Humidification system for small-sized PEM fuel battery test platform

A fuel cell and test bench technology, applied in the field of humidification system, can solve problems such as poor transmission capacity of proton exchange membrane, degradation of battery performance, and inability of protons to pass through

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

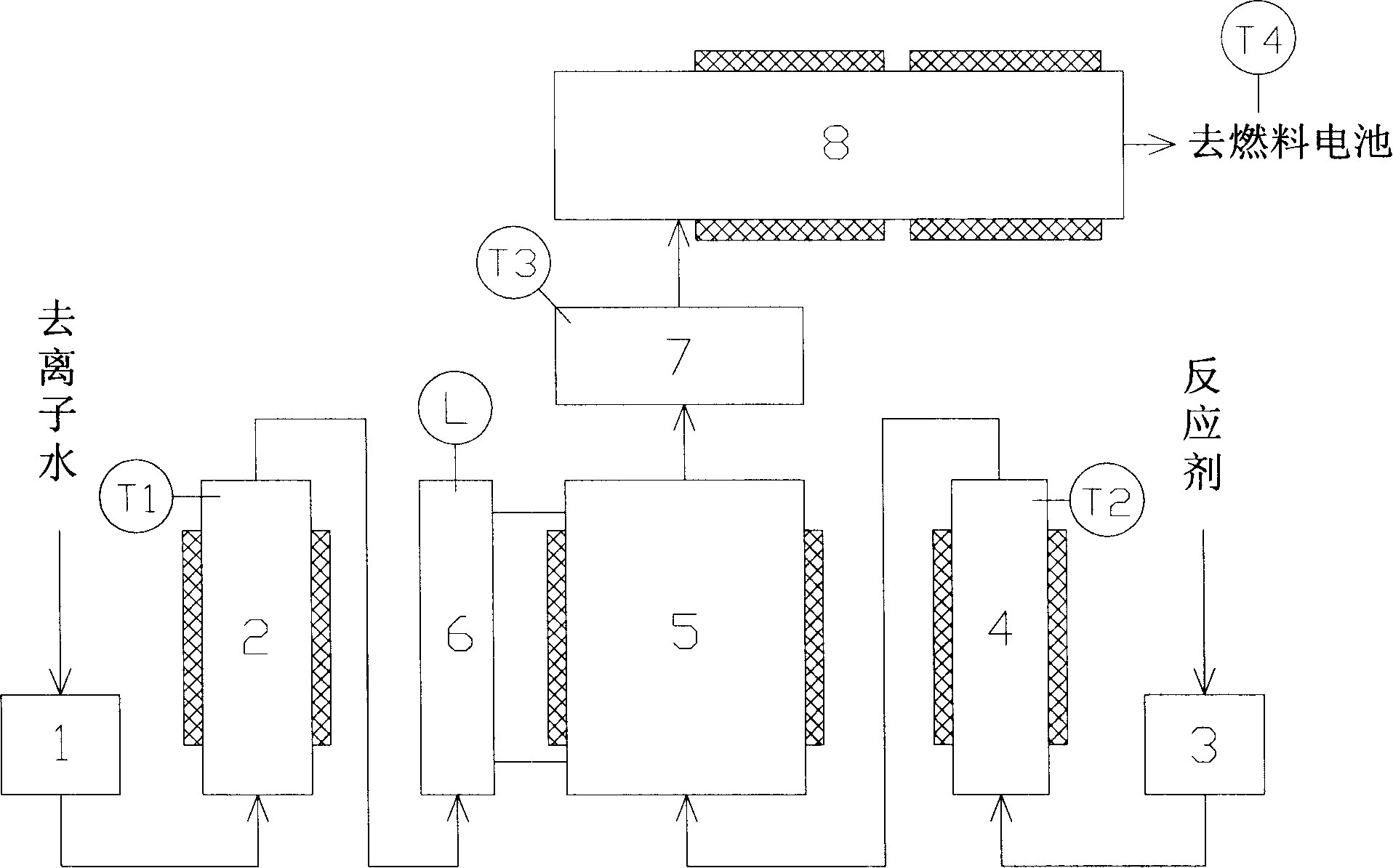

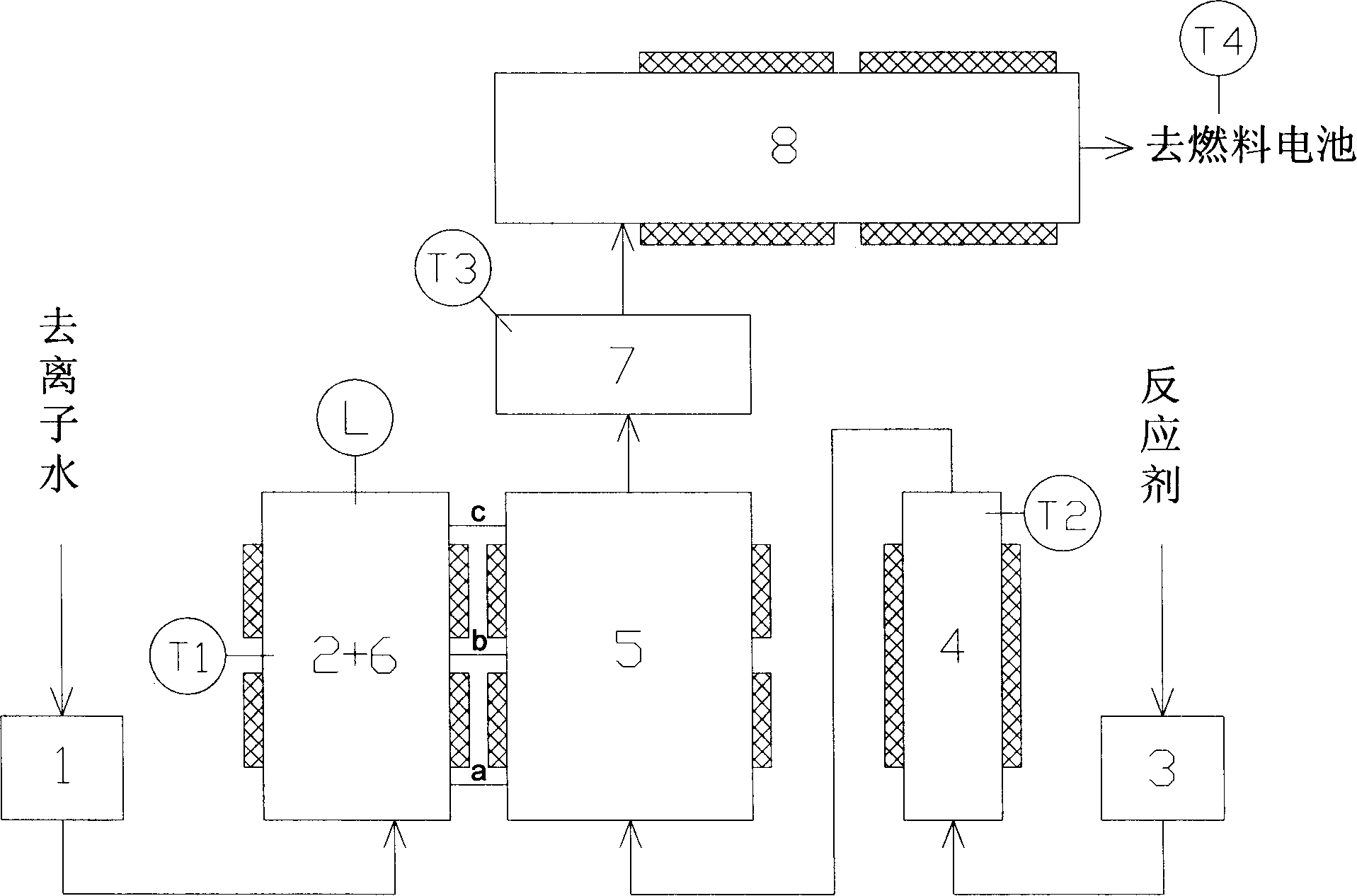

[0014] The deionized water from the deionized water pipeline enters the liquid phase heater 2 through the replenishment pump 1, and is sent to the balance tank 6 after being heated to a predetermined temperature T1. The reactant gas from the reactant gas source enters the gas preheater 4 after being metered by the gas flow controller 3 according to the specified flow rate, and enters the humidifier 5 after being heated to a predetermined temperature T2. The deionized water in the balance tank enters the humidifier 5 through the balance pipe to participate in gas-liquid exchange, and exchanges heat and moisture to the reactant until it reaches saturation. A humidifier with a high gas-liquid exchange area is equipped with a specific surface area of 700-2000M 2 / M 3 The theoretical number of boards per meter of filler can reach 8-40. This greatly strengthens the gas-liquid exchange between the reactants and the hot deionized water, ensuring that the humidified gas is fully sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com