Adjustable supporting device for Hopkinson test bar piece

A technology of supporting devices and test rods, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as the limitation of the diameter of the supporting rod, the inability to adjust the position of the rod, and the complexity of the structure and process, so as to achieve high-precision adjustment and ensure the same The effect of axiality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The support device of the Hopkinson bar is an important part of the Hopkinson test, and it is an important device to ensure the horizontal one-dimensional movement of the bar.

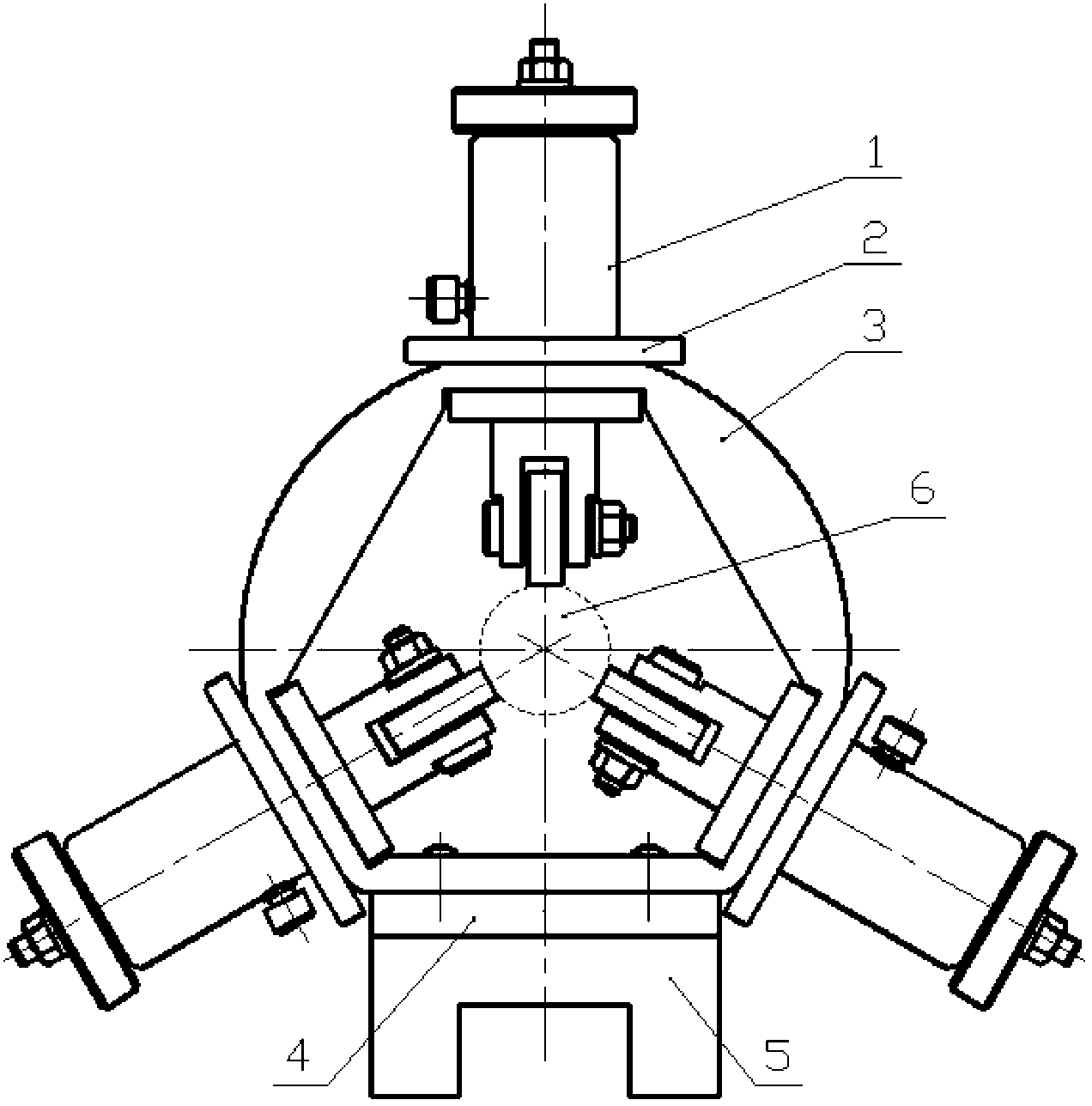

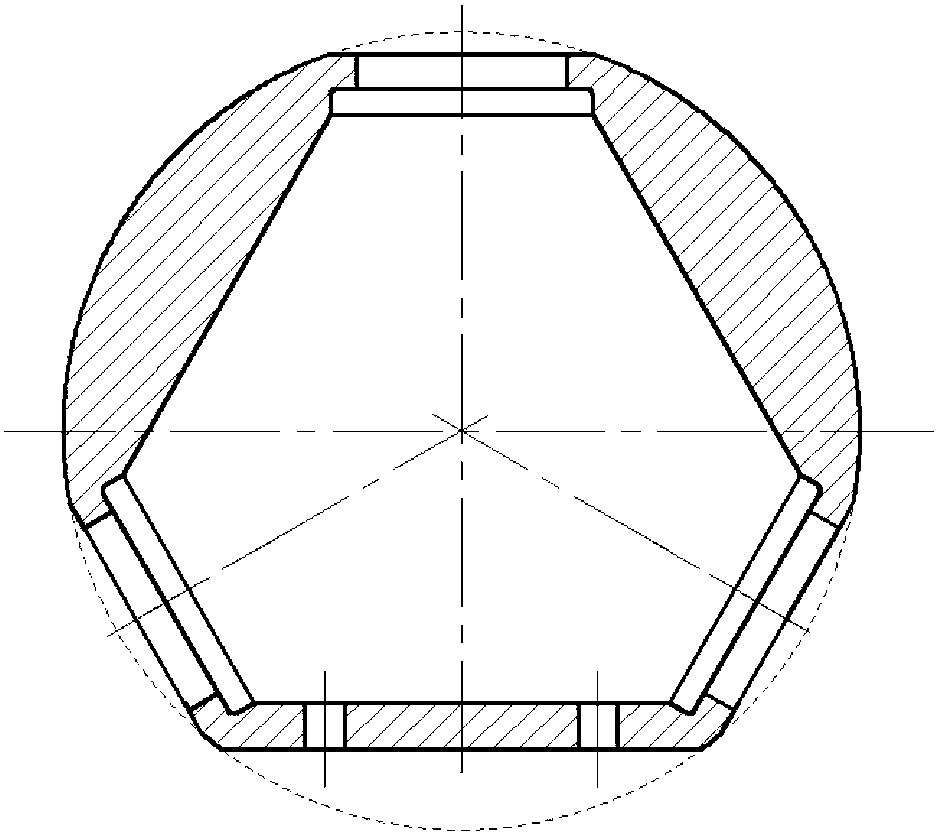

[0012] In conjunction with the accompanying drawings, an adjustable support device for a Hopkinson test rod of the present invention includes an adjustment member 1, a lock nut 2, a bracket 3, an adapter block 4, a slider 5 and a rod 6, and the slider 5 An adapter block 4 is arranged on it, and the adapter block 4 is fixedly connected to the bracket 3, and three adjustment pieces 1 for supporting the rod 6 are uniformly arranged on the bracket 3, and each adjustment piece 1 is fixed on the bracket 3 by a lock nut 2 , the included angle between the central axes of every two adjustment parts 1 is 120 degrees.

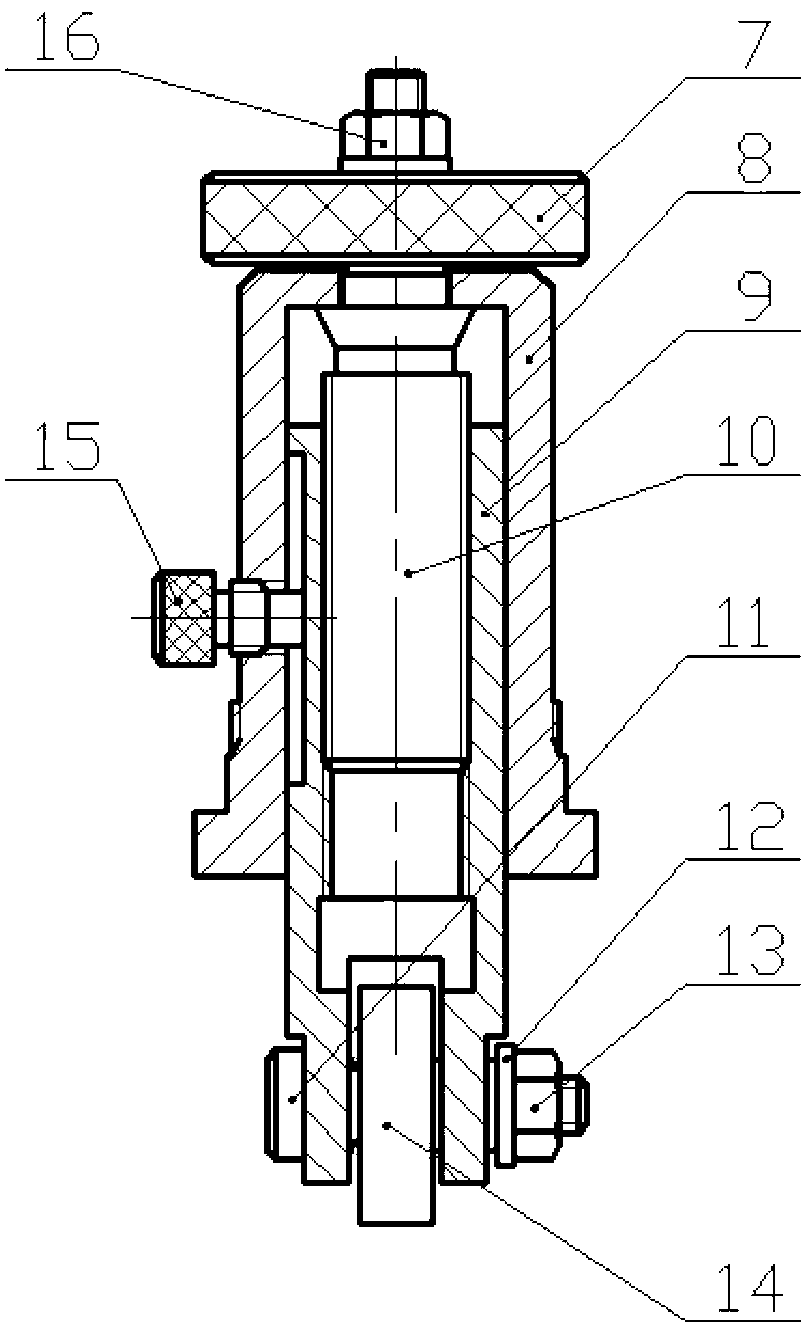

[0013] The adjusting part 1 includes a manual wheel 7, a sleeve 8, a plug shaft 9, an adjusting screw 10, a transverse shaft 11, a collar 12, a lock nut 13, a bearing 14, a brake screw 15 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com