Semi-dry method refuse burning fume cleaning treatment method and system thereof

A technology for waste incineration and flue gas purification, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle separation, etc. It can solve the problems of unreachable, easy blockage and wear of slurry pipes and nozzles, high investment costs, and promote uniform distribution. , good treatment effect, optimized absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

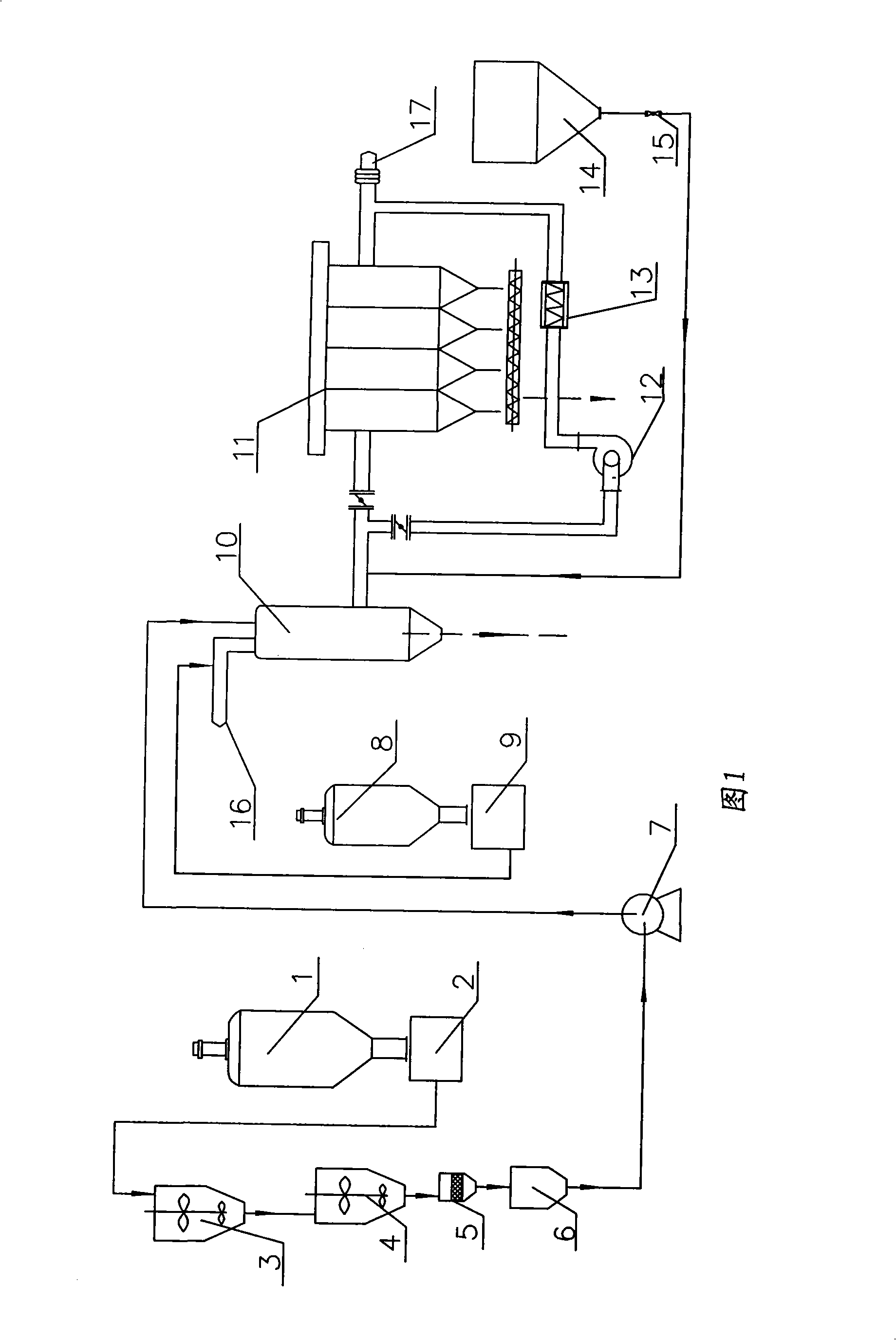

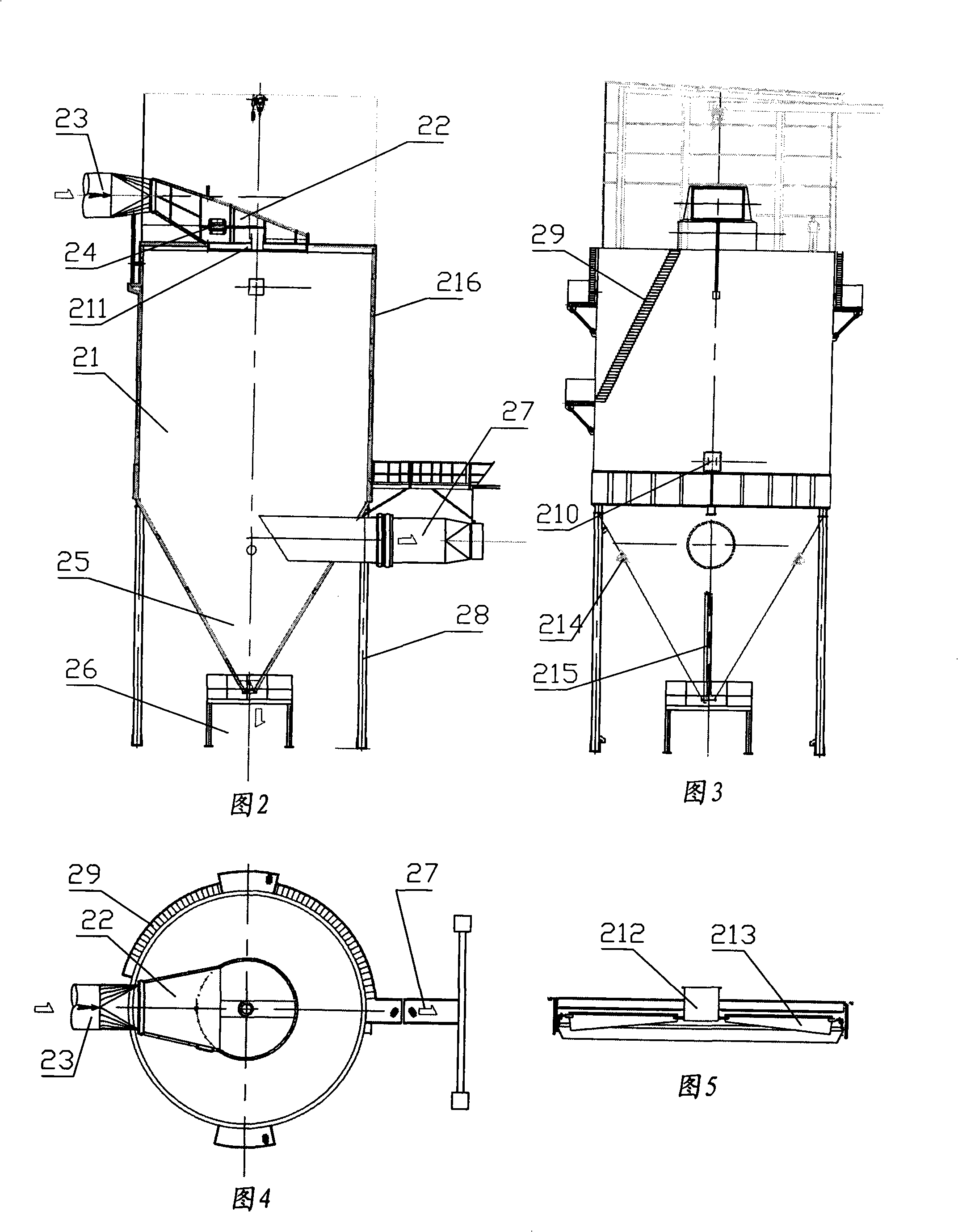

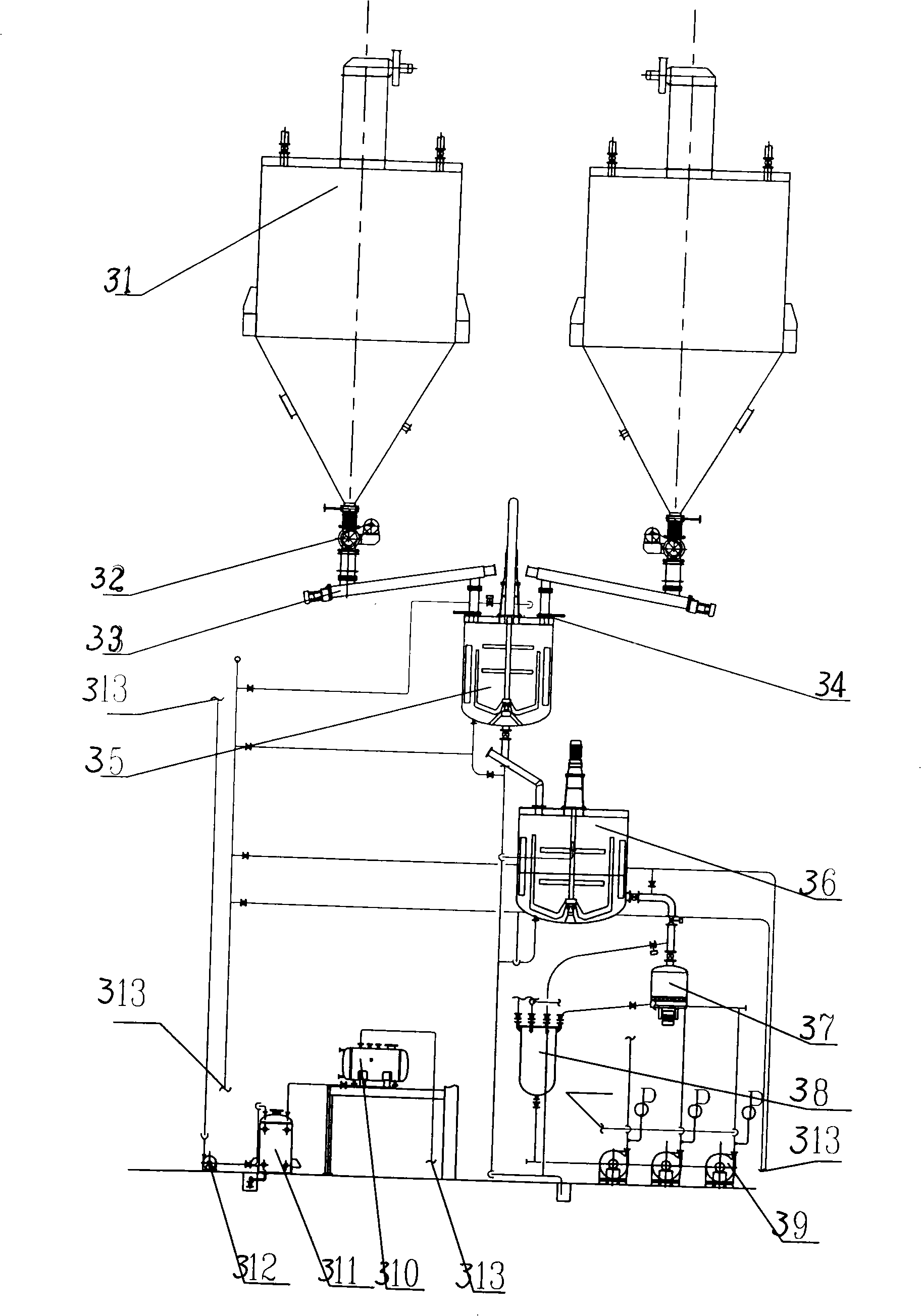

[0020] The flue gas purification process of the present invention is as follows: the flue gas enters the spray tower from the waste heat boiler at a temperature of 210°C, and injects activated carbon into the horizontal inlet flue before the flue gas enters the spray tower to remove dioxins, Heavy metals; at the same time, in the spray tower, the flue gas reacts with the alkaline neutralizer (such as lime emulsion with a concentration of 10%, 12% or 15% by weight) injected into the spray tower, and the harmful substances in the flue gas (such as HCl, HF, SOx, etc.) Most of them are purified by chemical reaction with the alkaline neutralizer; in the bag filter, when the flue gas passes through the filter layer formed by particulate matter, the gaseous pollutants can still The unreacted lime and activated carbon in the layer react to further purify. The dust collector a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com