In-place heat regeneration asphalt pavement remixer

A technology of recycled asphalt and mixer, which is applied in road repair, roads, roads, etc., can solve the problems of inability to complete the double-layer paving and repaving function, inability to complete the paving by itself, and construction process limitations, and achieves obvious energy-saving effect. , to facilitate on-site construction and improve the effect of regeneration quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

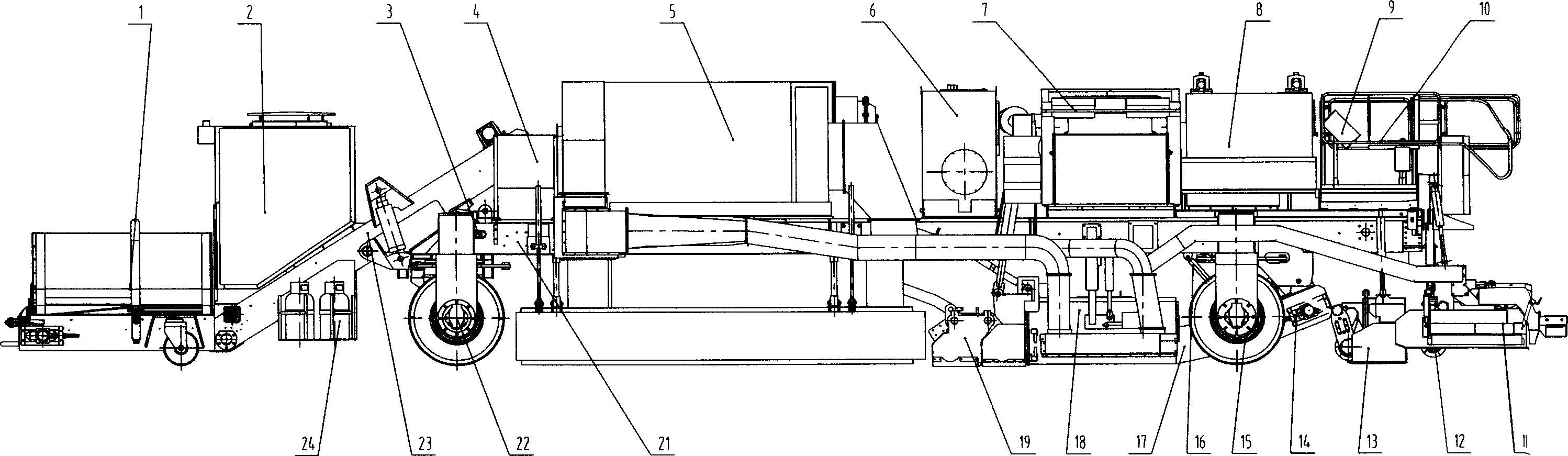

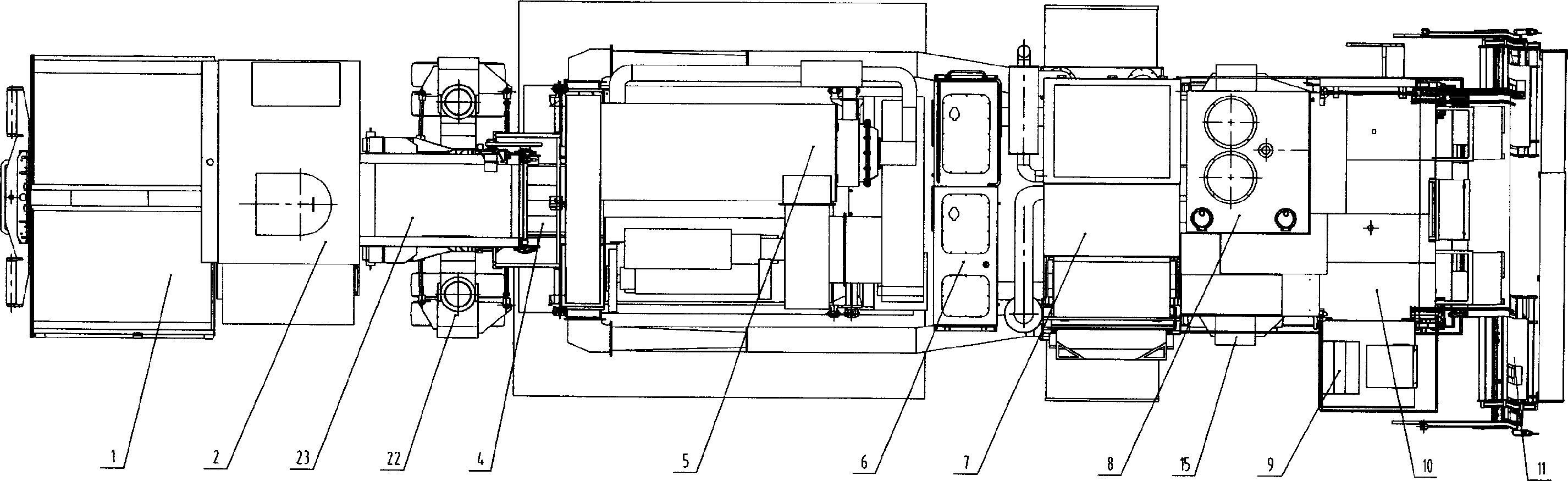

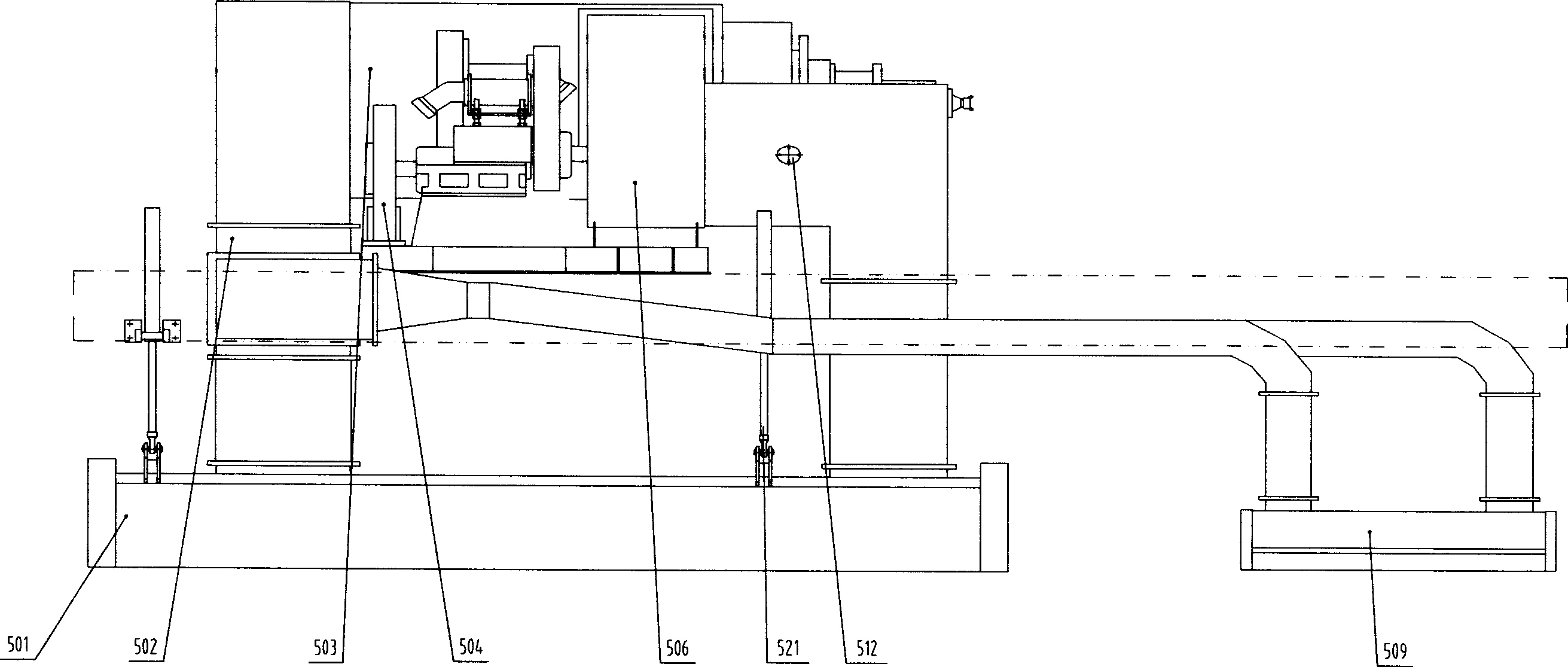

[0042] Such as figure 1 with figure 2 As shown, the hot-in-place recycled asphalt pavement remixer of the present invention includes a frame 21, a hopper 1, a spraying mechanism 2, a transfer hopper 4, a hot air circulation heating mechanism 5, a regeneration integration device, a paving mechanism, and a front axle 22 , rear axle 15, cab 10, control system 9 and power system 7, receiving hopper 1, spraying mechanism 2, transfer hopper 4, hot air circulation heating mechanism 5, continuous conveying mechanism and paving mechanism are fixed on the frame 21 in sequence , the receiving hopper 1 is connected to the transfer hopper 4 through the new asphalt front conveying device 23, the paving mechanism includes the recycled asphalt mixture paving device 13 and the new asphalt mixture paving device 11, the discharge port of the continuou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com