Installation and adjustment method of infrared lenses

An assembly and adjustment method and infrared lens technology, applied in the optical field, can solve problems such as failure to meet assembly and adjustment tolerance requirements, difficult assembly process guarantees, etc., to achieve high-precision adjustment, ensure reset accuracy, and improve measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

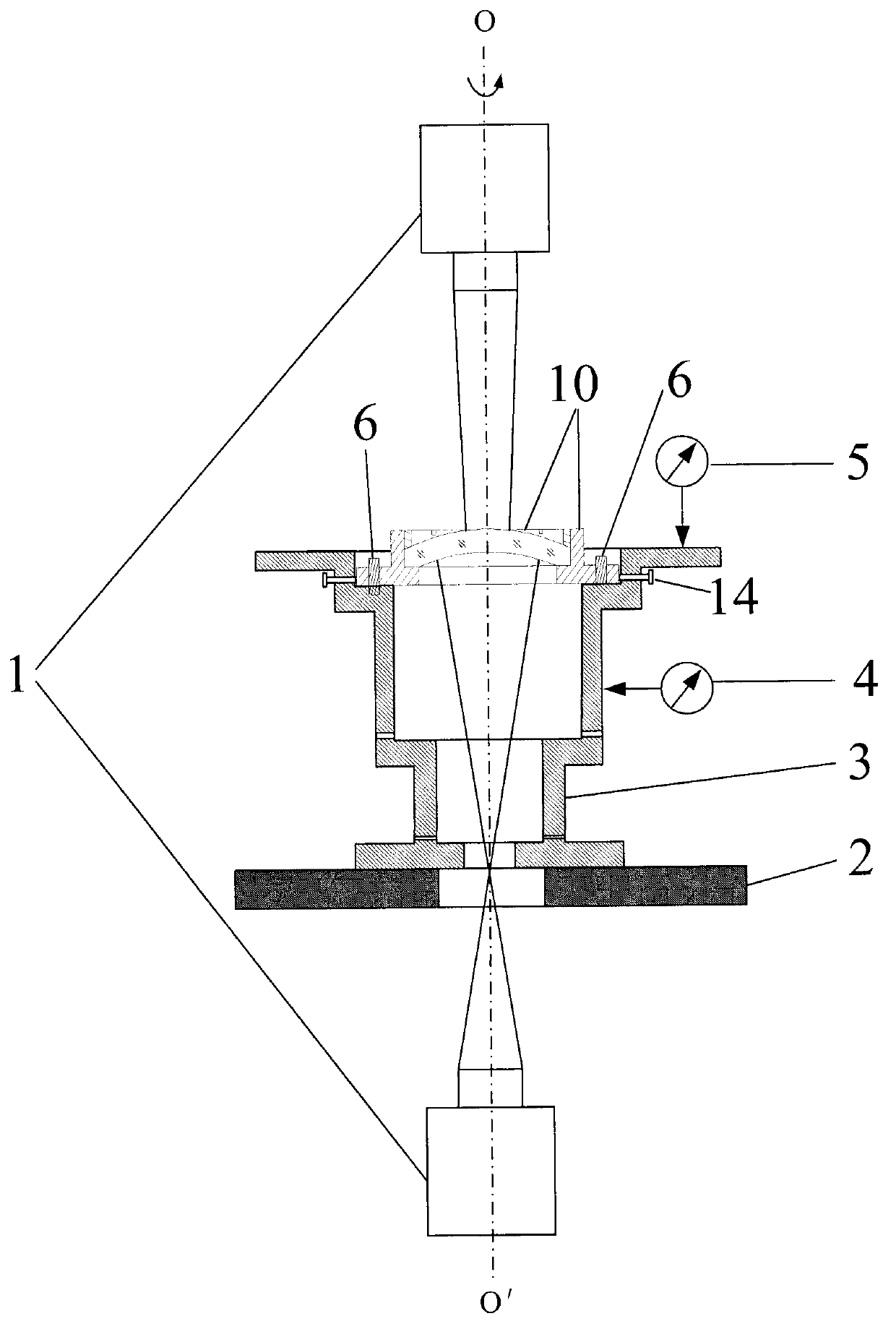

[0021] Such as figure 1 As shown, it is a principle diagram of the method of the present invention, the lens barrel 3 is fixed on the turntable 2, the first lens assembly 10 is installed on the lens step, the dial indicator 4 monitors the outer circle reference plane of the lens barrel, and the dial gauge 5 monitors the lens barrel The end face datum plane, the double optical path centering instrument 1 monitors the spherical center images of the two faces of the lens assembly.

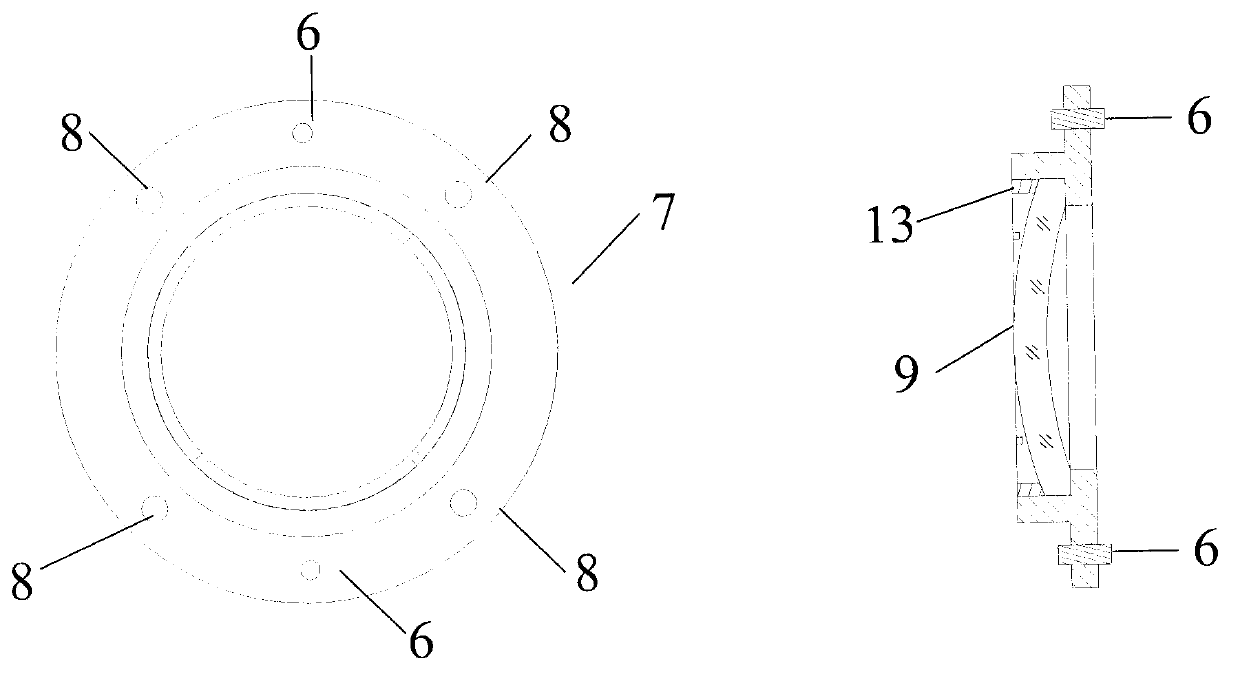

[0022] Such as figure 2 As shown, it is a schematic diagram of the first lens assembly 10 of the present invention, the first lens 9 is installed and fixed in the frame 7, the pin 6 is used to position the first lens assembly, and the screw 8 is used to fix the first lens assembly.

[0023] The structural composition and installation method of the second lens assembly 11 and the third lens assembly 12 are the same as those of the first lens assembly 10 .

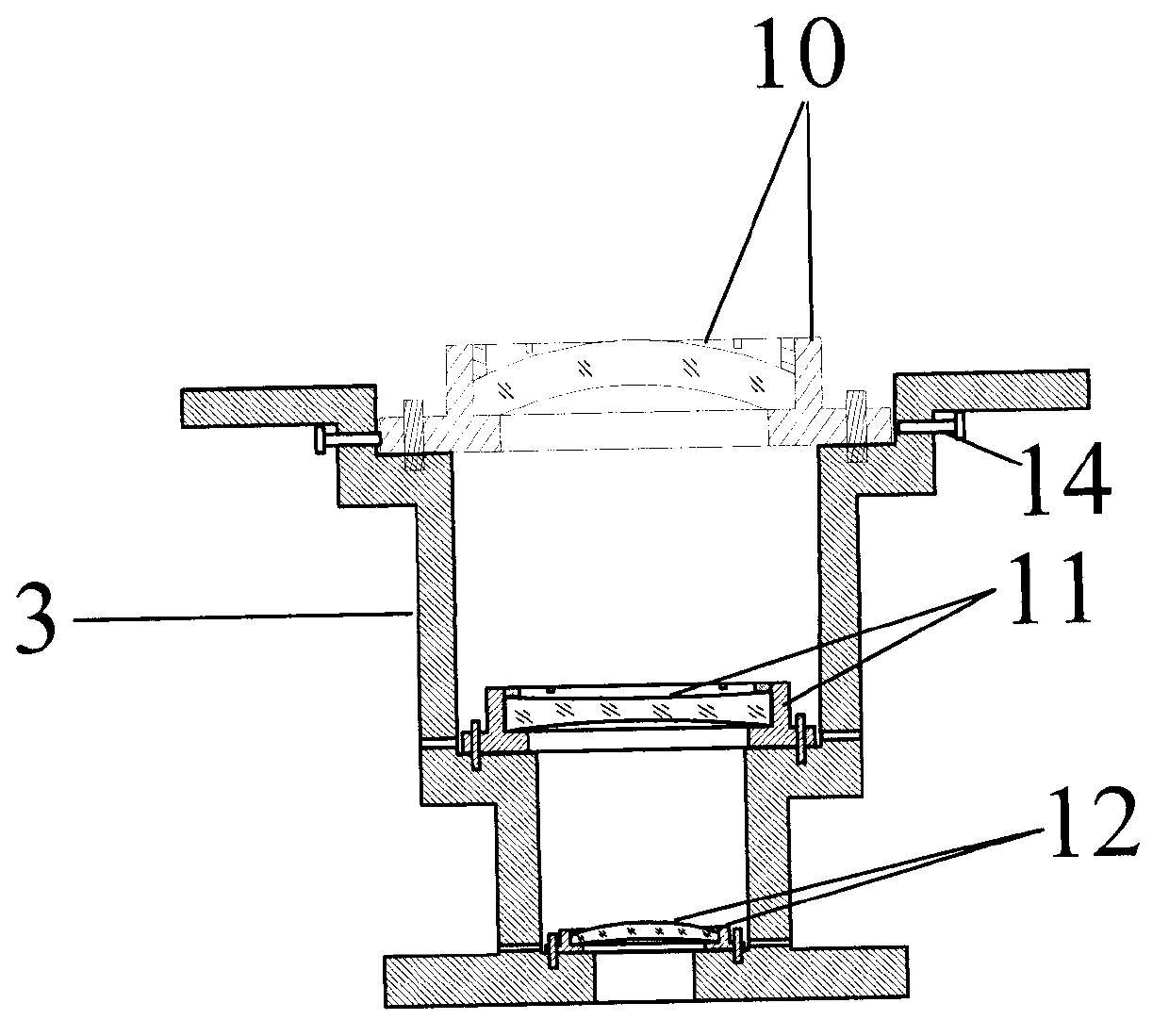

[0024] Such as image 3 Shown is a schema...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

| Roundness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com