Chip pick-up device and producing method thereof and production apparatus of semiconductor

A technology for picking up devices and chips, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical components, etc., and can solve the problem that the chip 102 is not easy to peel off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

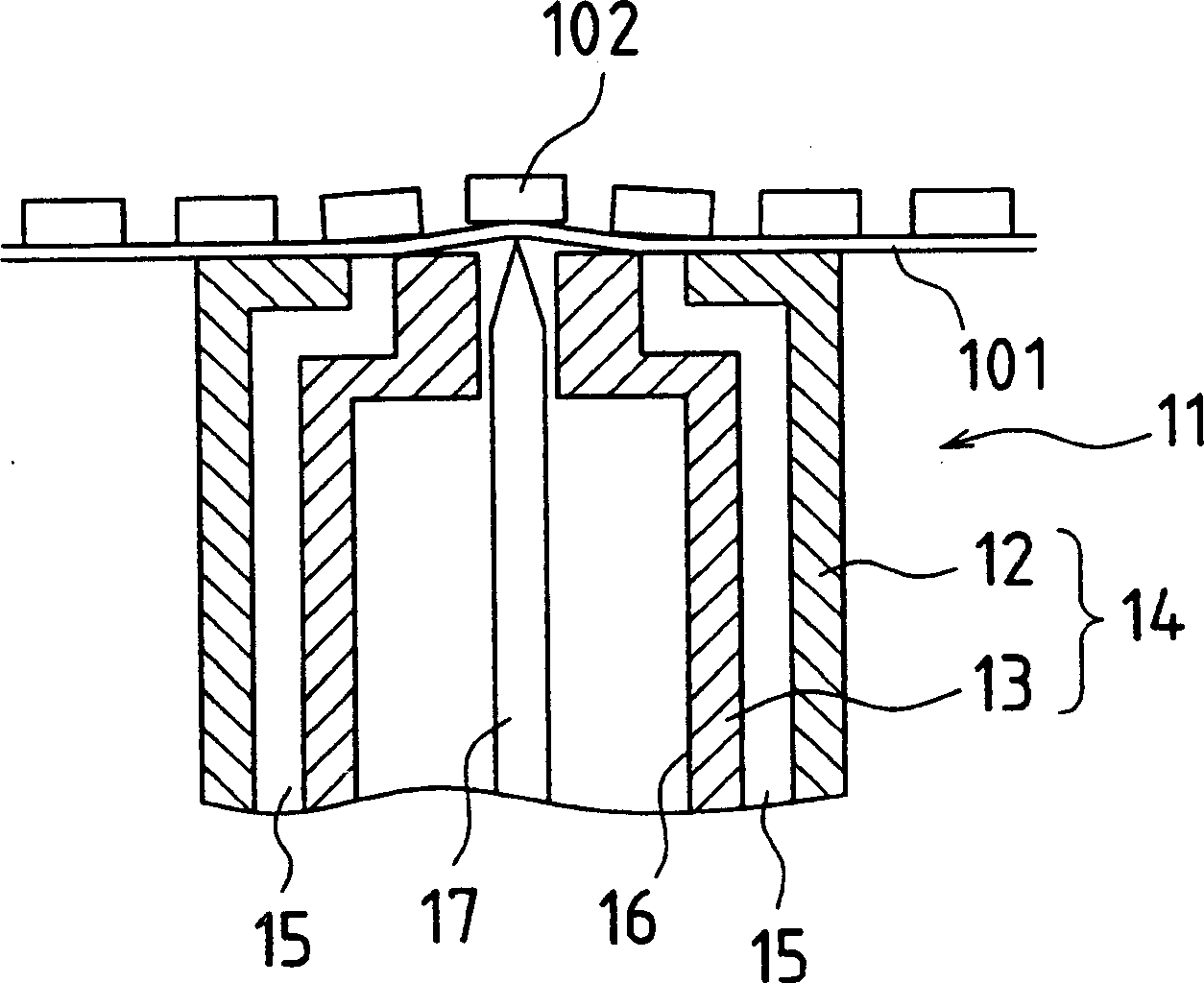

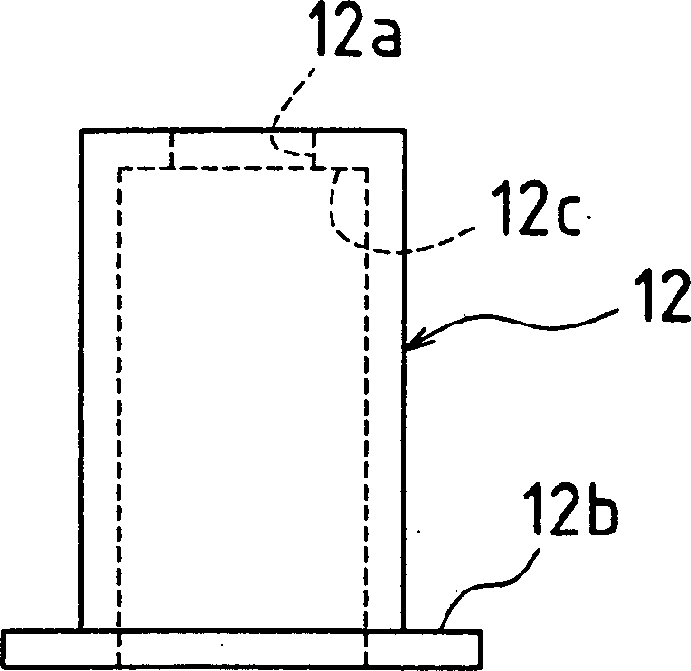

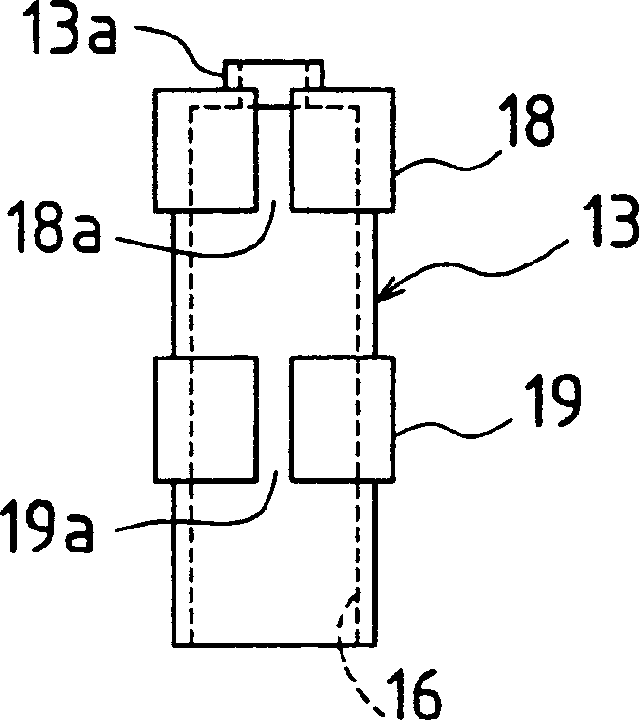

[0046] figure 1 It is a partial cross-sectional view showing one embodiment of the pickup device of the present invention. In the pick-up device 11 of the present embodiment, a cylindrical body 12 is erected, and a needle holder 13 is disposed inside the cylindrical body 12 to constitute a stage 14 . A gap is formed between the inner periphery of the cylindrical body 12 and the outer periphery of the needle holder 13, and this gap is used as a suction vent hole 15 for air. A needle hole 16 is formed in the needle holder 13 , and a needle 17 is inserted into the needle hole 16 .

[0047] The suction vent hole 15 is connected to a vacuum pump (not shown), and the air in the suction vent hole 15 is sucked by the vacuum pump. The pinholes 16 are formed completely apart from the suction vent holes 15, so the air in the pinholes 16 will not be sucked.

[0048] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com