Light alignment film and preparing method thereof, liquid crystal display substrate and device

A liquid crystal display and photo-alignment technology, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problems of low contrast of liquid crystal display devices, residual decomposition products, and inability to guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

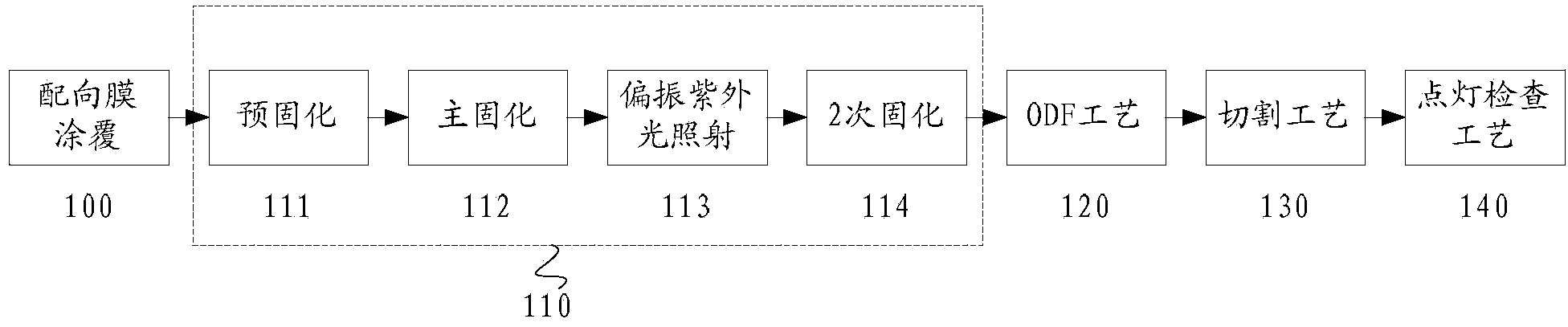

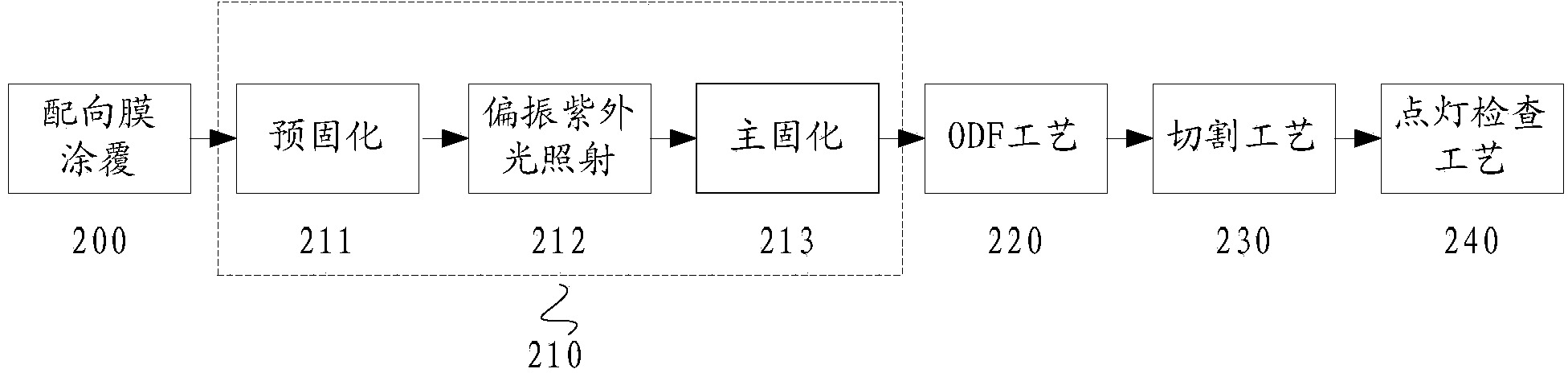

[0046] figure 2 A process flow diagram of a method for preparing a photo-alignment film provided in an embodiment of the present invention. Such as figure 2 As shown, the embodiment of the present invention provides a method for preparing a photo-alignment film, including:

[0047] Coating a photo-alignment material film layer on the substrate;

[0048] In this step, firstly, a layer of photo-alignment material film is coated on the substrate to prepare for preparing a photo-alignment film with an alignment function.

[0049] pre-curing the coated photo-alignment material film layer;

[0050] In this step, the coated photo-alignment material film layer is pre-cured. The purpose of the pre-cure is to make part of the photo-alignment material react and be better fixed on the substrate. Optionally, the temperature of the pre-curing step is 50-120° C., and the time is 0.5-10 minutes. Further preferably, the temperature of the pre-curing step is 60-100° C., and the time is 3...

Embodiment 1

[0081] Such as figure 2 As shown, the photo-alignment material film layer 200 is coated on the substrate; the coated film layer is pre-cured at 50°C for 30 minutes—211°C; Irradiate at 254 nm to react part of the photo-alignment material to obtain the substrate 212 with the alignment function of the film layer of the photo-alignment material; main cure the substrate after the above steps at 180°C for 1 hour, and then cure the photo-alignment material film At the same time, the by-product 213 formed by the reaction is removed; after that, the ODF process 220, the cutting process 230, and the lighting inspection process 240 are sequentially performed to prepare the optical alignment film 1.

Embodiment 2

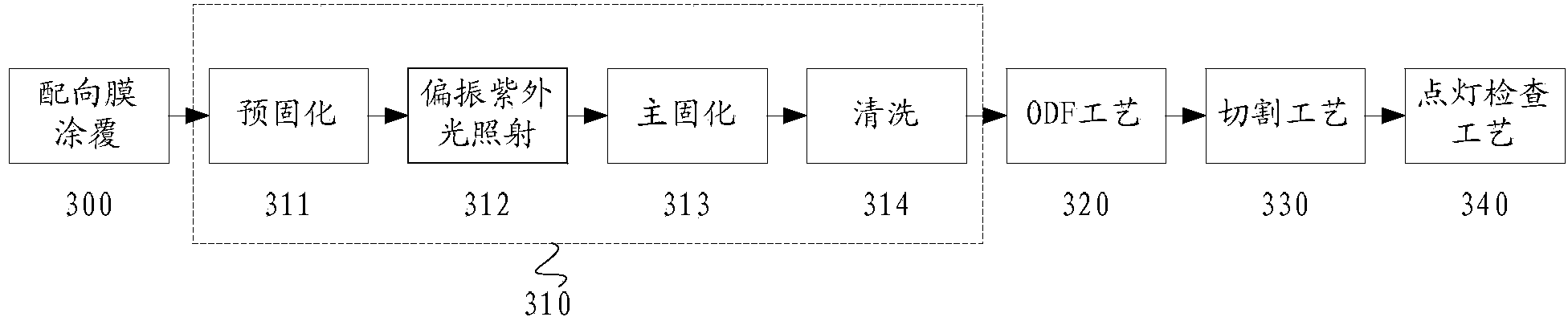

[0083] Such as image 3 As shown, the photo-alignment material film layer 300 is coated on the substrate; the coated film layer is pre-cured at 100° C. for 10 minutes—311; the pre-cured photo-alignment material film layer is linearly polarized Irradiate at 313nm to react part of the photo-alignment material to obtain the substrate 312 with the alignment function of the photo-alignment material film layer; main cure the substrate after the above steps at 300°C for 30 minutes, and then cure the photo-alignment material film At the same time, remove the by-products 313 formed by the reaction; perform a cleaning process 314 on the above-mentioned substrate; then perform an ODF process 320, a cutting process 330, and a lighting inspection process 340 in order to prepare a photoalignment film 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com