built-in handle

A built-in, handle technology, which is applied in handle connection, building locks, construction, etc., can solve the problems of weak keyhole protection of the lock cylinder, high requirements for lock installation, and unsatisfactory structure, so as to facilitate production scale and Replacement of parts, increase the sense of unlocking experience, facilitate the effect of large-scale production and streamlined operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

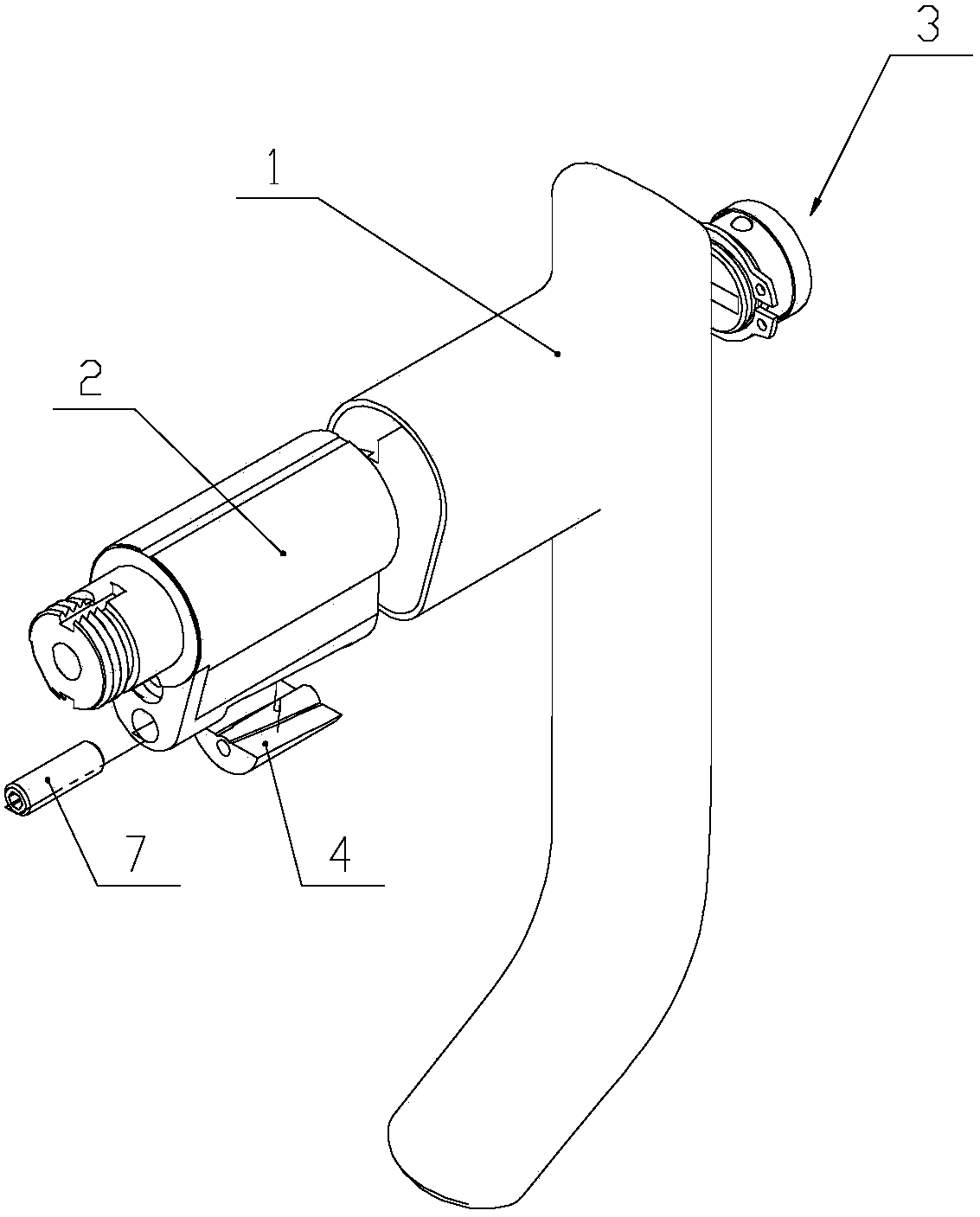

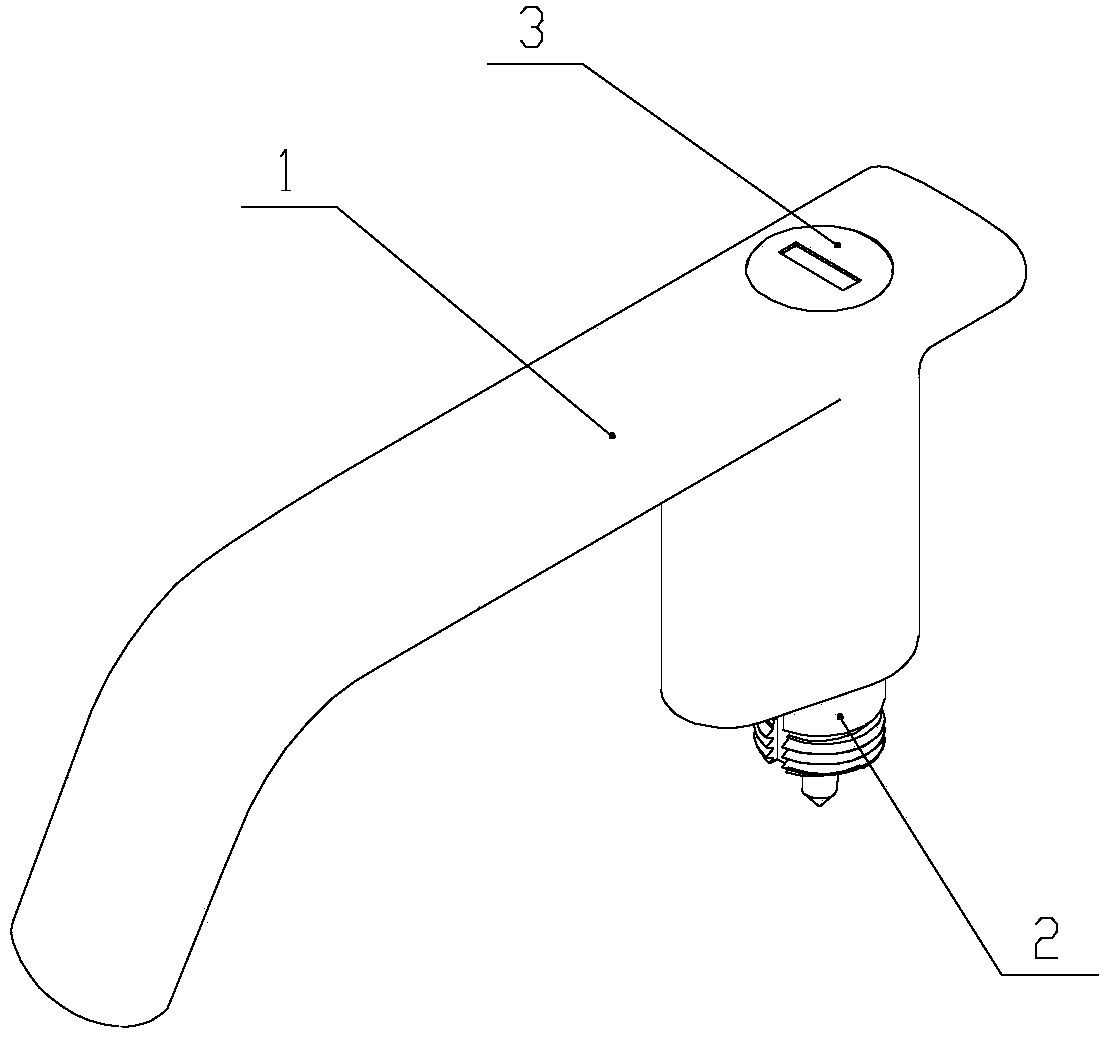

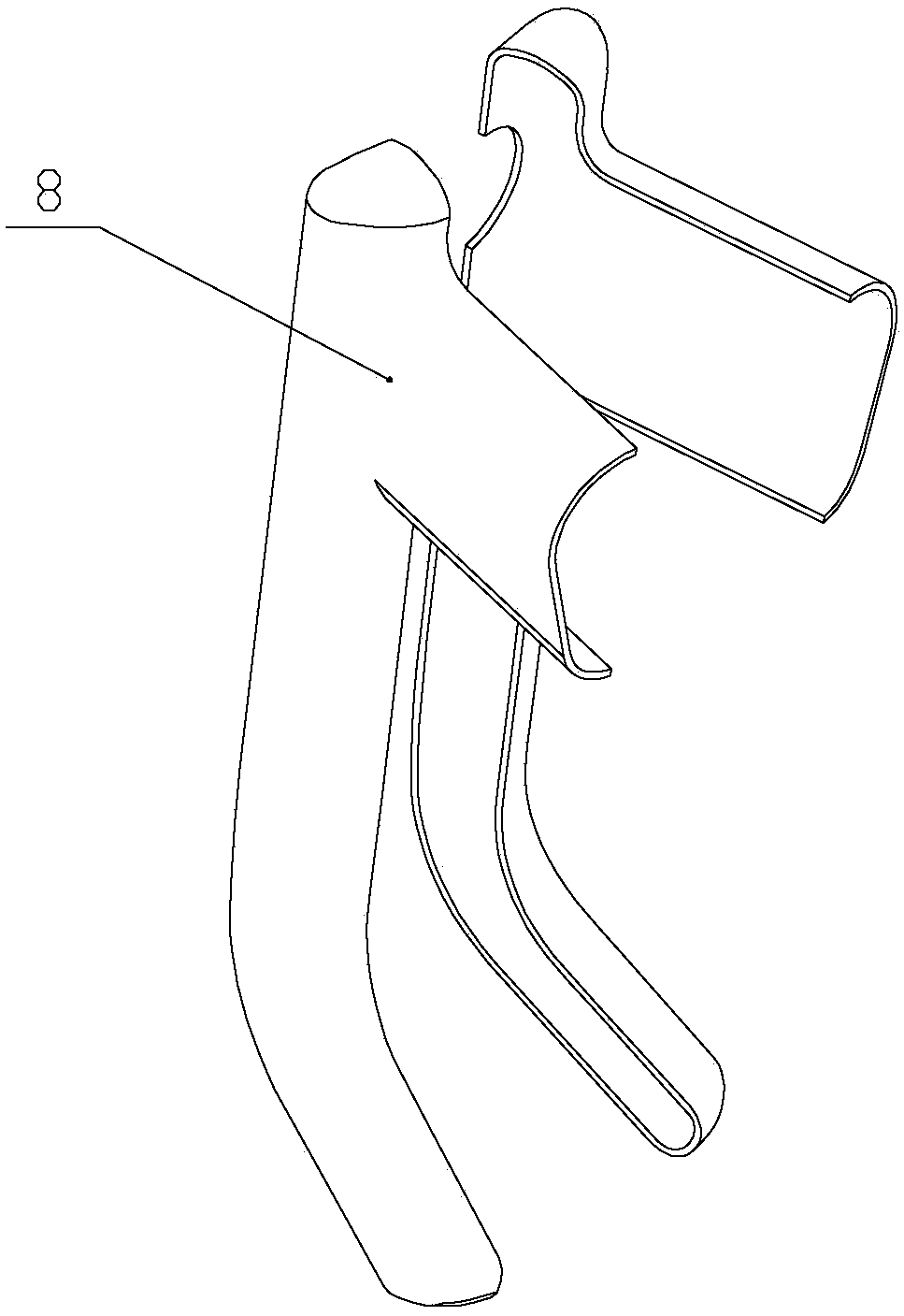

[0025] Such as figure 1 with figure 2 As shown, the present invention discloses a built-in handle, which includes a handle housing 1 , a handle lock cylinder 2 , a dustproof structure 3 and an inclined block 4 . Such as Figure 5 with Image 6 As shown, the handle lock cylinder 2 is located in the handle housing 1, and is locked in the handle housing 1 by the slanting block 4. The slanting block 4 has an arc surface 5 in contact with the inner wall of the handle and is in contact with the outer wall of the lock. The contacting inclined surface 6, the inclined block 4 is located in the cavity formed between the handle housing 4 and the handle lock cylinder 2, and the inclined block 4 is pressed and fixed in the cavity by the screw 7. The locking method is simpler, more efficient and more reliable, and enhances the safety of the handle lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com