Process and apparatus for purifying arene oxidizing tail gas

A technology for oxidizing tail gas and aromatic hydrocarbons, applied in chemical instruments and methods, separation methods, preparation of organic compounds, etc., can solve the problems of high consumption, large consumption of combustion accelerants, large investment, etc., and achieves the effect of reducing costs and facilitating industrial applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

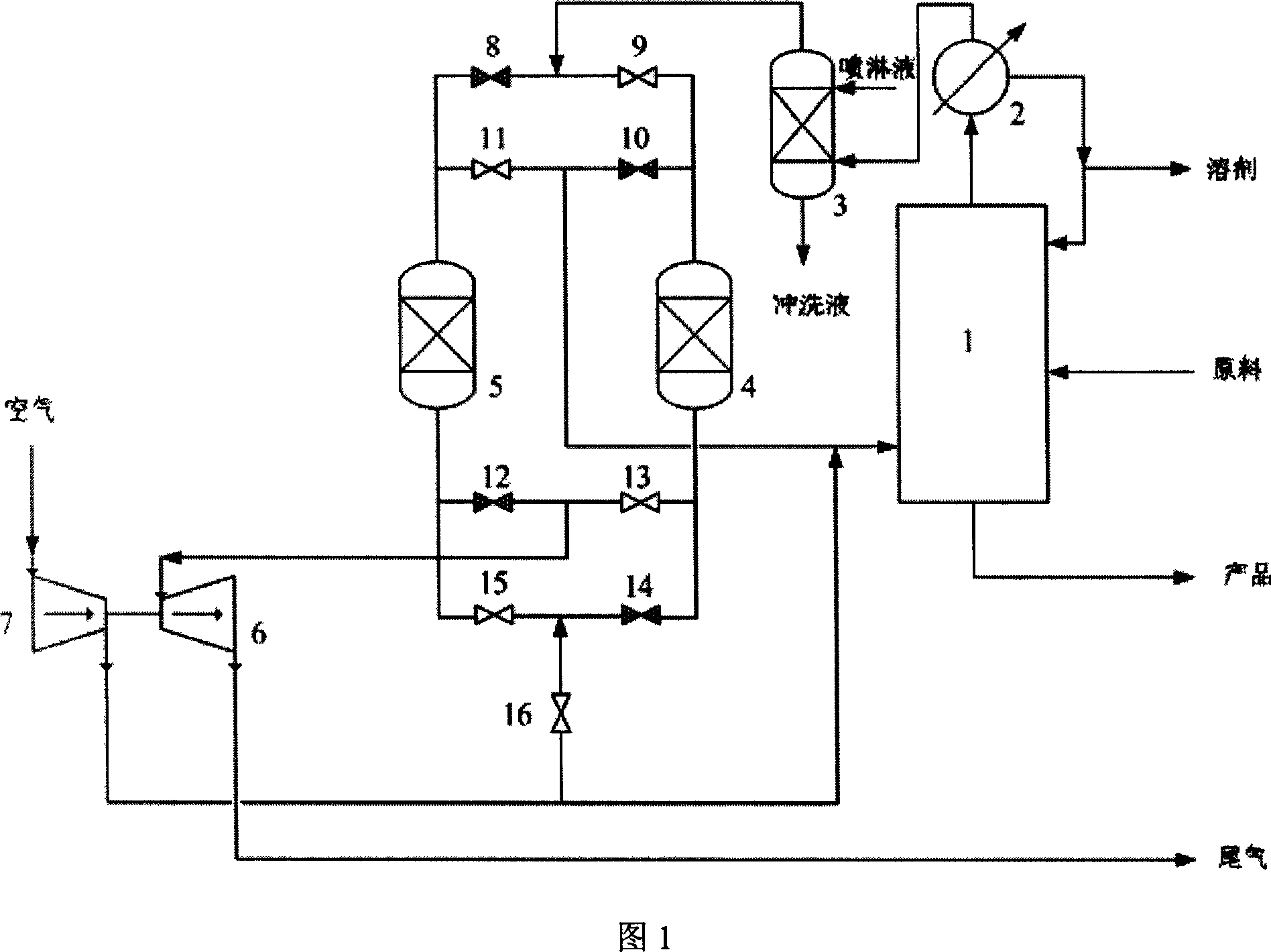

[0035] Considering the tail gas purification problem in the production process of terephthalic acid (TA), the technical scheme shown in Figure 1 is adopted. Raw material p-xylene (PX) and air are added to the oxidation reactor 1 and reacted therein to generate terephthalic acid. The tail gas after the reaction enters the condenser 2 and the washing tower 3 from the tail gas pipe to cool down and wash, and recover most of the organic components in the gas; The tail gas containing a small amount of organic matter enters the adsorption bed 4 for adsorption and purification before being discharged. Part of the compressed air drawn from the air feed pipe of the oxidation reactor enters the adsorption bed 5 through the side line desorption air pipe to contact with the saturated adsorbent in the bed, desorbs organic matter and then enters the oxidation reactor for recycling. The adsorption bed 4 and the adsorption bed 5 are regularly switched through the switching valves 8-15 to real...

Embodiment 2

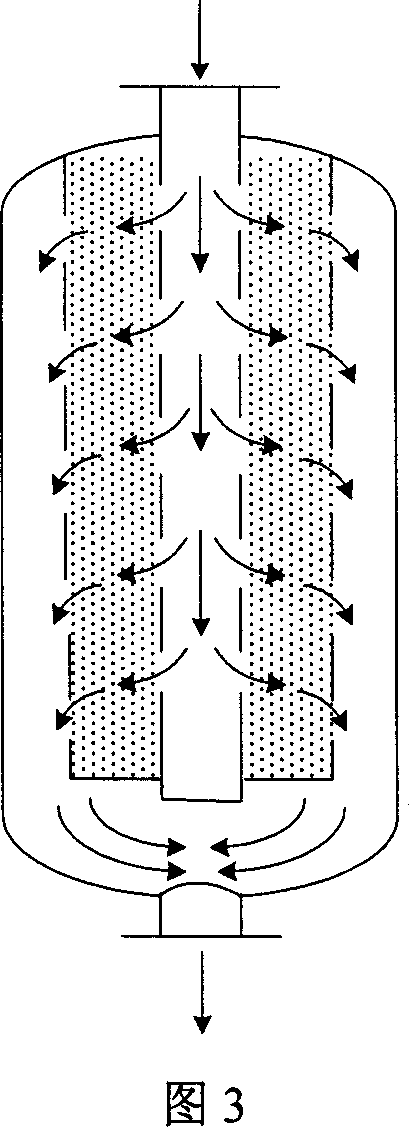

[0044] Considering the tail gas purification problem in the terephthalic acid production process, the technical scheme shown in Figure 1 is still adopted. The difference from Example 1 is that the adsorption bed adopts the radial bed shown in Figure 3 to reduce the pressure drop of the bed layer, and at the same time, the adsorbent adopts activated carbon fiber. The operating parameters of the adsorbent and the adsorption bed are listed in Table 4, and the remaining operating parameters are the same as in Example 1.

[0045] Adsorbent name

[0046] It can be seen from Table 4 that activated carbon fibers have a higher adsorption capacity than activated carbon particles, and the bed pressure is reduced. In this way, less adsorbent is needed to achieve the same purification purpose. In addition, the use of radial beds reduces the distance for gas to pass through the adsorbent bed, which greatly reduces the total pressure drop of the bed, which is beneficial to reduce e...

Embodiment 3

[0048] Considering the tail gas purification problem in the terephthalic acid production process, the technical scheme shown in Figure 4 is adopted. The main part is similar to Figure 1, the difference is that Figure 4 uses system nitrogen as the desorption gas, and the nitrogen comes from the terephthalic acid dryer. A part of the used purge gas is drawn from it, and the desorbed organic matter is returned to the desorption gas scrubber 16 for recovery and treatment along with the gas. Adsorption bed 4 performs adsorption operation at higher pressure and lower temperature, and the desorption gas used in adsorption bed 5 has a higher temperature and lower pressure, which is beneficial to the desorption operation. The operating parameters of adsorption bed 4 are the same as those in embodiment 1 or embodiment 2, and the operating parameters of adsorption bed 5 are listed in Table 5.

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com