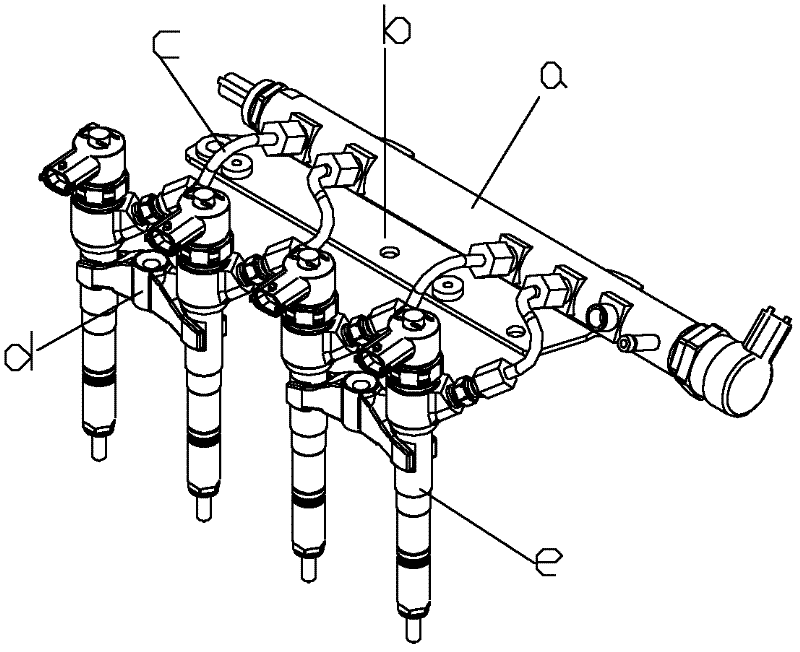

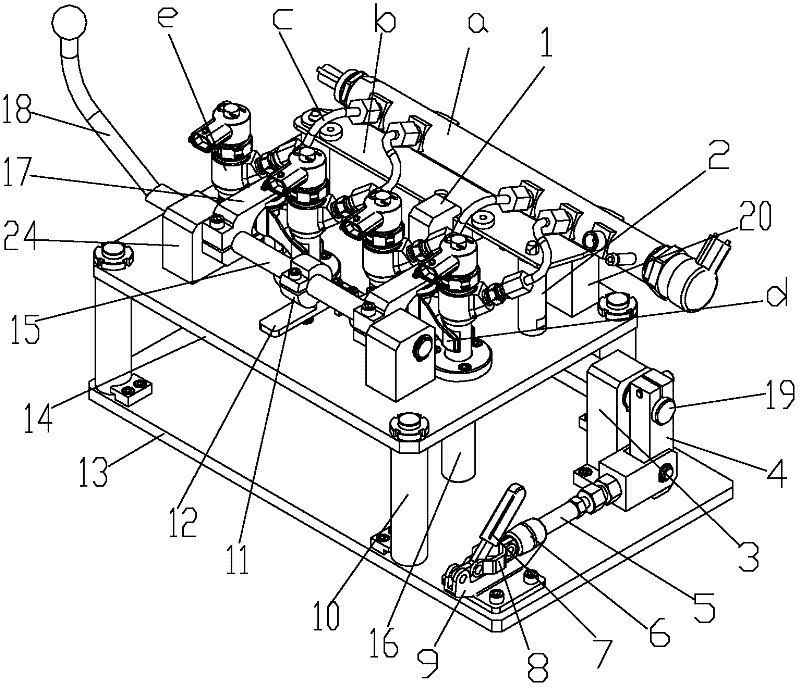

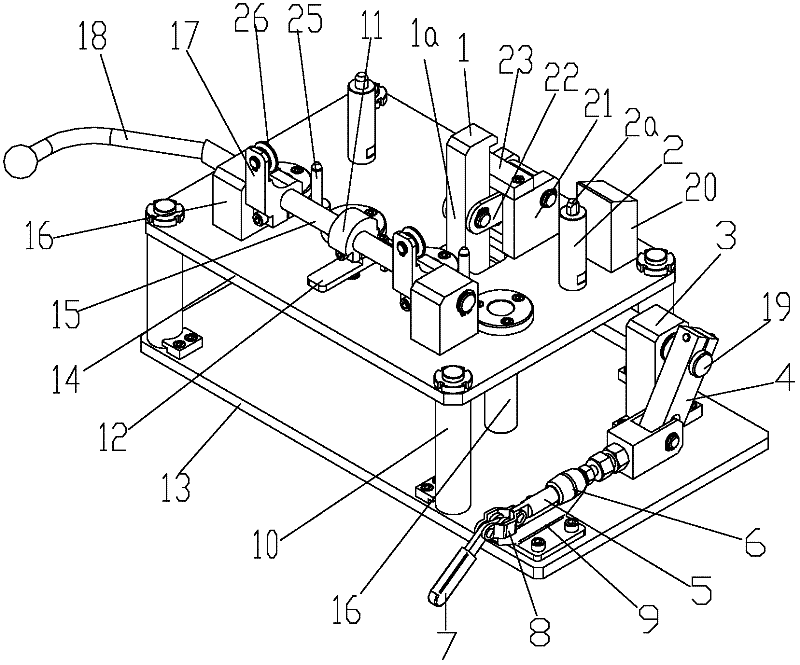

Split assembling mechanism of common rail injection system of diesel engine

A diesel engine and injection system technology, applied in workpiece clamping devices, hand-held tools, manufacturing tools, etc., can solve the problems of difficulty in online leak detection of sealing joints of parts, long engine off-line time, and impact on assembly efficiency. To achieve the effect of fast and reliable positioning and clamping, saving assembly time and reducing assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] figure 1 It is a structural schematic diagram of the common rail injection system of the present invention, figure 2 It is a schematic diagram of the structure of the present invention when it is used to install the common rail injection system, image 3 It is a schematic diagram of the structure of the present invention, Figure 4 It is a schematic structural diagram of the clamping state of the common rail pipe fixing assembly of the present invention, Figure 5 It is a structural schematic diagram of the open state of the common rail pipe fixing assembly of the present invention, Figure 6 It is a schematic structural diagram of the clamping state of the fuel injector fixing assembly of the present invention, Figure 7 It is a structural schematic diagram of the opened state of the fuel injector fixing assembly of the present invention, Figure 8 It is a schematic diagram of the locking structure of the injector locking wheel of the present invention, Figure 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com