Preparation method for nanometer mordenite molecular sieve with multi-stage holes

A nano-filament and denzeolite technology, which is applied in the field of synthesis of zeolite molecular sieves, can solve the problems of harsh preparation conditions, complexity, and environmental pollution, and achieve the effects of low cost, high repeatability, and simple synthesis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

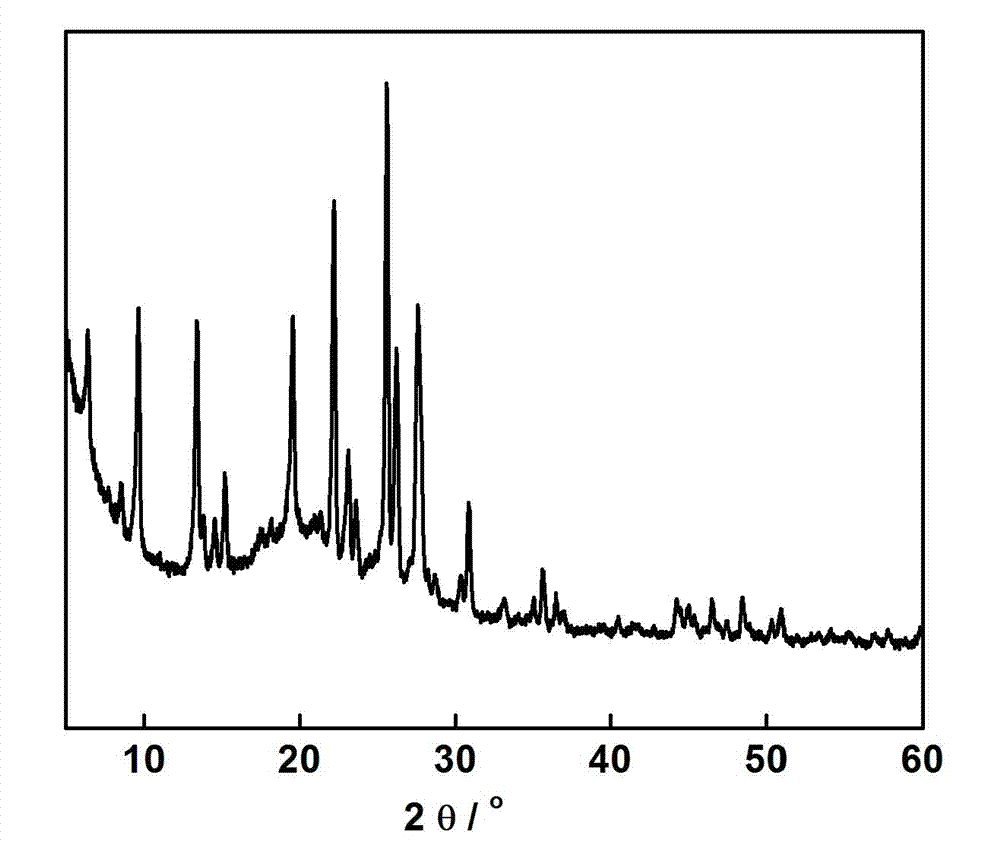

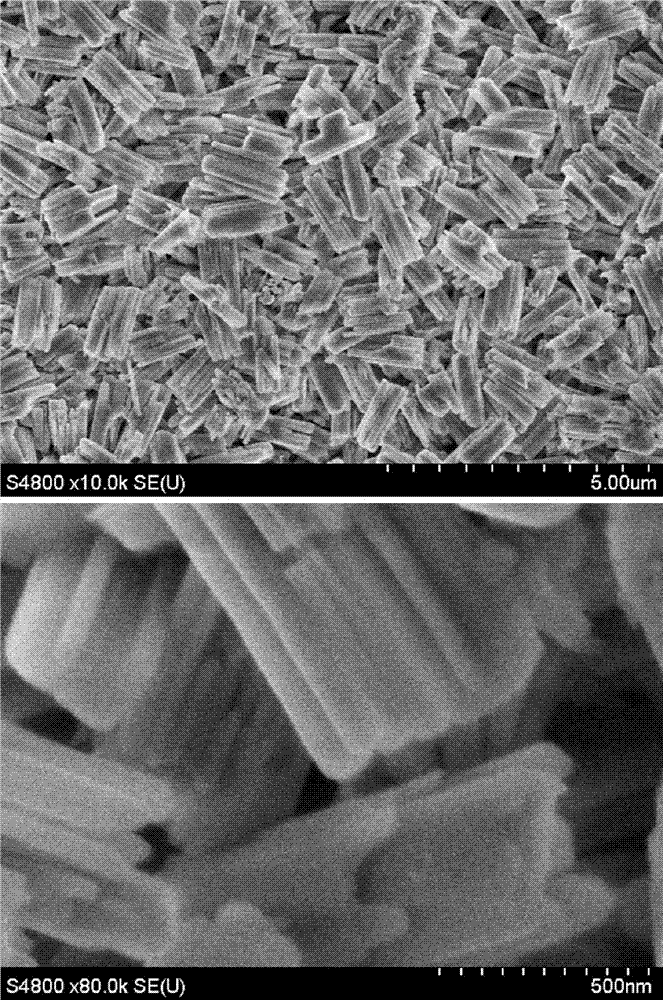

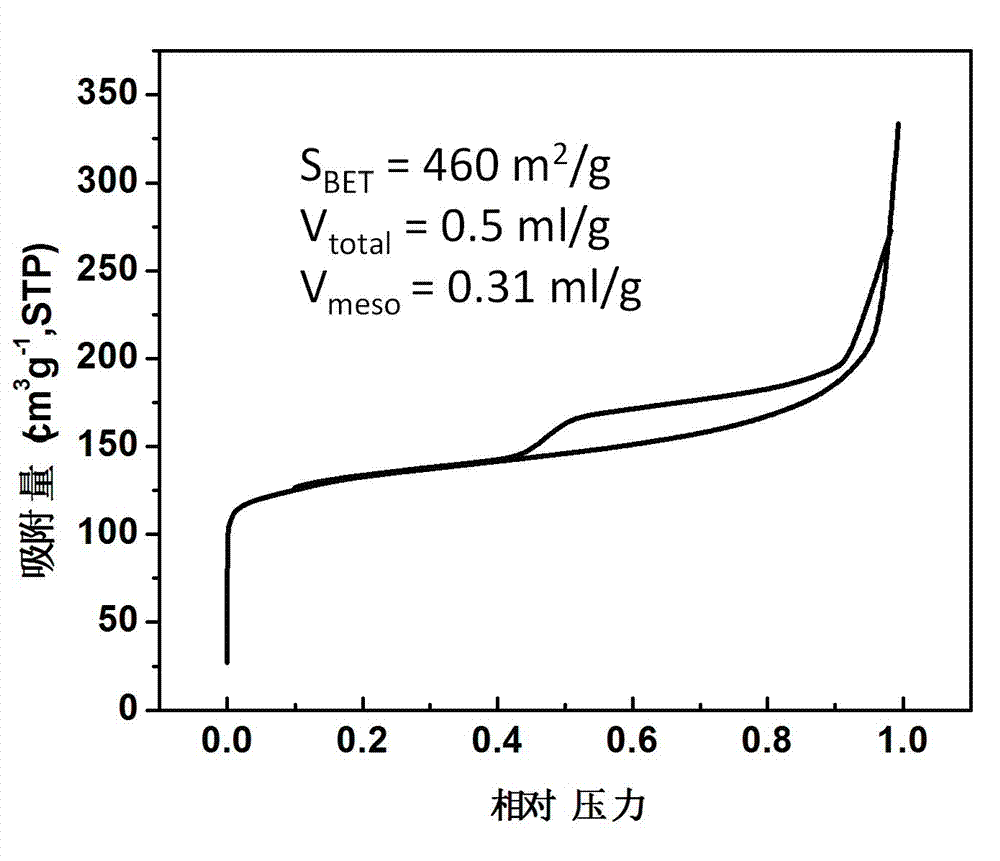

Embodiment 1

[0027] Mix 11.5g of hexadecyldimethylethylammonium bromide and 80g of water, and heat in a constant temperature water bath at 60°C for 2 hours to form A solution; in addition, mix 2.16g of sodium hydroxide with 67.8ml of deionized Mix with water, stir until clear liquid, add 0.7g aluminum isopropoxide to it, then heat in a constant temperature water bath at 60°C for 1 hour, after the aluminum isopropoxide is completely dissolved, slowly add 17.4g silica sol dropwise (30% SiO 2 ), then continue to keep the original temperature constant, and stir for two hours to form the B solution; finally, add the B solution dropwise to the A solution, continue to stir for 2 hours, and transfer the mixture to a stainless steel with a polytetrafluoroethylene liner Put it in a static crystallization kettle, and place it in an oven at 150°C for crystallization for 3 days, after conventional suction filtration, washing with deionized water, drying, and then roasting at 550°C for 5 hours to obtain...

Embodiment 2

[0030] Except that the silicon source in Example 1 was changed to fumed silica gel, other preparation conditions were the same as in Example 1, and the obtained solid product was analyzed as hierarchically porous nano-mordenite.

Embodiment 3

[0032] Except that the silicon source in Example 1 was changed to water glass, other preparation conditions were the same as in Example 1, and the obtained solid product was analyzed as hierarchically porous nano-mordenite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com