Plant volatile oil extractor and application thereof

A plant volatile oil and extraction device technology, applied in the field of plant volatile oil extraction devices, can solve the problems of incomplete essential oil composition, reduced oil yield of the tested plant essential oil, etc. Easy effect with unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

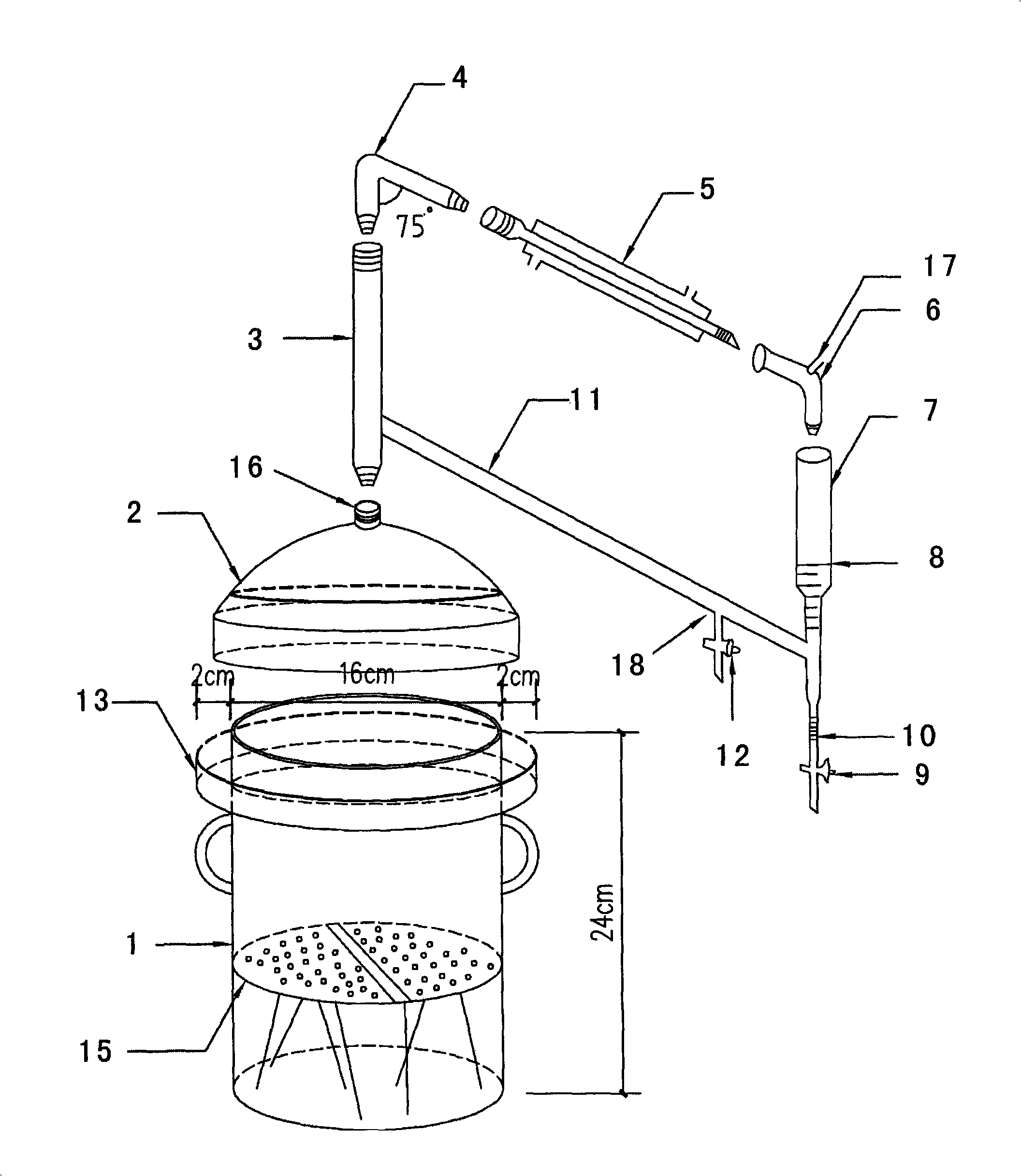

[0031] Embodiment 1, the structural design of volatile oil extraction and separation device

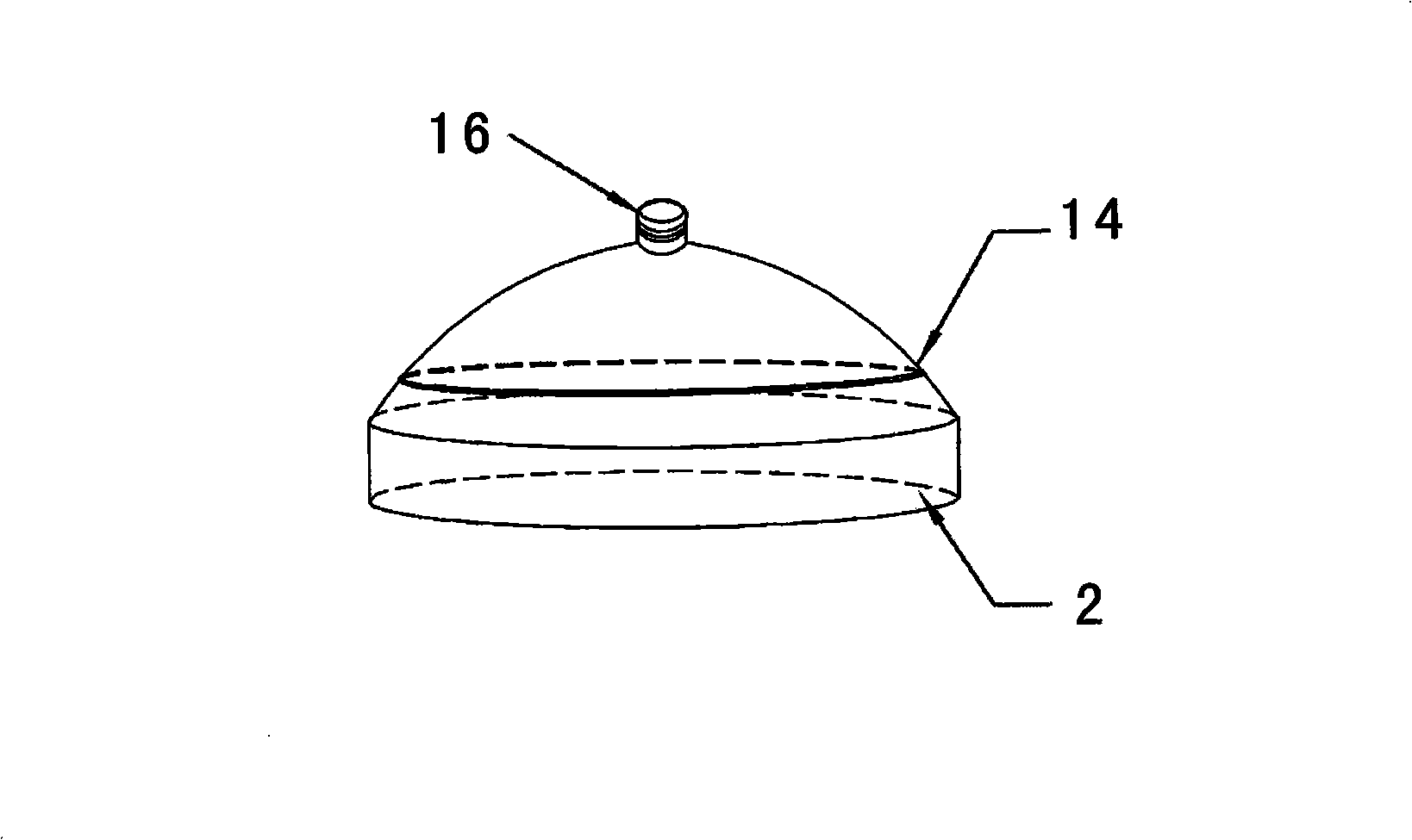

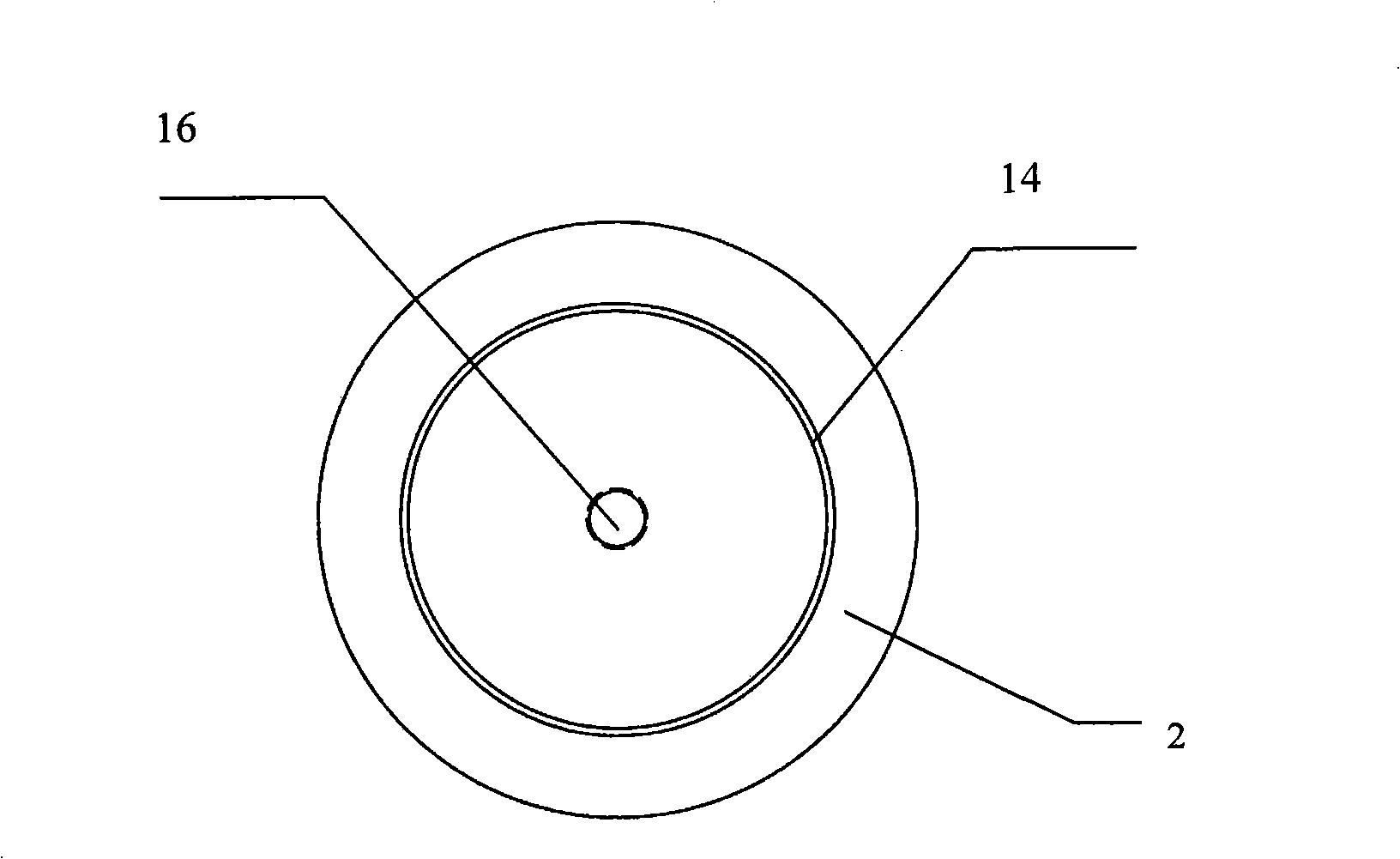

[0032] like Figure 1-4 Shown is the plant volatile oil extraction device provided by the present invention, including distillation device, condensation device and collection device;

[0033]Wherein, the distillation device includes a barrel-shaped distillation vessel 1 with an open upper part, a sealing cover 2 matching the distillation vessel 1 and a water-proof grate 15 matching the distillation vessel 1, and a through hole 16 is arranged on the top of the sealing cover 2; the distillation vessel 1 is Made of white iron or stainless steel, chemically stable, heat-resistant; diameter 16cm, height 24cm. The built-in water-retaining grate 15 is two semicircles, perforated on the top, supported by legs below, can be freely taken out from the distillation pot, and the grate is 10cm apart from the height of the bottom of the pot. The water-repelling grate 15 is made up of two semicircu...

Embodiment 2

[0051] Embodiment 2, prepare plant essential oil with the plant volatile oil extraction separation device of embodiment 1

[0052] One, the using method of plant volatile oil extraction separation device of the present invention is as follows:

[0053] 1. Put the water-separating grate 15 into the body 1 of the distillation pot, put the raw materials on the grate (water distillation), but the water surface should not be higher than the grate, and ensure that the raw material layer will not be splashed when the water boils until it evaporates; it can also be taken out Water-proof grate (distilled in water), add appropriate amount of water to the bucket, and put the raw materials into the water.

[0054] 2. Put the bell-shaped cover 2 on the water seal tank, and pour a certain amount of water into the water seal tank.

[0055] 3. Connect the distillation device, condensation device, collection device and liquid return device according to the above connection method.

[0056] 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com