Visual model testing device and method for simulating water gushing in tunnel

An experimental device and water inrush technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problem of lack of experimental devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

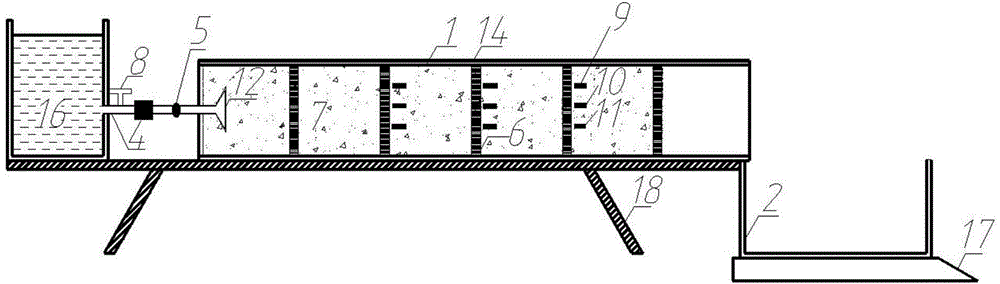

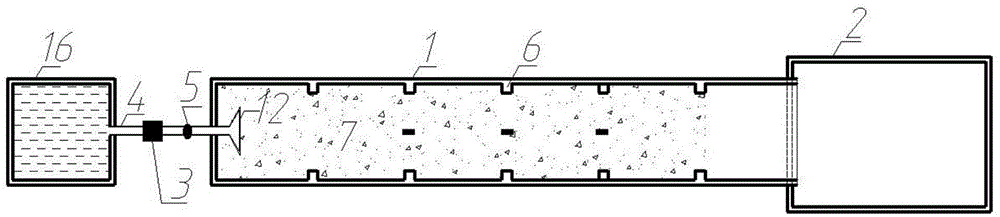

[0058] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown in is a visual test device for simulating tunnel water inrush. The water source required by the model is supplied by high-pressure water pump 3; the model box 1 is a cuboid device made of tempered glass, and the joints between the glasses are sealed with glass glue. To achieve no water seepage and no water leakage; the box is filled with fluid-solid coupling similar material 7, which is used to simulate the anti-outburst rock mass of the tunnel; the upper cover of the box body can be disassembled from the main body, and it is sealed with the box body by a rubber gasket 14 and bolts 15 Fixed; the right side of the box is open without any obstruction.

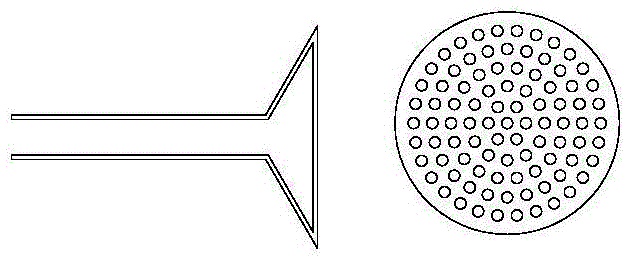

[0059] The left side of the box is connected to the high-pressure water pump 3 through a water inlet pipe 4 with a diameter of 50 mm. A flow meter 5 is arranged between the water inlet pipe 4 and the box body. The water inlet pipe 4 is located in the center of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com