Thin-wall pipe cutting system

A cutting system and pipe fitting technology, applied in the field of cutting processing, can solve the problems of easy vibration, uncontrollable pressure, concave pipe wall, etc., and achieve the effects of not easy to deform, prolong the service life, and accurately locate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

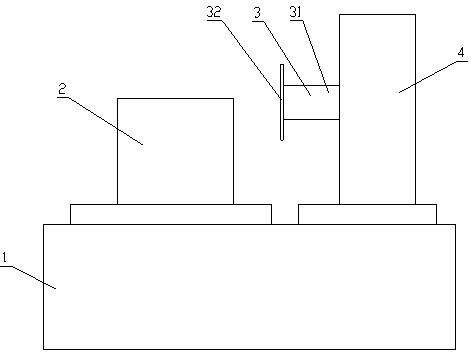

[0031] This embodiment provides a thin-wall pipe cutting system, such as Figure 1 to Figure 3 As shown, the thin-wall pipe cutting system includes a support 1 , a pipe positioning device 2 arranged on the support 1 , a cutting device 3 and a power system 4 for driving the cutting device 3 .

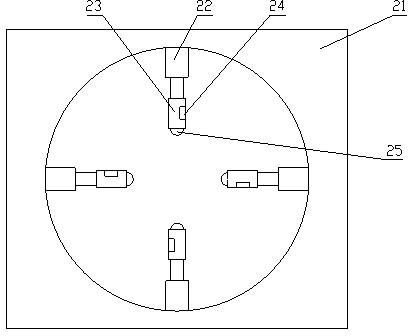

[0032] The pipe fitting positioning device 2 includes a bracket 21 and four cylinders 22 fixed on the bracket 21, the four cylinders 22 are evenly distributed along the circumferential direction, and a positioning rod 23 is fixed on the piston rod of the cylinder 22, and a positioning rod 23 is also provided for detecting The positioning rod 23 is a pressure sensor 24 for pipe pressure.

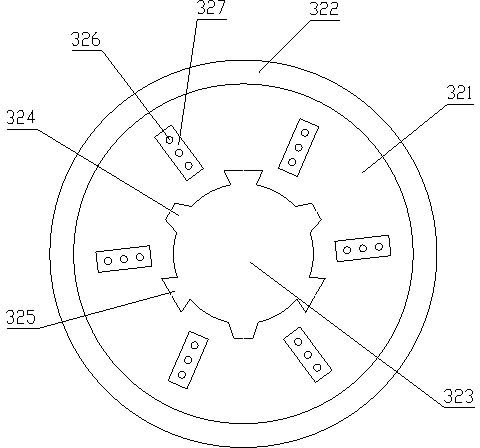

[0033] The cutting device 3 includes a support column 31 and a rotatable cutter 32 disposed on the support column 31 , the cutter 32 is disc-shaped, and the cutter 32 is parallel to the plane where the four cylinders 22 are located. The cutter 32 includes a cutter head 321, the outer edge of the cutter...

Embodiment 2

[0041] This embodiment provides a thin-wall pipe cutting system, the structure of which is basically the same as that of Embodiment 1, including a support, a pipe positioning device disposed on the support, a cutting device and a power system for driving the cutting device.

[0042] The difference is that if Figure 4 As shown, a plurality of stress grooves 327 are formed on the cutterhead 321 in the present embodiment along the circumferential direction, and the cooling holes 326 are opened on the bottom surface of the stress grooves 327 . The setting of the stress groove 327 further strengthens the use strength of the cutter 32 .

Embodiment 3

[0044] This embodiment provides a thin-wall pipe cutting system, the structure of which is basically the same as that of Embodiment 2, including a support, a pipe positioning device disposed on the support, a cutting device and a power system for driving the cutting device.

[0045] The difference is that if Figure 5 As shown, in this embodiment, reinforcing pieces 328 protrude inward on both side walls of the trapezoidal groove 324 and the inverted trapezoidal groove 325 . The shape of the reinforcing sheet 328 is not limited, and may be rectangular, semicircular or trapezoidal. The arrangement of the reinforcing sheet 328 further strengthens the use strength of the cutter 32 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com