Mud drying and incinerating integrated system and use method thereof

A sludge incineration and sludge drying technology, which is applied in combustion methods, dehydration/drying/concentrated sludge treatment, incinerators, etc., can solve the problems of low calorific value of sludge, low grade of heat source, low evaporation temperature, etc. Achieve the effects of less heat loss, high drying efficiency, and improved drying rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

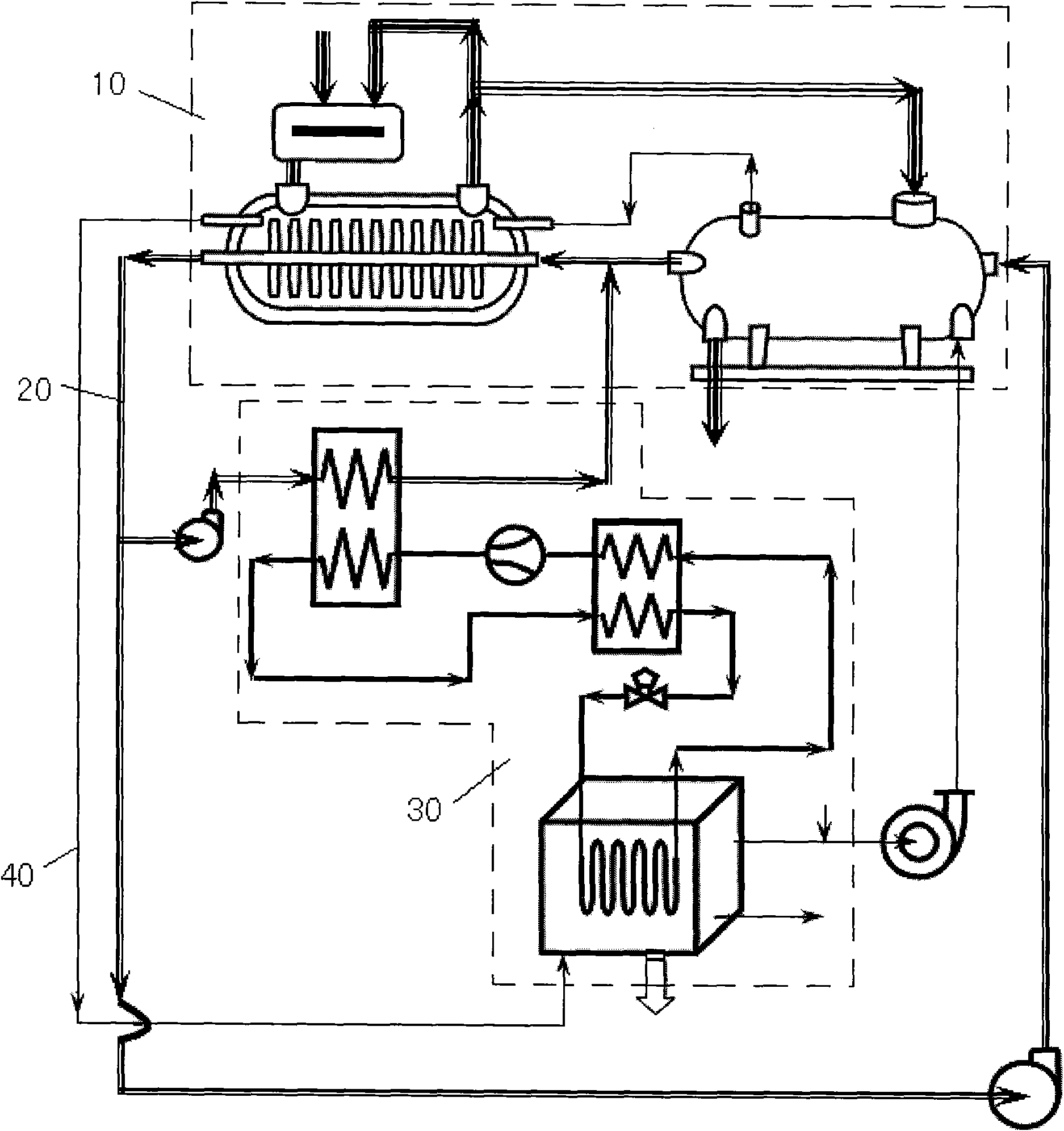

[0016] Such as figure 1 As shown, the present invention includes a sludge drying and incineration circuit 10 , a hot water circulation circuit 20 , a heat pump auxiliary heating circuit 30 and a carrier gas heating and waste heat recovery circuit 40 .

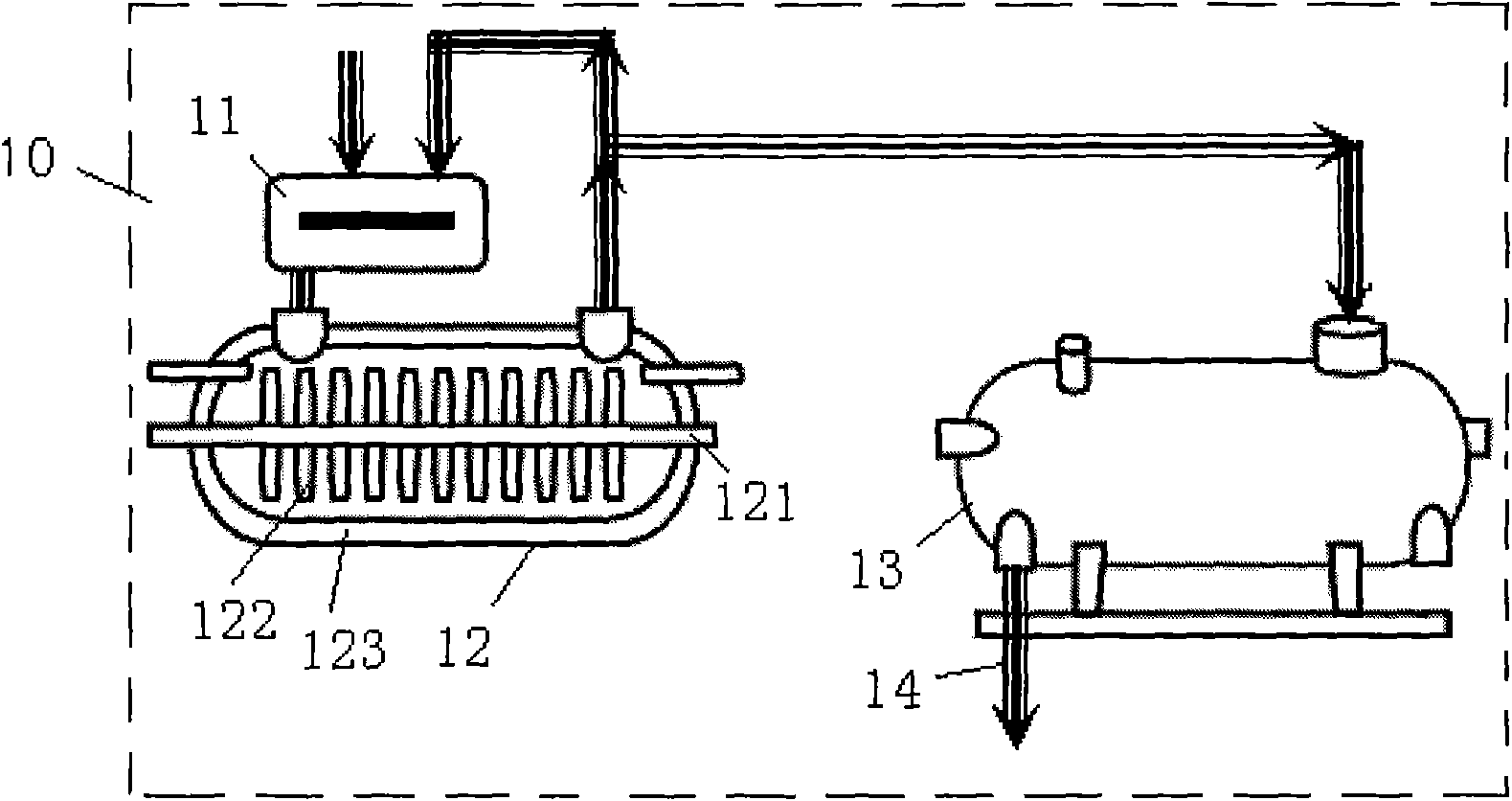

[0017] Such as figure 2 As shown, the sludge drying and incineration circuit 10 of the present invention includes a dry sludge remixing device 11 , a sludge dryer 12 and a sludge incinerator 13 . The wet sludge and part of the dried sludge treated by the sewage treatment plant enter the dry sludge back-mixing device 11 through the pipeline. The mud outlet of the dry mud back-mixing device 11 is connected to the mud inlet of a sludge dryer 12 through a pipeline, and the mud outlet of the sludge dryer 12 is respectively connected to the dry mud back-mixing device 11 and a sludge incinerator through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com