Melamine and ammonium carbonate joint production technology

A technology of melamine and process is applied in the field of co-production process of melamine and ammonium bicarbonate to achieve the effects of saving power consumption, low manufacturing cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

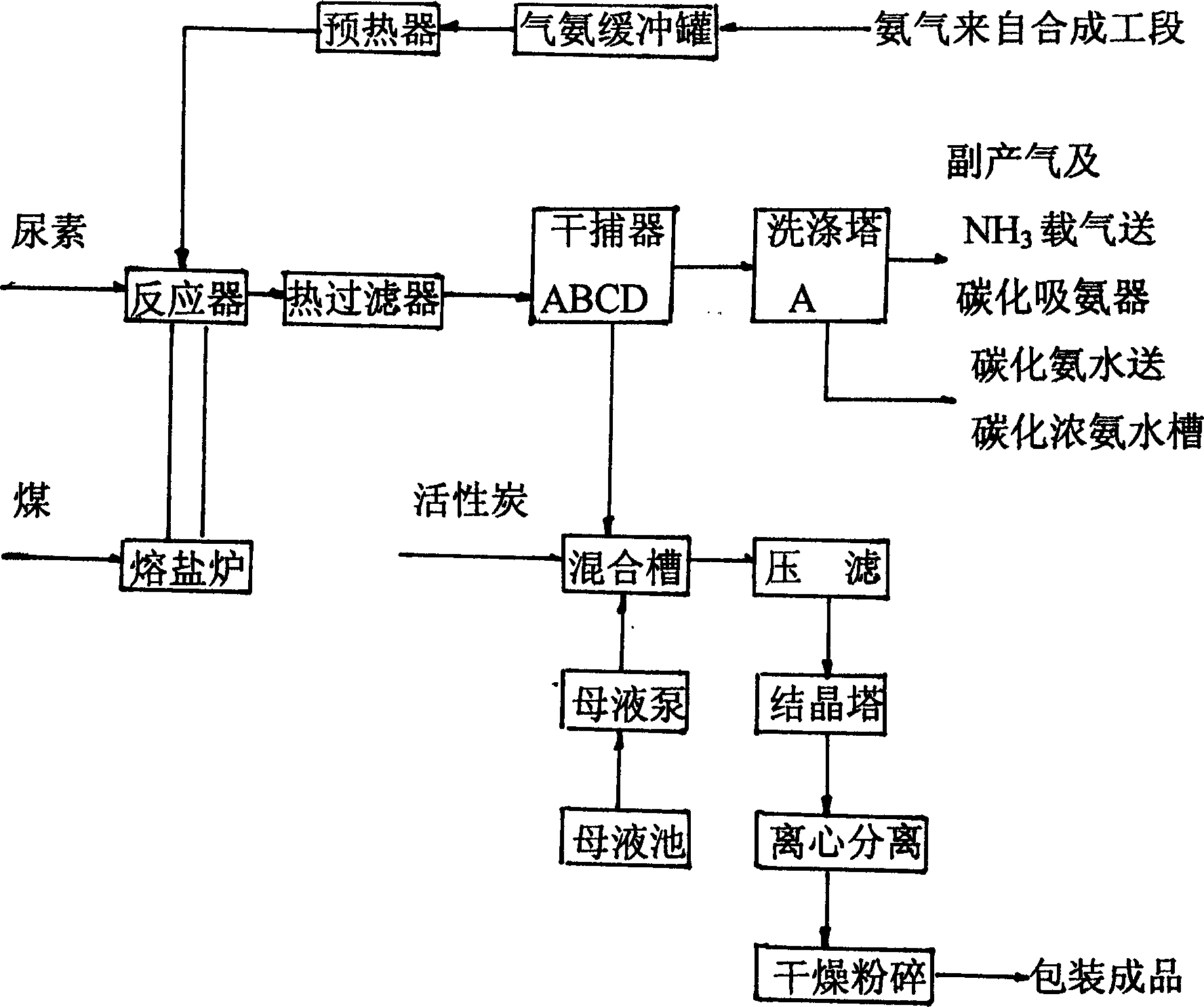

[0019] Referring to Figure 1, the co-production process of melamine and ammonium bicarbonate is to preheat the 0.10-0.20Mpa pure ammonia gas from the synthetic ammonia cooler to 250-350°C through steam and molten salt, and then enter the flow stream from the bottom of the fluidized bed. The fluidized bed reactor is used as the carrier gas, and the urea that is pressed into the feeder with air is sent into the fluidized bed. Under the action of the catalyst, it is decomposed at 370-420°C under normal pressure to produce melamine and The reaction gas of carbon dioxide and ammonia; the reaction gas is roughly filtered by the hot gas filter and then enters the dry trap to cool down naturally, so that the melamine in the reaction gas is precipitated and the crude melamine is obtained after 5-7 days of parking; and it contains carbon dioxide, ammonia and carrier gas The tail gas of ammonia is preliminarily washed with ammonia water to remove dust and cool down, and then enters the am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com