Vacuum debugging process for light cavity of high-power gas laser

A gas laser, high-power technology, used in lasers, laser parts, phonon exciters, etc., can solve the problems of optical cavity deformation, reduced position accuracy, difficult optical cavity adjustment, etc., to achieve stable laser output power and achieve High-precision adjustment, precise effect of optical cavity adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

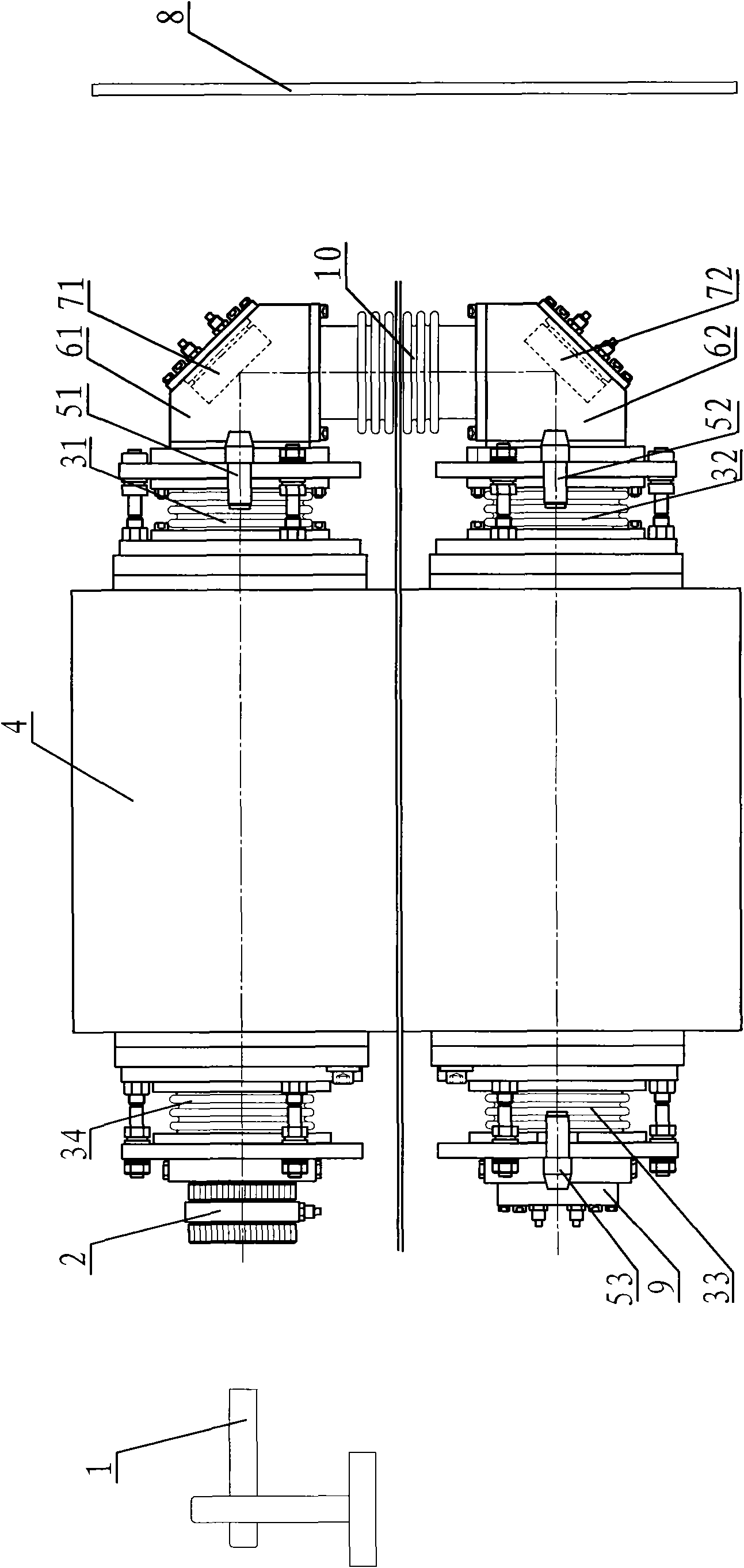

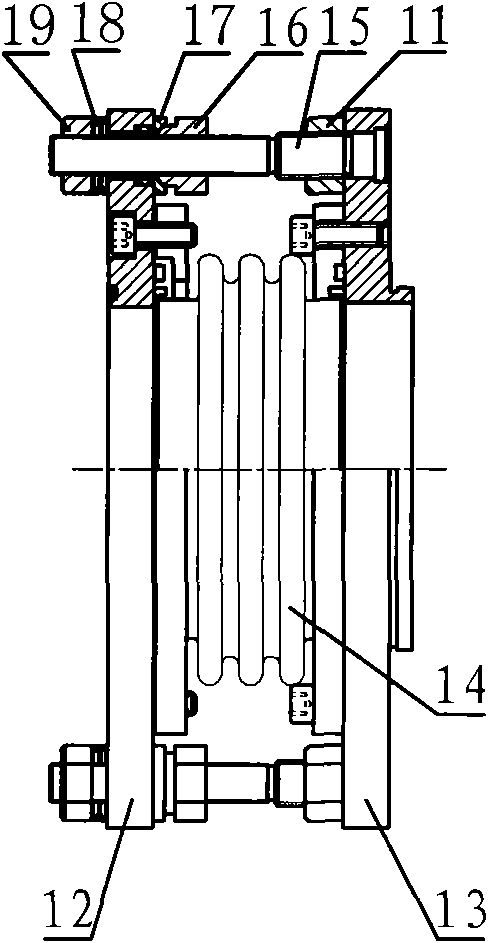

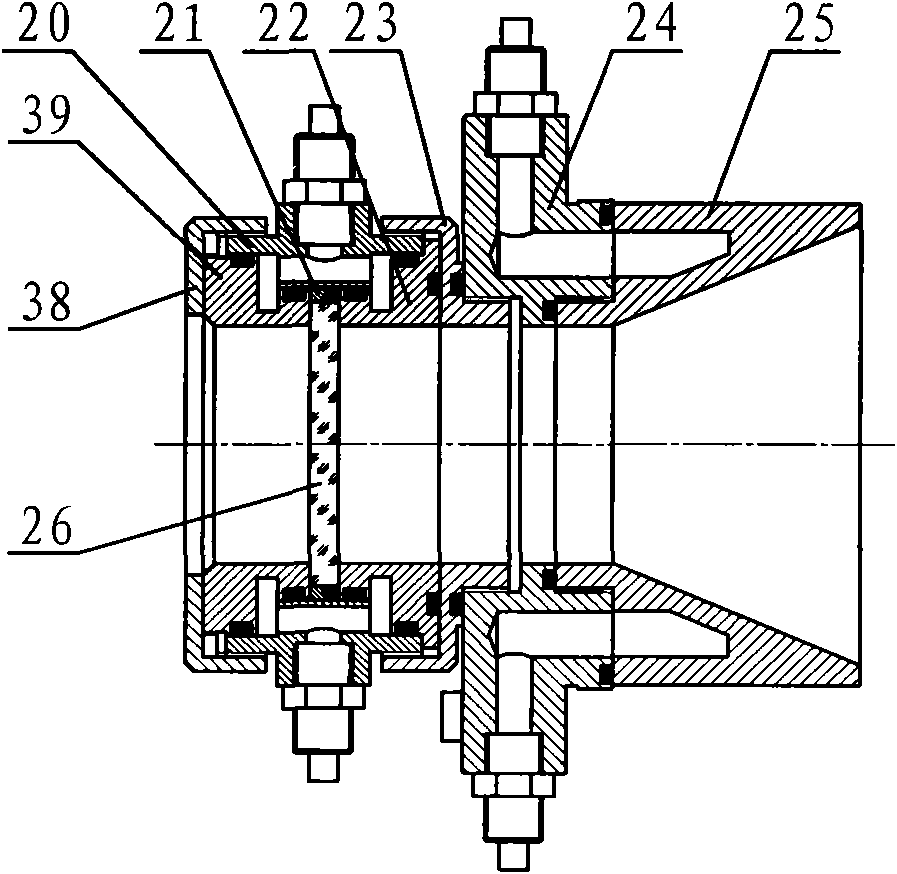

[0038] Embodiment 1: The optical system used in this example is a U-shaped folded optical cavity structure, refer to figure 1 , including a laser box 4, a front window mirror module 2, a rear mirror module 9, turning mirror mounts 61, 62, turning mirrors 71, 72, optical axis monitoring systems 51, 52, 53, a telescope 1 and a receiving screen 8, the front The window mirror module 2 is arranged on one side of the laser box 4 through the angle adjustment module 34, and the rear mirror module 9 is on the same side as the front window mirror module 2, and is arranged on the laser box through the angle adjustment module 33 with the optical axis monitoring system 53 4, there are two turning mirror mirror mounts 61, 62, which are respectively arranged on the other side of the laser box 4 through angle adjustment modules 31, 32 with optical axis monitoring systems 51, 52, and turning mirrors 71, 72 are respectively set On the turning mirror mirror bases 61, 62, during debugging, the te...

Embodiment 2

[0057] Embodiment 2: The optical system of this example is a single cavity structure, refer to Figure 6 , including a laser cabinet 4, a front window mirror module 2, a rear mirror module 9, an optical axis monitoring system 5, an inner focusing telescope 1 and a receiving screen 8, and the front window mirror module 2 is arranged on the laser cabinet 4 through an angle adjustment module 34 The rear mirror module 9 is arranged on the other side of the laser box 4 through the angle adjustment module 33 with the optical axis monitoring system 53. When debugging, the telescope 1 is located at the installation port side of the front window mirror module 2, and The distance between the installation port of the front window mirror module 2 is 1.5-3 meters, and the receiving screen 8 is located on the other side of the laser box 4 .

[0058] The structures of the angle adjustment module 34 and the optical axis monitoring system 53 in this example are the same as those in the first e...

Embodiment 3

[0069] Embodiment 3: The optical system of this example is a V-shaped cavity structure, refer to Figure 7, including a laser box 4, a front window mirror module 2, a rear mirror module 9, a turning mirror 7, an optical axis monitoring system 51, 53, a telescope 1 and a receiving screen 8, and the front window mirror module 2 is arranged on the laser through an angle adjustment module 34 On one side of the box body 4, the rear mirror module 9 is on the same side as the front window mirror module, and is arranged on the laser box body 4 through the angle adjustment module 33 with the optical axis monitoring system 53, and the turning mirror 7 passes through the camera with the monitoring system 51. The angle adjustment module 31 is arranged on the other side of the laser box body 4, and the axes of the turning mirror 7, the front window mirror module 2 and the rear mirror module 9 form a V shape. On the mouth side, the distance from the installation port of the front window mir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com