Separation method and device for reforming reaction product

A reforming reaction and product technology, applied in the petroleum industry, hydrocarbon distillation, etc., can solve the problems of consuming cooling load, increasing heating load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further explained below in conjunction with the examples, but the examples do not limit the present invention in any form.

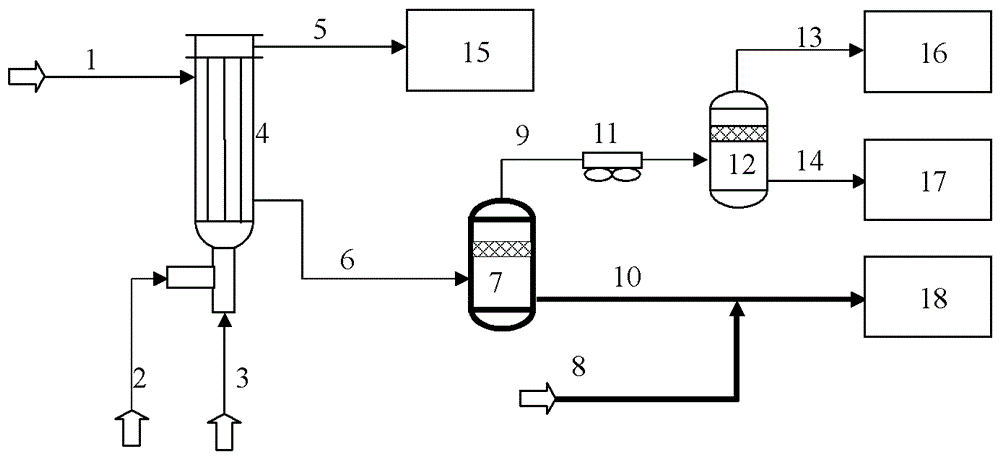

[0024] Taking the 800,000-ton / year continuous reforming unit of an oil refinery as an example, the pre-separation process of the present invention is illustrated. This device adopts UOP coaxial continuous reforming process. The reforming reaction temperature is 380~520℃ and the pressure is 0.34~0.45MPa. , and then cooled to about 40°C by air cooling, and enter the subsequent separation and re-contact part to separate circulating hydrogen and high-purity hydrogen. The analysis and composition data of the reforming reaction products are shown in Table 1.

[0025] number of carbon atoms alkanes Naphthenic Aromatics C1 11.91 - - C2 2.38 - - C3 0.0013 - - C4 0.039 - - C5 7.71 0.58 - C6 10.58 4.64 3.56 C7 7.51 8.30 3.37 C8 8.12 8.14 7.26 C9 5.56 5.67 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com