Method for optimization of an order for component mounting and apparatus for optimization of an order for component mounting

An optimization method and component technology, applied in the direction of electrical components, electrical components, multi-objective optimization, etc., can solve problems such as long computing time, inability to flexibly handle changes in production line organization, and achieve reduction of takt time, easy re-optimization, and flexible processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0059] Hereinafter, a component mounting system in a first embodiment of the present invention will be described with reference to the drawings.

[0060] (Component assembly system)

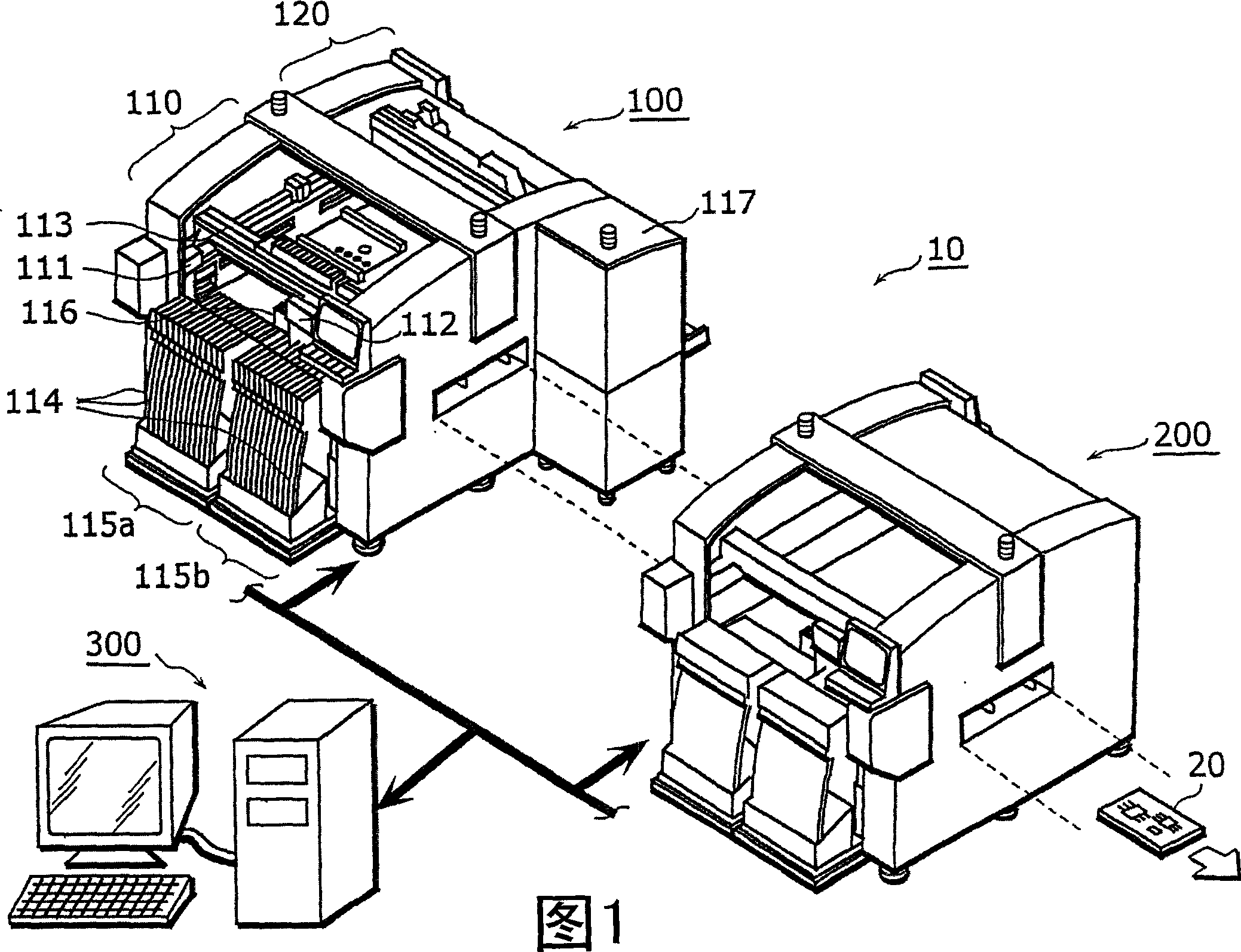

[0061] FIG. 1 is an external view showing the overall structure of a component mounting system 10 in the present invention. The assembly system 10 includes a plurality (here, two) of assemblers 100 and 200 , and an optimization device 300 . The assemblers 100 and 200 form a production line in which electronic components are assembled on a circuit board 20 conveyed downstream. The optimization device 300 optimizes the assembly sequence of the required electronic components according to information in, for example, multiple databases at the start of production, and the setting and control have been provided by information assembly of NC (Numeric Control, digital control) data generated by optimization devices 100 and 200.

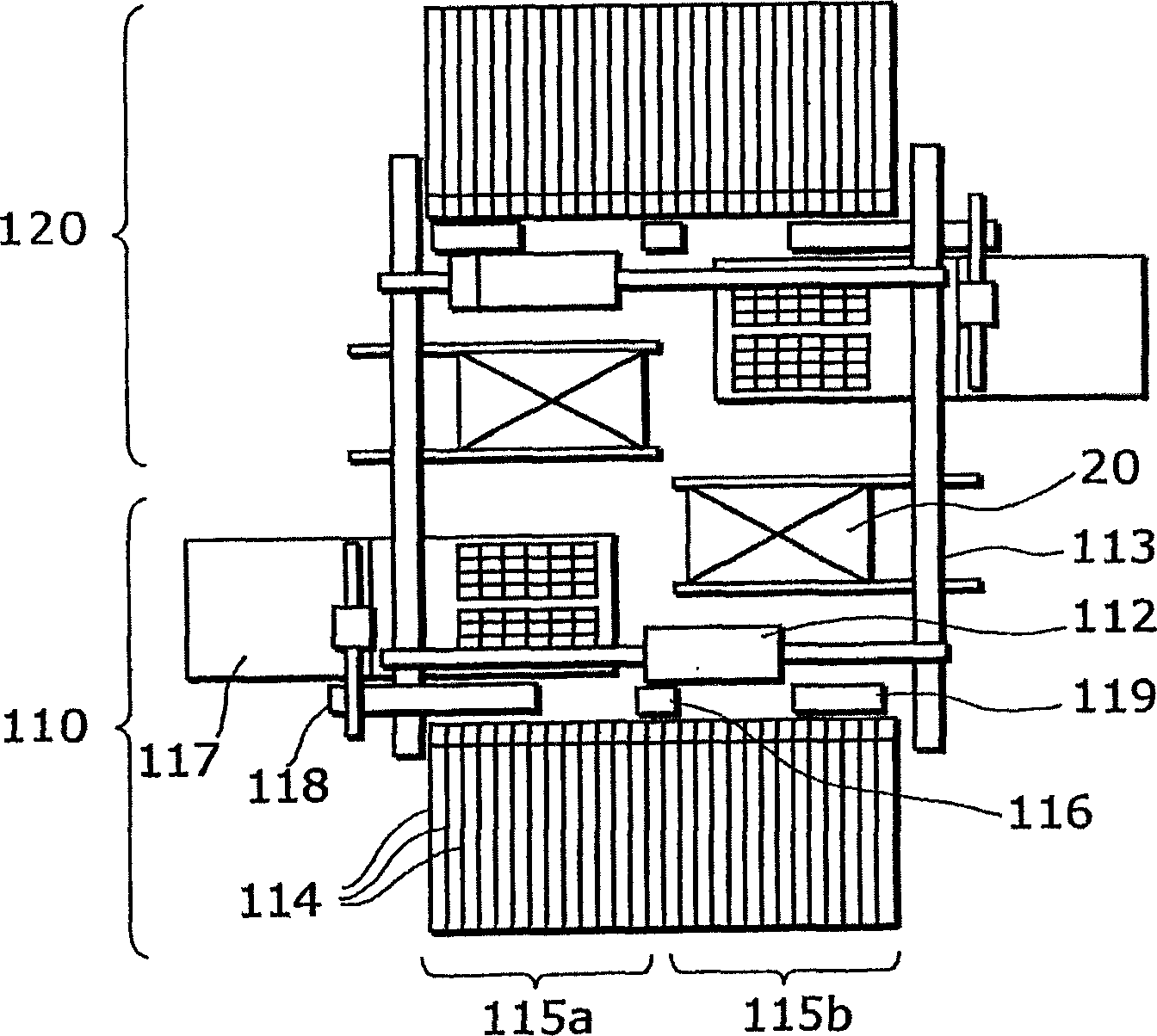

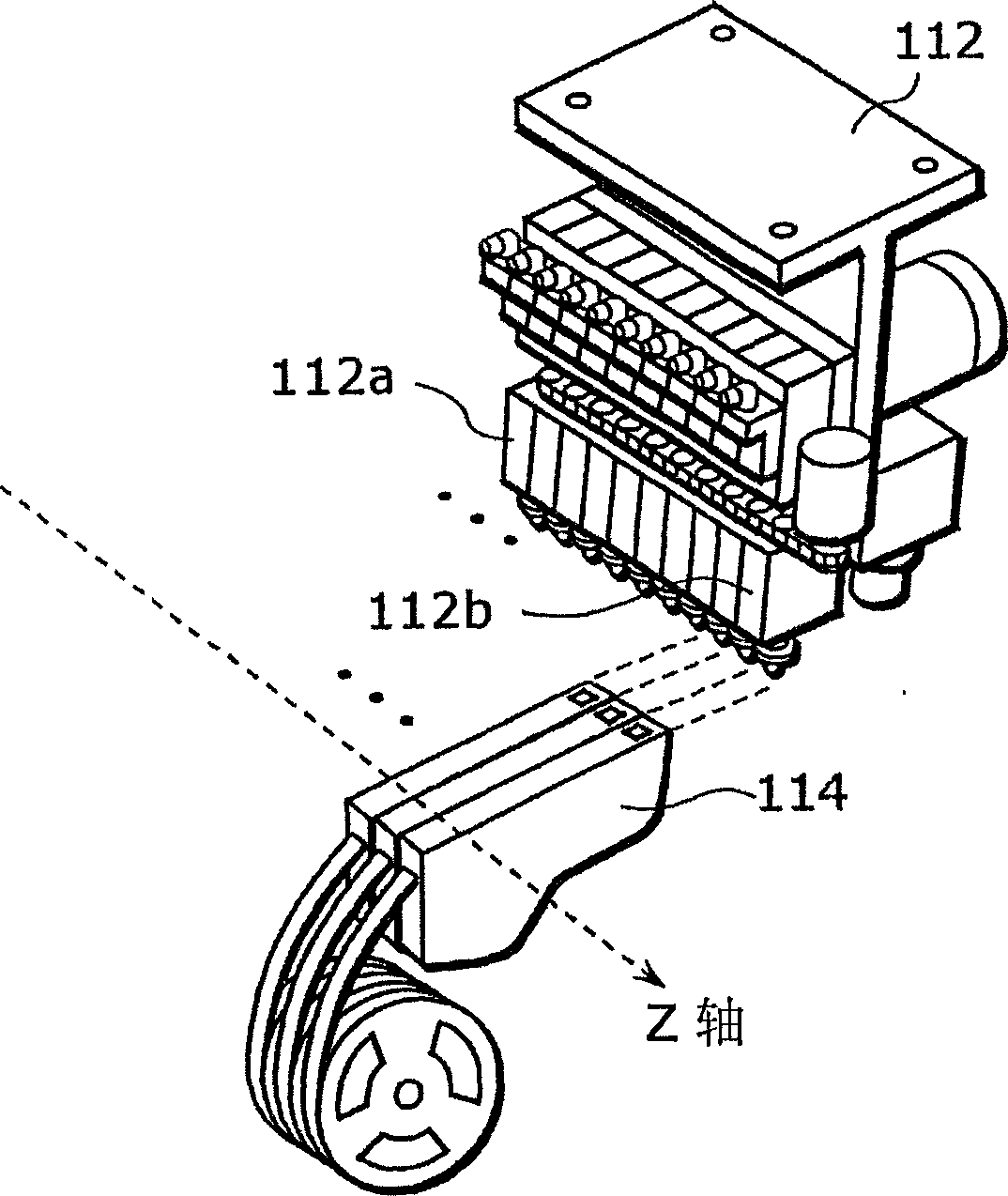

[0062] The assembler 100 is equipped with two subunits (a front terminal...

no. 2 example

[0160] Next, a component mounting system according to a second embodiment of the present invention will be explained.

[0161] The component mounting system according to the second embodiment has the same hardware structure as the component mounting system in the first embodiment. However, the assembler 100 in this embodiment is compatible with figure 2 Assembler 100 shown differs in that it does not include subunit 110 and subunit 120, instead it includes left subunit 410 and right subunit 420, as Figure 21 shown. To reduce the width of the space required for component assembly, the Figure 21 The center portion of the shown assembler is provided with reference pins for determining the position of the panels. The panel 20 enters from the right in the figure and is assembled with components through the right subunit 420 . Subsequently, the panel 20 is transferred to the left subunit 410 , and components are assembled by the left subunit 410 .

[0162] FIG. 22 is a flowc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com