Electrostatic Application Method And Electrostatic Application Apparatus

An electrostatic coating and coating technology, which is applied to spray discharge devices, devices for coating liquids on surfaces, coatings, etc., can solve the problems of difficult timing control, insufficient coating amount of liquid 1, discontinuity, etc., to prevent confusion. , to achieve the effect of takt time and improve responsiveness

Active Publication Date: 2015-05-27

PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

View PDF4 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

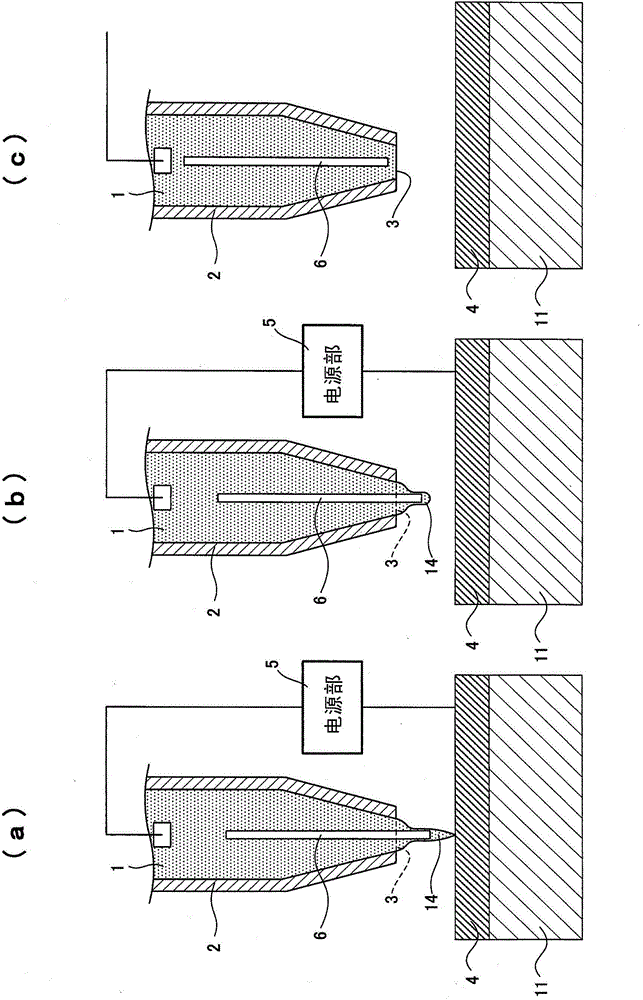

[0024] In this electrostatic force-based attraction, since the application of the voltage is stopped, Figure 18 The unstable state of (b) also continues, so the timing control for stopping the relative movement of the nozzle 2 and the object 4 to be coated is very difficult, and the position where the liquid collection part 34 is disconnected from the object 4 to be applied m

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

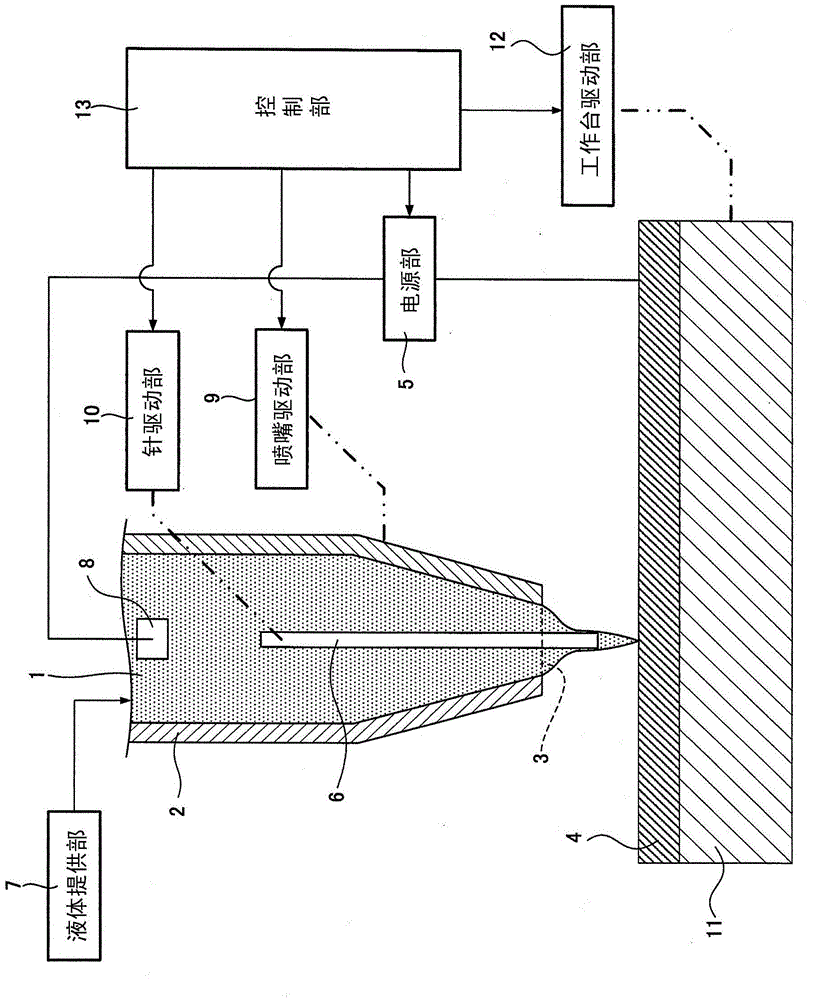

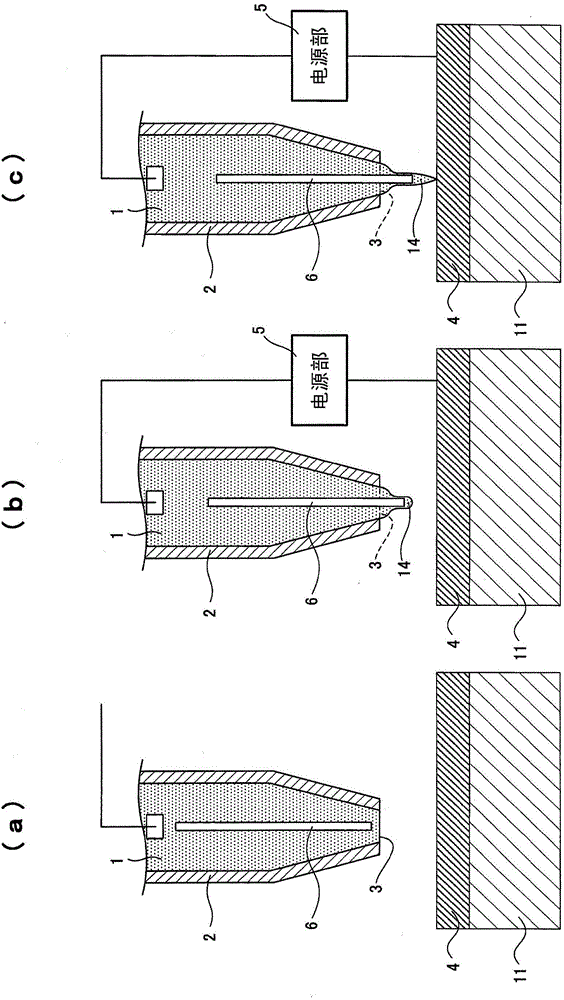

The present invention realizes the application which is good in edge linearity and uniform in pattern width. In an electrostatic application method, by applying a potential difference, a liquid gathering part extending towards an application object side is formed at the front end of a nozzle, and the front end of a pin in the nozzle is configured to protrude towards the liquid gathering part, so that the front end of the liquid gathering part is contacted with an application object, and the liquid contained in the nozzle is applied to the application object.

Description

technical field [0001] The present invention relates to an electrostatic coating method in which various liquids are finely drawn from the tip of a nozzle by electric power to form a fine pattern on a substrate. Background technique [0002] Conventionally, as a method of forming fine droplets to coat a fine pattern on a substrate, for example, a method using electrostatic attraction as described in Patent Document 1 is known. [0003] Figure 12 The method of patent document 1 is shown. [0004] In this method, the nozzle 2 is arranged to face the surface of the object 4 to be coated, a pulse voltage is applied from the power supply unit 30 between the object 4 to be coated and the nozzle 2, and the liquid 1 at the tip of the nozzle 3 is transferred to the surface of the object 4 by electrostatic force. The object to be coated 4 is sucked, and the liquid droplet 31 is dropped onto the object to be coated 4 . [0005] Although Patent Document 2 does not apply to an object ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B05D1/04B05B5/025

CPCB05B5/10B05D1/26B05D1/265B41J2/06B41J2/065B41J2002/061

Inventor 中平航太堀川晃宏名木野俊文土田修三

Owner PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com