Secondary zinc oxide slurry treating light concentration SO2 flue gas method and device thereof

A low-concentration zinc oxide technology, applied in chemical instruments and methods, separation methods, dispersed particle separation and other directions, can solve the problems of affecting the reuse of gypsum, low solubility, secondary environmental pollution, etc., and achieves technical conditions that are easy to control, The effect of high system operation rate and compact system configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

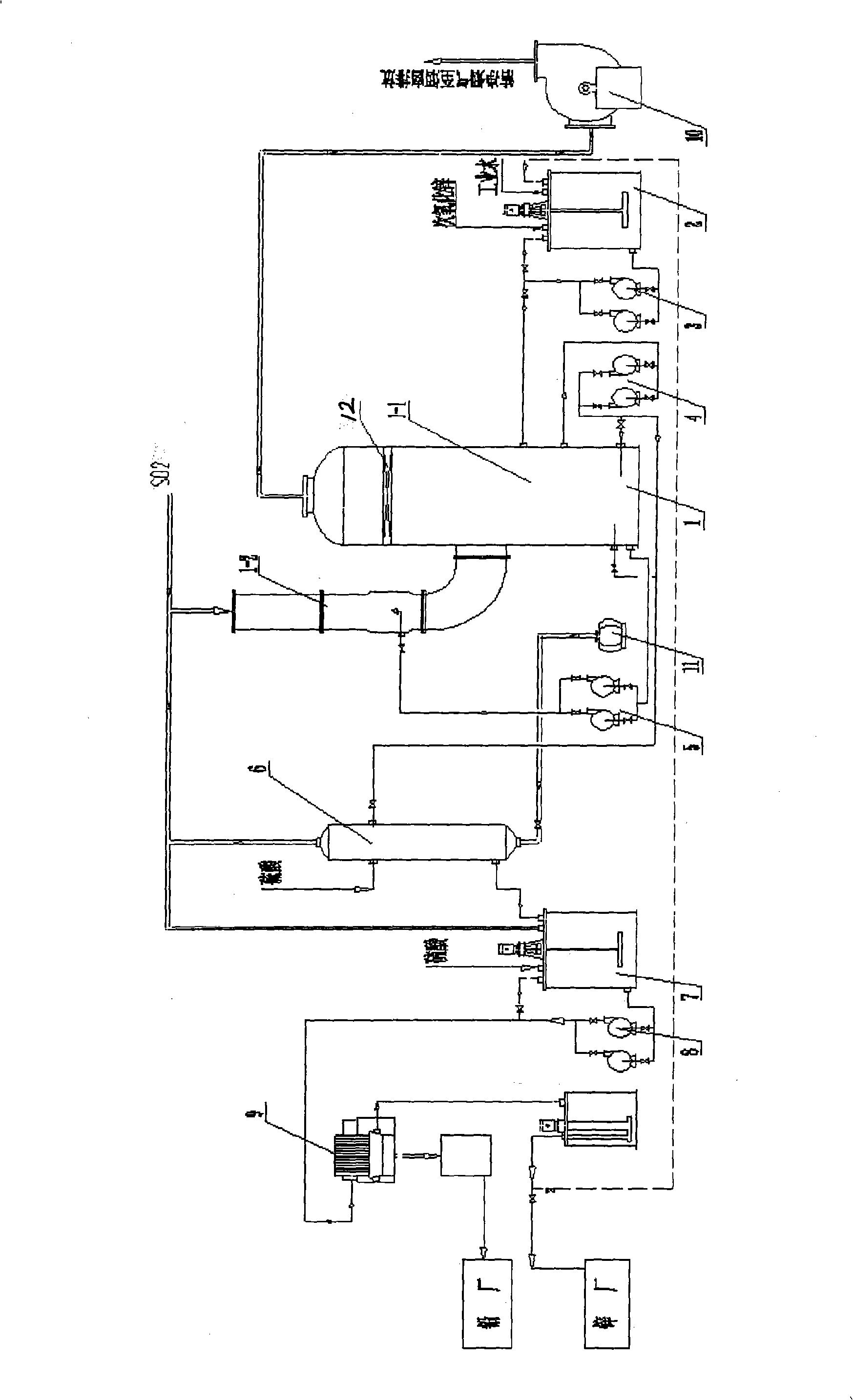

[0028] A kind of secondary zinc oxide slurry to treat low-concentration SO 2 A fume method comprising the steps of:

[0029] The first step: prepare a slurry with a solid content of 10-18% in a mechanically stirred slurry mixing tank 2 with water or filtrate from a filter press and secondary zinc oxide;

[0030]The second step: use a pump to transport the prepared slurry to the liquid collection tank 1-1 of 1 of the turbulent scrubber;

[0031] The third step: beat the slurry in the sump 1-1 into the nozzle of the reverse spray tower 1-2 of the turbulence scrubber 1 with the circulation pump 5, and the slurry is ejected from the nozzle from bottom to top, which is consistent with the The gas collides from top to bottom in the above-mentioned reverse spray tower, and the SO2 in the gas is absorbed by the slurry to generate zinc sulfite, lead sulfite and a small amount of zinc sulfate. The zinc sulfite and lead sulfite are still suspended in the slurry. Zinc sulfate is dissolv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com