Gear aligning mechanism

A technology of movable top and indicator plate, which is applied in the direction of metal processing machinery parts, metal processing, automatic control devices, etc., can solve the problems of multiple tooling and processes, inability to adjust the deviation value, and inconvenient maintenance, etc., to achieve the goal of locking The effect of simple tightening method, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific embodiment:

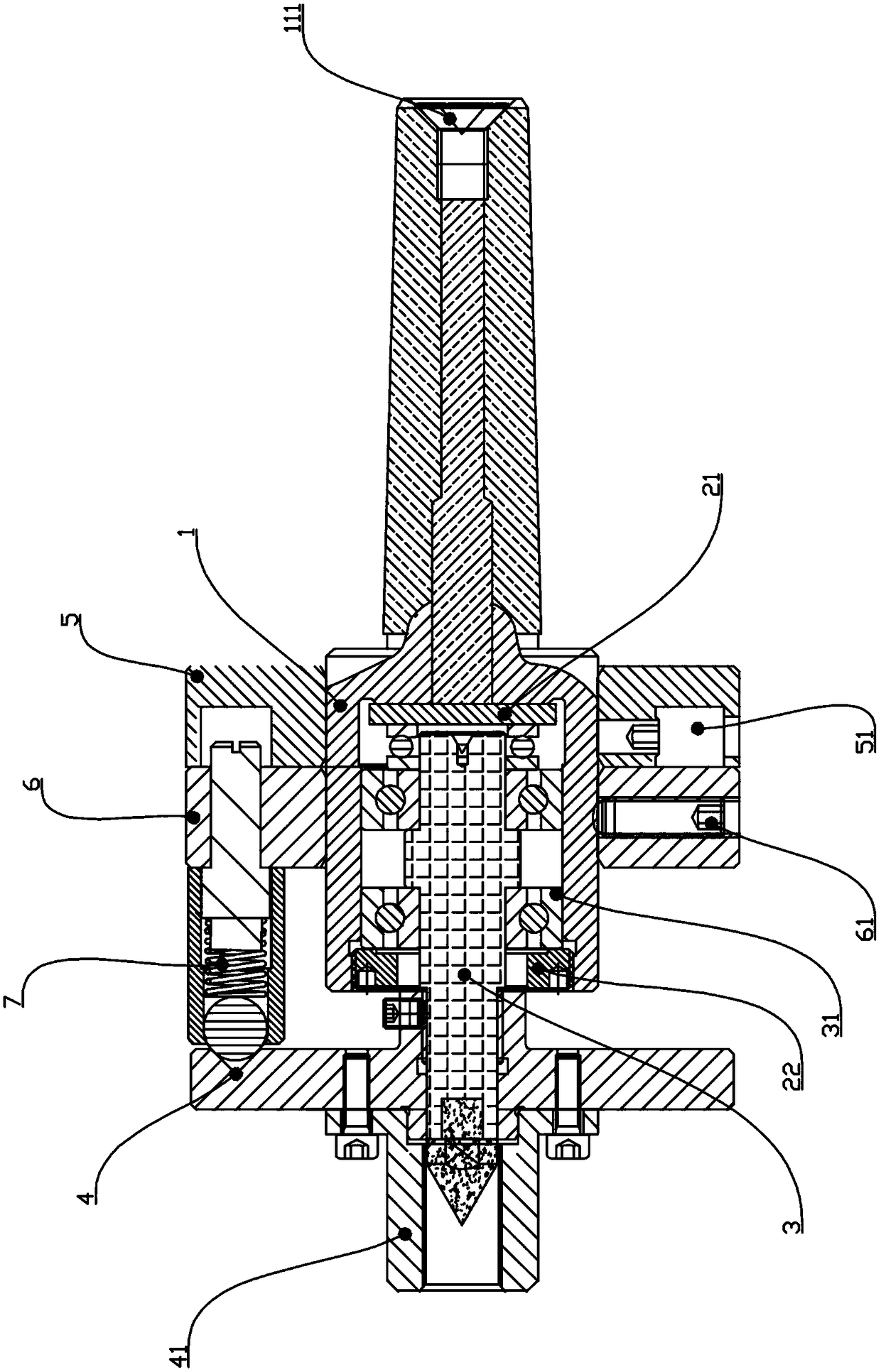

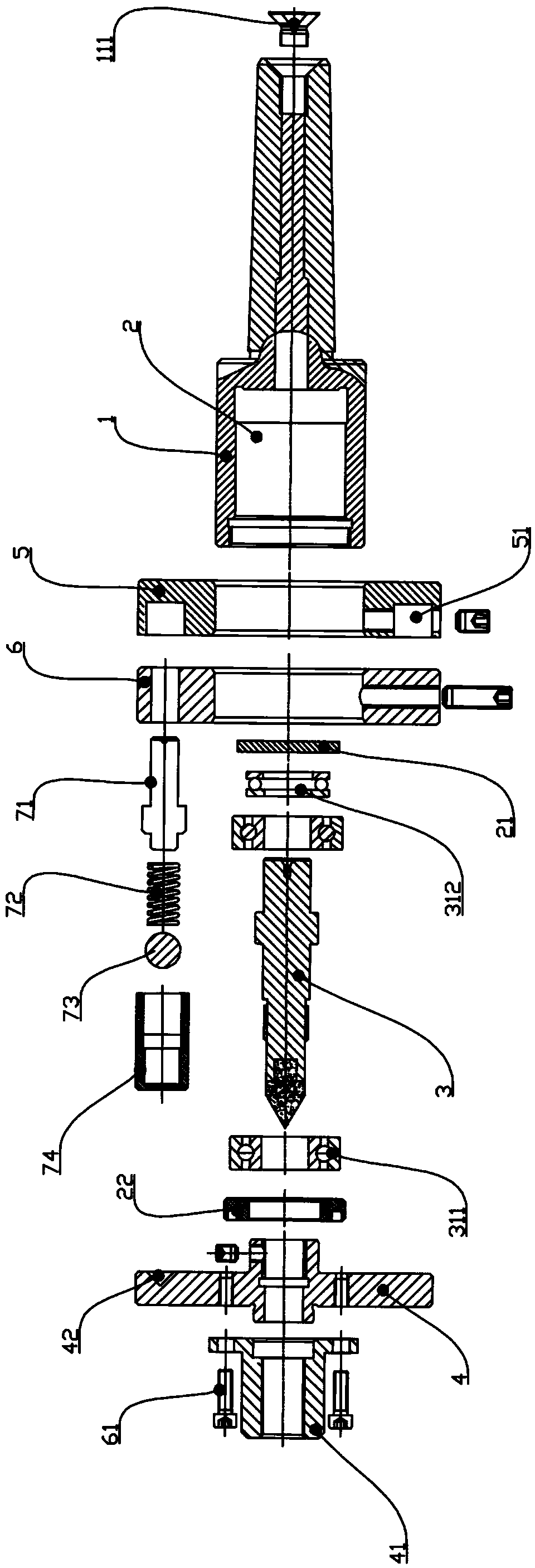

[0025] Such as Figure 1-2 As shown, a tooth-aligning mechanism includes a movable top shell 1, and one end of the movable top shell 1 is formed with an installation cavity 2, and a top shaft 3 is rotatably arranged in the installation cavity 2, and one end of the top shaft 3 is sleeved for Connect the positioning plate 4 of the workpiece, the right side of the movable top shell 1 is sleeved with a dial 5 and an indicator plate 6, and the indicator plate 6 is set to rotate relative to the dial 5; There is an elastic limiter 7, the elastic limiter 7 is in movable abutment with the positioning plate 4, and a locking screw 61 is screwed inside the indicator plate 6, and the locking screw 61 is used to abut against the movable top A locking indicator plate 6 is realized on the outer periphery of the shell 1 .

[0026] In actual use, a product is generally processed first for a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com