System for drying persistent organic pollutants (POPs) polluted soil through flue gas waste heat

A technology of organic pollutants and waste heat of flue gas, applied in the restoration of polluted soil, separation of dispersed particles, chemical instruments and methods, etc., can solve pollution and other problems, achieve reduced energy consumption, low energy consumption, and easy on-site construction and installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

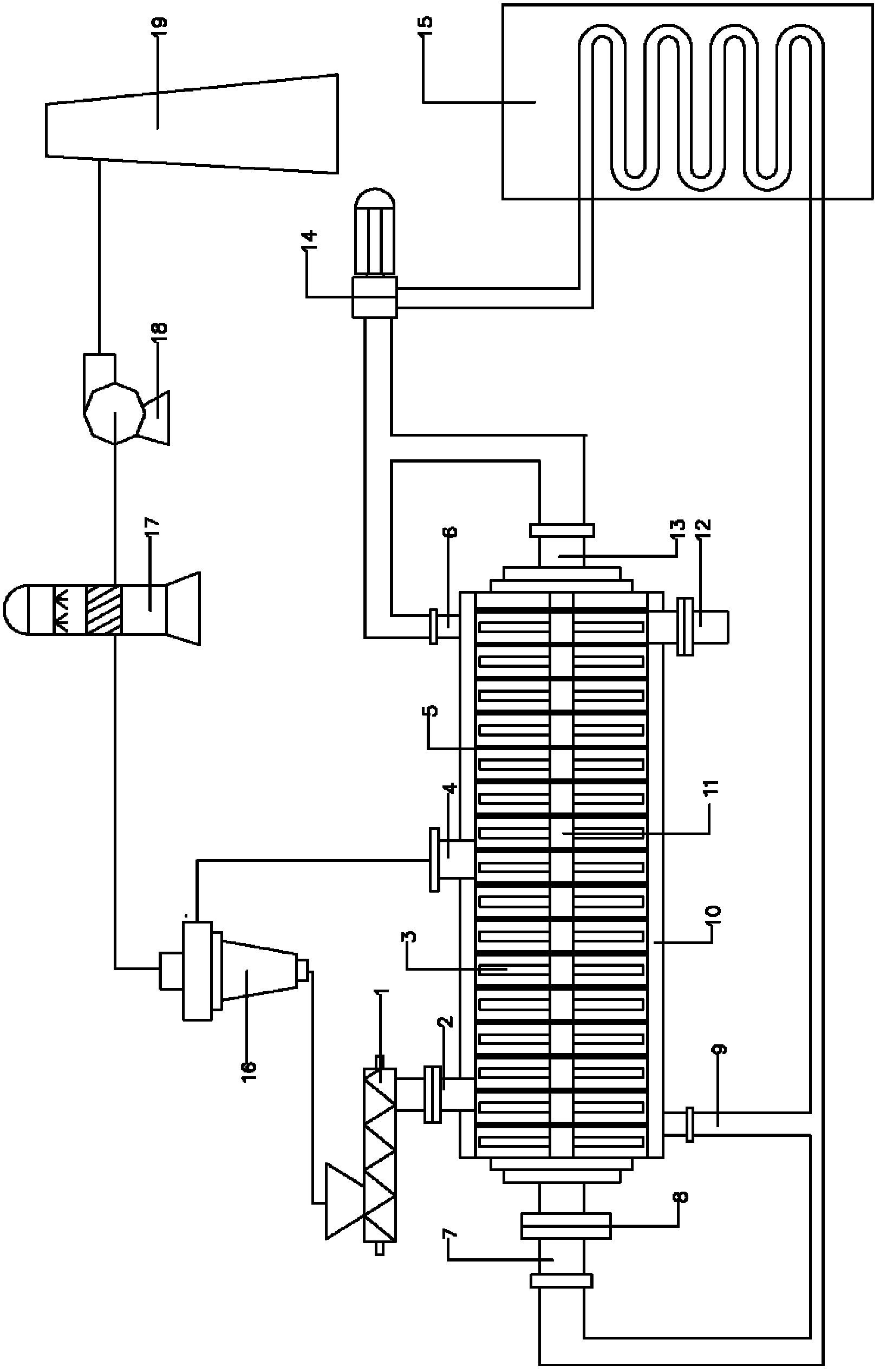

[0032] Referring to the accompanying drawings, the present invention will be described in detail below in conjunction with embodiments.

[0033] figure 1 The process flow diagram of the system for drying POP-contaminated soil with waste heat of flue gas is given, which is composed of soil drying components and tail gas treatment components.

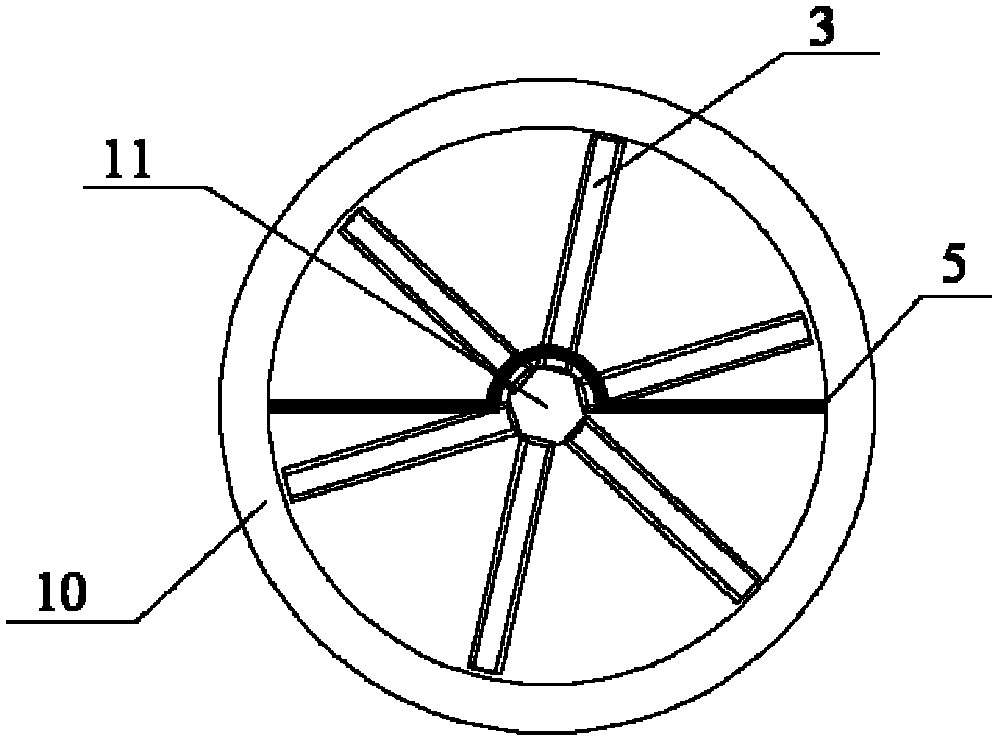

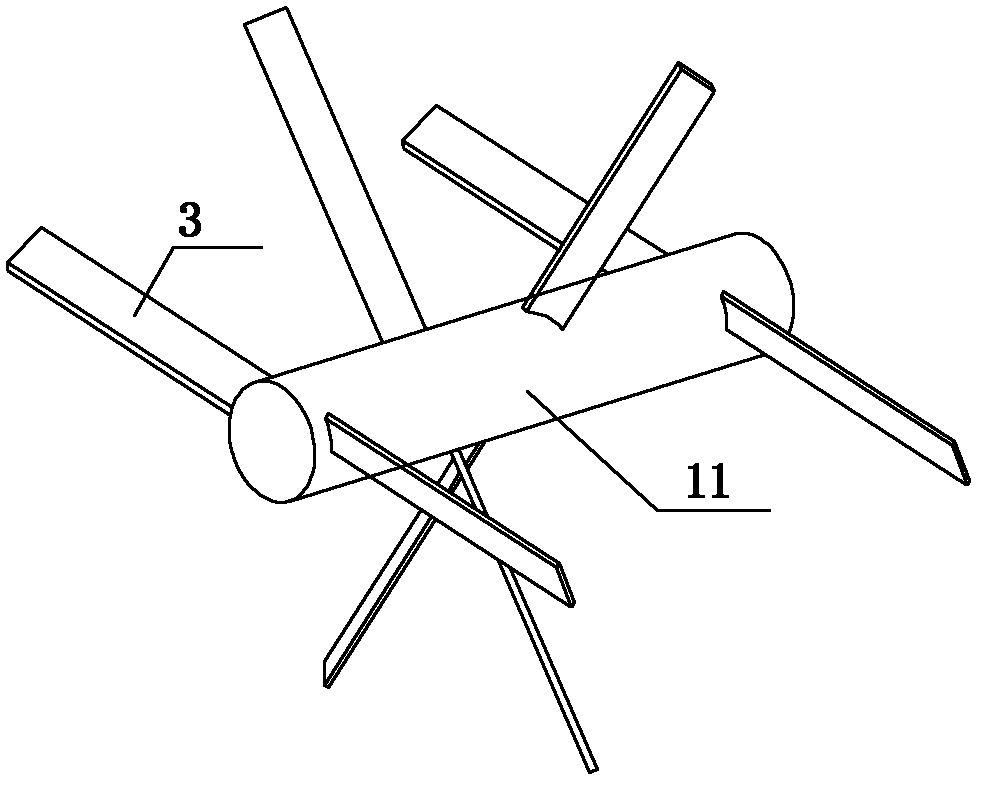

[0034] The soil drying components include a feeder 1, a self-cleaning paddle dryer, a heat transfer oil pump 14, and a heat exchanger 14, and the tail gas treatment components include a dust collector 16, a spray tower 17, an induced draft fan 18, and an exhaust tube 19; The feeder is connected to the self-cleaning paddle dryer, and the cylindrical shell of the self-cleaning paddle dryer is equipped with a hollow thermal shaft 11, and several groups of paddles 3 are arranged on the hollow thermal shaft 11, and the paddles 3 are double-bladed Arrangement distribution, self-cleaning scraper 5 is set between every two groups of paddles 3 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com