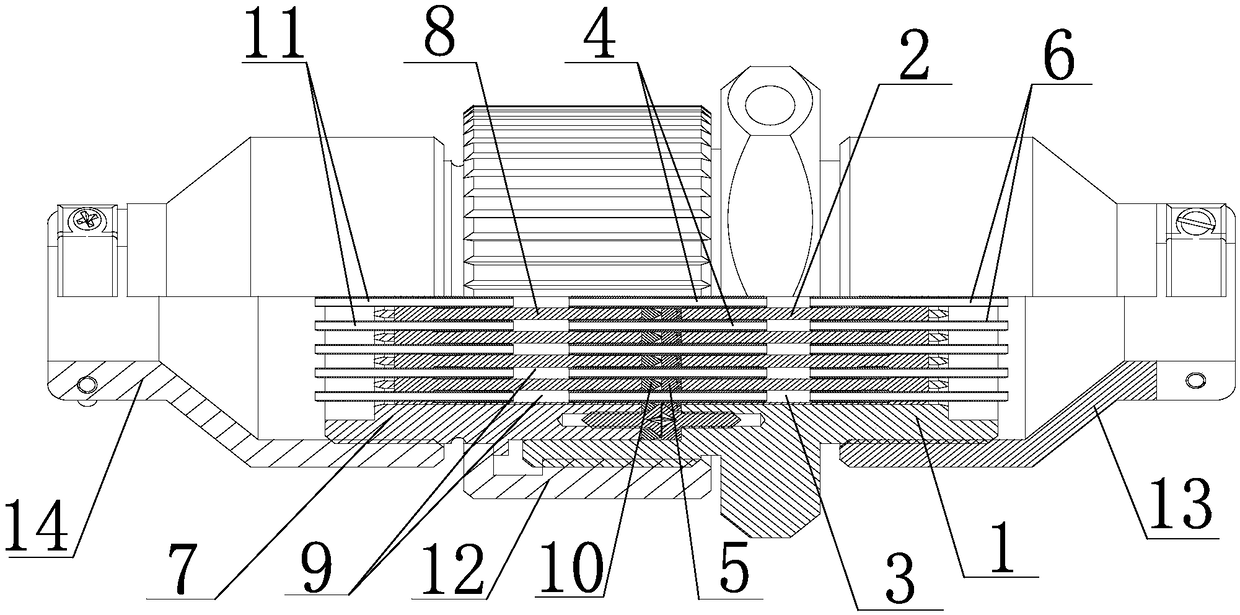

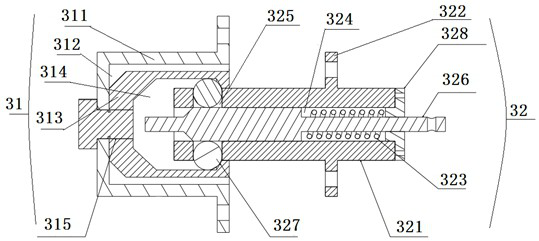

multi-hole fluid connector

ActiveCN109442107BSimple structureSimple locking methodJoints with sealing surfacesPorous flowAnatomy

The invention discloses a porous fluid connector. The porous fluid connector comprises a male end connector and a female end connector. The male end connector comprises a porous connection male end shell, a male end porous sealing body is arranged in the porous connection male end shell in a sleeved mode, the male end porous sealing body is internally provided with a plurality of male end dense pore channels. A male end porous baffle is arranged at one end of the male end porous sealing body, connecting pins are arranged at the ends, at which the male end porous baffle is located, of the maleend dense hole channels in an inserting mode, and male end capillary connecting pins are arranged at the other ends of the male end dense pore channels in an inserting mode. The female end connector includes a porous connection female end shell, a female end porous sealing body is arranged in the porous connection female end shell in a sleeved mode, and the female end porous sealing body is internally provided with a plurality of female end dense pore channels. A female end porous baffle is arranged at one end of the female end porous sealing body, and female end capillary connecting pins arearranged at the other end of the female end porous sealing body in an inserting mode. The porous fluid connector is simple in structure and locking mode, convenient to use for rapid testing, small insize, light in weight and convenient to operate.

Owner:万硕(成都)航空科技有限公司

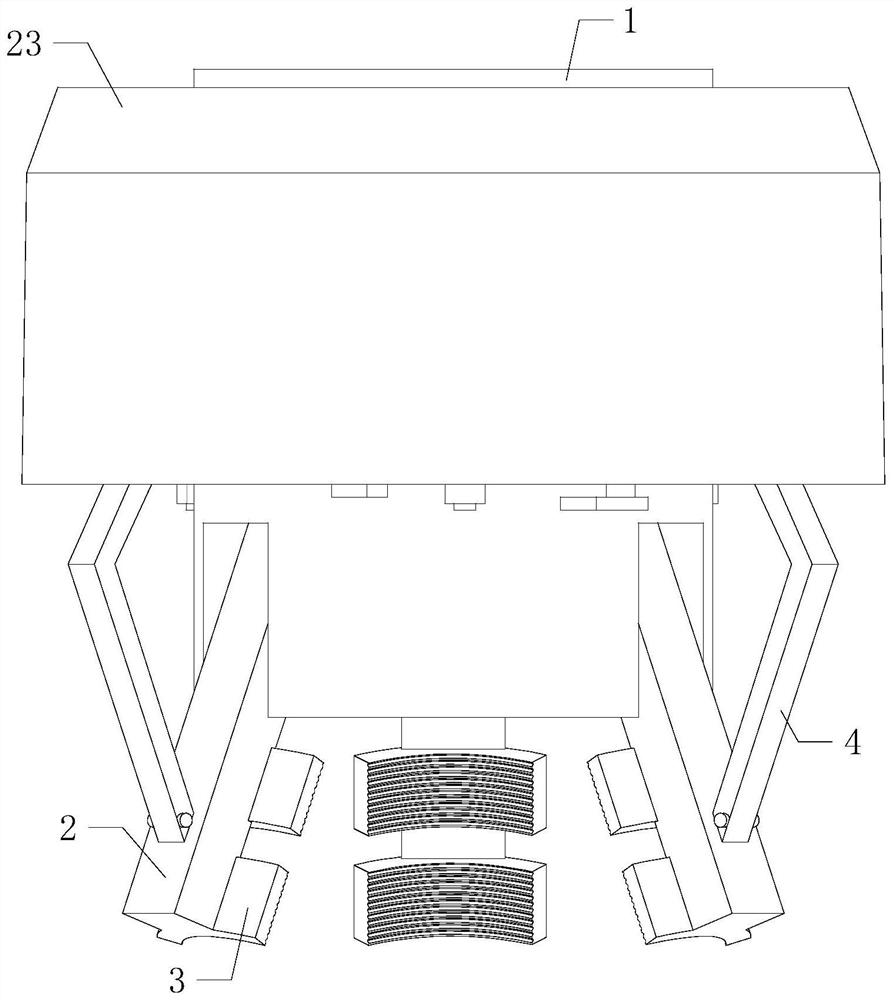

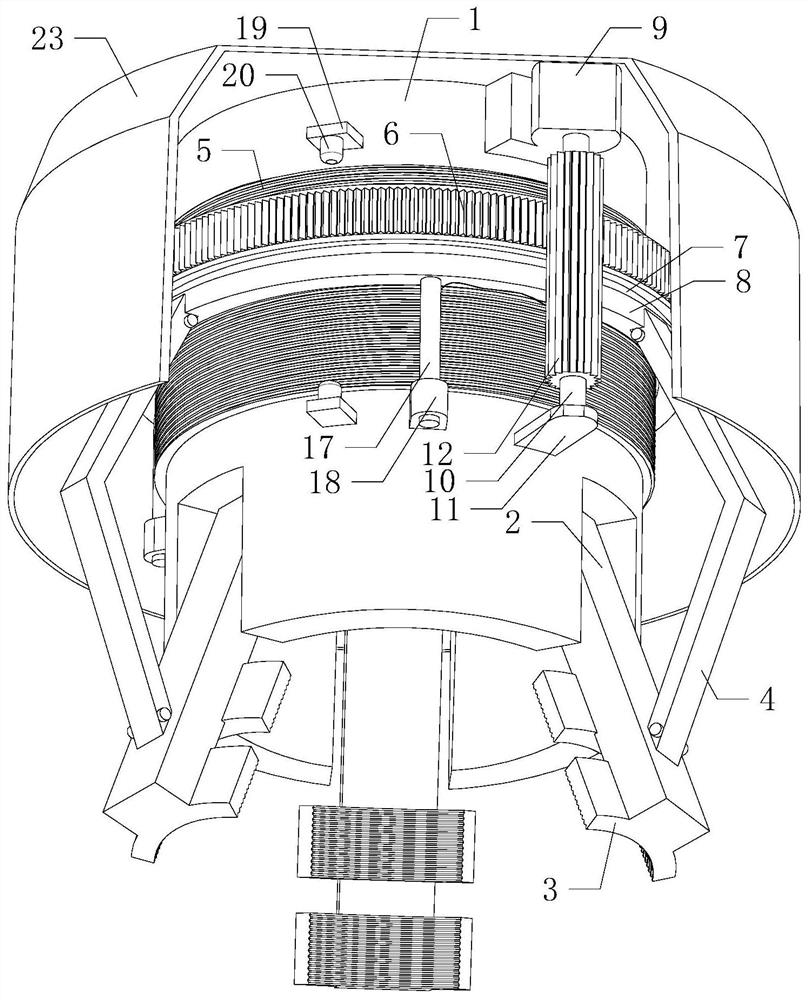

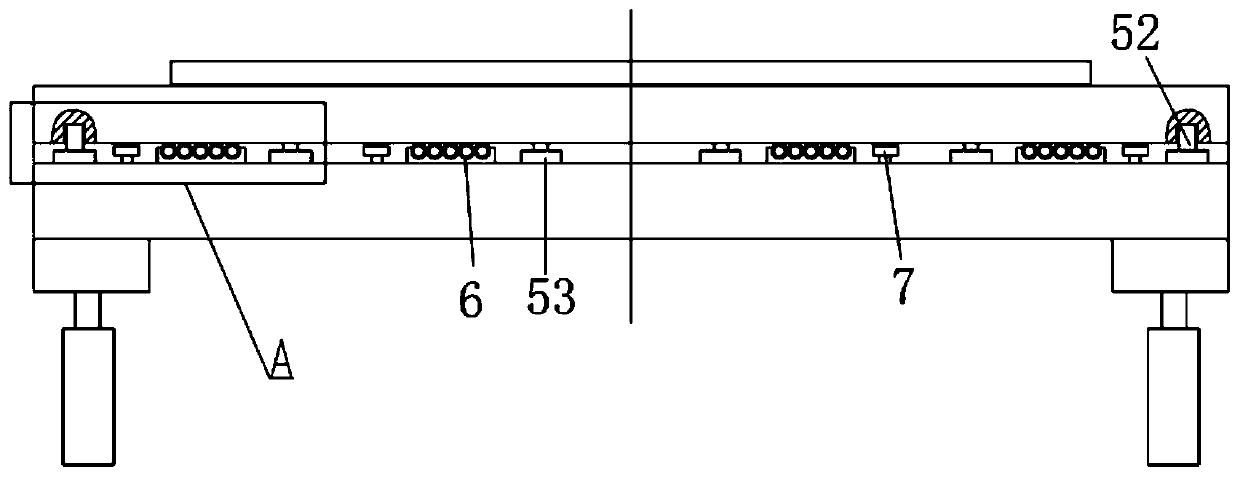

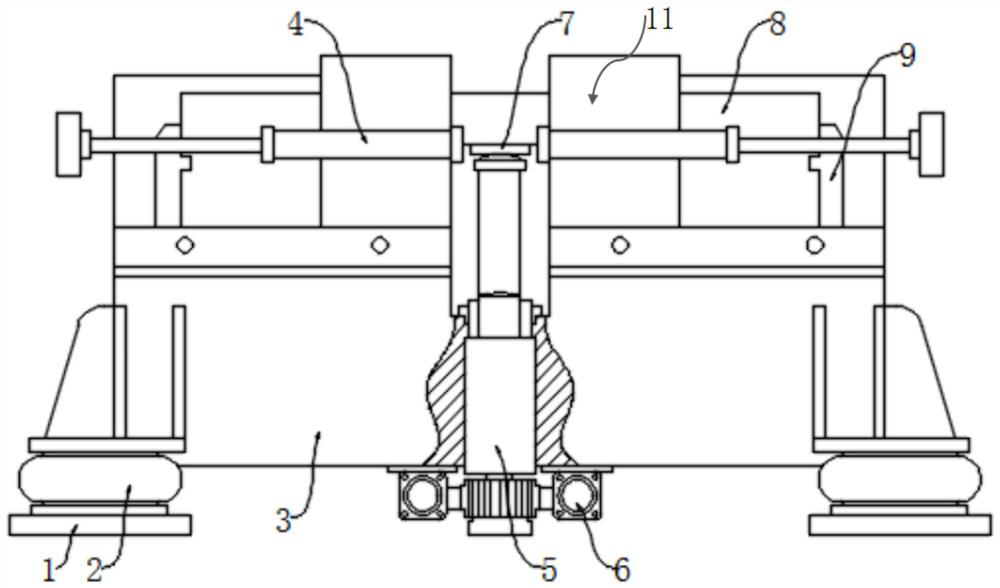

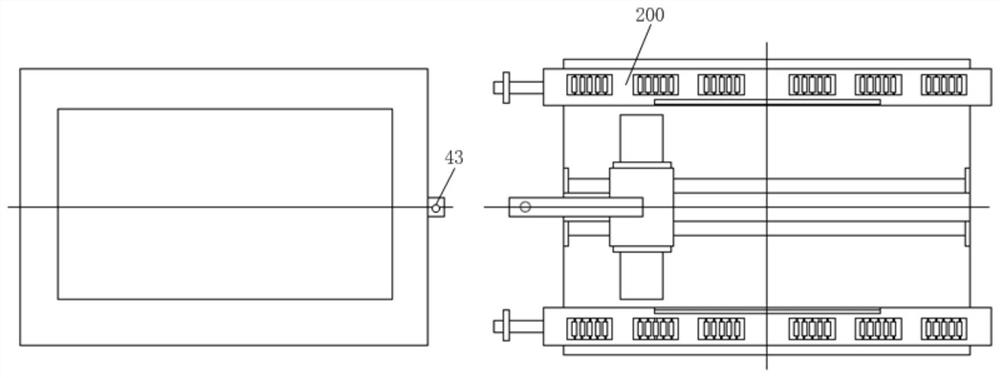

Spacecraft explosion shock response spectrum vertical excitation simulation system

PendingCN114046951AIncrease flexibilityEffective Area AdjustmentShock testingStrength propertiesControl theoryImpact area

The invention discloses a spacecraft explosion shock response spectrum vertical excitation simulation system. The system comprises a base, the top of the base is provided with a support assembly, the support assembly is provided with a resonance table top, the center of the bottom of the resonance table top is provided with a waveform generator, and the left side and the right side of the resonance table top are provided with constraint assemblies. And an impact assembly is arranged in the base, the impact assembly is arranged under the waveform generator, and a driving assembly used for driving the restraining assembly to move left and right is arranged on the base. The table top constraint assembly is arranged at the bottom of the resonance table top, the driving part and the guide wheel are arranged, and the table top constraint assembly can move left and right along the resonance table top and clamp and constrain the table top, so that the effective area of the resonance table top can be adjusted, the limited impact area of the resonance table top can be flexibly adjusted for test products with different sizes, and the test flexibility of the simulation system is improved.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

Orthopedic splint mounting and fastening device convenient to adjust for orthopedics department

InactiveCN114081705AEasy to adjust the length to useImprove breathabilityFractureOrthopedic departmentNursing care

The invention discloses an orthopedic splint mounting and fastening device convenient to adjust for the orthopedics department, and relates to the technical field of orthopedic appliances. The device comprises an upper fastening assembly, a lower fastening assembly, a first electric push rod, a breathable arc-shaped clamping plate and a sealed arc-shaped clamping plate, the upper fastening assembly comprises a left upper fastening block and a right upper fastening block, and the lower fastening assembly comprises a left lower fastening block and a right lower fastening block. According to the orthopedic splint mounting and fastening device, the arranged breathable arc-shaped clamping plate is poor in breathable effect, the area between the upper fastening assembly and the lower fastening assembly can be easily exposed, medicine can be conveniently smeared on the leg, the injured area of the leg is nursed or the injured area of the leg is carefully scratched, so that thediscomfort of the leg injured area is relieved, and itching is relieved. The device is provided with an opening and closing assembly, the size of an inner ring of the device can be automatically adjusted according to the thickness of the leg, the breathable arc-shaped clamping plate and the sealed arc-shaped clamping plate are arranged, the device has two use modes, the use modes are diversified, and functionality is high.

Owner:开封市中医院

Porous fluid connector

ActiveCN109442107ASimple structureSimple locking methodJoints with sealing surfacesEngineeringRapid testing

The invention discloses a porous fluid connector. The porous fluid connector comprises a male end connector and a female end connector. The male end connector comprises a porous connection male end shell, a male end porous sealing body is arranged in the porous connection male end shell in a sleeved mode, the male end porous sealing body is internally provided with a plurality of male end dense pore channels. A male end porous baffle is arranged at one end of the male end porous sealing body, connecting pins are arranged at the ends, at which the male end porous baffle is located, of the maleend dense hole channels in an inserting mode, and male end capillary connecting pins are arranged at the other ends of the male end dense pore channels in an inserting mode. The female end connector includes a porous connection female end shell, a female end porous sealing body is arranged in the porous connection female end shell in a sleeved mode, and the female end porous sealing body is internally provided with a plurality of female end dense pore channels. A female end porous baffle is arranged at one end of the female end porous sealing body, and female end capillary connecting pins arearranged at the other end of the female end porous sealing body in an inserting mode. The porous fluid connector is simple in structure and locking mode, convenient to use for rapid testing, small insize, light in weight and convenient to operate.

Owner:万硕(成都)航空科技有限公司

Gear aligning mechanism

PendingCN109262367AOutstanding and Beneficial Technical EffectsSimple structureAutomatic control devicesFeeding apparatusEngineeringMachine tool

The invention belongs to the technical field of machine tool processing, in particular to a gear aligning mechanism which comprises a movable apex shell, wherein an installation cavity is formed at one end of the movable top shell, a apex shaft, wherein the apex shaft is rotationally arranged in the installation cavity, a positioning disc, wherein the positioning disc for connecting a work-piece is sleeved at one end of the apex shaft. The right side of the movable apex shell is sleeved with a dial and an indicating disc, and the indicating disc is rotationally arranged relative to the dial. An elastic limiting device is arranged between the indicating disc and the positioning disc, wherein the elastic limiting device is movably abutted against the positioning disc. A locking screw is screwed in the indicating disc, and the locking screw is used for locking the indicating disc by abutting against the outer periphery of the movable apex shell. The gear aligning mechanism has the advantages of simple structure, low cost, simple operation, adjustable bias value, high gear aligning precision, convenient maintenance and the like.

Owner:浙江中智鲸工智能装备有限公司

Locking piece, connector and low-temperature rocket system

ActiveCN112722339AEffective lock stateAvoid offsetCosmonautic ground equipmentsSelf-propelled projectilesPhysicsEngineering

The invention provides a locking piece, a connector and a low-temperature rocket system, which are suitable for penetrating through a first piece and a second piece and have a locking state of fixing the first piece and the second piece and a separating state of unlocking the first piece and the second piece; the system further comprise a shaft sleeve structure with a built-in accommodating cavity having the end part abutted against the first piece, and a shaft core structure penetrating through the first piece and the second piece and comprising a locking sleeve, a limiting adjusting piece and an abutting piece; the limiting adjusting piece and the abutting piece are arranged on the locking sleeve, the abutting piece is arranged in a protruding mode in the circumferential direction of the locking sleeve and abuts against the second piece, and the limiting adjusting piece comprises a second elastic piece; and the limiting adjusting piece is suitable for having the locking state of being clamped with the accommodating cavity and the separation state of being separated from the accommodating cavity under the adjustment of the second elastic piece.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD +1

built-in handle

ActiveCN105952262BImprove securityImprove wear resistanceBuilding locksHandle fastenersForeign matterEngineering

The invention discloses a built-in handle. The built-in handle comprises a handle shell and a handle lock cylinder located in the handle shell, wherein a dustproof structure is arranged at a position corresponding to an outer lock hole on the handle shell; the handle lock cylinder is locked in the handle shell via an inclined block. According to the built-in handle, the inclined block is used for locking the handle lock cylinder and the handle shell; the locking manner is more simple, efficient and reliable; the safety of the handle lock cylinder is improved; secondly, the dustproof structure protects the lock hole in the lock cylinder from being damage by dust or other foreign matters, so that the usage performance of the handle lock cylinder is ensured, and the service life of the handle lock cylinder is prolonged; furthermore, the handle shell is formed by welding two symmetrical half shells; the welding process is reliable, so that the performance of the handle shell is excellent; the large-scale production and the streamlined operation are facilitated; the service life of the product is prolonged; the production cost is reduced.

Owner:NANJING EASTHOUSE ELECTRIC CO LTD

A Die Changing System for a Large Tonnage Press

ActiveCN110861208BReduce frictional resistanceAchieve demouldingAuxillary shaping apparatusMould fastening meansStructural engineeringMechanical engineering

Owner:FOSHAN HENGLITAI MACHINERY

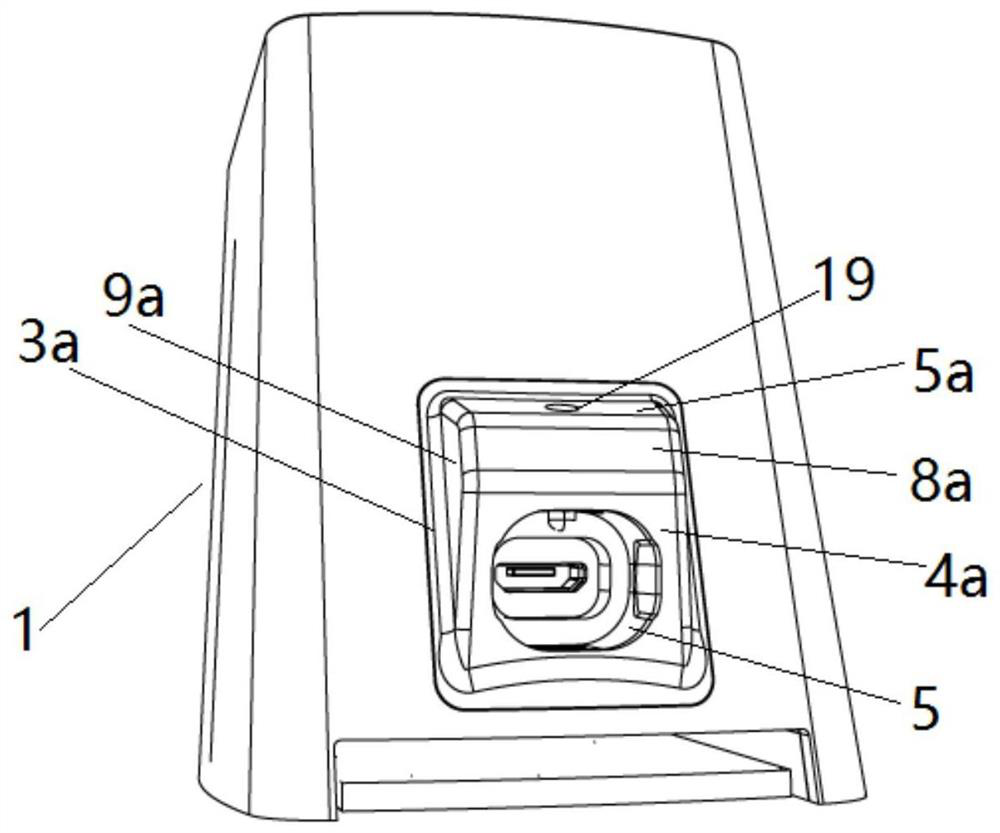

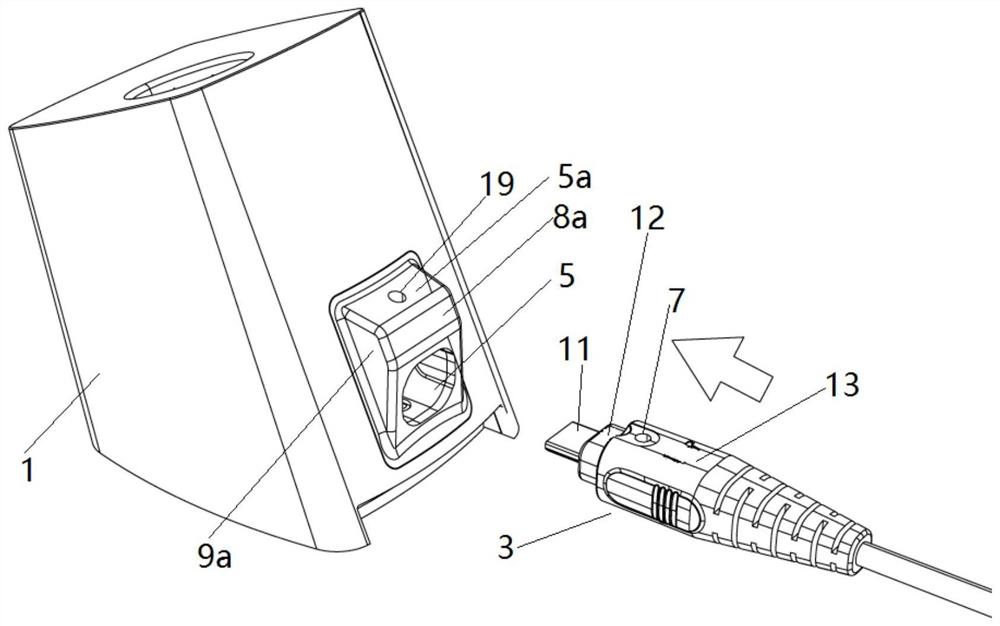

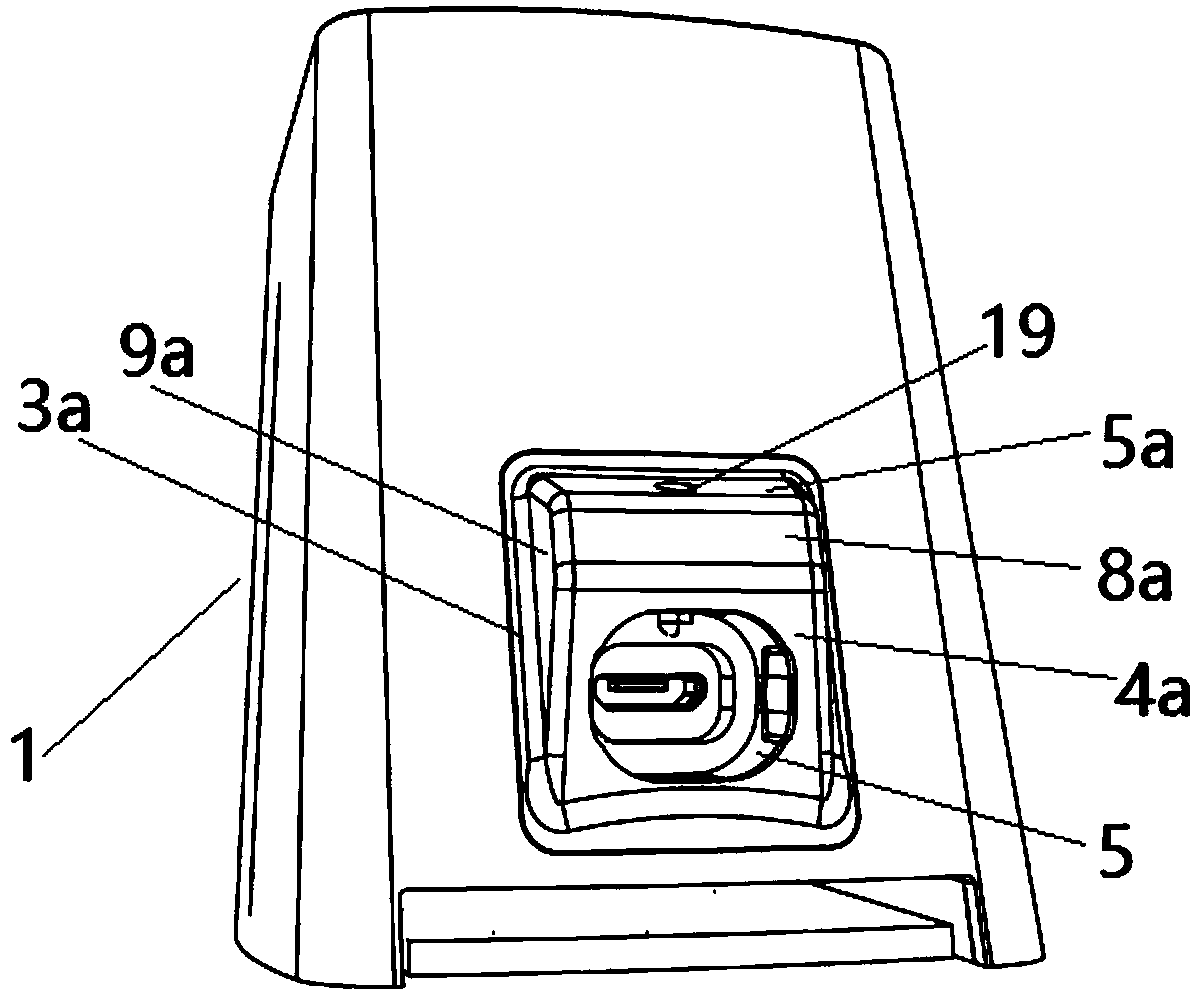

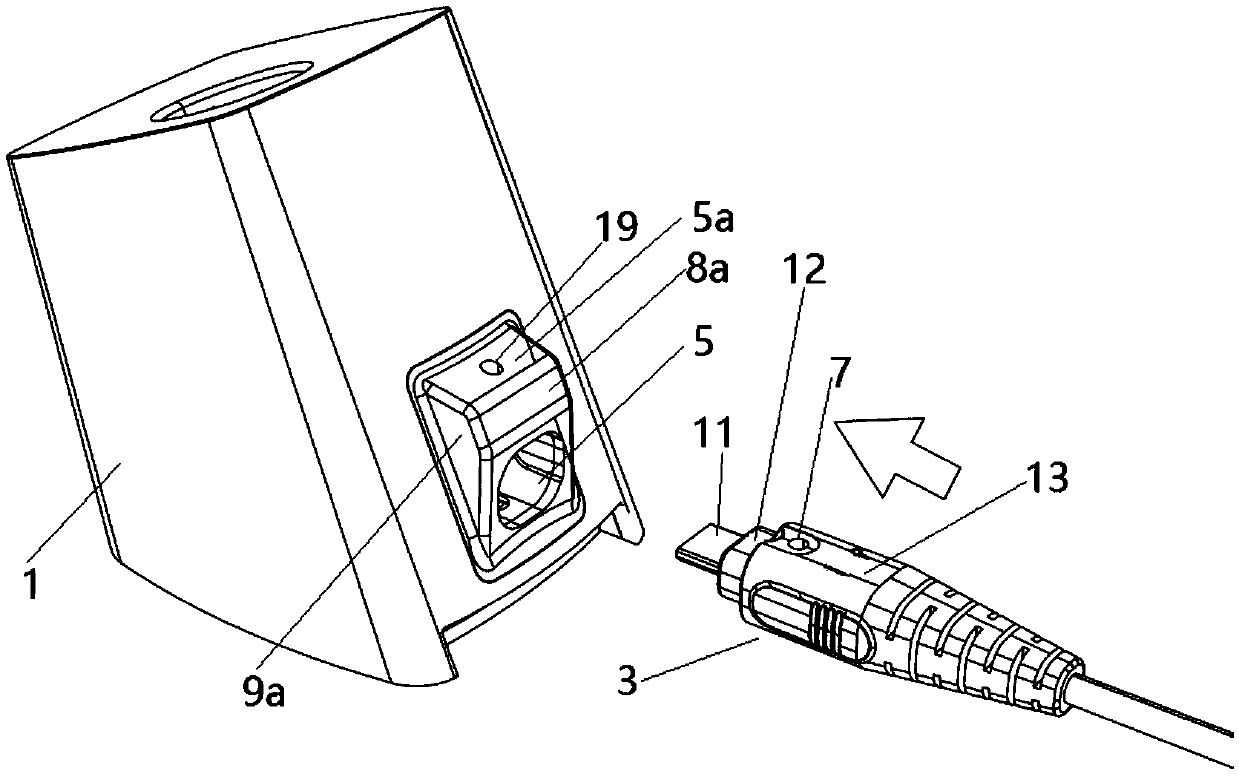

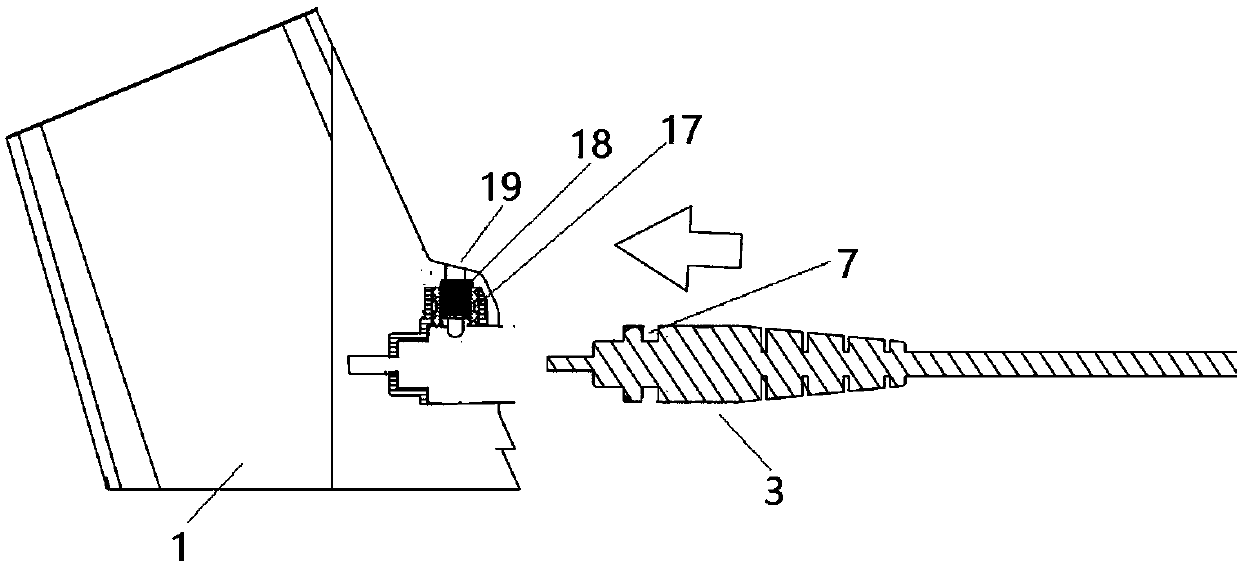

A locking mechanism and locking method for commodity anti-theft

ActiveCN110005281BMeet the needs of simple lockingMeet different needsLocks for portable objectsLocking mechanismComputer security

The present invention provides a locking mechanism for commodity theft prevention, comprising: a first member, including a locking assembly, the locking assembly is configured to include at least a first locking state and a second locking state, and can be in the first locking state and the second locking state Switch between the second locking state; the second member is configured to be able to combine with the locking assembly; when the locking assembly is initially combined with the second member, the locking assembly is in the first locking state, and the locking mechanism is in the preliminary locking state ; When the locking assembly is fully combined with the second member, the locking assembly is in the second locking state, and the locking mechanism is in a fully locked state. The invention also provides a locking method for commodity theft prevention. The locking mechanism of the present invention can be in at least one first locking state and one second locking state. By adjusting the locking assembly, the elastic lock head can move relative to the first passage, and the moving distance can be different, so that the locking mechanism can be in different locking states.

Owner:HANGZHOU LANGHONG KECHUANG TECH CO LTD

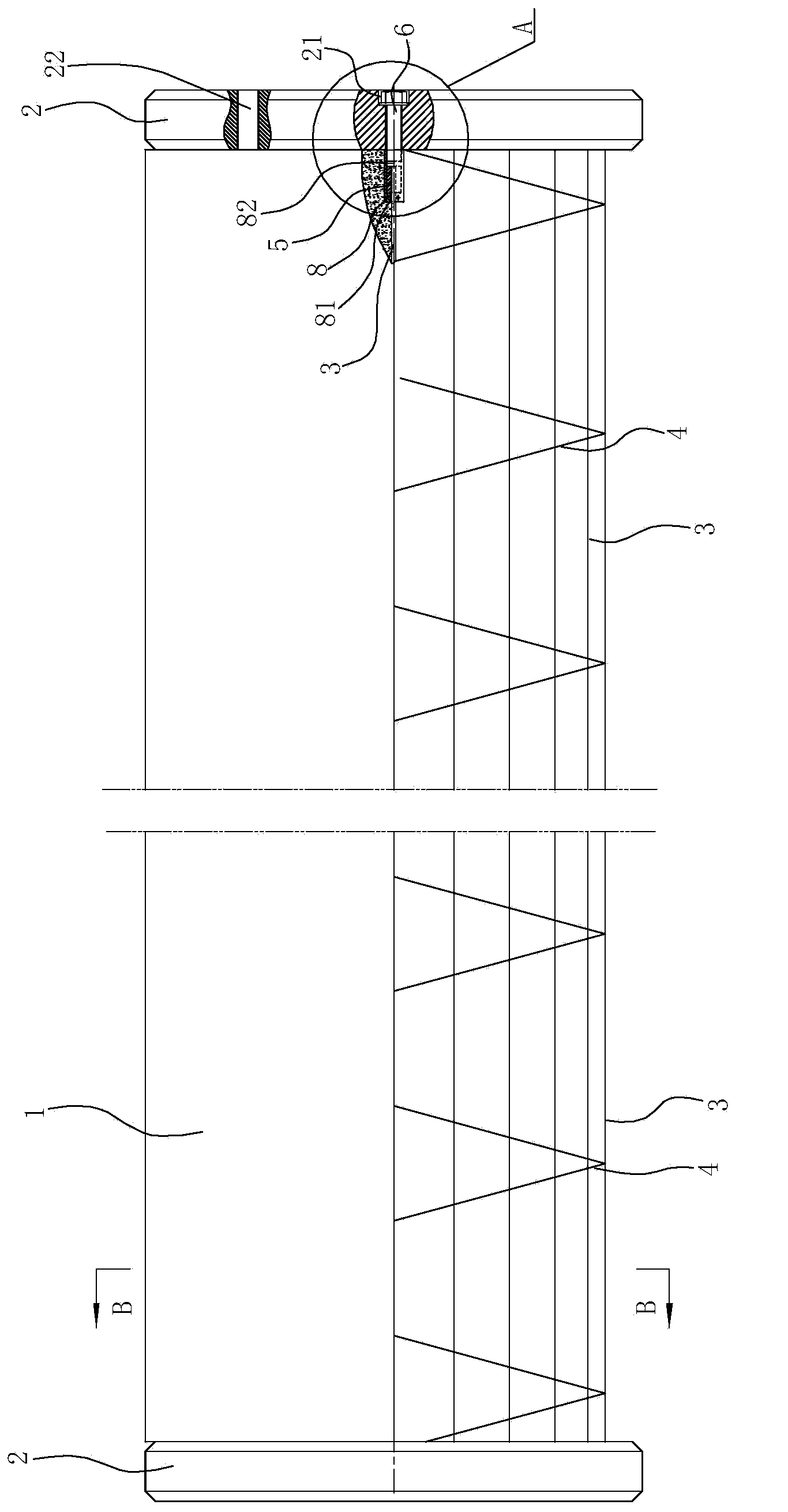

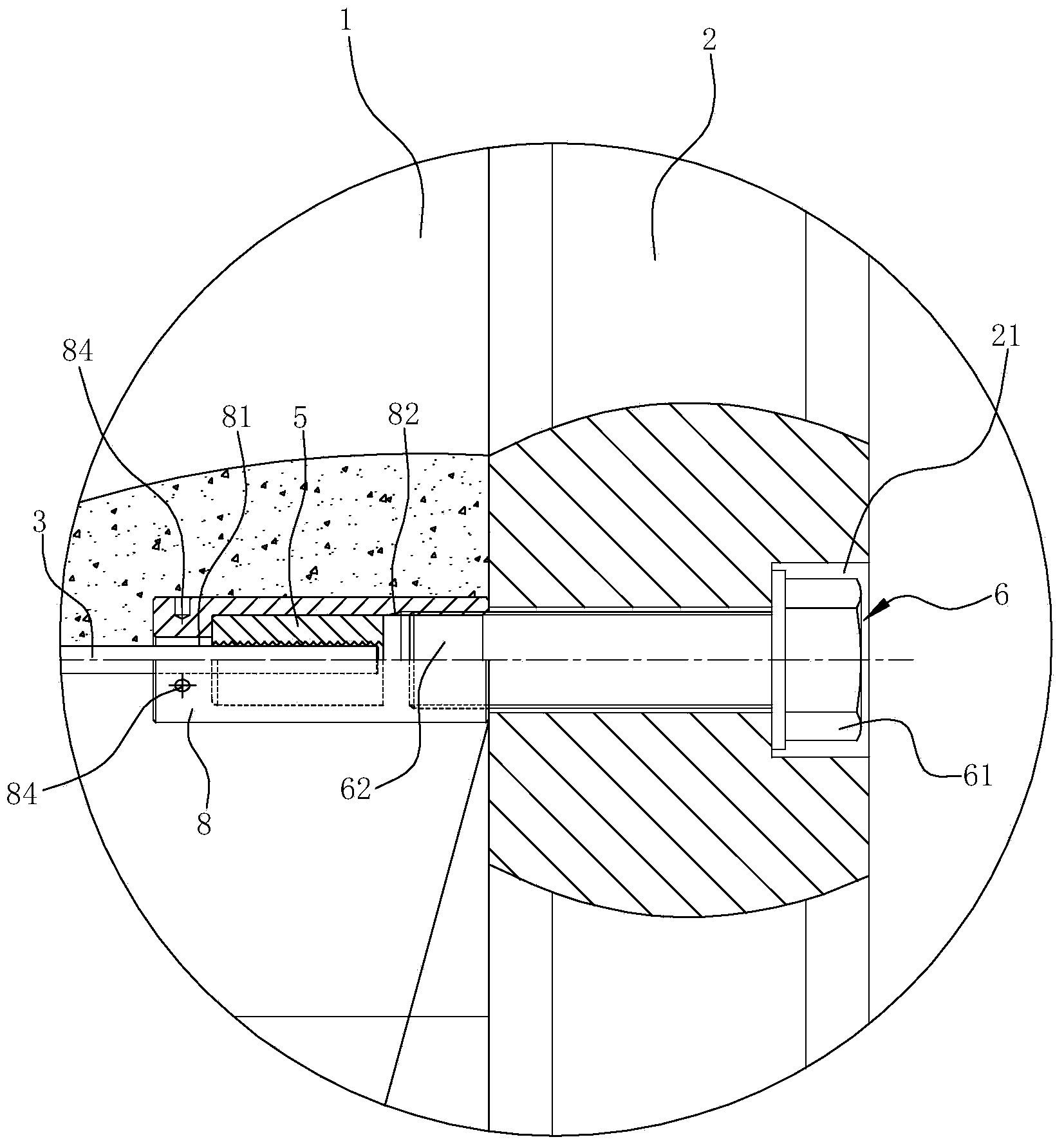

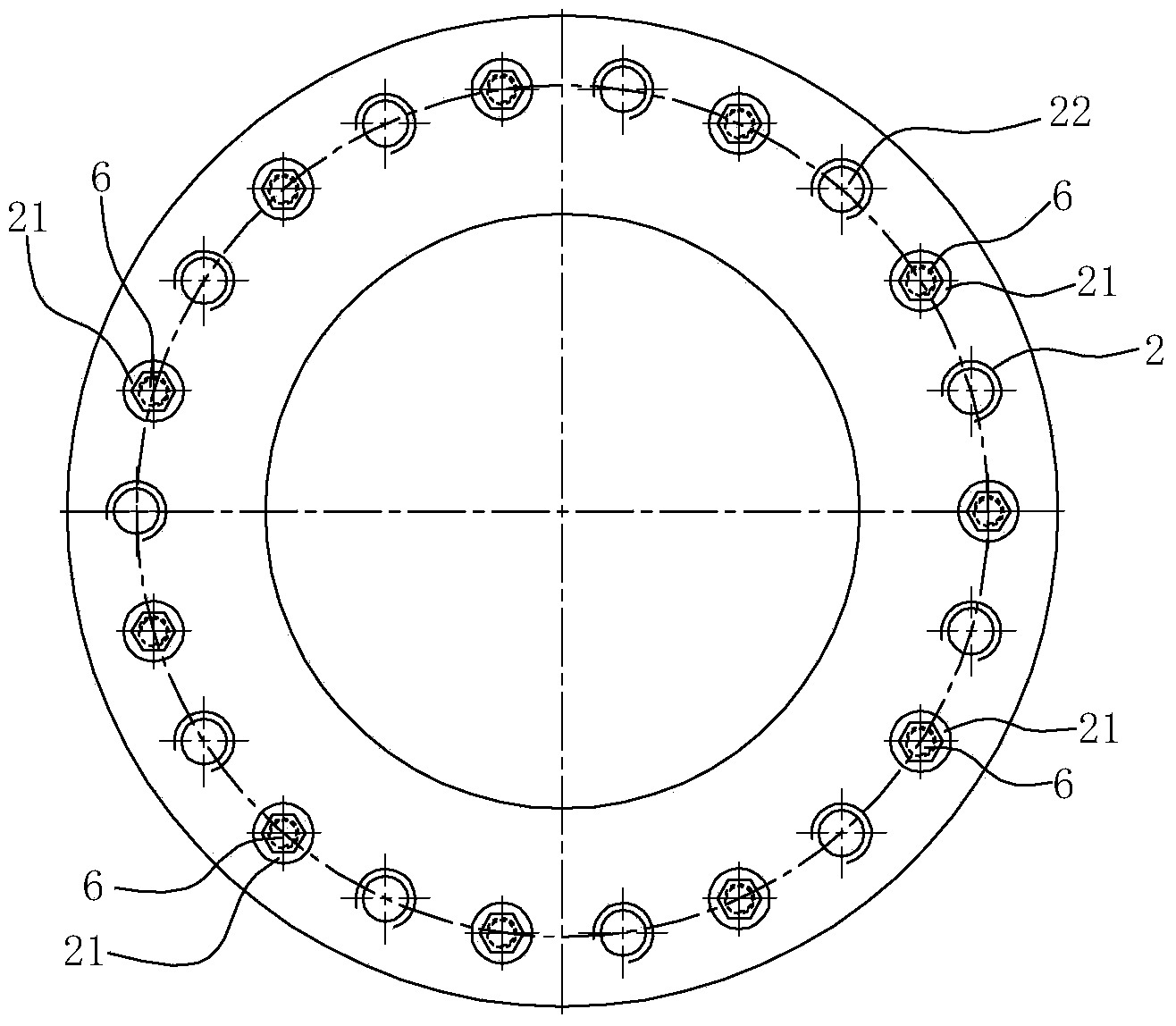

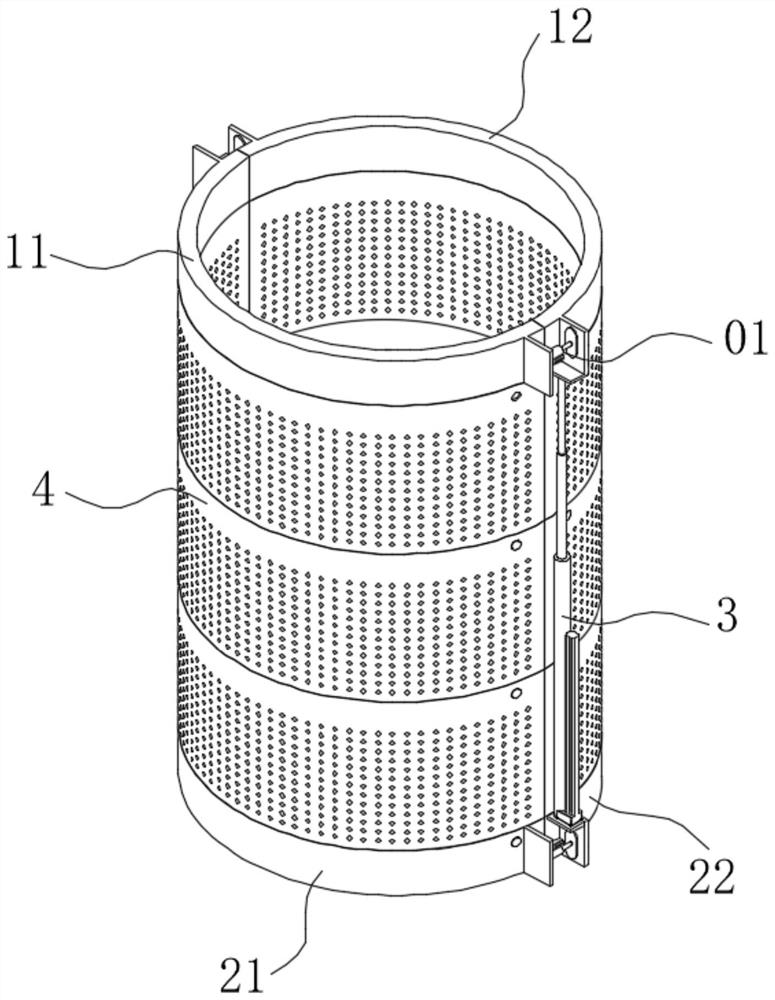

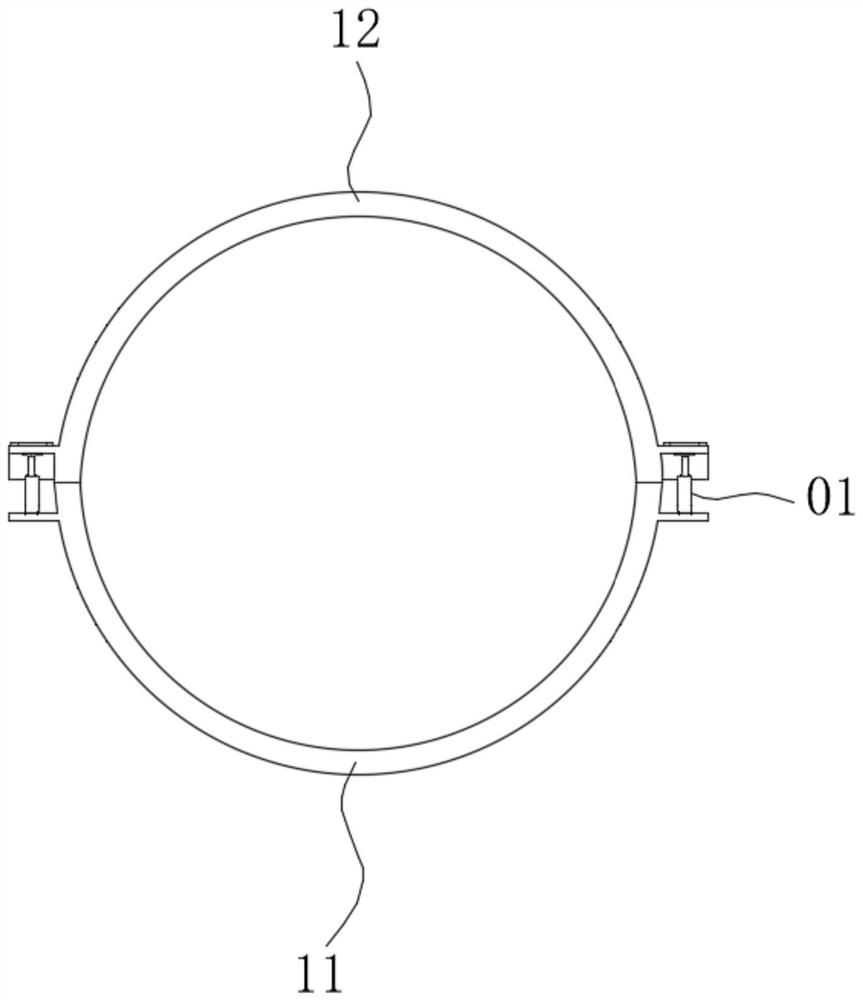

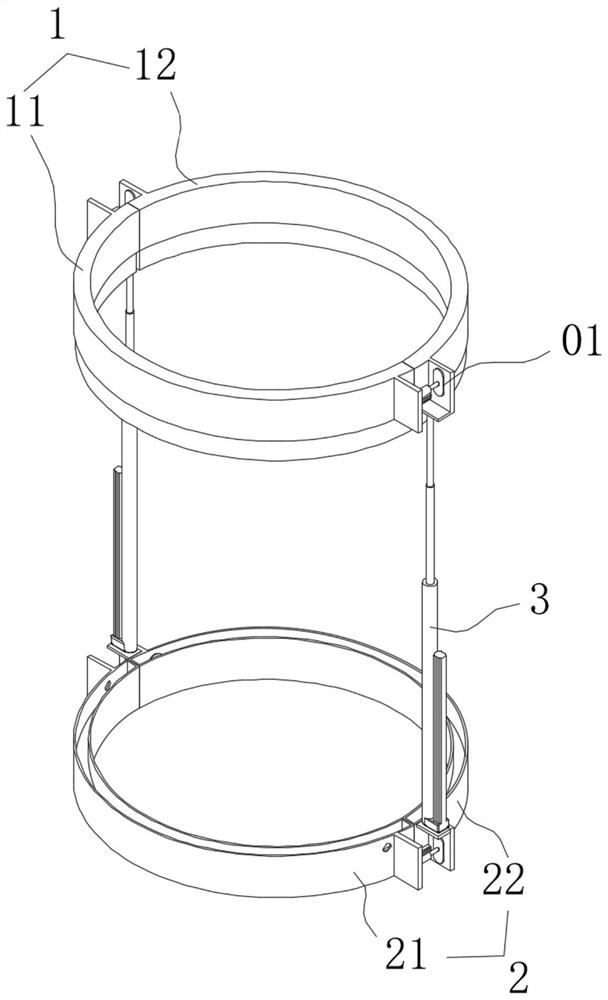

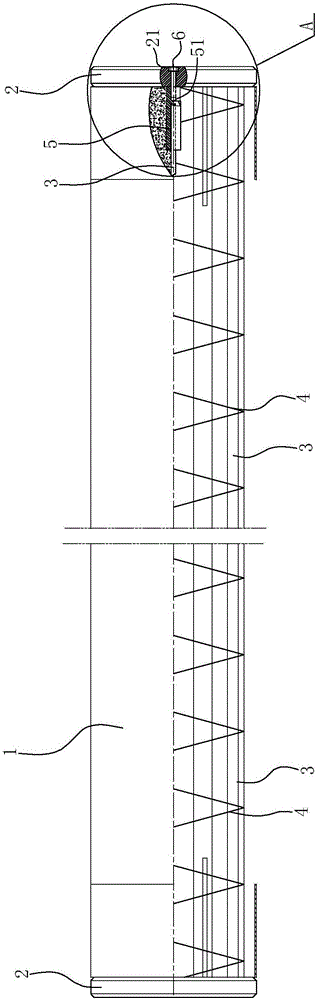

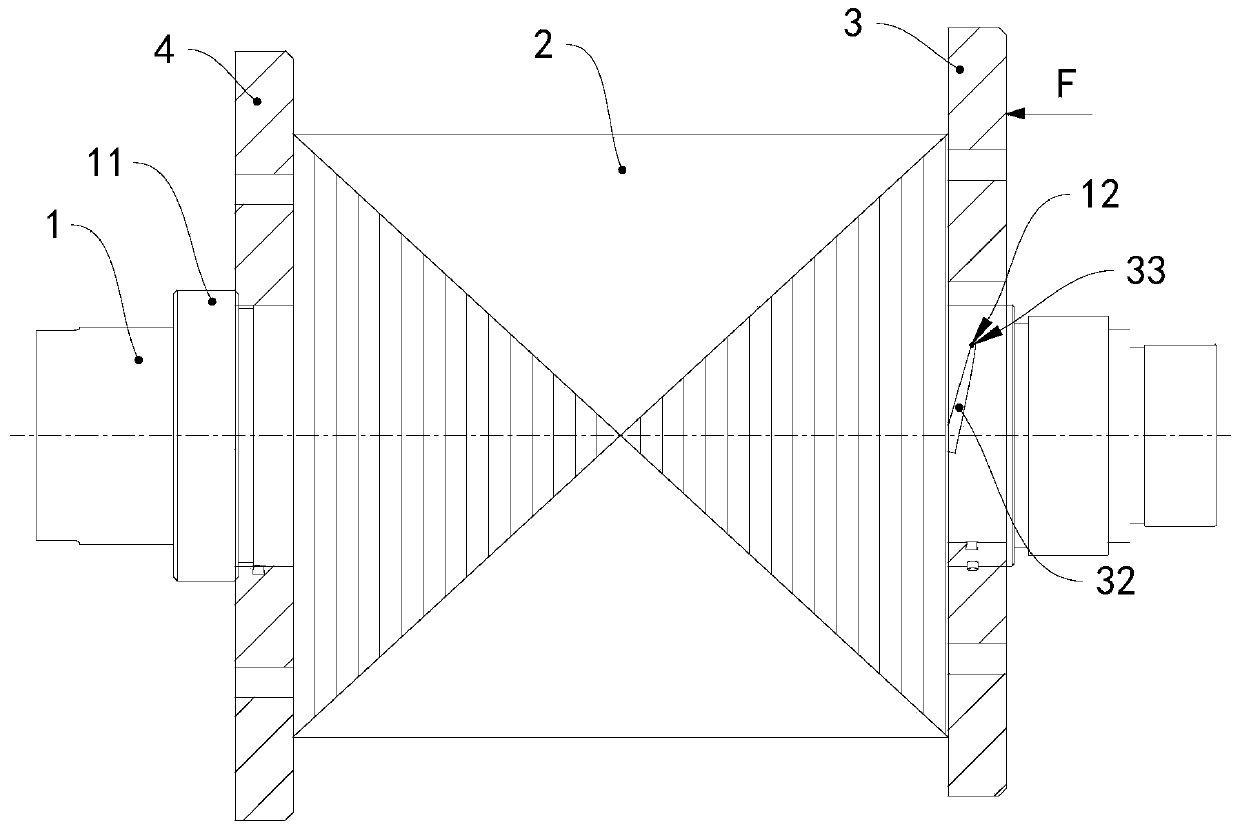

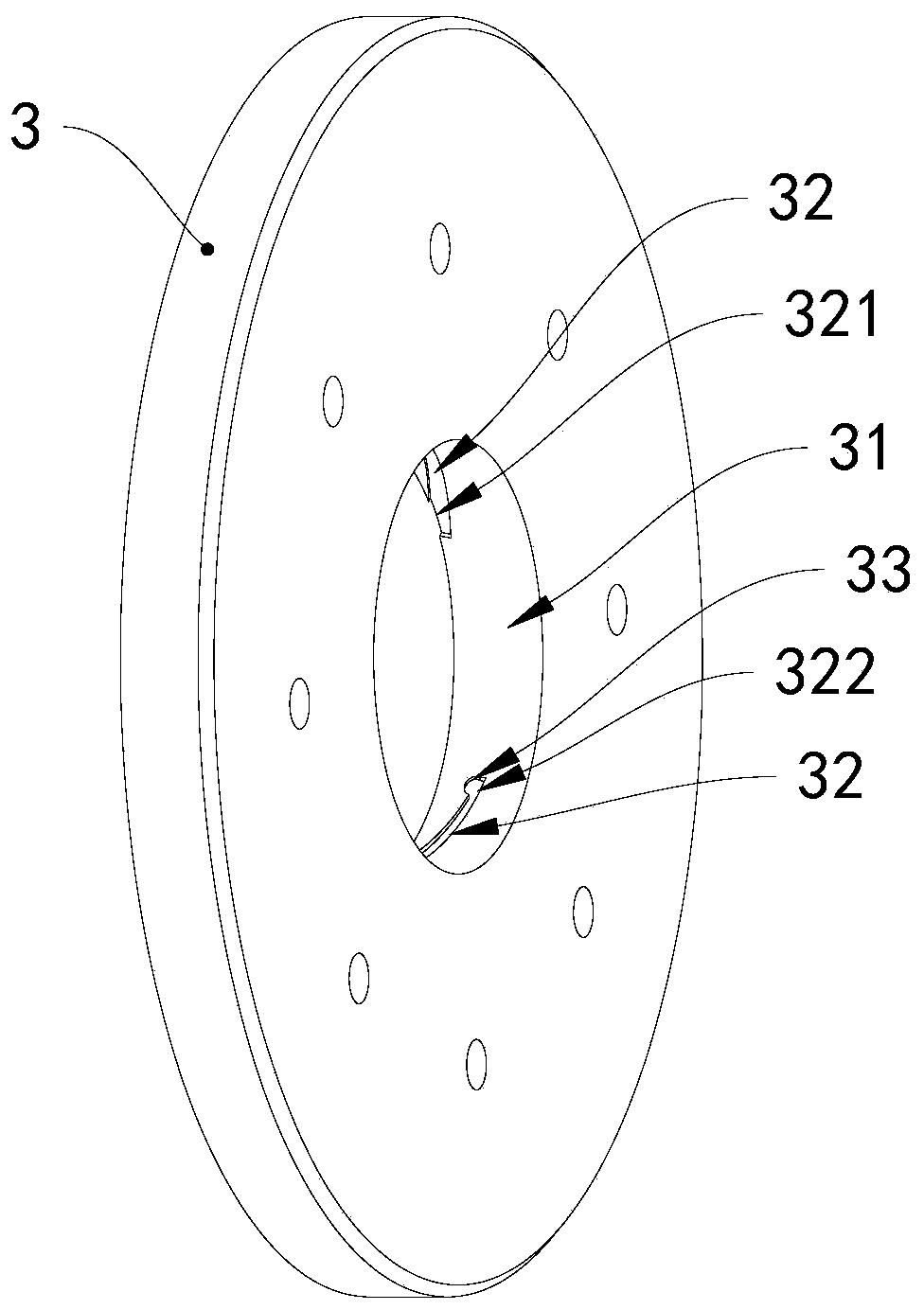

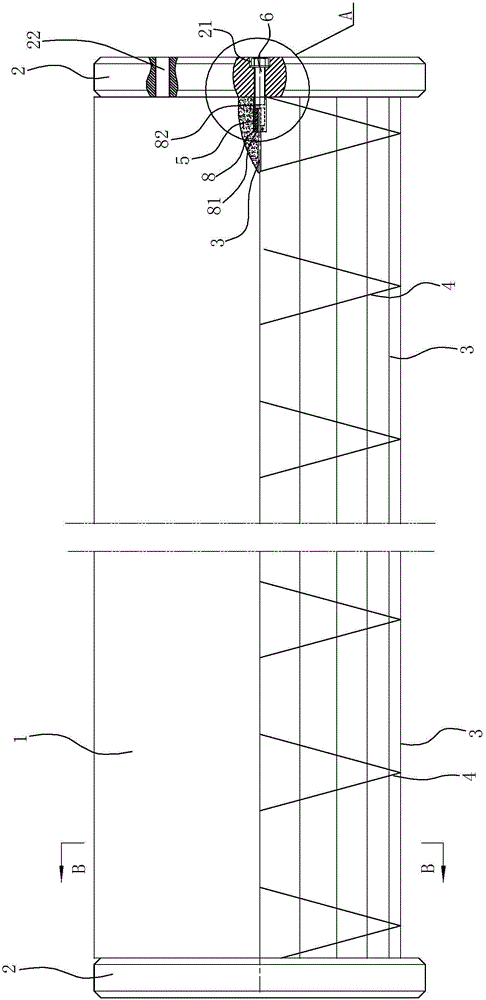

A pretensioned centrifugal concrete pile with steel strands and its manufacturing method

ActiveCN103741675BConsistent tensile strengthImprove performanceCeramic shaping apparatusBulkheads/pilesPre stressRebar

The invention relates to a pretensioned centrifugal concrete pile with steel stranded wires. The pretensioned centrifugal concrete pile comprises a concrete pile body (1) and a rebar cage positioned in the concrete pile body (1), and the rebar cage comprises axially-arranged prestressed main rebars and stirrups (4) wound outside the main rebar. The pretensioned centrifugal concrete pile is characterized in that the prestressed main rebars are the steel stranded wires (3), the steel stranded wires (3) at at least one end of the rebar cage are combined with squeezing-type anchors (5) by means of squeezing, the outer end faces of the squeezing-type anchors (5) are flush with or slightly lower than that of the concrete pile body (1), and a thread for connection is arranged on each squeezing-type anchor (5). In the process of manufacturing of the pile body, the squeezing-type anchors and a tensioning plate can be fixed together through threaded connection to realize tensioning and applying of the steel stranded wires as the main rebars in the rebar cage, and bending resistance, shearing resistance and tensioning resistance of the pretensioned centrifugal concrete pile are greatly improved; end plates can be freely mounted according to actual needs. The invention further relates to a manufacturing method of the centrifugal concrete pile.

Owner:俞向阳

A self-anchored steel strand pretensioned centrifugal concrete pile and its manufacturing method

ActiveCN103741673BConsistent tensile strengthImprove performanceCeramic shaping apparatusBulkheads/pilesCentrifugationPre stress

The invention relates to a self-anchored steel strand pretensioned centrifugal concrete pile. The self-anchored steel strand Pretensioned centrifugal concrete pile comprises a hollow concrete pile body and a steel reinforcement cage located in the concrete pile body, wherein the steel reinforcement cage comprises prestressed main reinforcements arranged in the axial direction, stirrups and end plates. The self-anchored steel strand Pretensioned centrifugal concrete pile is characterized in that the prestressed main reinforcements are steel strands, a plurality of through holes allowing the steel strands to pass through are formed on each end plate, the through holes correspond to the steel strands one to one so that the steel strands passing through the through holes of the end plates can be connected with an external steel strand locking structure, and a plurality of threaded connecting holes for connection with the steel strand locking structure are further formed on the end plates. In this way, the steel strands can be tensioned through the steel strand locking structure outside, and then centrifugal molding is carried out, after molding is finished, an anchor plate is unloaded, and finally, the steel strands exposed out of the end plates are cut off and ground; the finished centrifugal concrete pile has no anchor part projecting from the end plate, and the centrifugal concrete pile with the steel strands is practicable and feasible.

Owner:俞向阳 +1

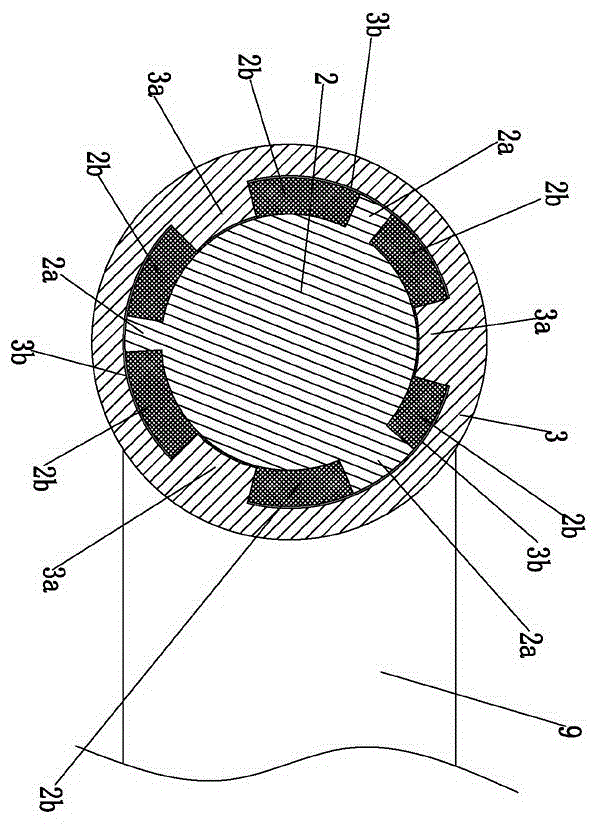

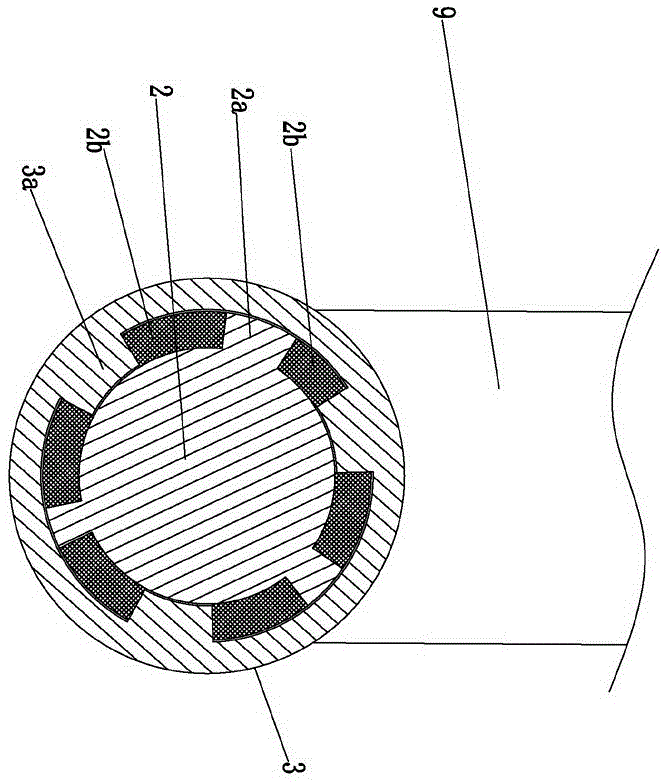

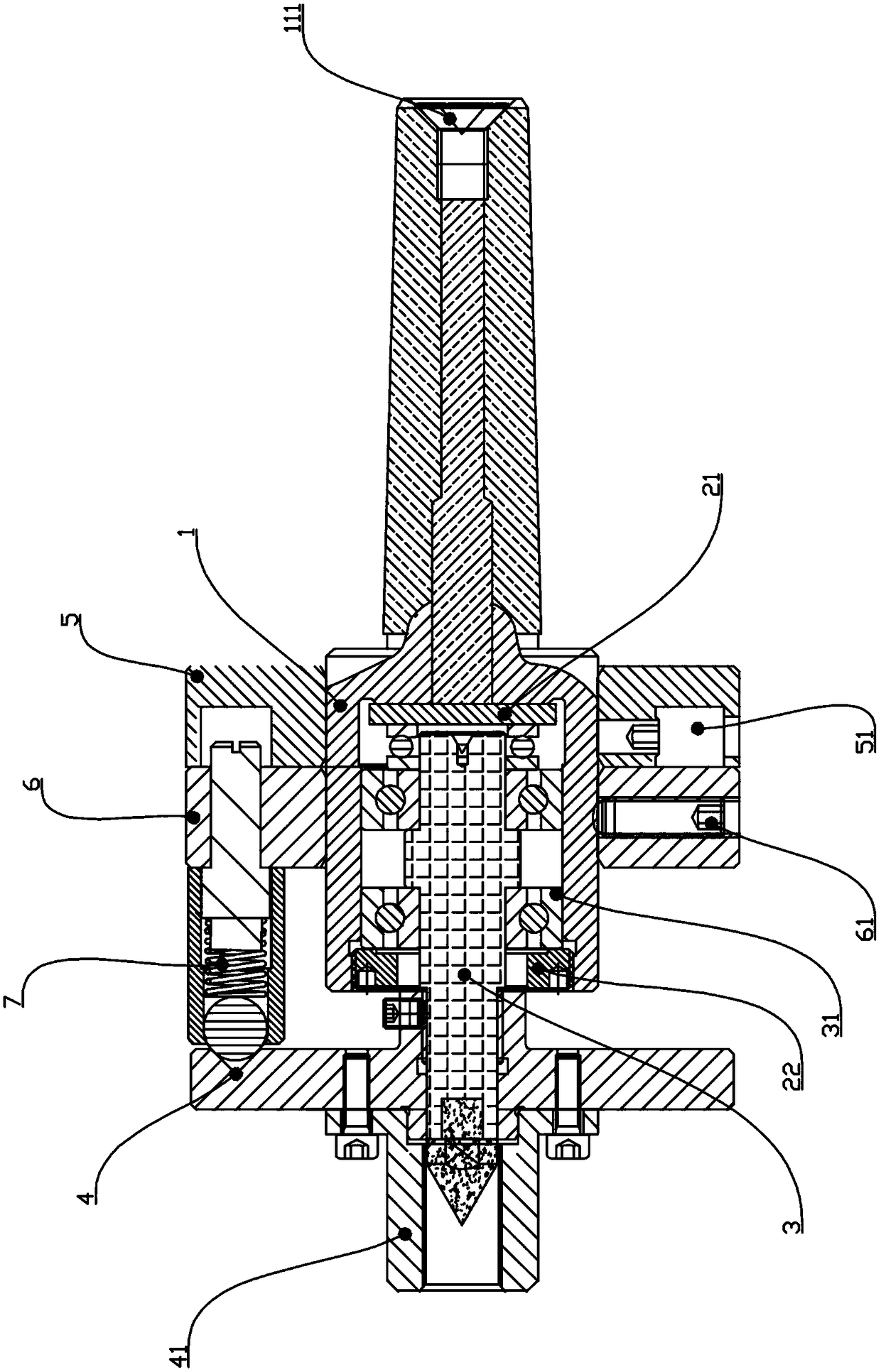

Rotor, motor, rotor locking method and means of transportation

ActiveCN110350695BSimplify the assembly processLarge locking forceMagnetic circuit rotating partsManufacturing stator/rotor bodiesElectric machineryEngineering

The invention provides a rotor, a motor, a locking method of the rotor and a transportation tool. The rotor comprises a rotor shaft, a rotor core and a baffle plate, wherein the rotor core and the baffle plate are both sleeved on the rotor shaft, and the rotor core is limited between a shaft shoulder of the rotor shaft and the baffle plate in the axial direction of the rotor shaft. A circular holeis formed in the baffle plate in a penetrating mode and is in clearance fit with the rotor shaft. The rotor also comprises a connecting assembly, and the connecting assembly is connected between thecircular hole and the rotor shaft. The connecting assembly comprises a guide groove and a limiting protrusion, and the limiting protrusion can move in the extending direction of the guide groove. Theguide groove comprises an inlet and an outlet, wherein the outlet is provided with a limiting groove communicated with the guide groove, the projection of the limiting groove on the axis of the rotorand the projection of the inlet on the axis of the rotor are arranged at intervals, and the limiting groove limits the displacement of the limiting protrusion in the axial direction of the rotor. Therotor is simple in assembly process, large in locking force and detachable.

Owner:GREE ELECTRIC APPLIANCES INC

Locking mechanism and method for goods theft prevention

ActiveCN110005281AMeet the needs of simple lockingMeet different needsLocks for portable objectsLocking mechanismEngineering

The invention provides a locking mechanism for goods theft prevention. The locking mechanism for goods theft prevention comprises a first member and a second member, wherein the first member comprisesa locking assembly, the locking assembly is configured to comprise at least one first locking state and a second locking state, and the locking assembly is switched to be in the first locking statesor the second locking state; the second member is configured to be combined with the locking assembly; when the locking assembly is initially combined with the second member, the locking assembly is in the first locking states, and the locking mechanism is in a preliminary locking state; and when the locking assembly is fully combined with the second member, the locking assembly is in the second locking state, and the locking mechanism is in a fully locking state. The invention further provides a locking method for goods theft prevention. The locking mechanism can be in at least one first locking state and the second locking state, and an elastic lock head can be moved relative to a first channel by adjusting the locking assembly, and the moving distance is different, so that the locking mechanism can be in different locking states.

Owner:HANGZHOU LANGHONG KECHUANG TECH CO LTD

A pretensioned centrifugal concrete pile with steel strands and its manufacturing method

ActiveCN103882856BImprove performanceFirmly connectedCeramic shaping apparatusBulkheads/pilesPre stressEngineering

The invention relates to a pre-tensioning method centrifugal concrete pile with steel strands. The pre-tensioning method centrifugal concrete pile comprises a hollow concrete pile body, end plates and a steel bar cage. The steel bar cage comprises main prestressing bars and stirrups, wherein the main prestressing bars are axially arranged, and the stirrups are wound around the main bars. The pre-tensioning method centrifugal concrete pile is characterized in that the main prestressing bars are the steel strands, the steel strands of at least one end of the steel bar cage are combined with extrusion anchor devices, the peripheries of the extrusion anchor devices are sleeved with connecting sleeves, the connecting sleeves are provided with stepped through holes, the connecting sleeves are provided with threads for connection, a plurality of connecting counter holes are formed in the end plates, a threaded connecting piece is arranged inside each connecting counter hole, the end plates are connected with the threads for connection on the connecting sleeves through the threaded connecting pieces, and the end plates are further provided with a plurality of threaded connecting holes used for connection. According to the pre-tensioning method centrifugal concrete pile with the steel strands, in the pile manufacturing process, the steel strands combined with the extrusion anchor devices can be fixedly connected with the end plates through the connecting sleeves, tensioning plates of the end plates are fixedly connected in a threaded mode, the steel strands used as the main bars in the steel bar cage are tensioned and applied, and the anti-bending, anti-shearing and anti-tensioning performance is greatly improved. The invention further relates to a manufacturing method of the pre-tensioning method centrifugal concrete pile.

Owner:俞向阳

A pretensioned centrifugal concrete pile with steel strands and its manufacturing method

ActiveCN103898902BConsistent tensile strengthImprove performanceCeramic shaping apparatusBulkheads/pilesPre stressEngineering

The invention relates to a pre-tensioning method centrifugal concrete pile with steel strands and a manufacturing method. The pre-tensioning method centrifugal concrete pile comprises a hollow concrete pile body, an end board and a steel reinforcement cage, wherein the steel reinforcement cage comprises prestress main ribs, stirrups and the end board, and the prestress main ribs are axially arranged, and the stirrups are wound on the main ribs. The pre-tensioning method centrifugal concrete pile is characterized in that the prestress main ribs are the steel strands, the steel strands on at least one end of the steel reinforcement cage are tightly combined with a squeezing anchor in a squeezed mode, the squeezing anchor is provided with connection threads, the end board is provided with a plurality of connection counter bored holes, a thread connection part is arranged in each connection counter bored hole, and the end board is connected with the connection threads on the squeezing anchor through the thread connection parts; the end board is further provided with a plurality of thread connection holes for connection. In a pile body manufacturing process, the squeezing anchor can be fixed to the end board, then the end board is fixedly connected to a tensioning board through the threads, so that the steel strands serving as the main ribs in the steel reinforcement cage are tensioned and applied, and bending resistance, shearing resistance and tensile strength of the pre-tensioning method centrifugal concrete pile are enhanced. The invention further relates to the manufacturing method of the centrifugal concrete pile.

Owner:俞向阳

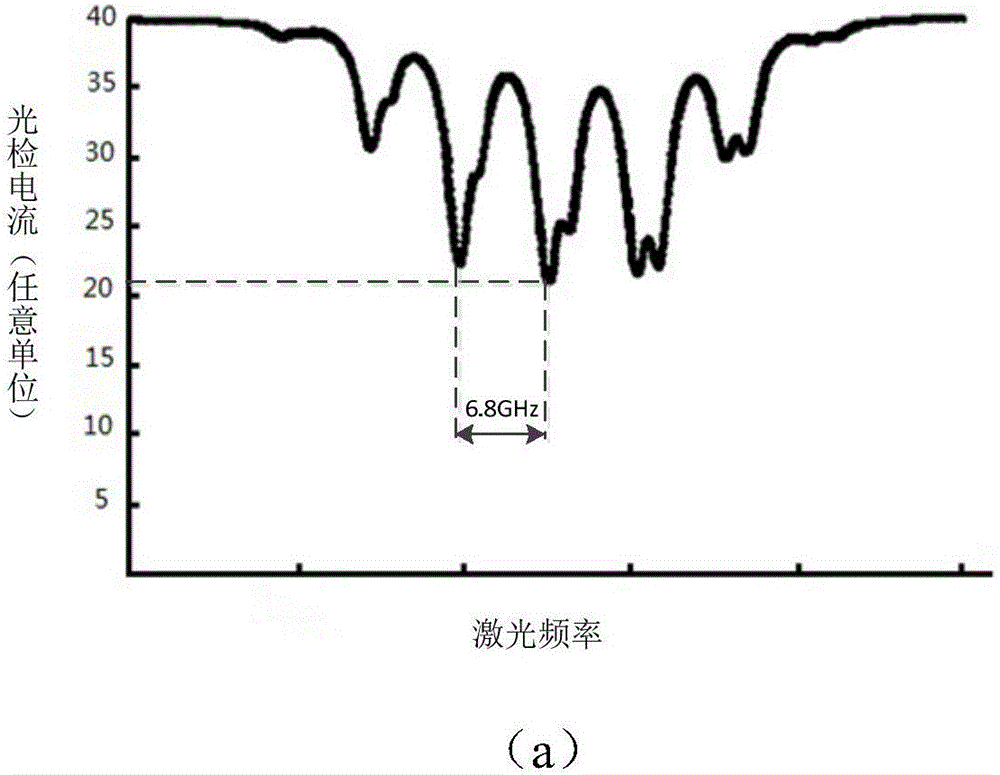

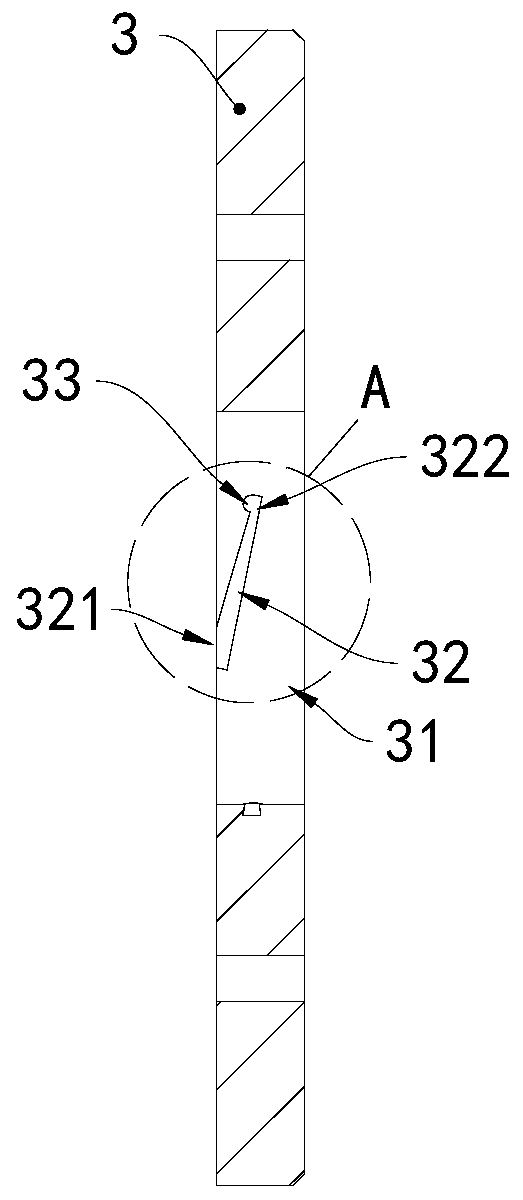

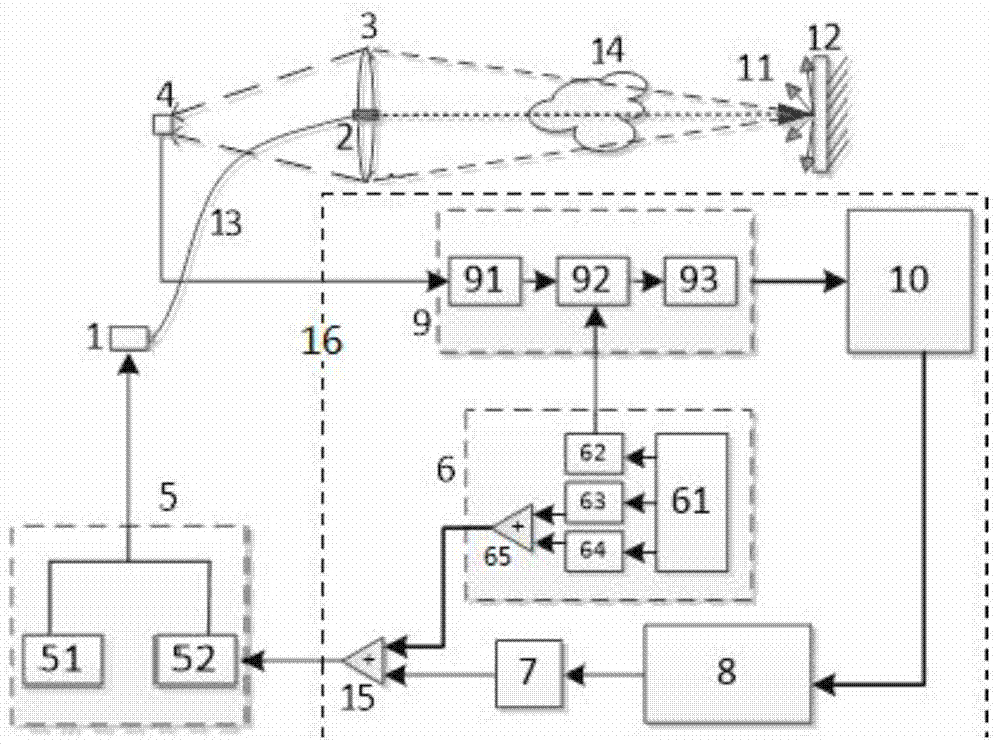

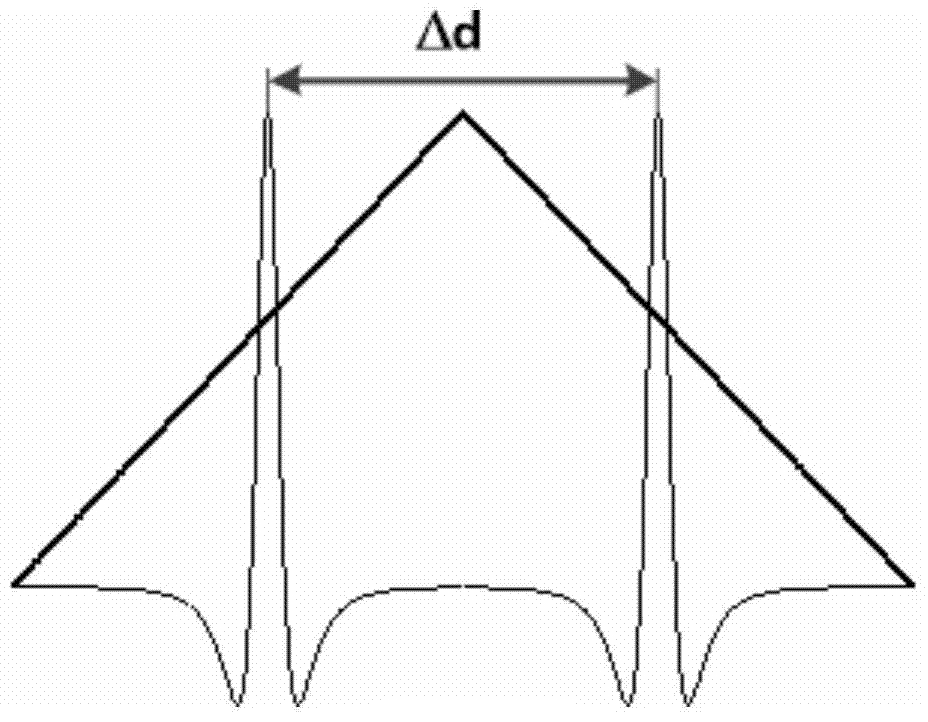

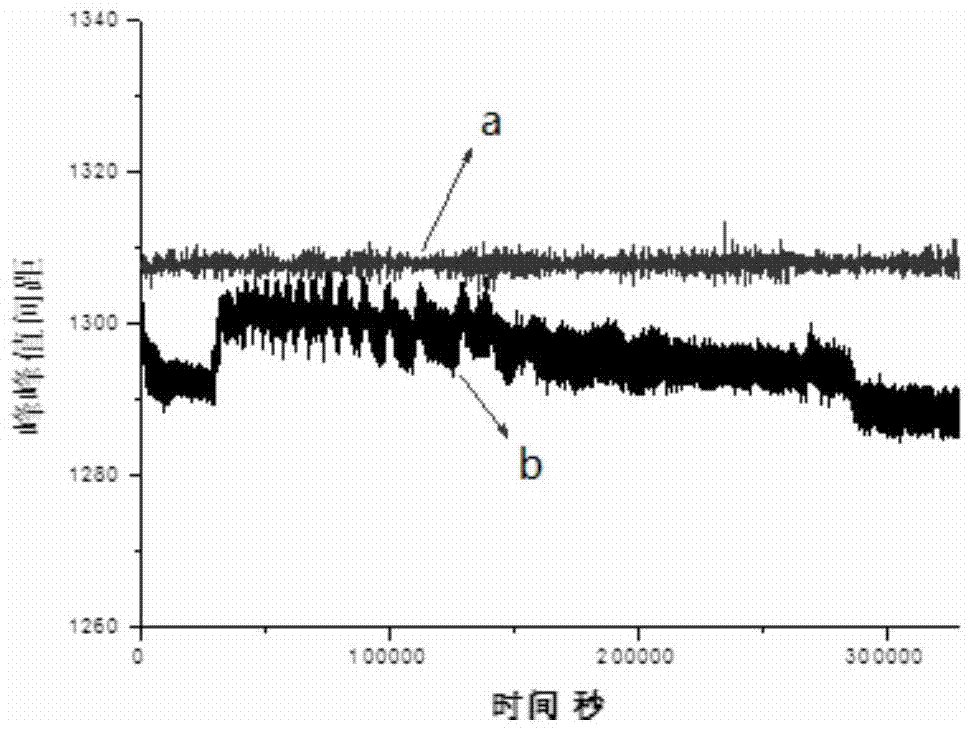

Frequency locking device and locking method based on tunable laser absorption spectrum

InactiveCN104655588BReasonable structureInhibition effectColor/spectral properties measurementsFrequency stabilizationPhotodetector

The invention discloses a frequency locking device and a locking method based on tunable laser absorption spectrum. The device includes a laser (1), an optical fiber (13), a collimating optical fiber (2), a scattered light collection lens (3), a photodetector (4), a temperature and current control component (5) and a frequency stabilization component (16), wherein , the frequency stabilization part (16) is a lock-in amplifier device (9), a data acquisition analysis device (10), an analog PID device (8), an operational amplifier device (7) and an addition device (15) connected in series, and a signal generation Device (6); the method is to adopt the modulation of triangular wave superimposed sine wave to the laser and the spacing between the two absorption peaks produced by the rising edge and falling edge in the scattered light signal containing gas absorption information received as variable value, draw The frequency stabilization feedback control signal stabilizes the frequency on a specific absorption peak. It can be widely used to detect the composition and content of substances in the atmosphere.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

drone

ActiveCN107458574BSave internal spaceEasy to operateFuselage framesAir-flow influencersLocking mechanismUncrewed vehicle

In order to solve the problems of the existing unmanned aerial vehicle that realizes the retractable and foldable arm of the machine, the structure is complex, the occupied volume is large, and the volume of the unmanned aerial vehicle is increased, the present invention provides an unmanned aerial vehicle, which includes a body and several arms; There are a number of support bases corresponding to the number of machine arms; the support bases are provided with limit projections; the hinged ends of the machine arms are provided with fixed locking parts and motion locking mechanisms. The unmanned aerial vehicle provided by the present invention is provided with a limit projection on the support seat, and a fixed locking part and a motion locking mechanism are arranged on the hinged end of the machine arm, so that the unfolding and locking function of the machine arm can be realized; at the same time, Through the driving mechanism arranged on the locking slider, the locking of the locking slider can be released, so as to realize the retraction and folding of the machine arm. The fit and locking of the machine arm is more firm and smooth; the machine arm locking method provided by the present invention is simple and practical, involves relatively few parts, occupies a small space, and can effectively save the internal space of the drone. Moreover, the assembly is convenient, the cost is low, and the retractable operation is convenient and quick.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com