Reaction tower with reaction shallow pools and method for preparing ethylene carbonate by using reaction tower

A reaction tower and reaction technology, applied in the field of new reaction towers, can solve the problems of low yield of ethylene carbonate, incomplete conversion of urea, large amount of ethylene glycol polymerization, etc., so as to reduce back mixing, reduce polymerization amount, and reduce heat effect of load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

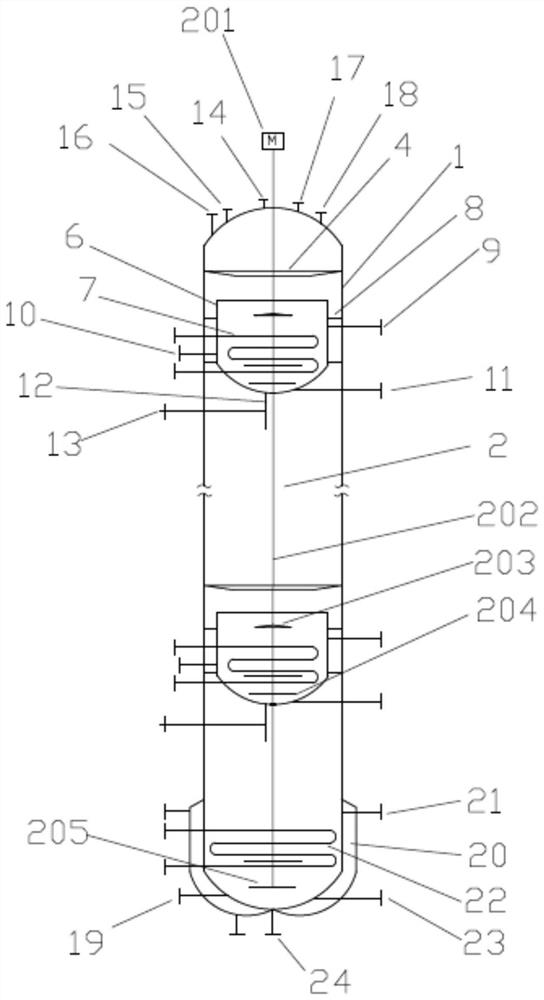

[0035] Such as figure 1 As shown, a reaction tower with a shallow reaction pool includes a tower body 1 and an agitator 2. The tower body 1 is divided into an upper reaction zone and a tower reactor reaction zone, and the upper reaction zone is from top to bottom A primary reaction shallow pool is provided, and a liquid collection ring 4 is arranged above the reaction shallow pool to collect condensate; the agitator 2 is used to stir the reaction liquid in the tower body 1; the reaction zone of the tower reactor is provided with two No. 22 heating coils.

[0036] The shallow reaction tank includes a cylinder body 6 and a No. 1 heating coil 7, the No. 1 heating coil 7 is arranged in the cylinder body 6, and the cylinder body 6 is fixedly connected with the tower body 1 through a fixing frame 8; The side wall of the cylinder body 6 is provided with the upper interface 9 of the liquid level gauge of the reaction shallow pool passing through the side wall of the tower body 1 and ...

Embodiment 2

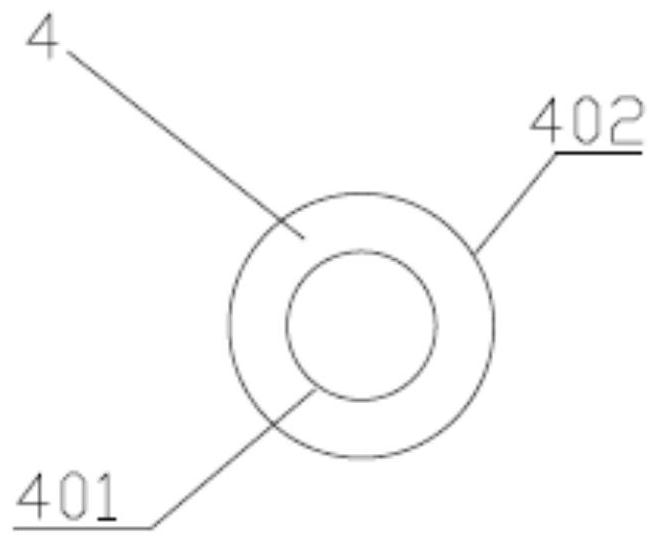

[0046] The reaction tower of this embodiment is the same as that of Embodiment 1, and the difference from Embodiment 1 is that 25 reaction shallow pools are arranged from top to bottom in the tower body 1, and liquid collection rings 4 are arranged above the reaction shallow pools. The diameter of the body 1 is 10000 mm; the feed port 14 is 300 mm away from the central axis of the reaction tower; the drain pipe 12 is 300 mm away from the central axis of the reaction tower.

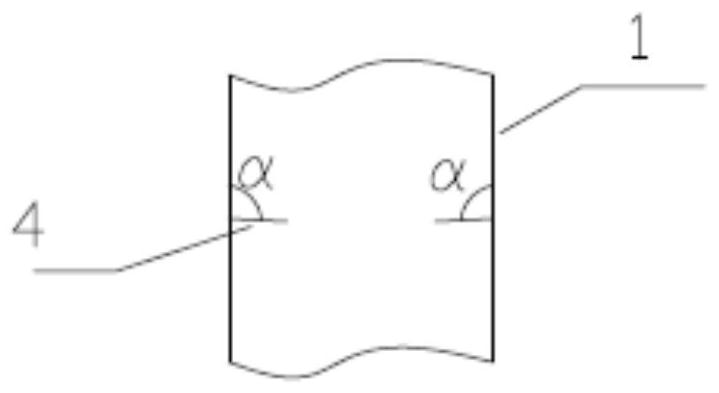

[0047] The diameter of the inner edge 401 of the liquid collecting ring 4 is 3000 mm, the angle α between the liquid collecting ring 4 and the tower body 1 is 90.5°, and the liquid collecting ring 4 above the shallow reaction tank of the first stage is located 1000 mm below the head of the tower top.

[0048] The liquid distribution plate 203 is a disc with five baffles evenly distributed radially from the center of the disc to the edge of the disc. The diameter of the disc is 1000 mm, and the vertical dis...

Embodiment 3

[0059] The reaction tower of this embodiment is the same as that of Embodiment 2. The difference from Embodiment 2 is that there are 12 reaction shallow pools from top to bottom in the tower body 1, and a liquid collection ring 4 is arranged above the reaction shallow pools. The diameter of the body 1 is 5000 mm; the feed port 14 is 200 mm away from the central axis of the reaction tower; the drain pipe 12 is 220 mm away from the central axis of the reaction tower.

[0060] The diameter of the inner edge 401 of the liquid collecting ring 4 is 1500 mm, the angle α between the liquid collecting ring 4 and the tower body 1 is 93°, and the liquid collecting ring 4 above the shallow reaction pool of the first stage is located 600 mm below the head of the tower top.

[0061] The liquid distribution plate 203 is a disc with four baffles evenly distributed radially from the center of the disc to the edge of the disc. The diameter of the disc is 600 mm, and the vertical distance from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com