Cable connection structure and cable connection method

一种电缆连接、同轴电缆的技术,应用在导电连接、连接、固定连接等方向,能够解决电缆导体短路、电缆导体无法完全容纳等问题,达到操作性及功能性提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

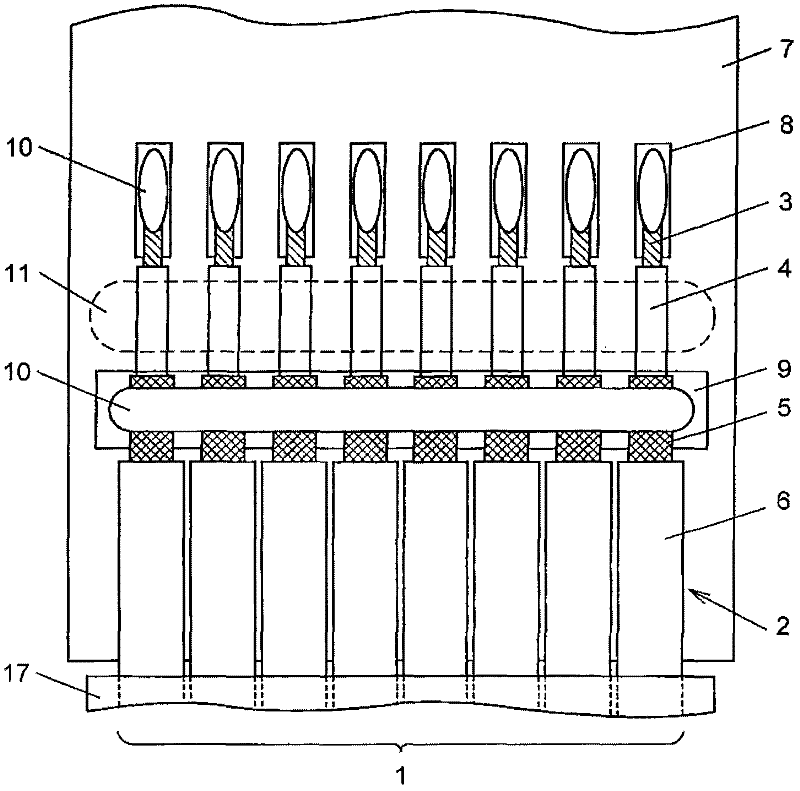

[0037] (Structure of multi-core cable)

[0038] exist figure 1 In , reference numeral 1 representing the whole is a multi-core cable arranged on a printed circuit board 7 (hereinafter referred to as "substrate 7"). The illustrated multi-core cable 1 is configured by arranging eight ultra-fine coaxial cables 2 in parallel at an arrangement pitch of 0.15 mm and integrally covering them with an insulating laminated tape 17 .

[0039] Such as figure 1 As shown, eight ultra-fine coaxial cables 2 constituting the multi-core cable 1 are integrally formed by the following components: a central conductor 3 whose outer diameter becomes 0.03 mm by twisting seven core wires with a diameter of 0.01 mm; An inner insulator 4 with an outer diameter of 0.06mm on the outer periphery of the center conductor 3; a core wire covering the outer periphery of the inner insulator 4 and having an outer diameter of 0.016mm constitutes an outer conductor 5 with an outer diameter of 0.1mm around the shield...

no. 2 approach

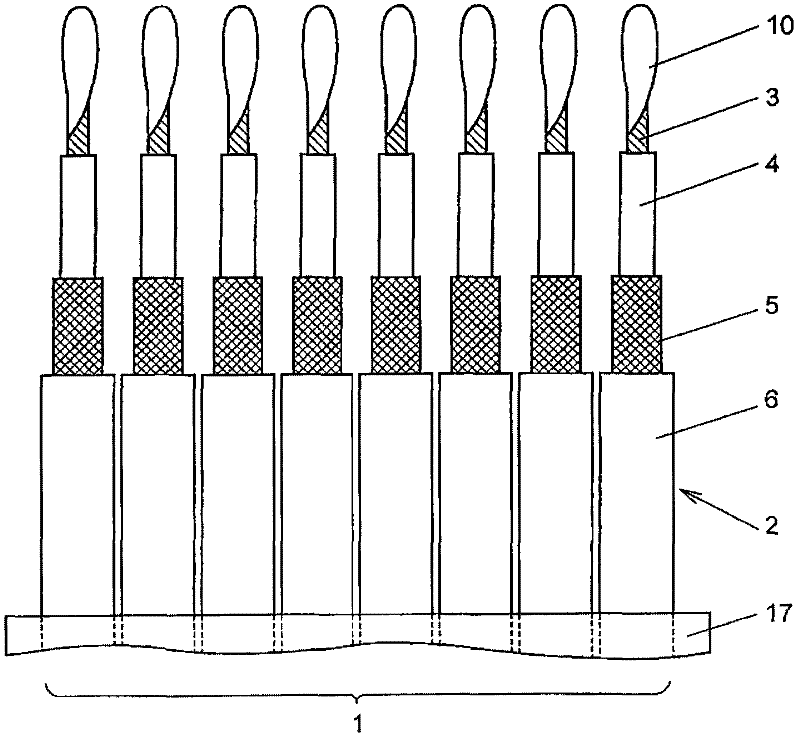

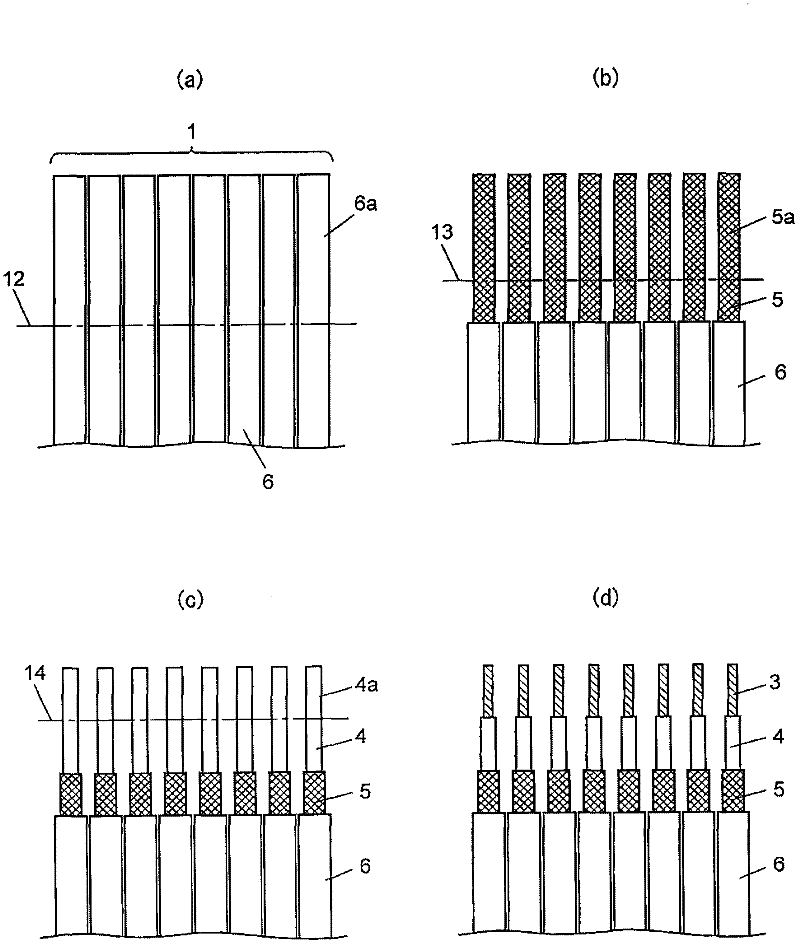

[0066] Below, refer to Figure 2 ~ Figure 6 , the cable connection method for obtaining the cable connection structure of the above-mentioned first embodiment will be described in detail by citing specific embodiments. In addition, in this second embodiment, a typical example of the above-mentioned first embodiment was given, but of course the present invention is not limited to the illustrated example.

[0067] (end processing of multi-core cables)

[0068] Before the eight ultra-fine coaxial cables 2 integrated with the laminate tape 17 are electrically connected to the signal electrodes 8 and the ground electrodes 9 of the substrate 7, the sheath cutting process, the outer conductor cutting process, and the inner insulator In each end processing process of cutting processing, CO 2 The end processing of the multi-core cable 1 is performed by laser or YAG laser. According to the preferred mode, it is possible to use image 3 The end-finishing process shown effectively yie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com