System and method for producing trichlorosilane by cold hydrogenation of silicon tetrachloride

A technology of silicon tetrachloride and trichlorosilane, applied in the direction of halogenated silicon compounds, halogenated silanes, etc., can solve the problems of hydrogenation reactors and pipes, inner wall wear of valves, deterioration of trichlorosilane product quality, refrigerant and heat medium Waste and other problems, to achieve the effect of increasing the primary hydrogenation rate, lowering the temperature, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

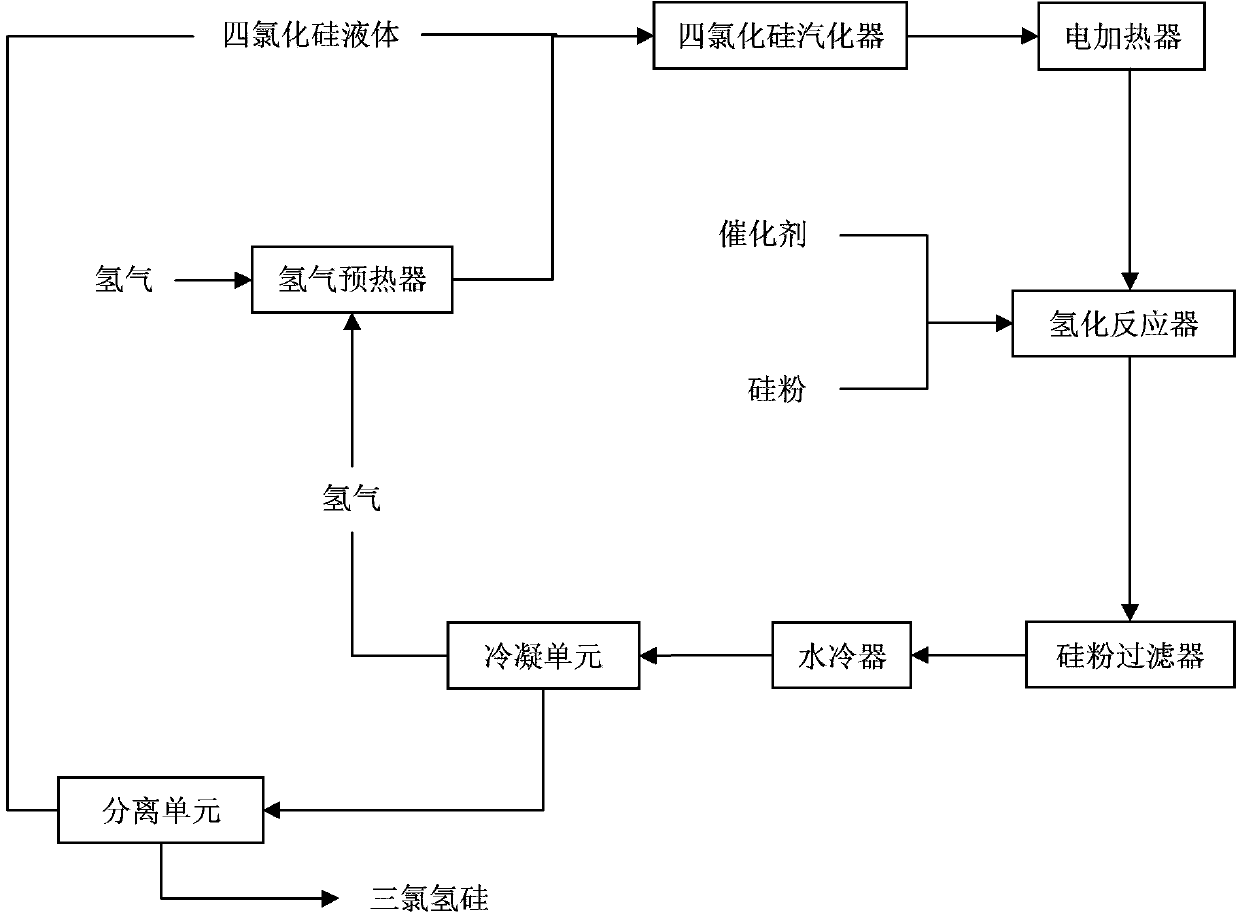

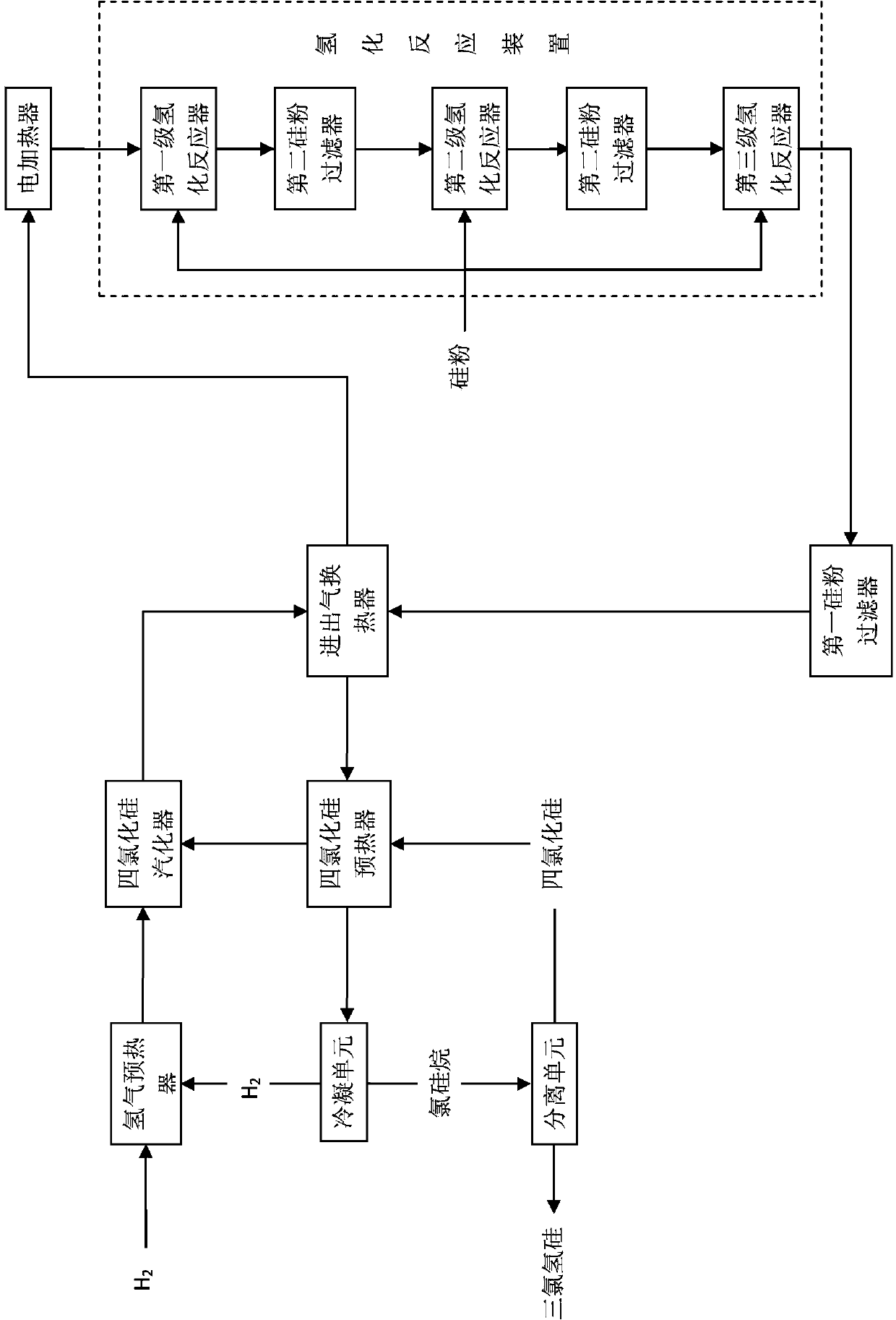

[0027] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, specific embodiments will be described in detail below with reference to the accompanying drawings.

[0028] The system for producing trichlorosilane by cold hydrogenation of silicon tetrachloride provided in the embodiments of the present invention may include a hydrogenation reaction device for cold hydrogenating raw materials comprising silicon tetrachloride, hydrogen and silicon powder to generate the desired Trichlorosilane. The hydrogenation reaction device includes a series of multi-stage hydrogenation reactors. During operation, silicon tetrachloride passes through each stage of hydrogenation reactors sequentially, and cold hydrogenation reactions are carried out in them respectively. The temperature of the total reaction product gas discharged from the hydrogenation reaction device is about 550°C, which contains about 25% trichlorosilane, 75%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com