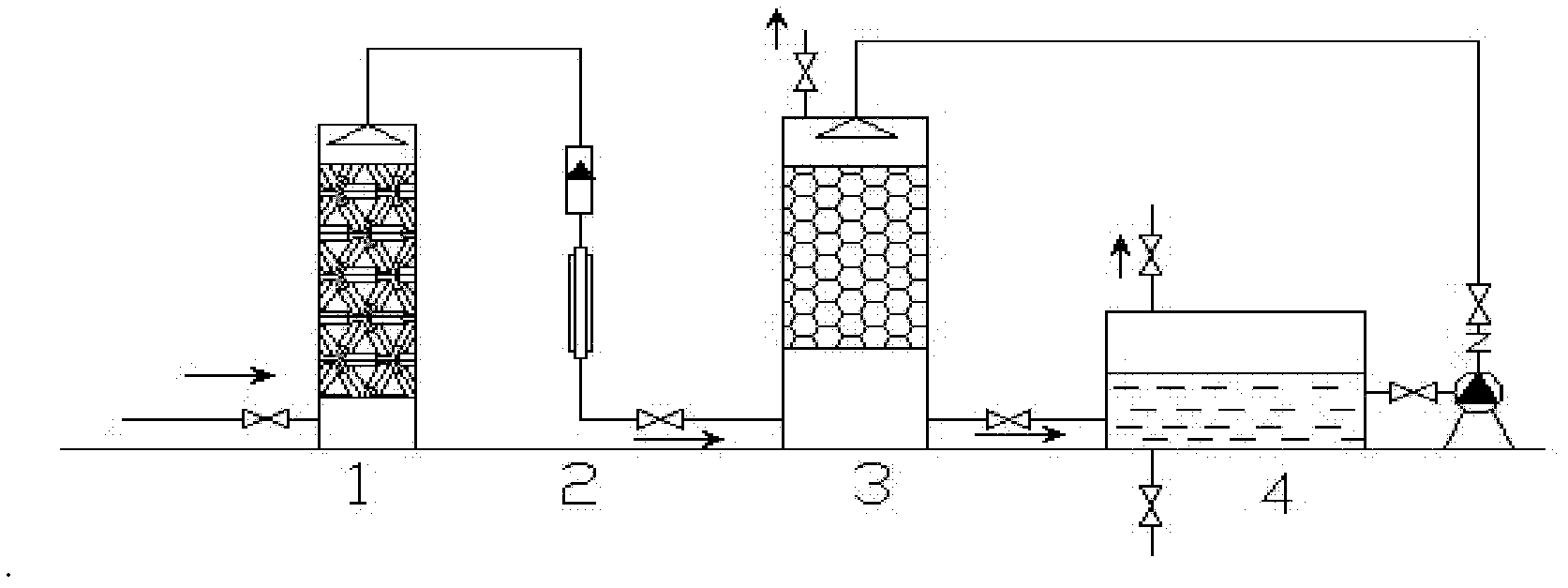

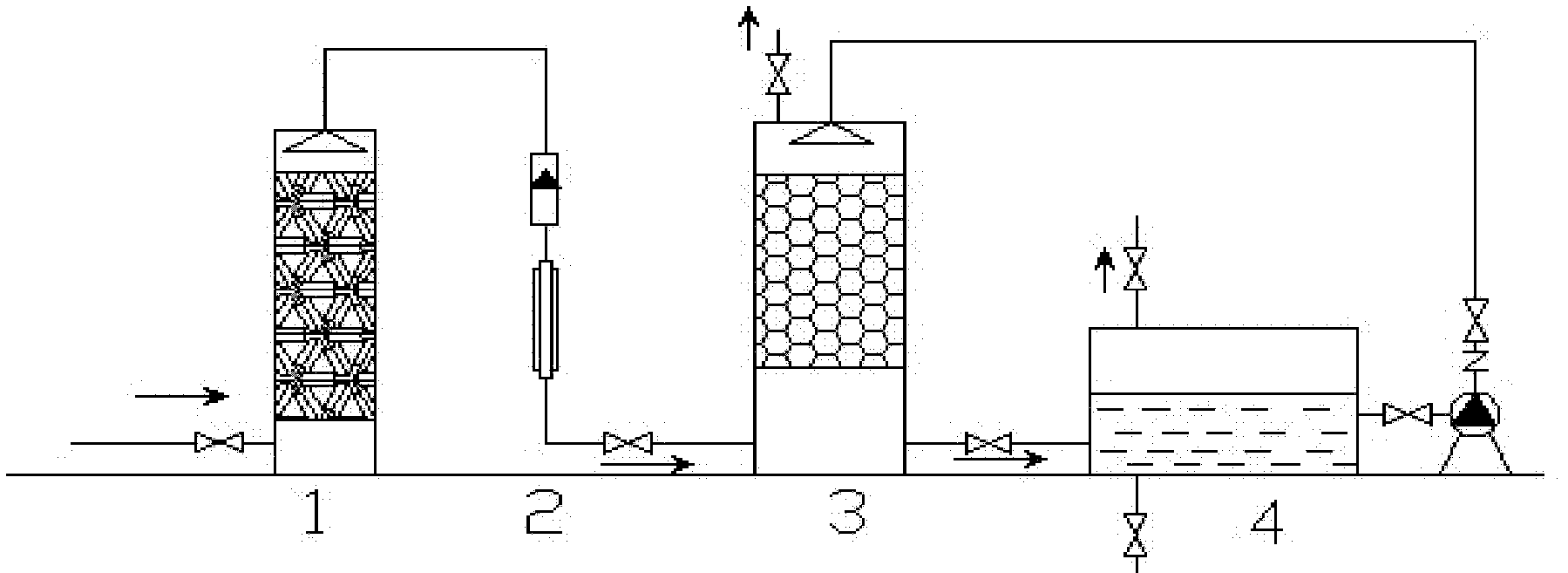

Method for removing VOCs by UV light catalytic oxidation cooperating with biofiltration

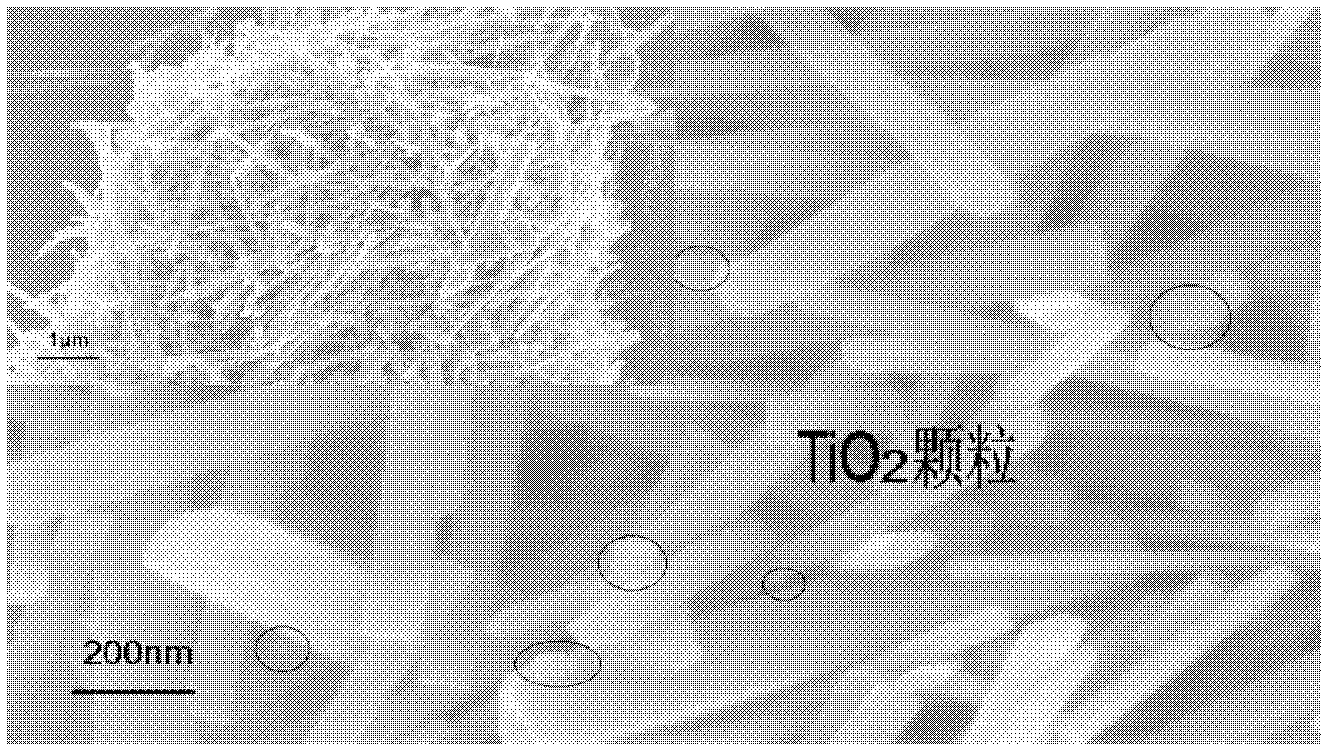

A catalytic oxidation and biological filtration technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of slow degradation of refractory organic matter, and achieve efficient and rapid degradation, promote permeability, and high specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] VOCs use o-dichlorobenzene with a higher boiling point; after the successful and stable operation of the biofiltration tower, the organic gas is passed into the spray tower at a flow rate of 1.5m 3 / min, the initial concentration of o-dichlorobenzene is 500mg / m 3 , after being pretreated by the spray tower, it enters the photocatalyst and stays for 60s, and the photocatalyst contains 10.0g nanometer Na 2 Ti 6 o 13 / TiO 2 Catalyst, irradiated with a 30W ultraviolet lamp, the partially oxidized organic waste gas after photocatalysis enters the biological filter tower, and the volume of the packing in the tower is 1m 3 , discharge after staying for 30s, the reflux flow rate of the nutrient solution is 3.5L / h, and the outlet concentration of o-dichlorobenzene in the organic gas is 4.5mg / m 3 , VOCs removal rate is 99.1%.

Embodiment 2

[0035] VOCs use o-dichlorobenzene with a higher boiling point; after the successful and stable operation of the biofiltration tower, the organic gas is passed into the spray tower at a flow rate of 3.0m 3 / min, the initial concentration of o-dichlorobenzene is 500mg / m 3 , after being pretreated by the spray tower, it enters the photocatalyst and stays for 60s. The photocatalyst contains nano-Na 2 Ti 6 o 13 / TiO 2 Catalyst 20.0g, irradiated with a 60W ultraviolet lamp, the partially oxidized organic waste gas after photocatalysis enters the biological filter tower, and the volume of the filler in the tower is 2m 3 , stay for 60s, the reflux flow rate of the nutrient solution is 3.5L / h, and the outlet concentration of o-dichlorobenzene in the organic gas is 3.5mg / m 3 , The removal rate of VOCs is 99.3%.

Embodiment 3

[0037] VOCs use toluene with a higher boiling point; after the successful and stable operation of the biofiltration tower, the organic gas is passed into the spray tower at a flow rate of 1.5m 3 / min, the initial concentration of toluene is 500mg / m 3 , after being pretreated by the spray tower, it enters the photocatalyst and stays for 60s. The photocatalyst contains nano-Na 2 Ti 6 o 13 / TiO 2 Catalyst 10.0g, irradiated with a 30W ultraviolet lamp, the partially oxidized organic waste gas after photocatalysis enters the biological filter tower, and the volume of the filler in the tower is 1m 3 , stay for 180s, the reflux flow rate of the nutrient solution is 3.5L / h, and the outlet concentration of toluene in the organic gas is 2mg / m 3 , The removal rate of VOCs is 99.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com