Heat Utilization System and Heat Utilization Method for Middle Stage Oil of Catalytic Cracking Unit

A catalytic cracking unit and heat technology, which is applied to the heat utilization system and the heat utilization field of the oil in the first middle section of the catalytic cracking unit, can solve the problems that the heat cannot be effectively utilized and the energy consumption of the device is large, so as to improve the heat utilization grade and reduce the heating rate. load, the effect of reducing the amount of steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

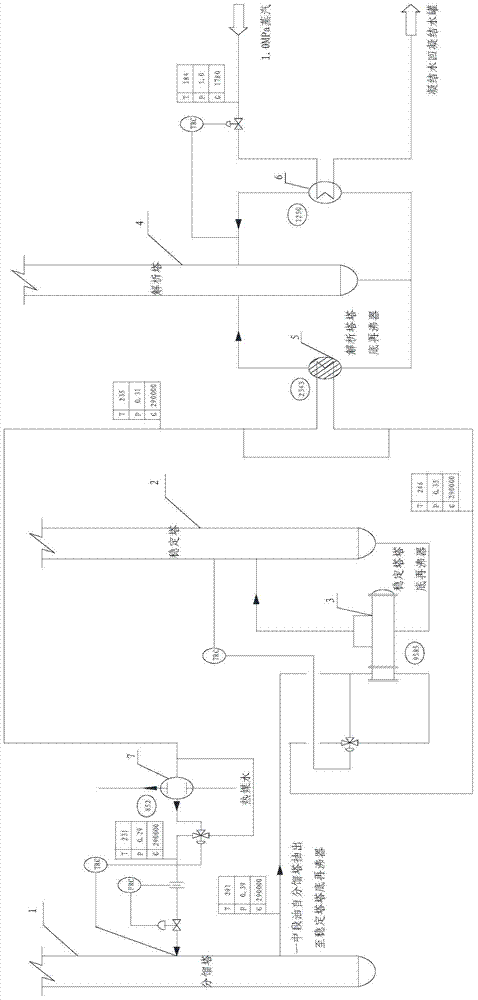

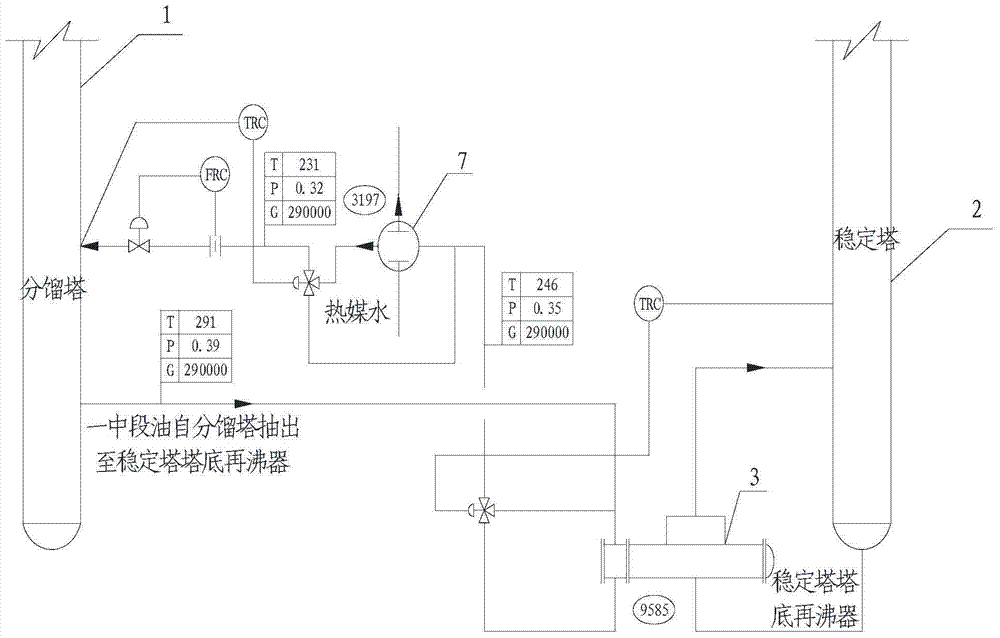

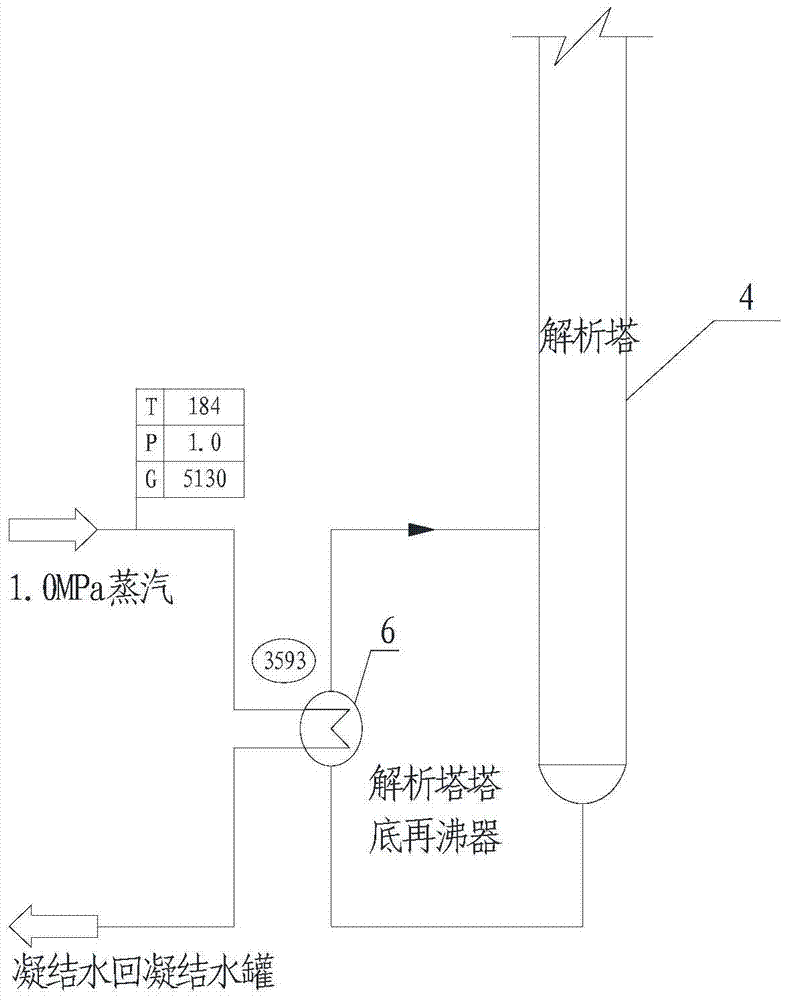

[0031] Such as figure 1 As shown, the present embodiment provides a heat utilization system of a catalytic cracking unit-middle section oil, and the system includes: a fractionation tower 1, a stabilizing tower system, an analysis tower system and a heat medium water heat exchanger 7, and the stabilizing tower system includes Stabilizing tower 2 and stabilizing tower bottom reboiler 3, desorption tower system includes desorption tower 4 and desorption tower bottom reboiler 5, a middle oil outlet of fractionation tower 1 and stabilization tower bottom reboiler 3, desorption tower The bottom reboiler 5 is connected to the heat medium water heat exchanger 7 in sequence, and a middle oil outlet of the heat medium water heat exchanger 7 is connected to the feed port of the fractionation tower 1 .

[0032] Wherein, the desorption tower system also includes a desorption tower steam reboiler 6, and the temperature of the desorption tower 4 in the desorption tower system is controlled ...

Embodiment 2

[0035] In this embodiment, the system described in Embodiment 1 is used for heat utilization, and the specific method is as follows:

[0036] In catalytic cracking, the middle-stage oil with a temperature of 250-300°C produced by the fractionation tower 1 first enters the bottom reboiler 3 of the stabilization tower, and is used as a heat source for the bottom reboiler 3 of the stabilization tower for heat exchange. After the heat exchange, the middle-stage oil The temperature dropped to 246°C;

[0037] Then, a middle-section oil enters the reboiler 5 at the bottom of the desorption tower again, and performs heat exchange as a heat source of the reboiler 5 at the bottom of the desorption tower, and the temperature of a middle-section oil after the heat exchange drops to 235° C.;

[0038] Finally, the heat-exchanged mid-stage oil enters the heat medium water heat exchanger 7 to exchange heat with the heat medium water, and the mid-stage oil with a temperature of 231° C. returns...

Embodiment 3

[0048] Except that the temperature of a middle section oil after heat exchange with the bottom reboiler 3 of the stabilization tower is 270°C, the temperature of a middle section oil after heat exchange with the bottom reboiler 5 of the desorption tower is 260°C, and the temperature of a middle section oil and heat medium water Except that the temperature of the heat exchanger 7 after heat exchange is 250° C., other operating steps are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com