Method and system for deep purification of polysilicon reduction tail gas

A polysilicon and tail gas technology, applied in chemical instruments and methods, separation methods, liquefaction, etc., can solve the problems of large cooling capacity consumption, large fluctuations in hydrogen quality, and increased load on the absorption tower, so as to reduce costs, energy consumption, and The effect of cooling energy consumption and reducing delay time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a method for deep purification of polysilicon reduction tail gas. The reduction tail gas comes from the upstream polysilicon production process, and specifically includes a mixed gas of hydrogen, hydrogen chloride, chlorosilane and a small amount of impurities, wherein the chlorosilane includes silicon tetrachloride, trichloro A mixed gas of hydrogen silicon and dichlorodihydrogen silicon, the impurities include phosphorus, boron, iron, etc., and the content of the impurities in the reducing tail gas is 2ppm-5ppm.

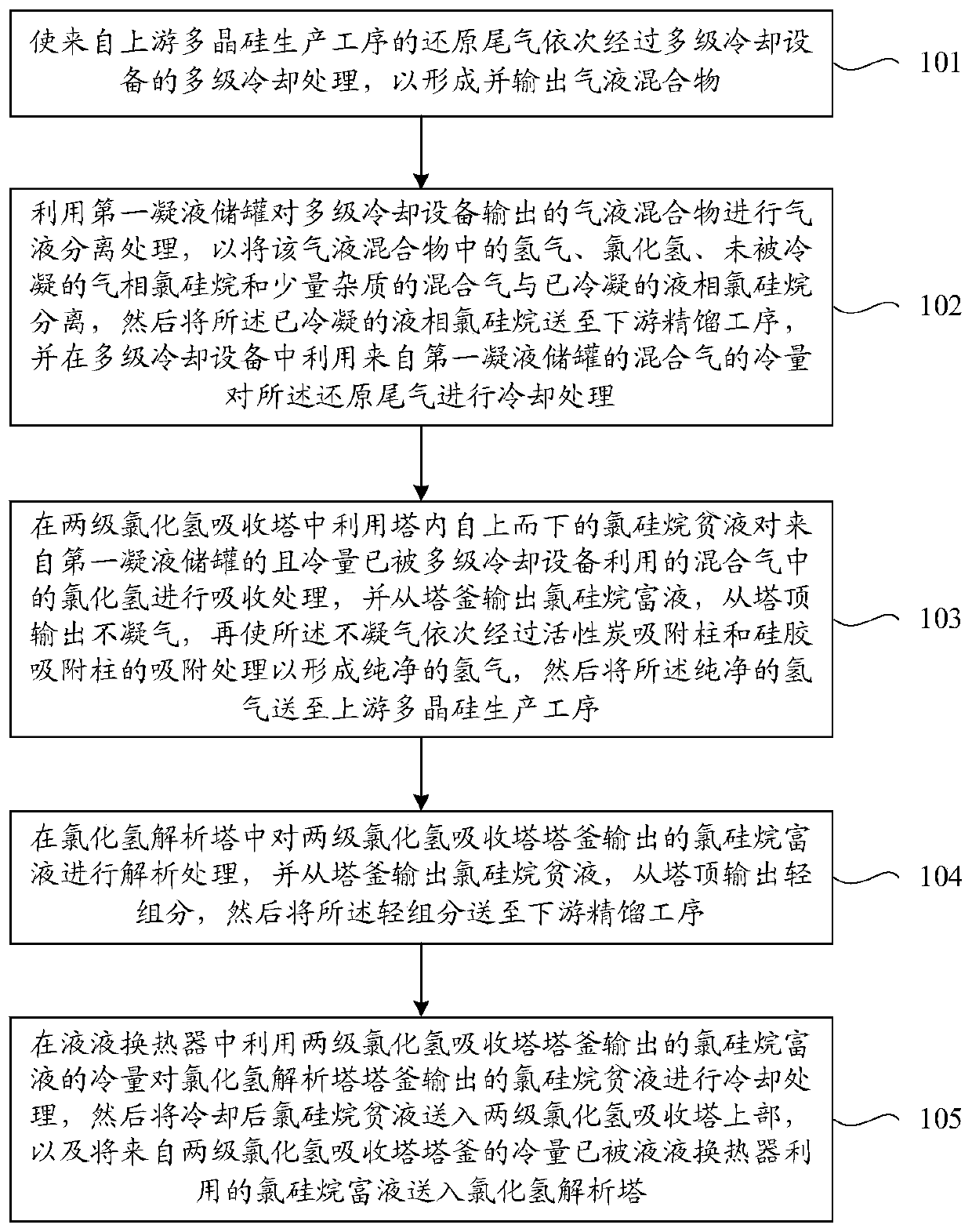

[0042] Such as figure 1 As shown, the purification method includes the following steps S101 to S105.

[0043] S101. Make the reduction tail gas from the upstream polysilicon production process sequentially undergo multi-stage cooling treatment of multi-stage cooling equipment to form and output a gas-liquid mixture, which includes hydrogen, hydrogen chloride, uncondensed gas phase chlorosilane and a small amount of impurities. Mixed...

Embodiment 2

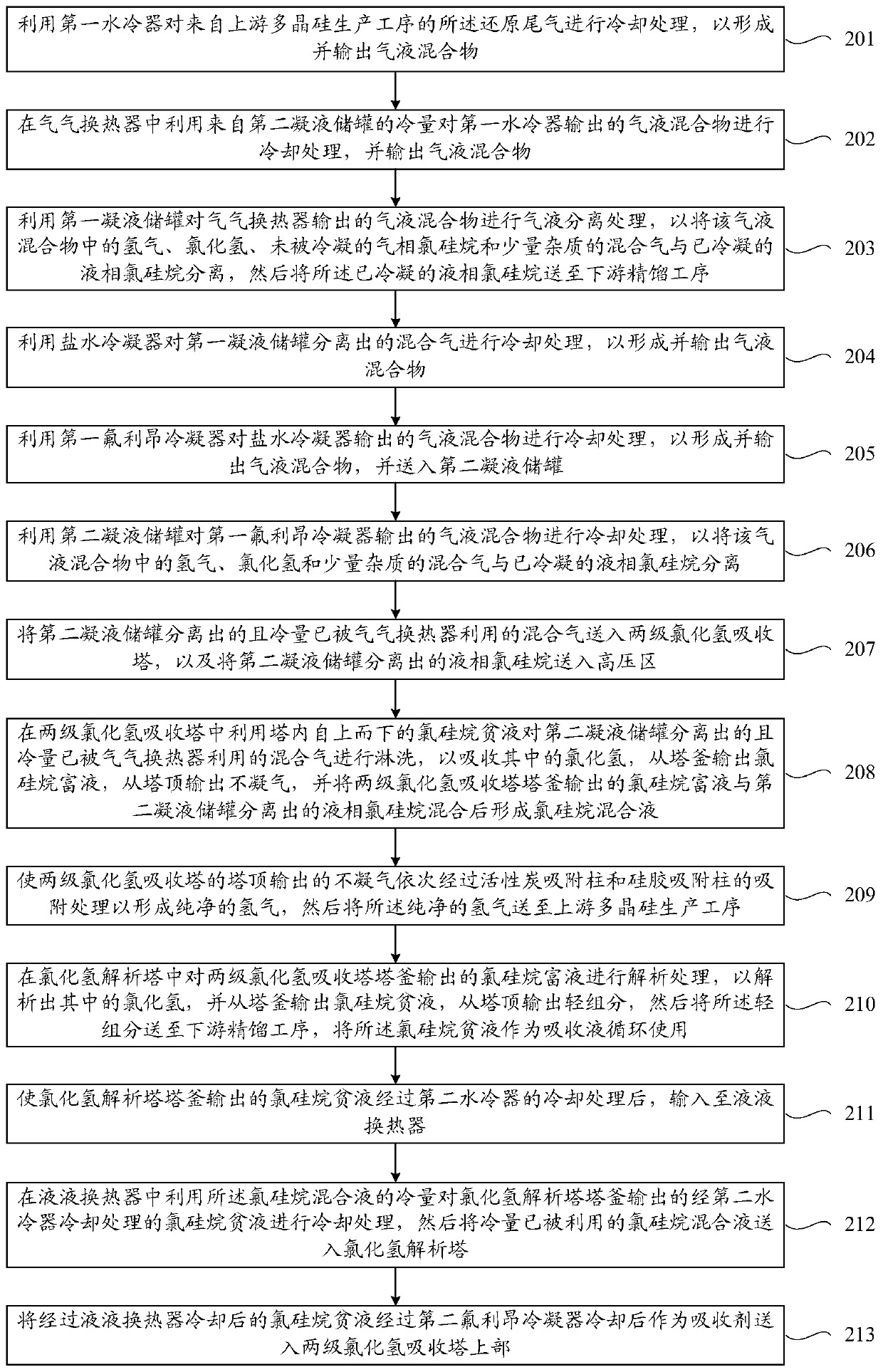

[0058] This embodiment provides a method for deep purification of polysilicon reduction tail gas. Such as figure 2 As shown, the purification method includes the following steps S201 to S213.

[0059] It should be noted that the first water cooler, air-gas heat exchanger, first condensate storage tank, first delivery pump, brine condenser, first Freon condenser, and second condensate storage tank involved in the following steps and the second delivery pump are located in the low-pressure area, the pressure range is 0.3-0.5MPa, preferably 0.45MPa. The compressor, two-stage hydrogen chloride absorption tower, liquid-liquid heat exchanger, hydrogen chloride desorption tower, second water cooler, circulation pump, second Freon condenser, deep cooler, activated carbon adsorption column and silica gel adsorption column are all located in the high-pressure area. Among them, the pressure range adopted by the two-stage hydrogen chloride absorption tower is 1.4~1.7MPa, preferably 1.6...

Embodiment 3

[0111] This embodiment provides a polysilicon reduction tail gas deep purification system. The reduction tail gas comes from the upstream polysilicon production process, and specifically includes a mixture of hydrogen, hydrogen chloride, chlorosilane and a small amount of impurities, wherein the chlorosilane includes silicon tetrachloride, trichloro A mixed gas of hydrogen silicon and dichlorodihydrogen silicon, the impurities include phosphorus, boron, iron, etc., and the content of the impurities in the reducing tail gas is 2ppm-5ppm.

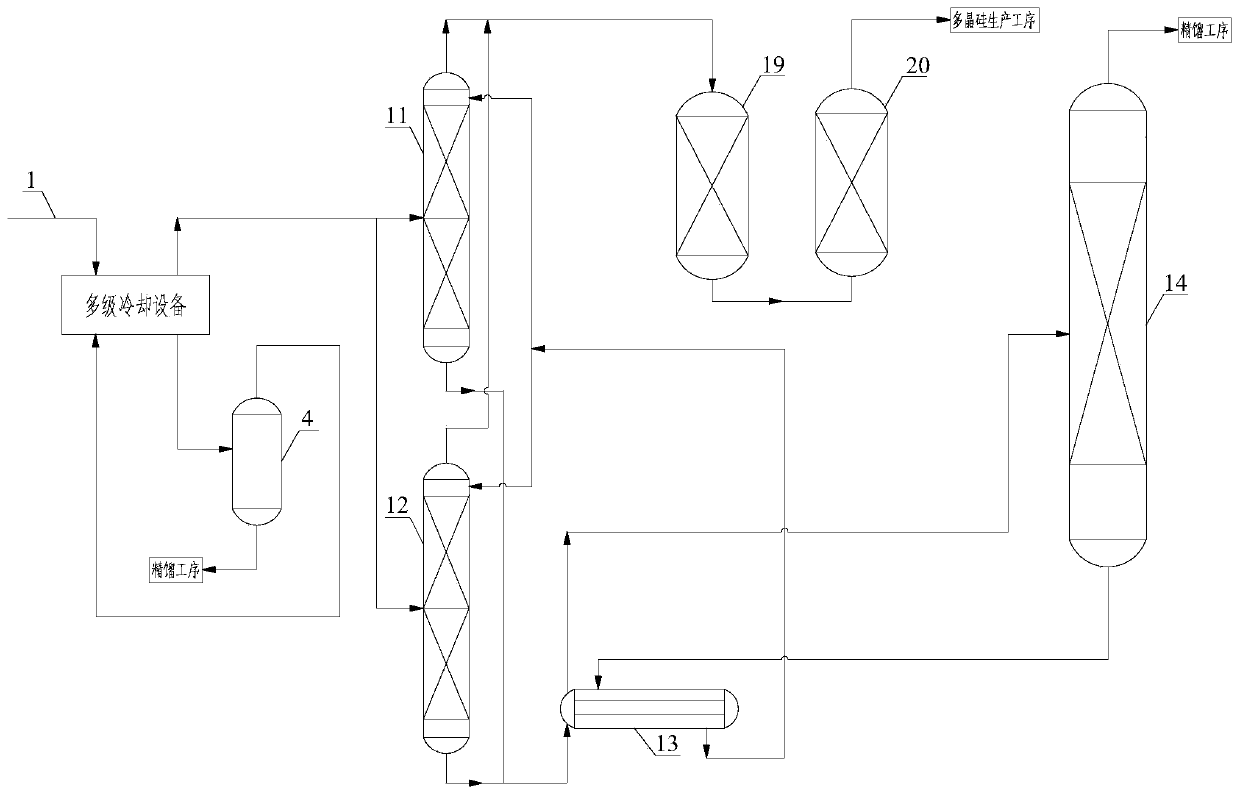

[0112] Such as image 3 and 4 As shown, the purification system includes multi-stage cooling equipment, the first condensate storage tank 4, two-stage hydrogen chloride absorption towers 11 and 12, activated carbon adsorption column 19, silica gel adsorption column 20, hydrogen chloride desorption tower 14 and liquid-liquid heat exchanger 13.

[0113] The multi-stage cooling equipment is used to receive the reduction tail gas 1 from the ups...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com