Appearance inspecting device for substrate

A technology for an appearance inspection device and a substrate, which is applied to measurement devices, image detector methods, image signal processing, instruments, etc., can solve problems such as difficulty in saving space in manufacturing equipment, inability to shorten production takt time, etc. Takt time, miniaturization, and the effect of reducing setup space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0040] Next, a substrate appearance inspection device according to a first embodiment of the present invention will be described with reference to the drawings.

[0041] The substrate appearance inspection device 1 of the present embodiment is mainly installed in a substrate production line and used to inspect the surface of a substrate conveyed by a conveyor or the like.

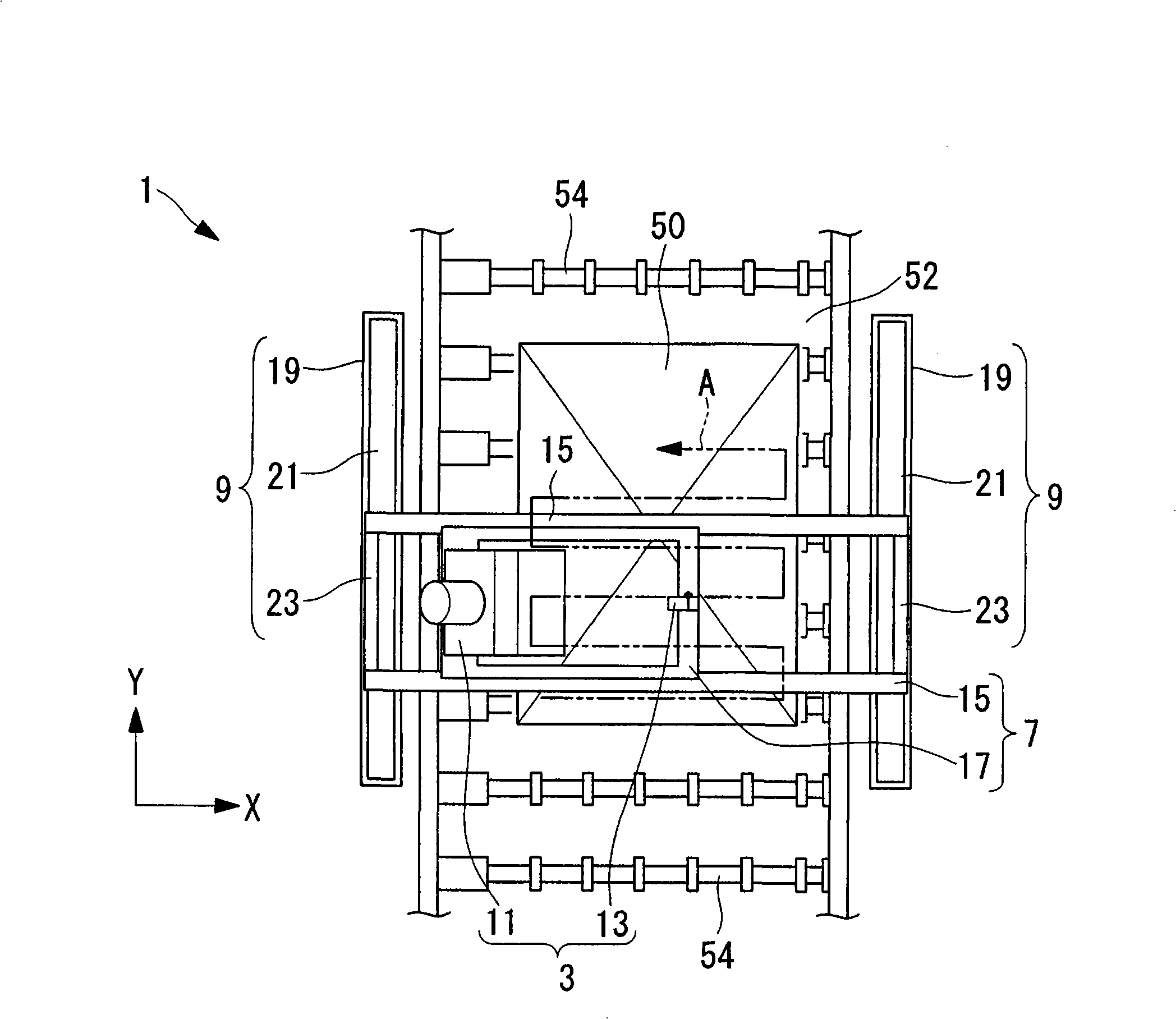

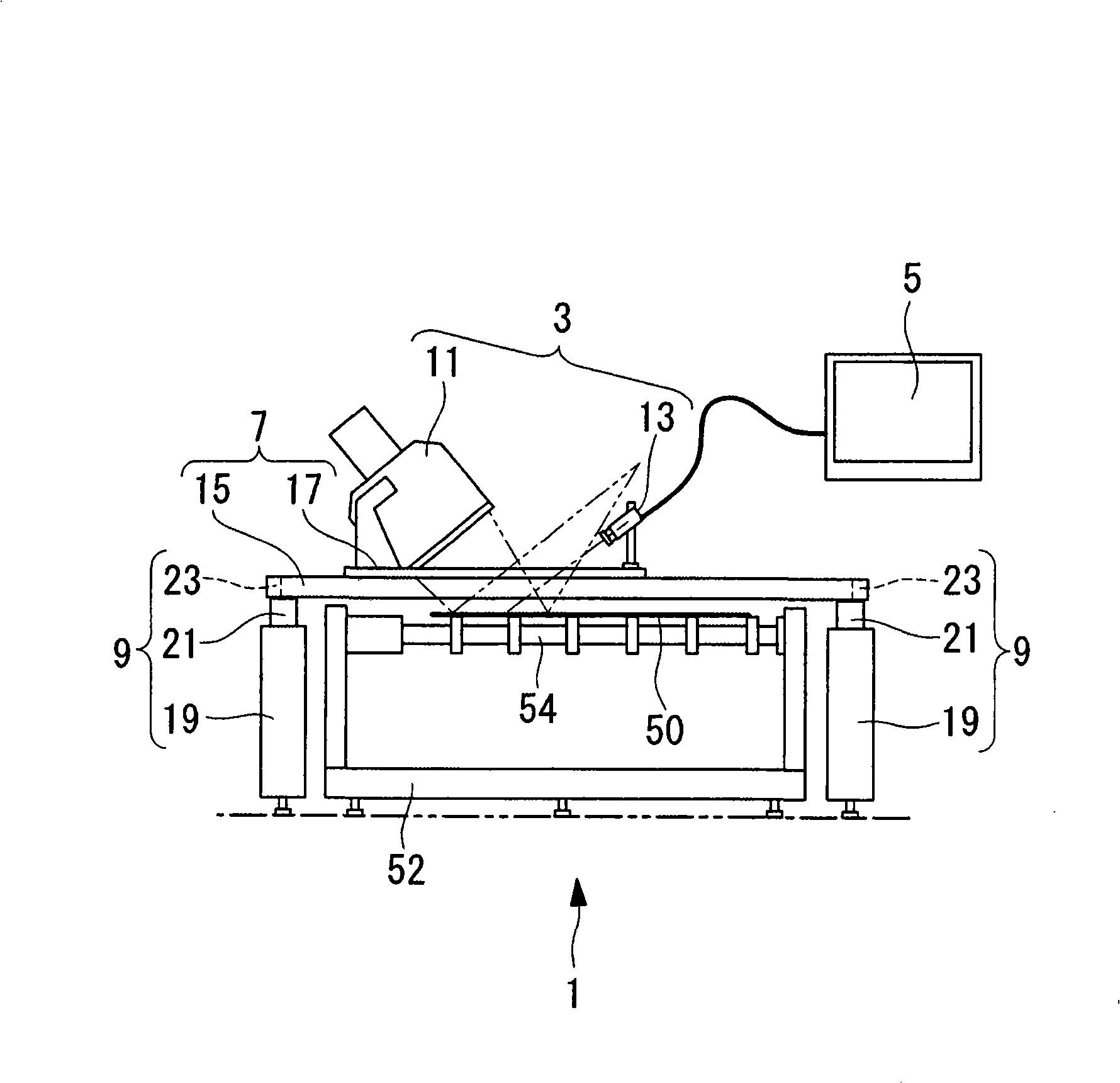

[0042] Such as figure 1 with figure 2As shown, the substrate appearance inspection device 1 has: an inspection device unit 3, which observes the appearance of the surface of the substrate 50 conveyed on the production line 52; a monitor 5, which displays an image taken by the inspection device unit 3; a moving mechanism 7 that moves the inspection device unit 3 in a direction intersecting the substrate 50 conveyance direction; and a second movement mechanism 9 that moves the inspection device unit 3 in the substrate 50 conveyance direction.

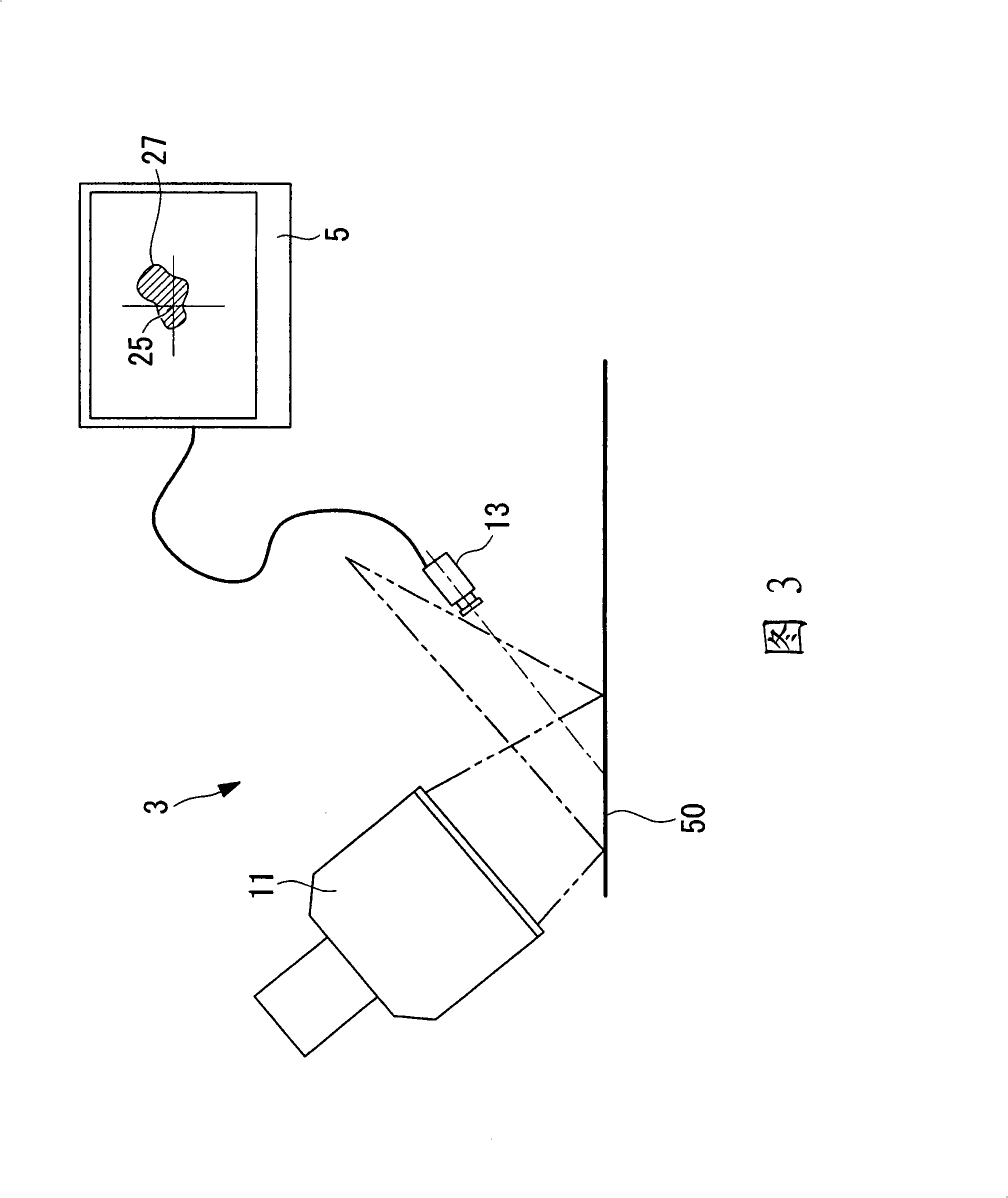

[0043] As shown in FIG. 3 , the inspection device unit 3 has:...

no. 2 Embodiment approach

[0080] Next, refer to Figure 5 with Image 6 A substrate appearance inspection device 31 according to a second embodiment of the present invention will be described.

[0081] The inspection device unit 3 of the substrate appearance inspection device 31 of the present embodiment has a guide (rotation mechanism) 33 .

[0082] Hereinafter, the same reference numerals are assigned to the same parts as those of the substrate appearance inspection apparatus 1 according to the first embodiment, and description thereof will be omitted.

[0083] The guide 33 rotates the camera 13 so that the optical axis of the camera 13 always faces the center position 35 of the irradiation range of the illumination light irradiated from the illumination device 11 on the substrate 50 . Specifically, the guide 33 is a semicircular guide rail, and the camera 13 is installed so as to be movable along the guide 33 .

[0084] Furthermore, the guide 33 is installed at an angle of about 45° relative to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com