Lithium battery pole piece coater drying system adopting heat pump heat recovery and barrel pump circulating

A drying system and heat recovery technology, applied in heat recovery systems, battery electrodes, electrode collector coatings, etc., can solve the problems of expensive spray towers, inability to completely remove exhaust gas pollutants, and large space occupation , to achieve the effect of large latent heat of phase change, saving power consumption, and saving plant space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

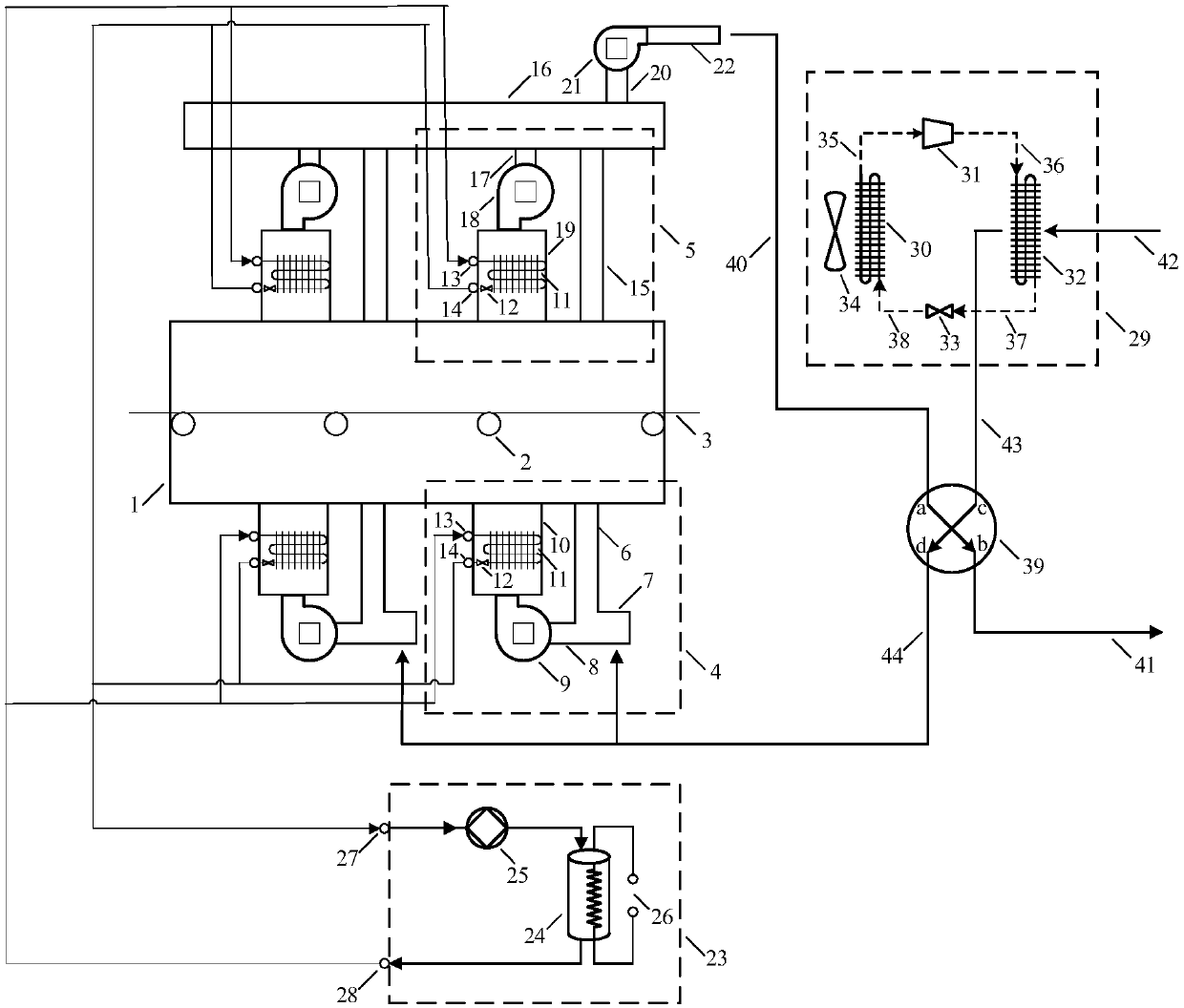

[0058] refer to figure 1 , a lithium battery pole piece coating machine drying system using heat pump heat recovery and barrel pump circulation, including: the main structure includes a drying tunnel 1, a lower heating assembly 4, an upper heating assembly 5, a host 23, a heat pump system 29 and air heat exchanger 39.

[0059] A supporting roller 2 is arranged in the drying tunnel 1 , and the pole piece 3 moves on the supporting roller 2 .

[0060] The lower heating assembly 4 arranged below the drying tunnel 1 contains refrigerant passages and air passages for mutual heat exchange. The refrigerant passages of the lower heating assembly 4 communicate with the refrigerant passages of the host 23, and the air passages of the lower heating assembly 4 are used for Provide heated air to the drying tunnel 1, the lower heating assembly 4 includes the lower return air duct 6, the fresh air duct 7, the lower fan 9, the lower heating box 10 and the condenser 11, the lower return air du...

Embodiment 2

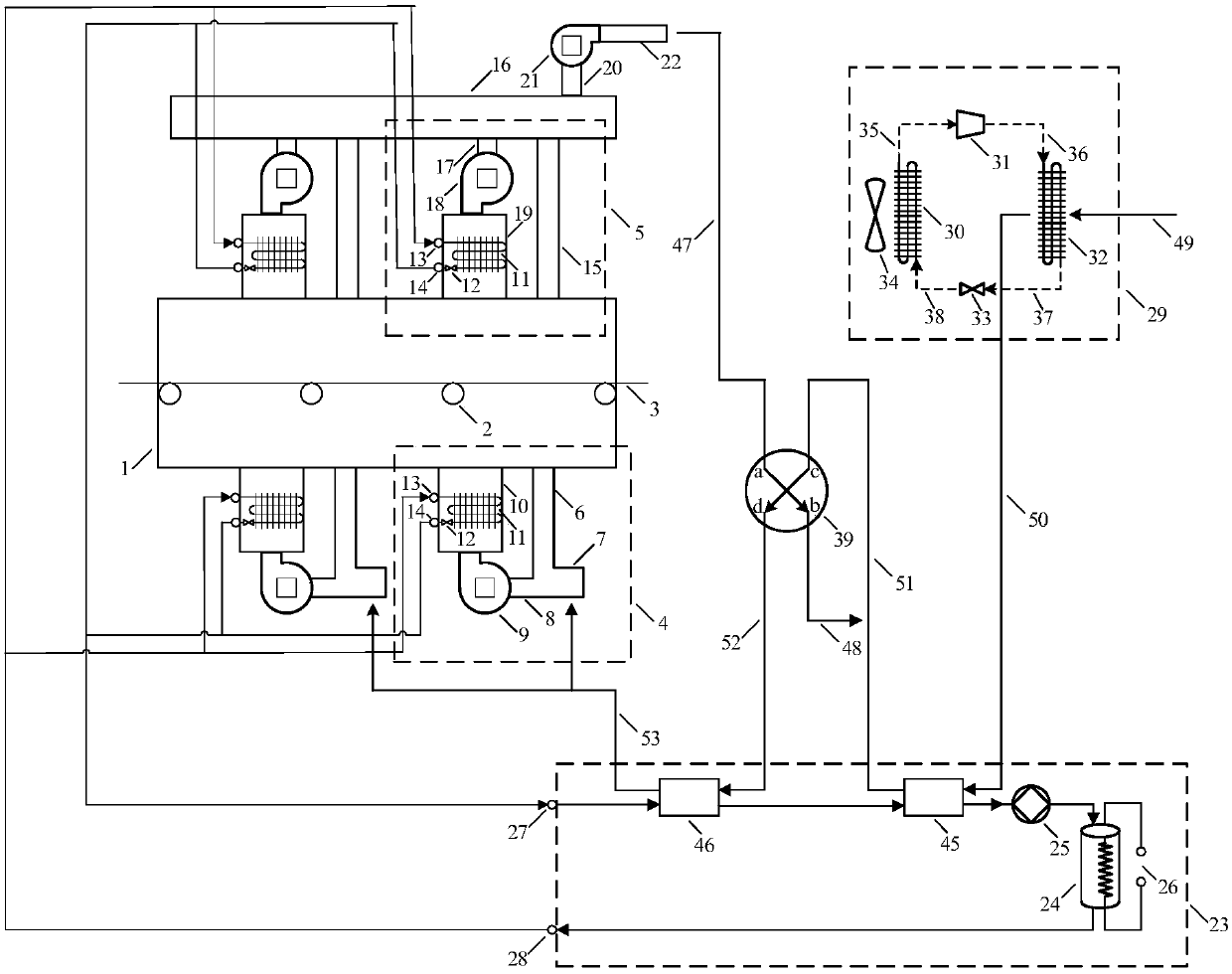

[0075] In the barrel pump cycle of Embodiment 1, if the temperature of the refrigerant in front of the refrigerant pump 25 is too high, causing the refrigerant pump 25 to fail to work normally, you can refer to the solution of Embodiment 2.

[0076] refer to figure 2 , compared with Embodiment 1, in the host machine 23, a first subcooler 45 and a second subcooler 46 are added before the refrigerant pump 25.

[0077] The host 23 is also provided with a first subcooler 45 and a second subcooler 46, the first subcooler 45 and the second subcooler 46 both include refrigerant channels and air channels, the host liquid pipe interface 27, the second The refrigerant channel of the subcooler 46, the refrigerant channel of the first subcooler 45, the refrigerant pump 25, the refrigerant barrel 24 and the air pipe interface 28 of the main engine are sequentially connected through the refrigerant connecting pipe to form the main engine part of the barrel pump cycle One end of the air ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com