Method for continuously producing L-calcium lactate

A calcium lactate solution technology, applied in the field of continuous production of L-calcium lactate, can solve the problems of calcium lactate waste, low production efficiency, low crystallization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

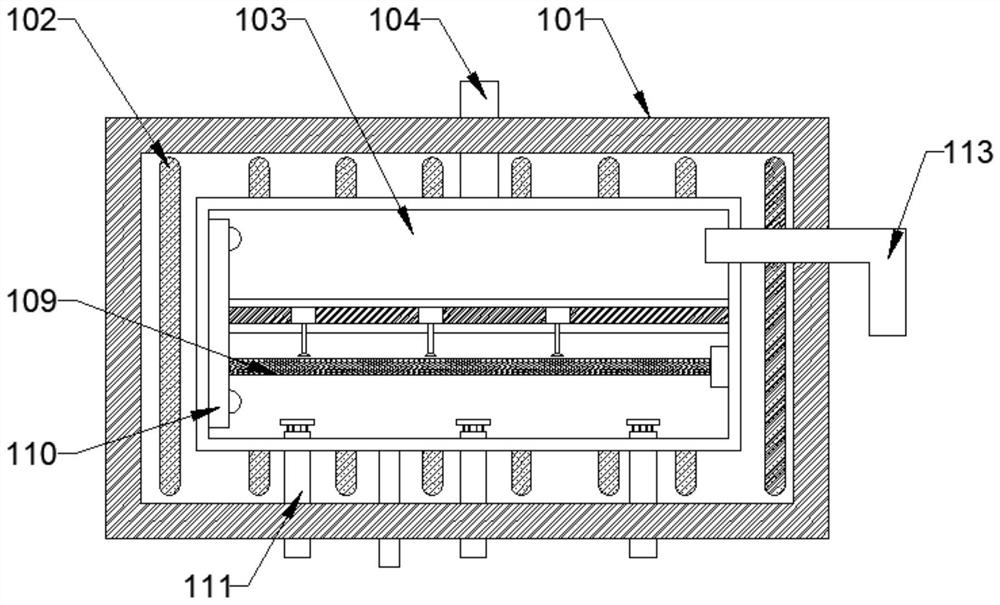

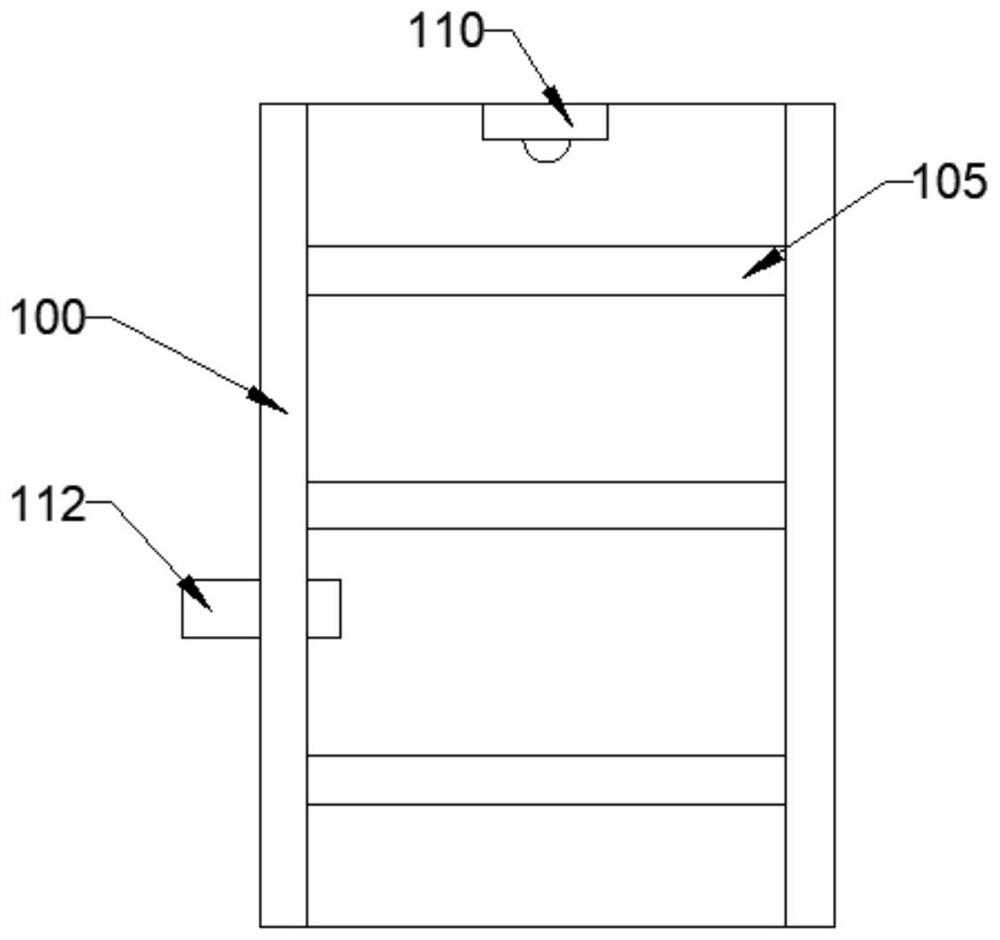

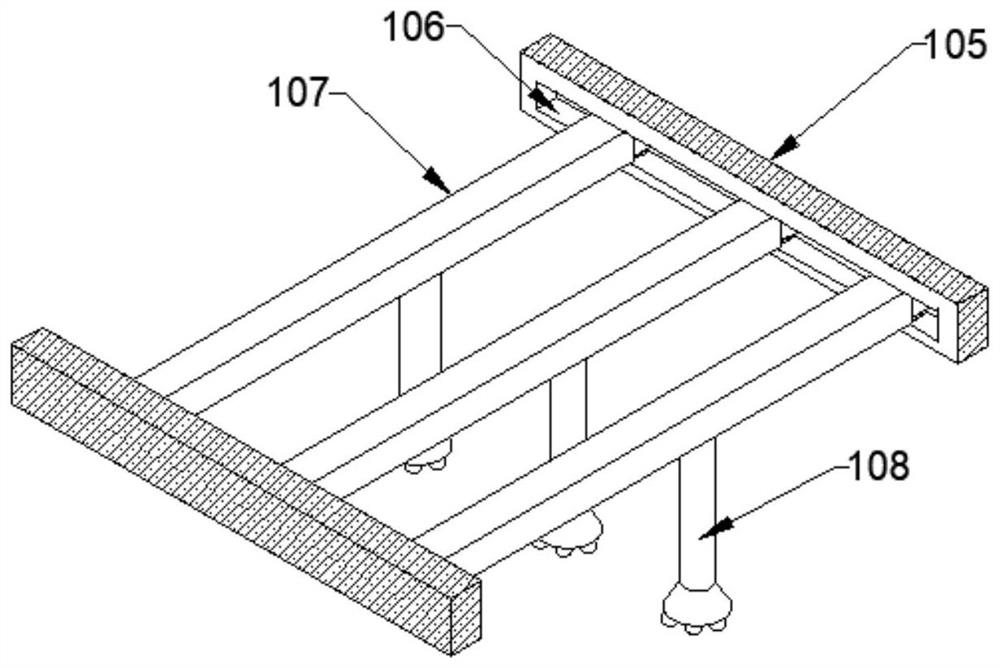

[0037] A method for continuously producing L-calcium lactate, comprising the steps of:

[0038] Step A: adding the L-calcium lactate solution into the heating reserve mechanism 100, and heating and concentrating the L-calcium lactate solution;

[0039] Step B: add the concentrated L-calcium lactate solution into the inside of the cooling mechanism 200 for cooling and crystallization;

[0040] Step C: The cooled and crystallized L-calcium lactate crystals are sent to the inside of the drying mechanism 300;

[0041] Step D: Transporting the dried L-calcium lactate crystals to the inside of the crushing mechanism 400;

[0042] Step E: The crushing mechanism 400 uniformly crushes the L-calcium lactate crystals to obtain L-calcium lactate powder.

[0043] The cooling mechanism 200 is connected with the heating storage mechanism 100 , the drying mechanism 300 is fixedly installed at the bottom of the cooling mechanism 200 , and the crushing mechanism 400 is connected with the dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com