Spiral push type low temperature pyrolysis carbonation furnace

A low-temperature pyrolysis and screw propulsion technology, applied in carbonization furnaces, coke ovens, special forms of dry distillation, etc., can solve the problems of waste heat from exhaust gas, low biomass carbon yield, and insufficient utilization of pyrolysis carbonization gas. Improve thermal efficiency, achieve self-supply of energy, and improve the quality of carbonized products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

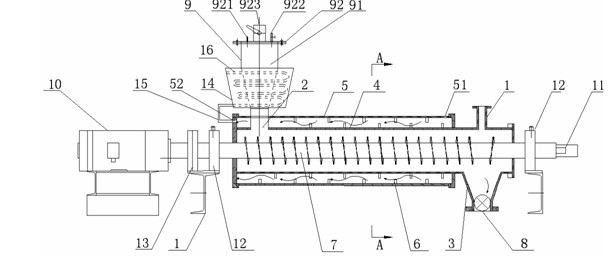

[0017] The specific content of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

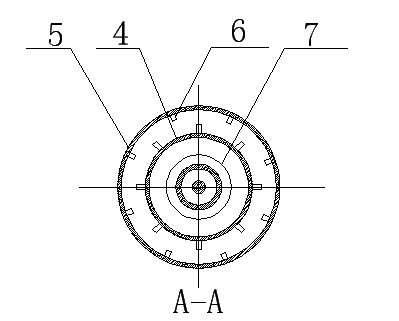

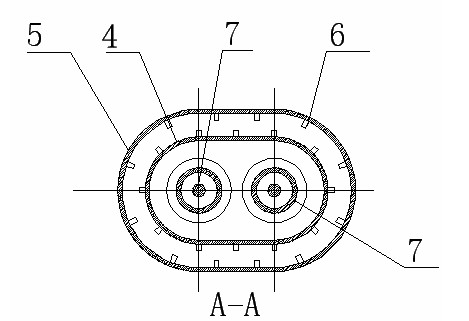

[0018] like figure 1 , figure 2 As shown, Embodiment 1 of the spiral-propelled low-temperature pyrolysis and carbonization furnace according to the present invention: the spiral-propelled low-temperature pyrolysis and carbonization furnace, including: a support 1, a furnace body, and the furnace body is provided with a feed port 2 and a discharge Port 3, the furnace body includes an inner heating cylinder 4 and an outer heating cylinder 5 that are sleeved together, the end of the inner heating cylinder 4 passes through the outer heating cylinder 5, and the end of the inner heating cylinder 4 is provided with a tail gas outlet 41, and the discharge port 3 is also arranged at the end of the inner heating cylinder 4, the outer heating cylinder 5 is provided with a high temperature flue gas inlet 51 and a high temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com