Vacuum four-column differential pressure thermal coupling device and method for refining of crude phenol

A differential pressure thermal coupling, crude phenol technology, applied in the field of coal chemical industry, can solve the problems of high energy consumption, complex operation, low product purity, etc., and achieve the effect of high product recovery rate, good product purity and yield, and saving heating load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

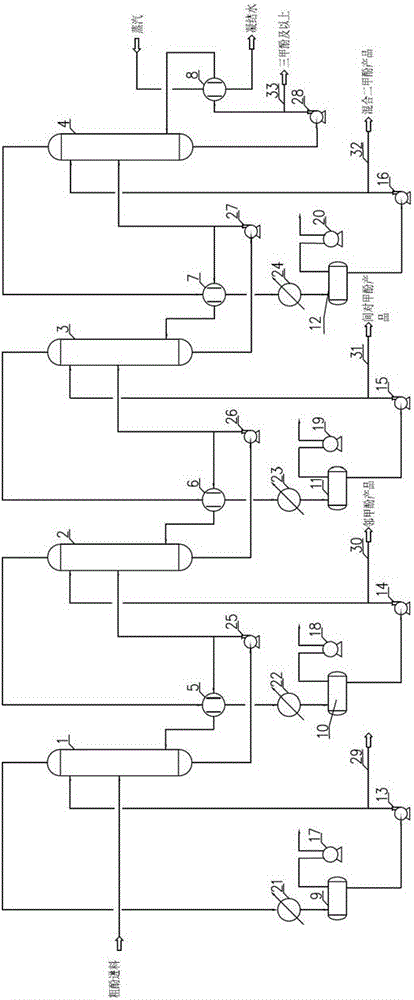

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] figure 1 Schematically shows a vacuum four-tower differential pressure thermal coupling method and device for refining crude phenol according to the present invention.

[0034] A kind of vacuum four-tower differential pressure thermal coupling method for refining crude phenol provided in this embodiment includes:

[0035] The phenol tower connected to the external crude phenol extraction device through a pipeline, the top of the phenol tower 1 is connected with a phenol rectification combination through a pipeline, and the phenol rectification combination includes a phenol tower cooler 21 connected in sequence by a pipeline provided , the phenol tower reflux tank 9 and the phenol tower heavy reflux pump 13, the phenol tower reflux tank 9 is also connected with the phenol tower vacuum pump 17, and the output end of the phenol tower heavy reflux pump 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com