Large bore packer and methods of setting same

a packer and large bore technology, applied in the direction of sealing/packing, wellbore/well accessories, drilling pipes, etc., can solve the problems of loss of inch of diameter in usable area, reduce the usable diameter within the well, etc., to save useable cross-sectional area, reduce the useable area, and increase the diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

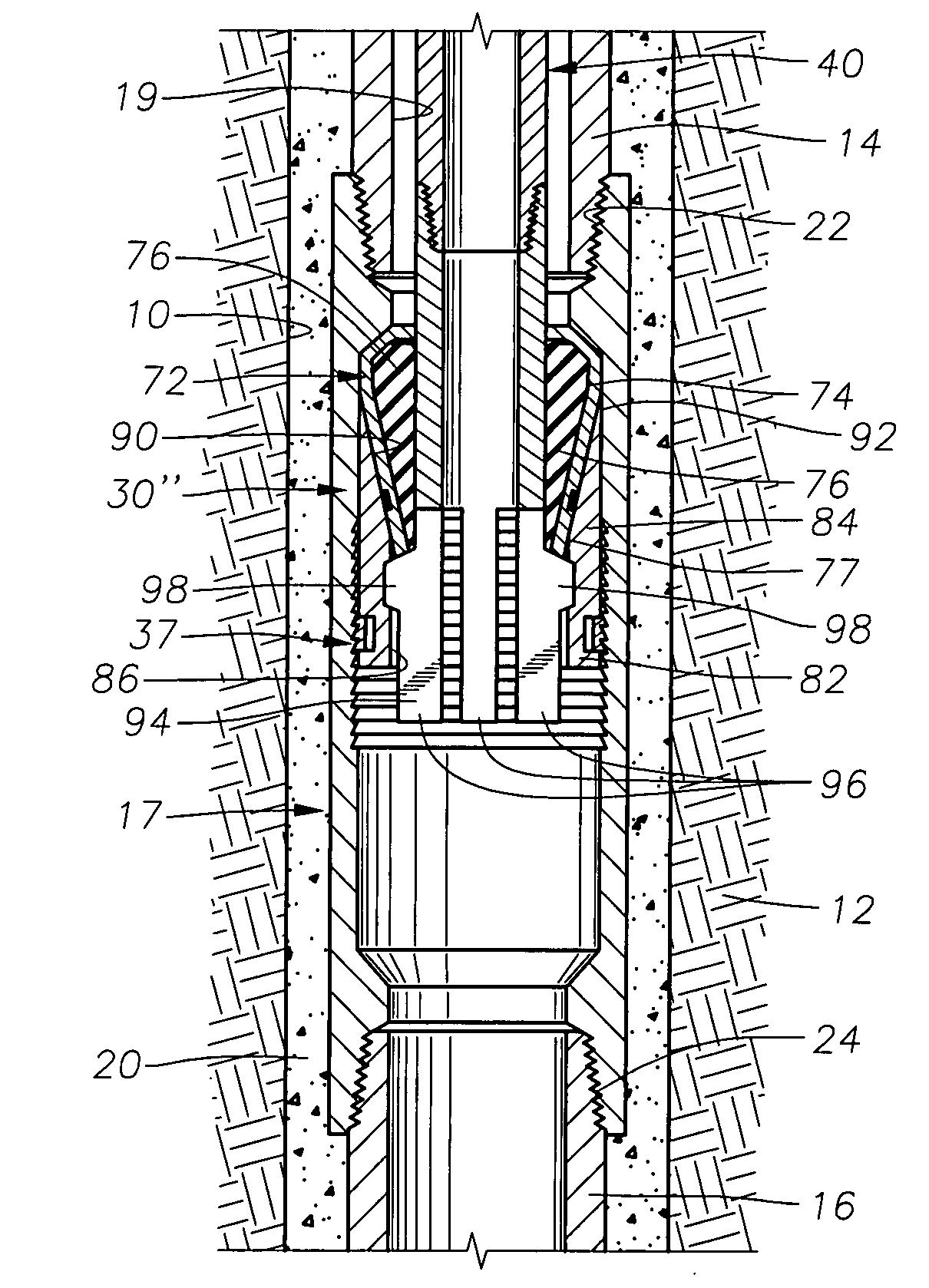

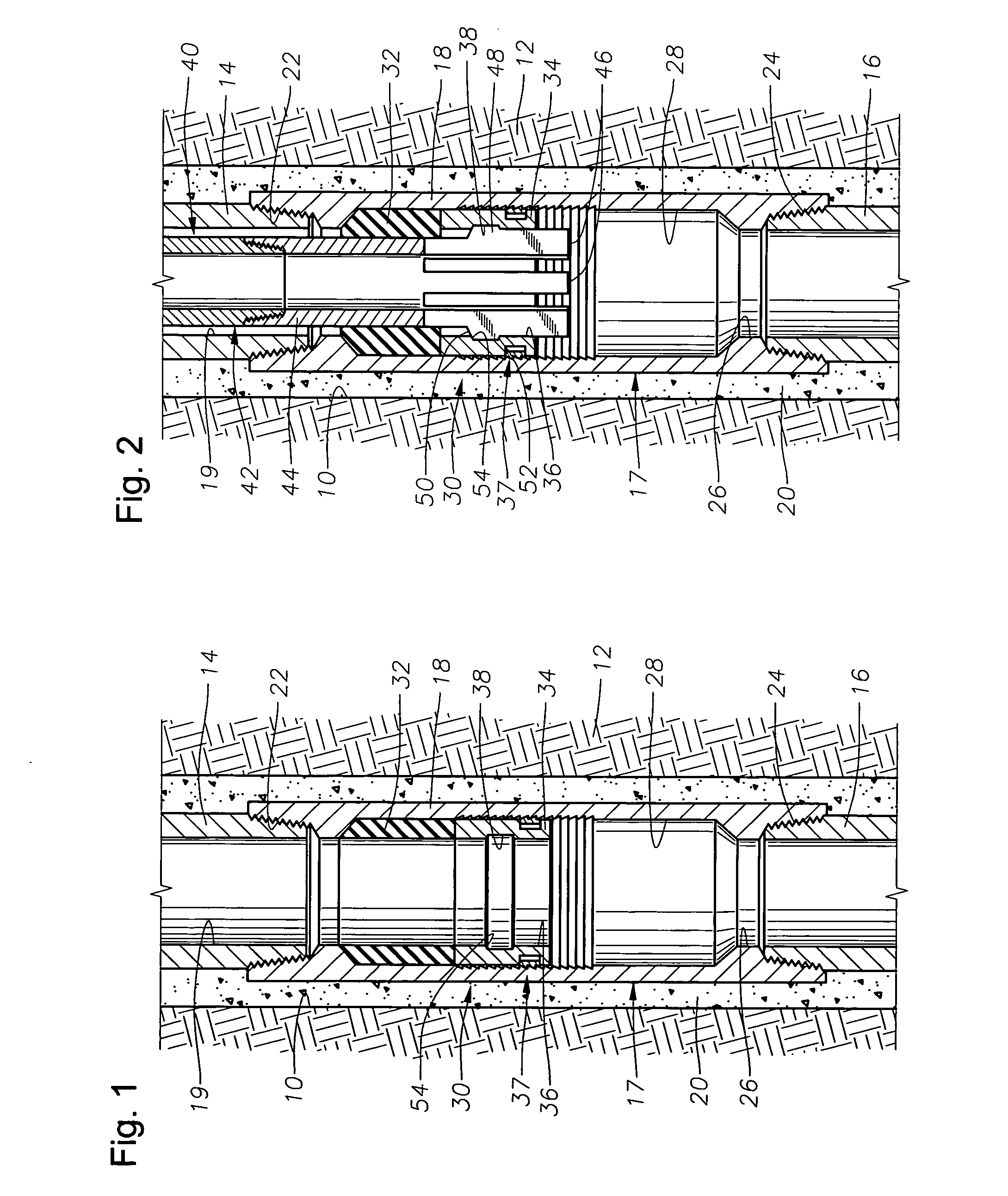

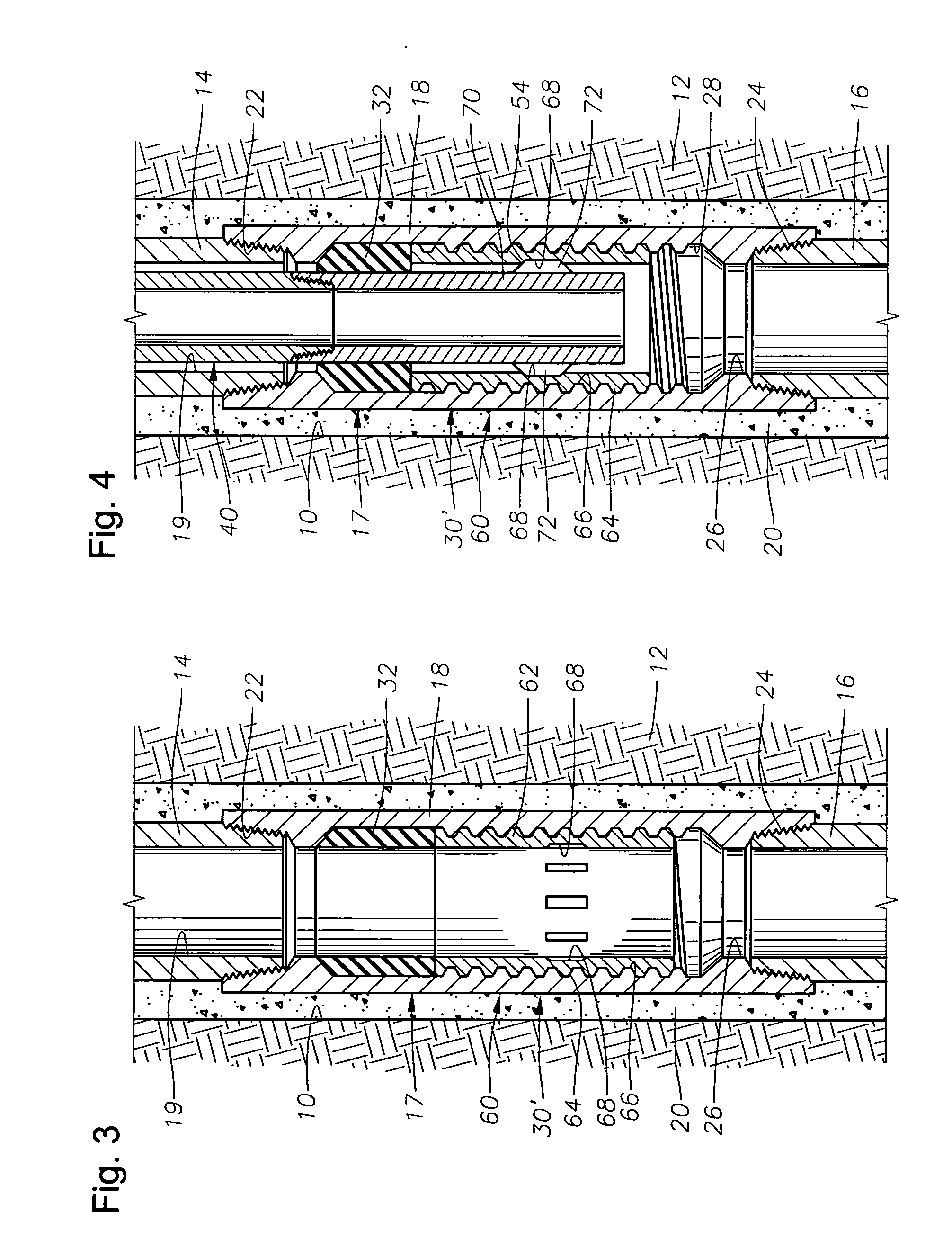

[0024]FIGS. 1 and 2 illustrate an exemplary wellbore 10 that has been drilled through the earth 12. The wellbore 10 is lined with a string of casing, of which two casing sections 14, 16 are depicted. A casing coupler 18 interconnects the casing sections 14, 16 to form a casing string 17 that defines a central bore 19 along its length. Cement 20 surrounds the casing sections 14, 16 and casing coupler 18. It is noted that the casing coupler 18 has a greater diameter than the casing sections 14, 16 and is secured to each of the casing sections 14, 16 via threaded connections 22, 24, respectively.

[0025]The casing coupler 18 includes an axial bore 26 for passage of tools and fluid through the casing coupler 18. The bore 26 has an enlarged diameter chamber portion 28. A packer device 30 is disposed within the enlarged diameter chamber portion 28. The packer device 30 includes a cylindrical elastomeric packer sealing element 32 and a cylindrical setting sleeve 34. The setting sleeve 34 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com