Kitchen waste disposer

A technology of food waste and processing machine, which is applied in the direction of solid waste removal, etc., can solve the problems of low production efficiency, unfavorable fermentation, unsuitable for centralized treatment of food waste, etc., and achieve a high degree of integration, easy centralization, and high production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described in further detail:

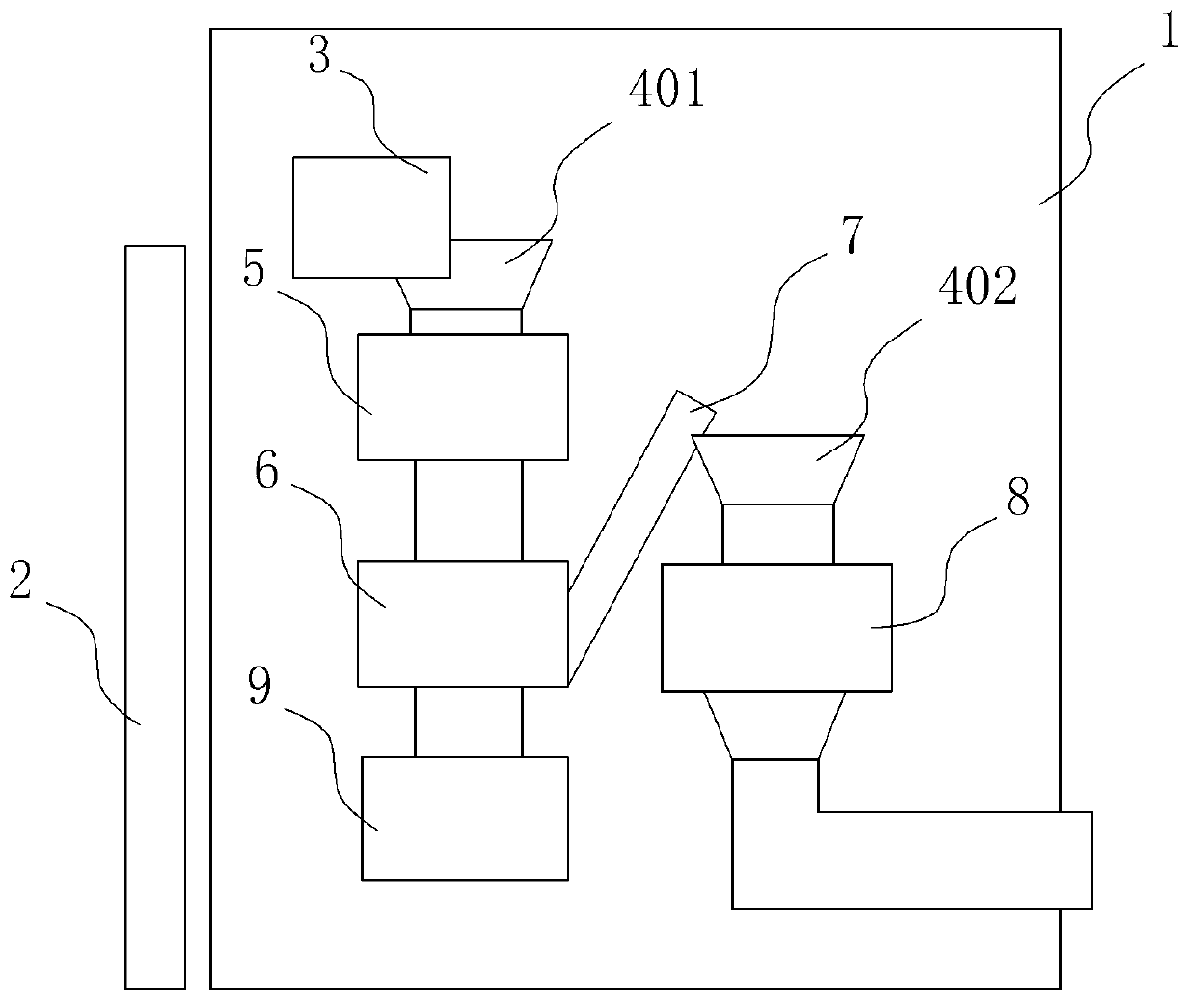

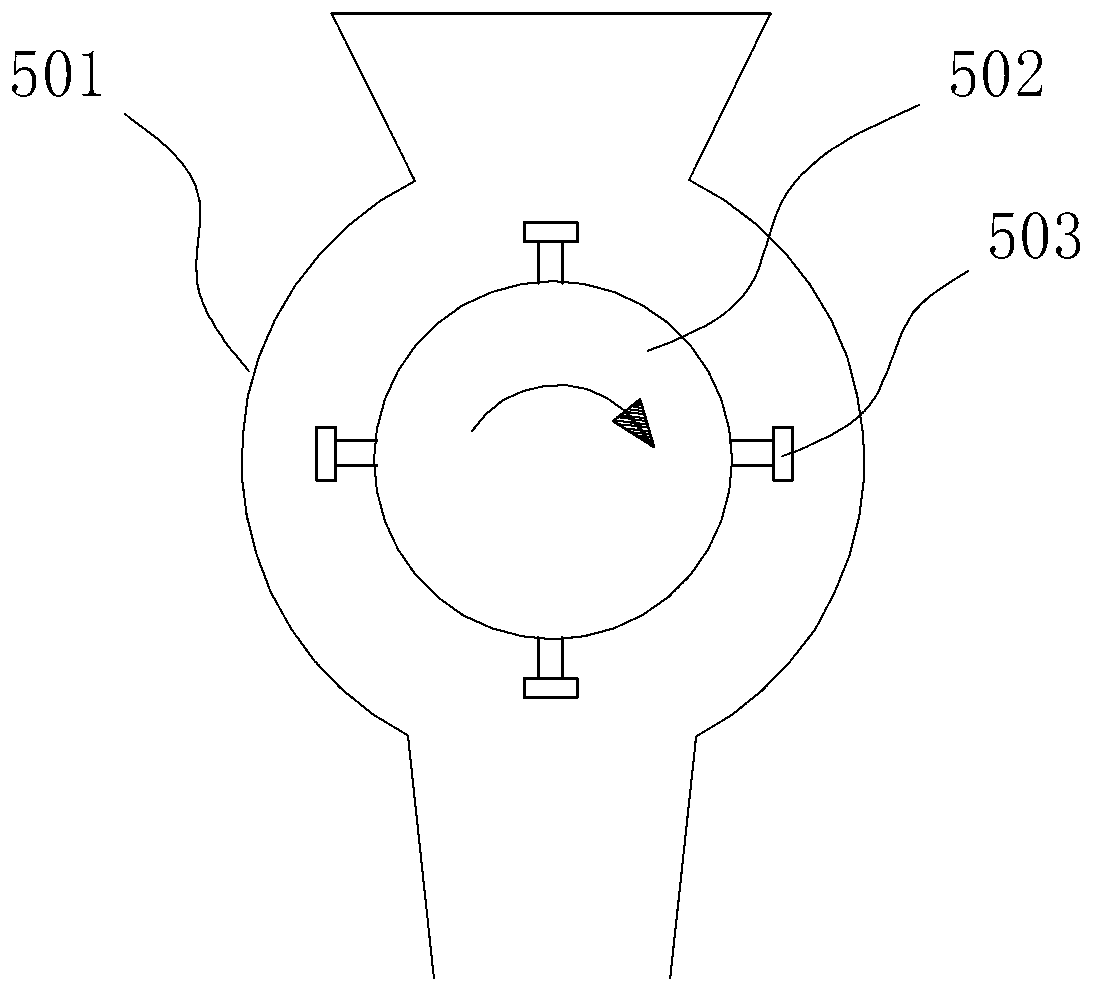

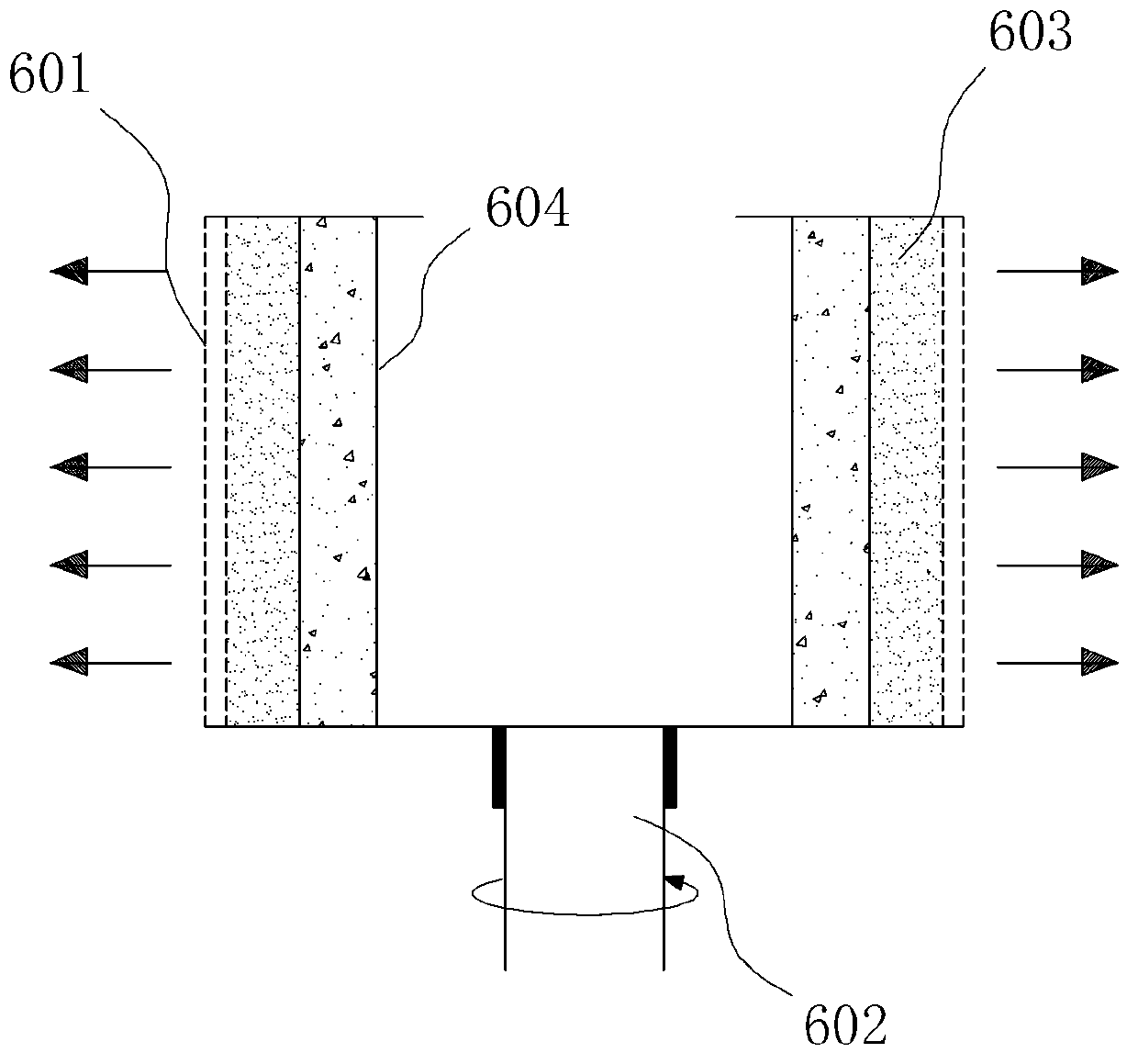

[0037] combine figure 1 As shown, the food waste disposer includes a frame body 1 and a lifting and turning device 2, a switch door cover 3, a hopper, a crushing device 5, a solid-liquid separation device 6, and a squeezing and lifting device that are jointly arranged on the frame body. 7. Fermentation drying device 8 and oil-water separation device 9. Wherein, the hopper includes a first hopper 401 located directly above the crushing device 5 and a second hopper 402 located directly above the fermentation and drying device 8 .

[0038]The lifting and turning device 2 is arranged parallel to a certain side wall of the frame body 1, and is used to lift the kitchen waste to the opening and closing door cover 3 of the frame body, and perform the turning operation when the opening and closing door cover is in the open state Pour the kitchen waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com