Sewage treatment plant odor collection and treatment system and method

A sewage treatment plant, odor technology, applied in the direction of gas treatment, separation methods, cleaning methods and appliances, etc., can solve the problems of small specific surface area, high cost and strong impact resistance of fillers, so as to avoid insufficient nutrients and slow down The effect of replacing the frequency and prolonging the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate those skilled in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

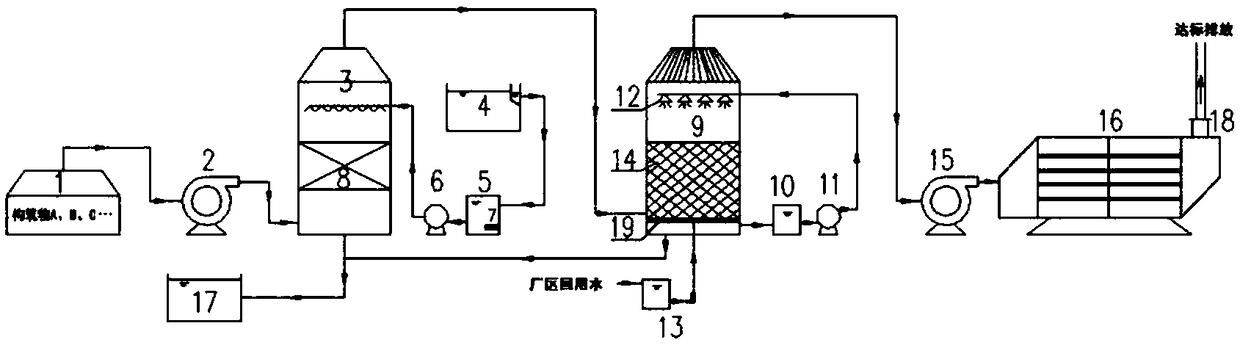

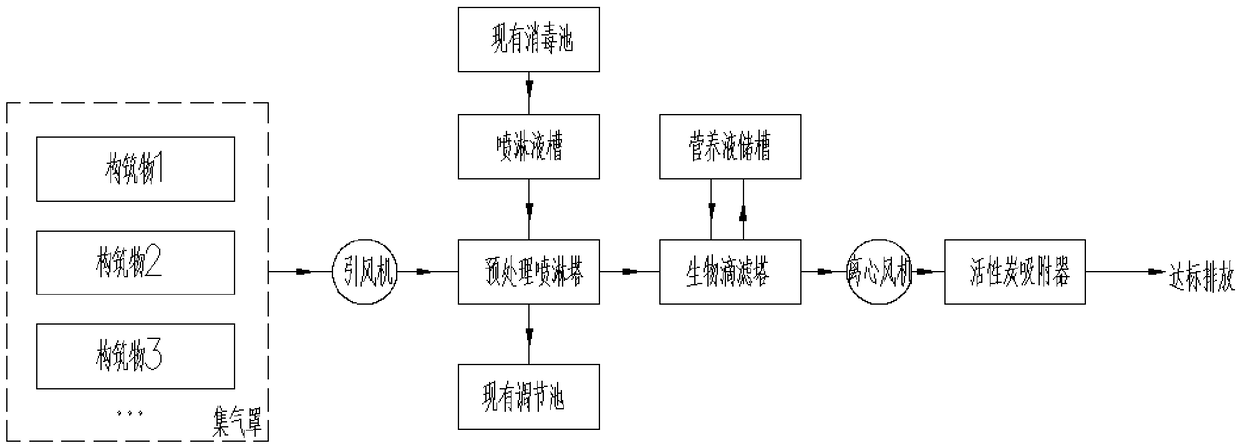

[0025] please see figure 1 , a kind of sewage treatment plant odor collection and treatment system provided by the present invention, comprises gas collecting hood 1, induced draft fan 2, pretreatment spray tower 3, disinfection pool 4, spray liquid tank 5, spray water pump 6, Heater 7, polypropylene step ring 8, biological trickling filter tower 9, nutrient solution tank 10, nutrient solution circulation pump 11, nozzle 12, backwashing device 13, packing 14, centrifugal fan 15, activated carbon adsorber 16, regulating tank 17 , terminal exhaust port 18, packing support assembl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com