Preparation of SAPO-34 molecular sieve film for selectively separating methane gas

A SAPO-34, a technology for separating methane, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology and other directions, can solve the problems of no patent reports, reduce membrane permeability, increase paths, etc., to achieve good separation performance, repeatability Good performance and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

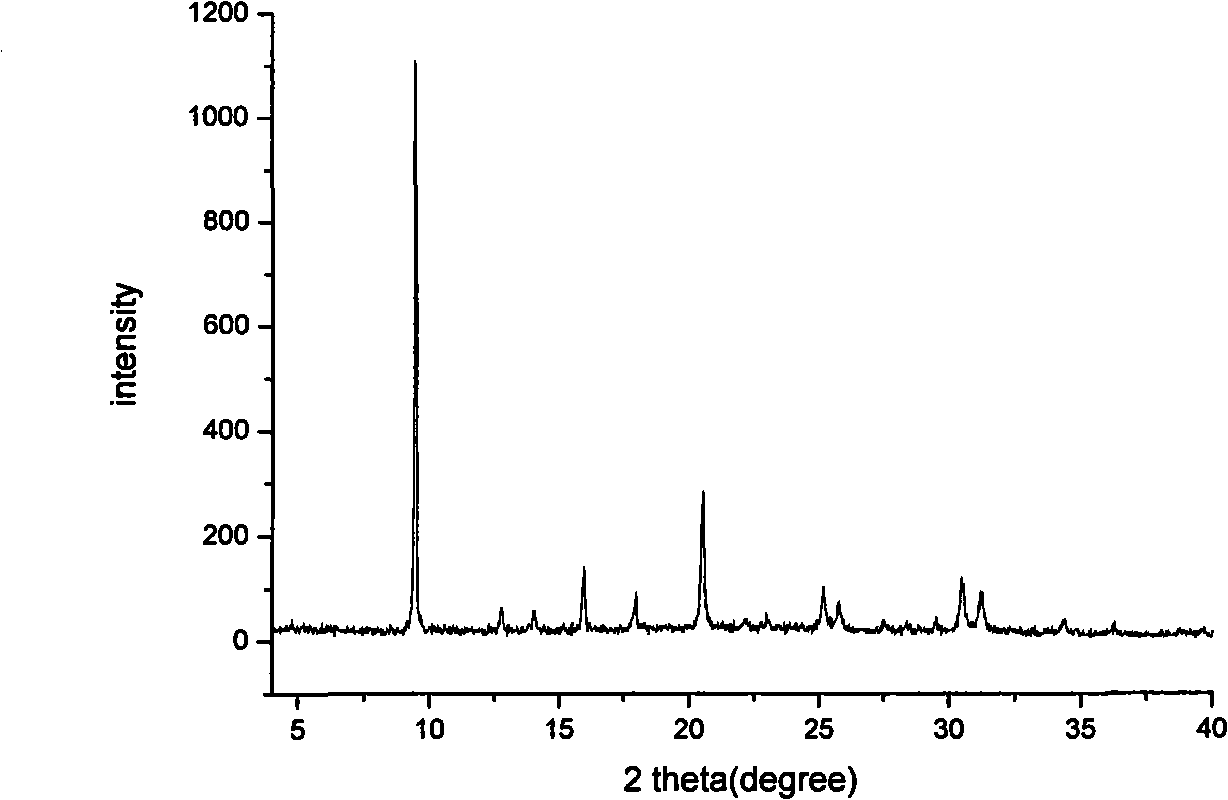

[0031] Step A: Synthesis of SAPO-34 Molecular Sieve Seed Crystals

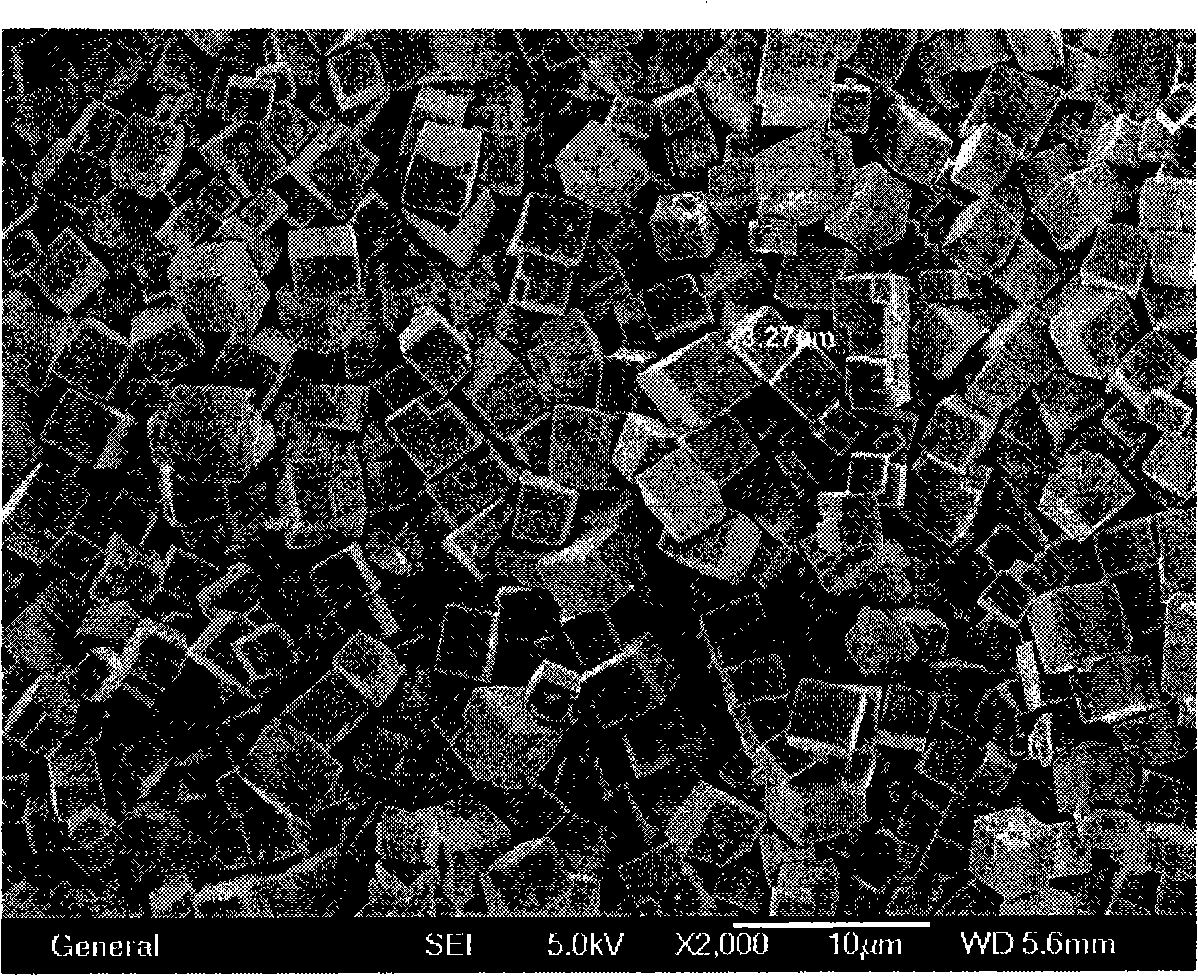

[0032] Add 2 g of aluminum isopropoxide into 5 g of deionized water, stir well for hydrolysis. Add 1 g of phosphoric acid solution (H 3 PO 4 , mass fraction 85%), 8.47 gram tetraethylammonium hydroxide aqueous solution (TEAOH, mass fraction 20%), 0.32 gram silica sol (SiO 2 Aqueous solution, mass fraction 30%), add 0.3 g of concentrated hydrochloric acid solution (HCl, mass fraction 37%), at this time the pH value of the mother liquor is 6, 180 ° C hydrothermal crystallization for 3 days, the product is taken out and washed with deionized water Drying to obtain seed crystal powder, the grain size of which is 3-5 microns.

[0033] Step B: Preparation of seeded base film

[0034] Add deionized water to the seed crystal powder that step A obtains, be made into the suspension of 3g / L, 300 order stainless steel wire meshes (Xinxiang Bashan Precision Filter Material Co., Ltd.) Cleaner, Kunshan Ultrasonic Instru...

Embodiment 2

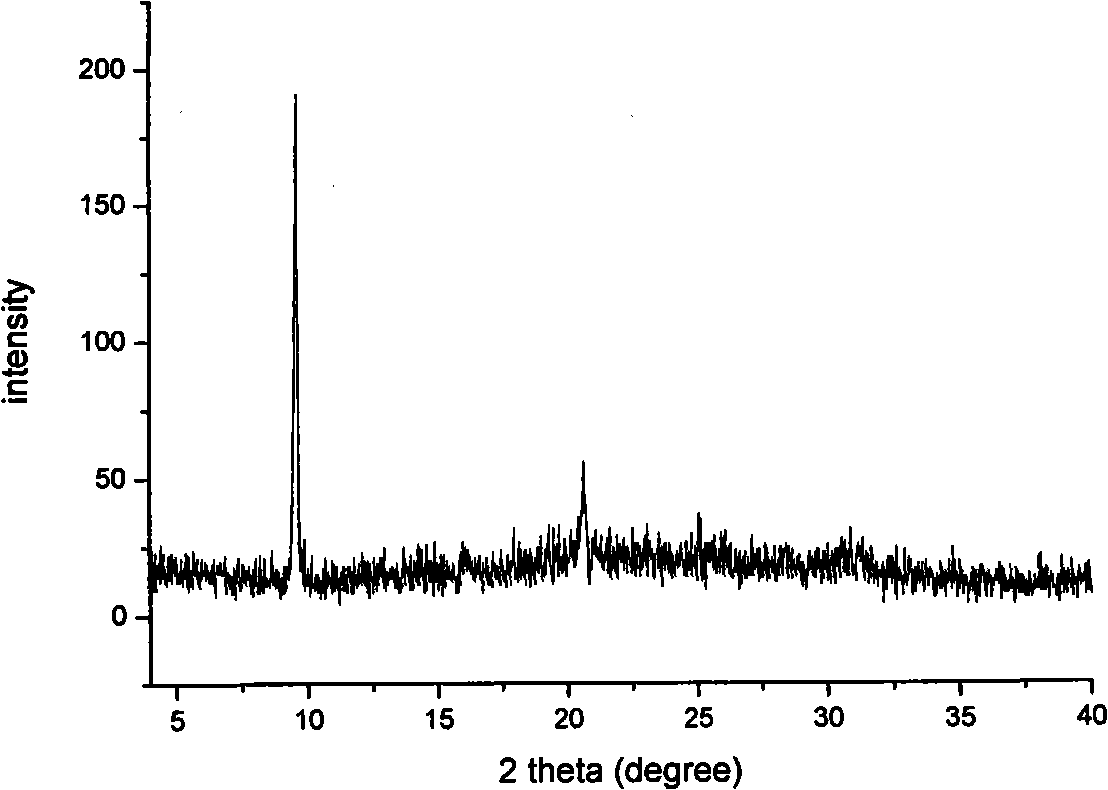

[0038] The difference from Example 1 is that after the synthesis, step C of Example 1 was repeated, and the SAPO-34 molecular sieve membrane was synthesized again to repair the intergranular defects on the surface of the membrane. It can be seen from Table 1 that the separation performance of the membrane is further improved.

Embodiment 3

[0040] The difference from Example 1 is that three samples are used to carry out a parallel test in this proportion to test its repeatability, and the rest are the same as in Example 1. The results are listed in Table 2, and it can be seen that the method has good repeatability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com