Electric spindle reliability test bed with hydraulic-type energy recovery function

A technology of energy recovery and electric spindle, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., and can solve problems such as energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

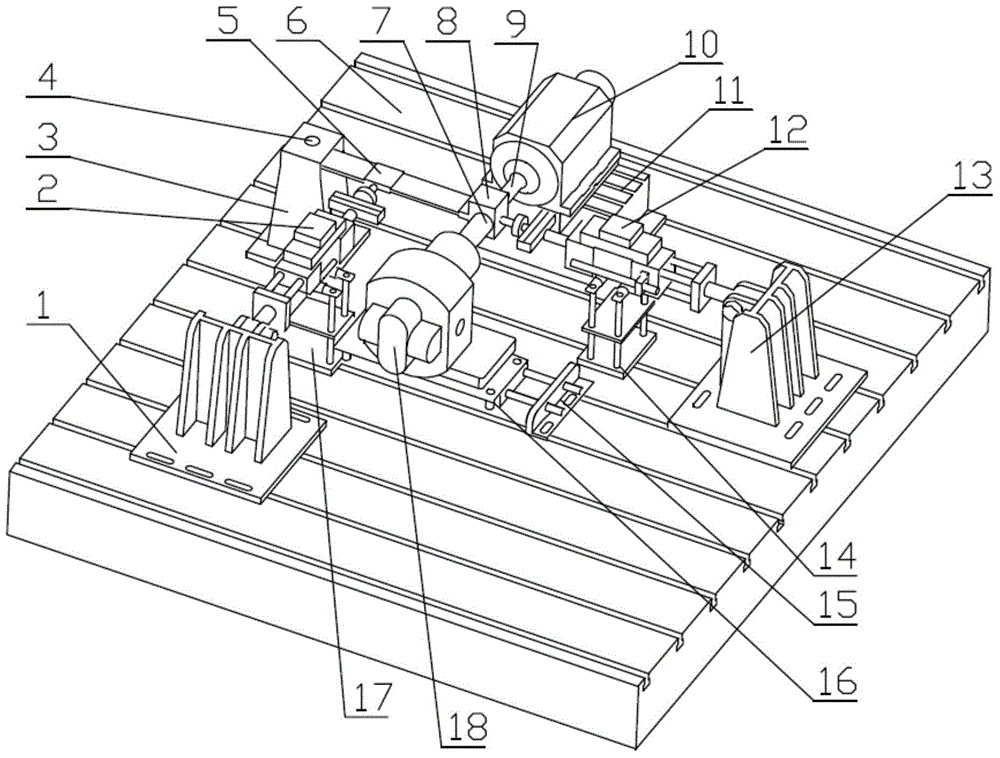

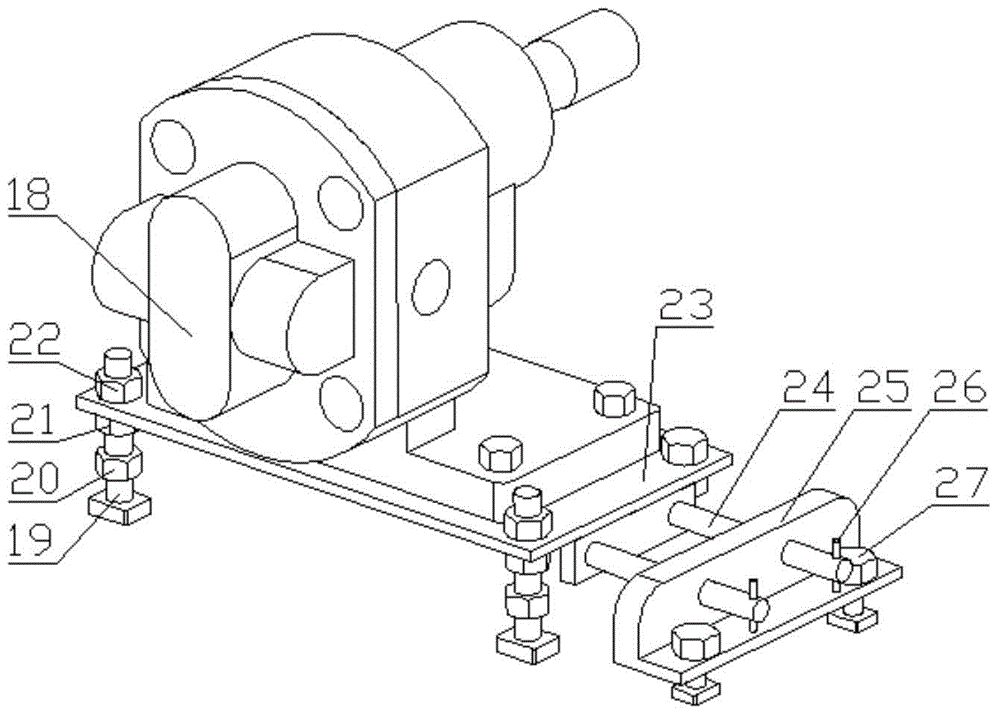

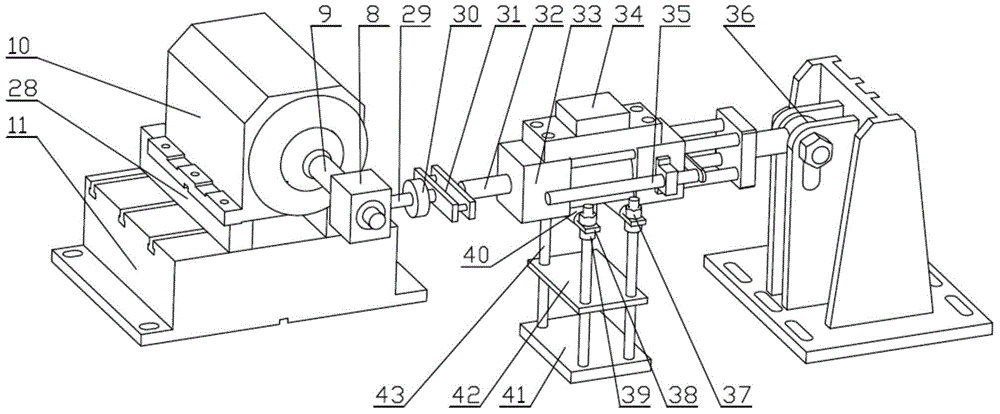

[0050] refer to figure 1 , an electric spindle reliability test bench with hydraulic energy recovery, the test bench includes electric spindle, electric spindle support part, loading bar 9, bearing loading unit, radial force loading part, axial force loading part, automatic control Part, characterized in that the test bench also includes a torque loading part and a hydraulic oil circuit part connected to the torque loading part through a pipeline, wherein the torque loading part includes a torque loading device and a hydraulic pump support adjustment for supporting the torque loading device device, the axes of the electric spindle 10, the loading rod 9, the bearing loading unit 8, and the hydraulic pump 18 of the torque loading part are coaxial; the axis of the No. 1 loading rod 29 of the radial force loading part and the bearing loading unit 8 The axis lines are perpendicular to each other; the axis of the No. 2 loading rod 44 of the axial loading part and the axis of the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com